An electric fenton device for treating organic wastewater

A technology for organic wastewater and drainage pipes, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low operating costs and ineffective effects, and achieve low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

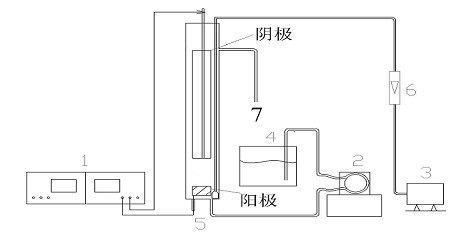

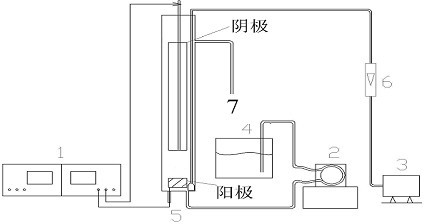

Method used

Image

Examples

Embodiment 1

[0030] Use dilute sulfuric acid solution to adjust the pH of the solution to 3, and the area of the activated carbon fiber as the cathode is 500cm 2 , the flow meter controls the aeration rate of the air pump to 300mL / min, and the output voltage of the DC stabilized power supply is 15V. According to the titanium salt colorimetric method in the national standard GB / T23499-2009, the hydrogen peroxide concentration in the water is measured, and the sample is analyzed every 15 minutes. The concentration of hydrogen peroxide in the solution is 18.857mg / L, 25.853mg / L, 31.826mg / L, 36.519mg / L, 39.164mg / L, 40.017mg / L, 41.553mg / L respectively until 120min and 41.724mg / L, the concentration of hydrogen peroxide in the solution increases with time, and after increasing to a certain concentration, the concentration of hydrogen peroxide tends to be stable.

Embodiment 2

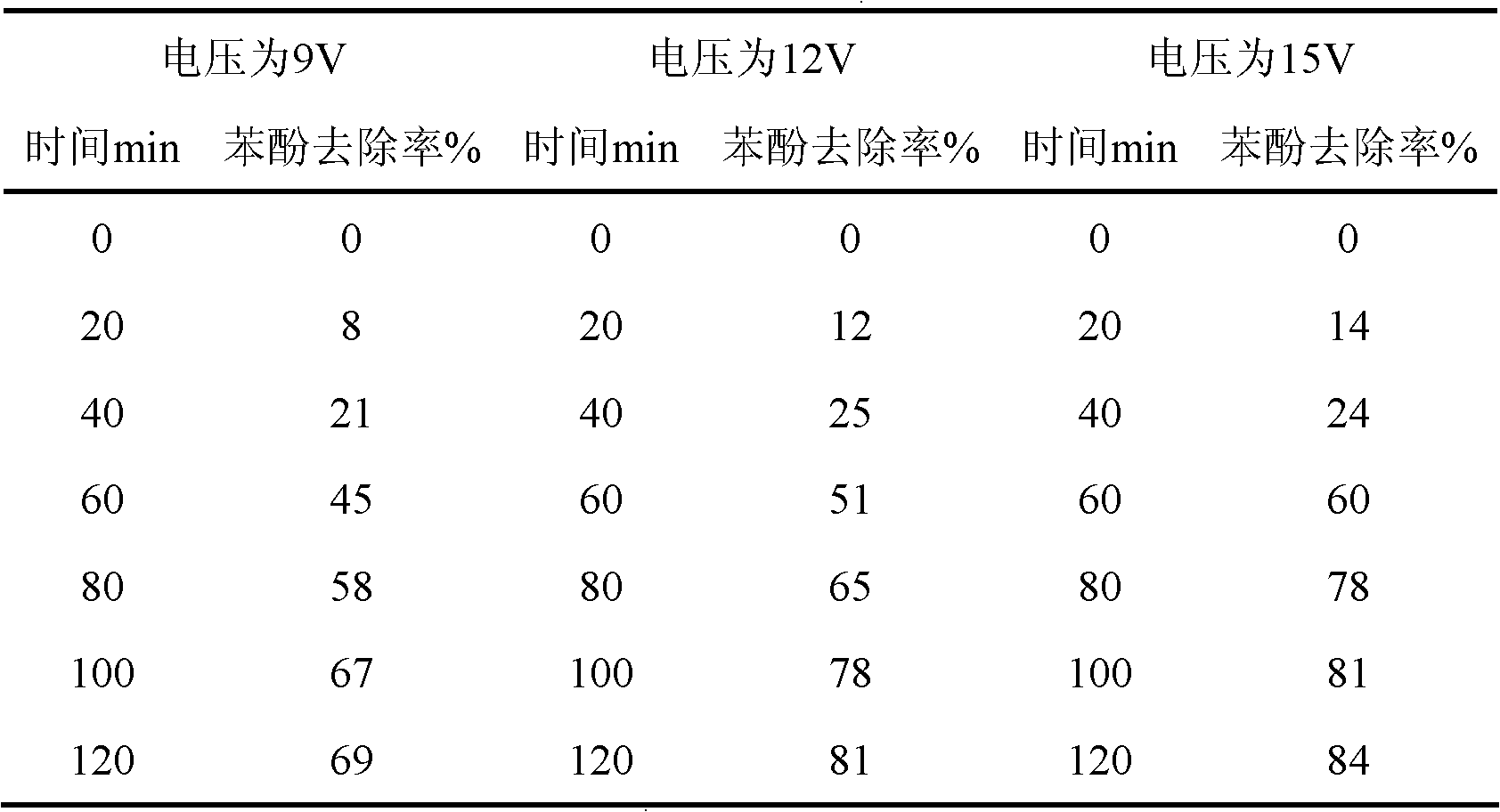

[0032] Prepare the initial concentration of phenol as 100mg / L, adjust the pH of the solution to 3 with dilute sulfuric acid solution, and use activated carbon fiber as the cathode area of 500cm 2 , the concentration of ferrous ions in the solution is 0.15mmol / L, the aeration rate of the air pump controlled by the flowmeter is 300mL / min, and the output voltage of the DC stabilized power supply is 9V, 12V, and 15V, and it is determined by high performance liquid chromatography The concentration of phenol in the solution was sampled and analyzed every 20 minutes until 120 minutes, and the removal rate of phenol was shown in Table 1.

[0033] Table 1 Variation of phenol removal rate with time at different voltages

[0034]

[0035] It can be seen from Table 1 that the removal rate of phenol increases with the gradual increase of voltage. When the voltage is 15V, the removal rate of phenol reaches 84% after electrolysis for 120 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com