System and method for assembling a solar cell matrix

A solar cell and matrix technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

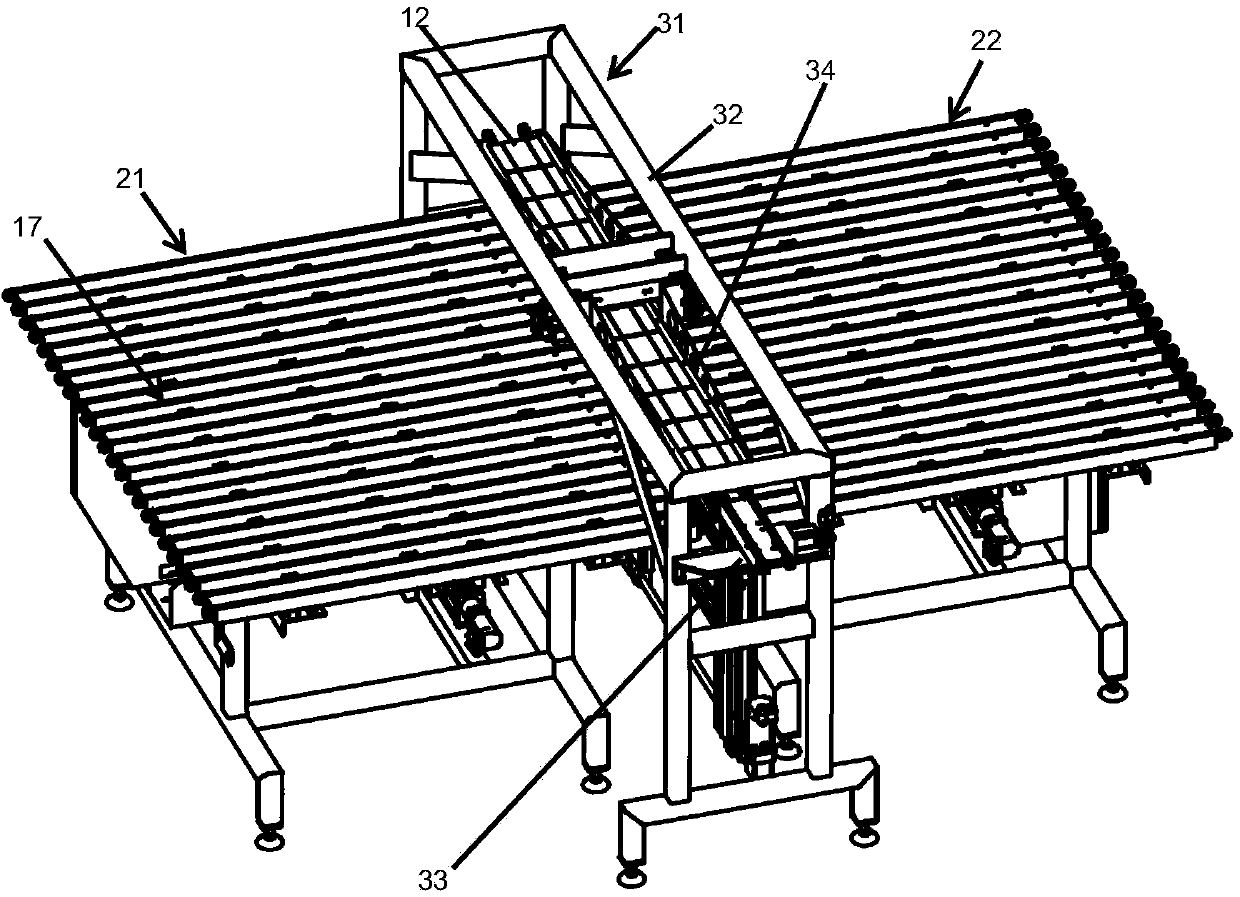

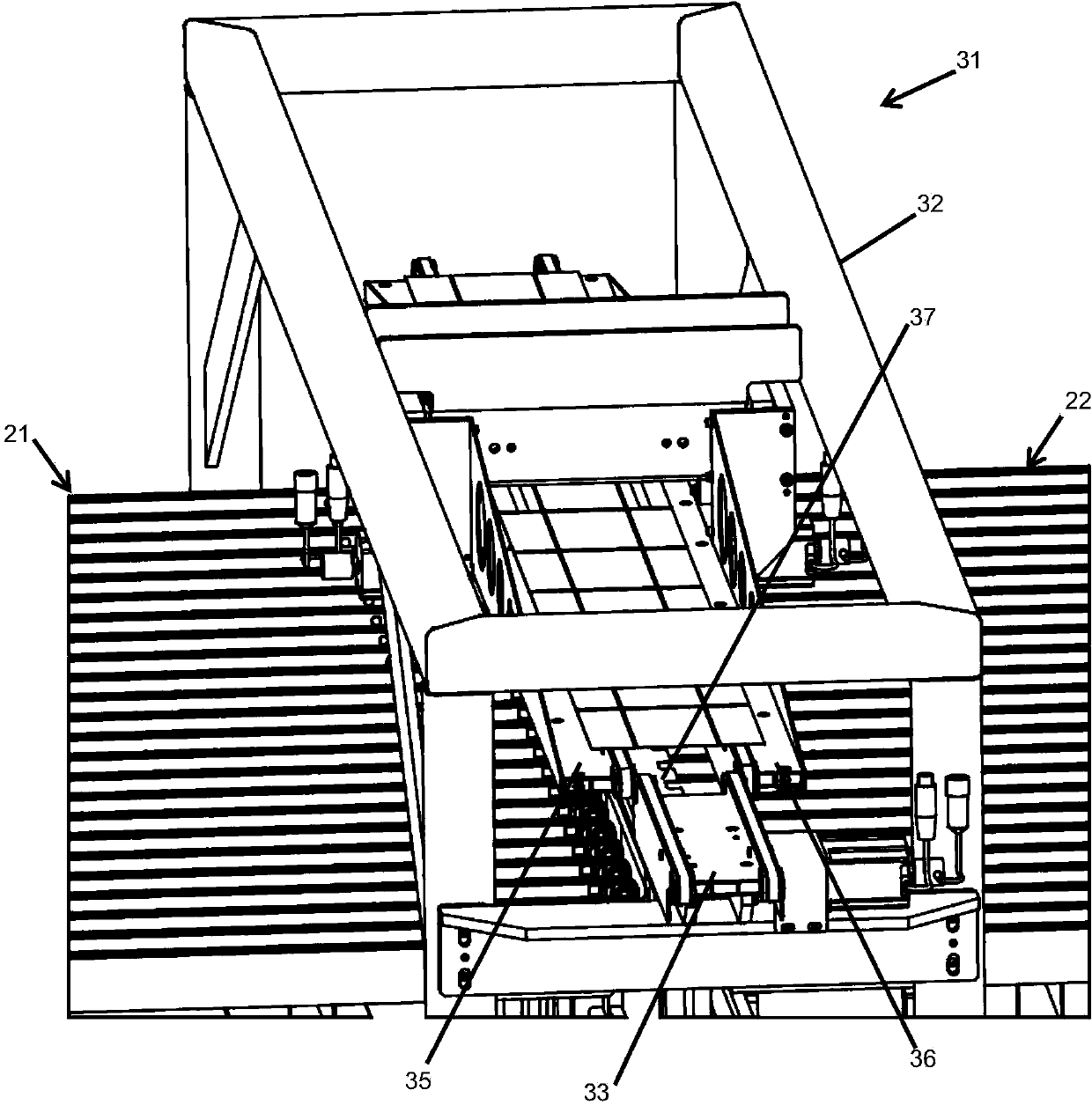

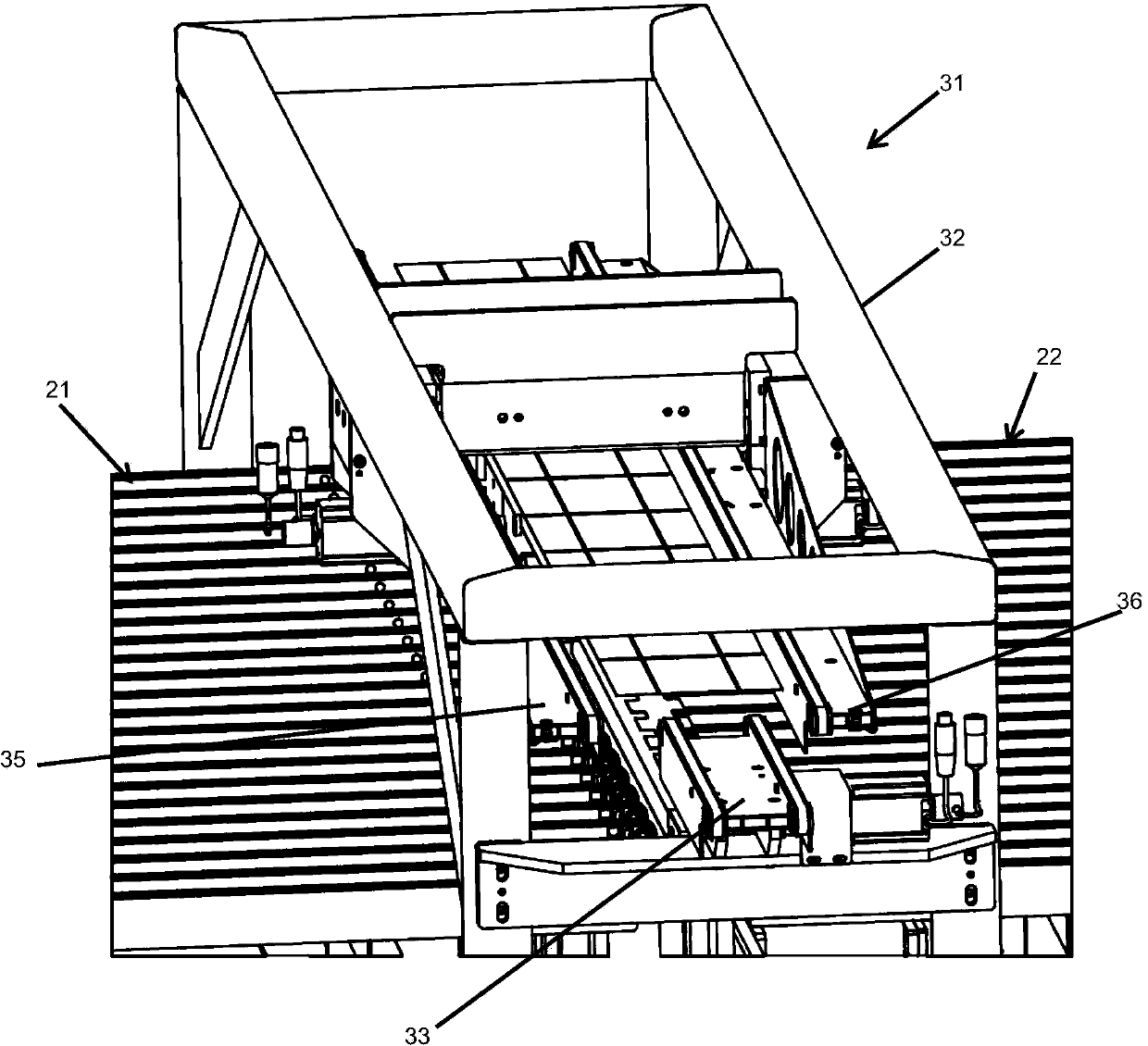

[0092] The following figure is one possible design of the system of the present invention.

[0093] figure 1 An embodiment system 11 of the invention is shown for forming a solar cell matrix. The system 11 is modular and can be arranged separately according to the process to be performed and / or local possibilities or needs. The system 11 comprises a conveying unit 16 for conveying strings 12 in at least one conveying direction (arrow 19) having an input area 17 at one end and an output area at the other end, the input area 17 being suitable for For receiving the string 12 of solar cells, the output area is adapted to hold the matrix 13 of solar cells. In the present embodiment, a total of five conveyor devices 21 - 25 form the conveyor unit 16 , all of which have the same basic structure and are arranged in a straight line. A spacing is provided between the conveying devices 21-25, and each conveying device conveys the string 12 from one station to the next. Control box 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com