Method for pretreatment on industrial wastewater by nascent state ferrous iron reduction

A technology for industrial wastewater and new ecology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as increased treatment costs, difficult-to-treat wastewater, and poor regulation effects. Achieve the effect of optimizing coagulation and sedimentation conditions, improving reducing ability, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

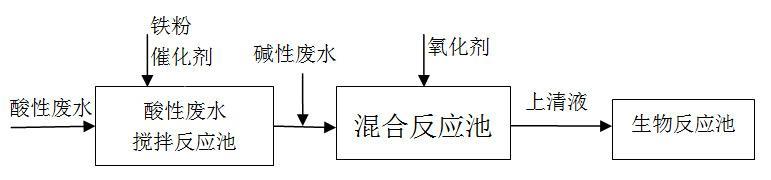

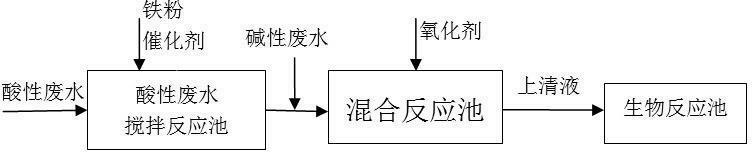

Image

Examples

Embodiment 1

[0018] Take 1L of acidic chemical wastewater (water quality conditions as shown in the table below), add 2g of reduced iron powder and CuCl 2 Aqueous solution, Cu / Fe mass ratio is 0.5%, stirring reaction for 2h, regular sampling and centrifugation, analysis of ferrous concentration, chroma, pH, COD of supernatant Cr 、BOD 5 . Table 1 shows that after acidic chemical wastewater is treated with iron powder, the pH is significantly improved, the chroma is significantly removed, and the BOD of the wastewater 5 / COD Cr The improvement effect is remarkable, and the toxic pollutants in the waste water can be reduced and transformed by the iron powder, thereby improving the biodegradability of the waste water. And the dissolved ferrous iron of 1384mg / L was produced after reacting 2h.

[0019] Table 1 Effect of iron powder on acid wastewater treatment

[0020] pH Fe 2+ Concentration / mg.L -1 Chroma COD Cr / mg.L -1 BOD 5 / COD Cr raw wastewater 1.5 ...

Embodiment 2

[0022] Take 1L of acidic wastewater with different initial pH, add 2g / L reduced iron powder, and CuCl 2 Aqueous solution, Cu / Fe mass ratio is 0.3%, stirring reaction for 6h, regular sampling analysis of ferrous concentration, chroma, pH in wastewater. Table 2 shows that when the initial pH is greater than or equal to 1.5, a good pH adjustment effect can be achieved, and a large amount of new ecological ferrous iron can be generated under low pH conditions.

[0023]Table 2 The effect of iron powder on acidic wastewater with different initial pH

[0024] initial pH 1.25 1.5 1.75 2 pH after reaction 1.7 5 6 6.7 Fe 2+ Concentration / mg.L -1 1976 1734 1384 716

Embodiment 3

[0026] A: Take 2L of acidic wastewater with an initial pH value of 2.5 (600 times the initial chromaticity), add 0.5g / L reduced iron powder, and CuCl 2 Aqueous solution, Cu / Fe mass ratio is 1%, stirring reaction for 1h, regular sampling analysis of ferrous concentration and chromaticity in wastewater.

[0027] B: Take 2L of acidic wastewater with an initial pH value of 2.5 (600 times the initial chromaticity), add 0.5g / L reduced iron powder, stir and react for 1 hour, and regularly take samples to analyze the ferrous concentration and chromaticity in the wastewater.

[0028] Table 3 shows the concentration of ferrous iron in the wastewater after the reaction and the chromaticity of the wastewater, and the results show that CuCl 2 The addition of can significantly promote the dissolution of iron powder and the formation of ferrous iron.

[0029] Table 3 Cu 2+ Effect on dissolution of iron powder

[0030] Fe 2+ Concentration / mg.L -1 Wastewater color A 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com