Non-diaphragm upflow type continuous flow bio-electrochemical apparatus for treating difficultly degraded waste water

A bioelectrochemical, refractory technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and low efficiency of BESs, and avoid pH gradient, Effect of cost reduction and prevention of pH gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

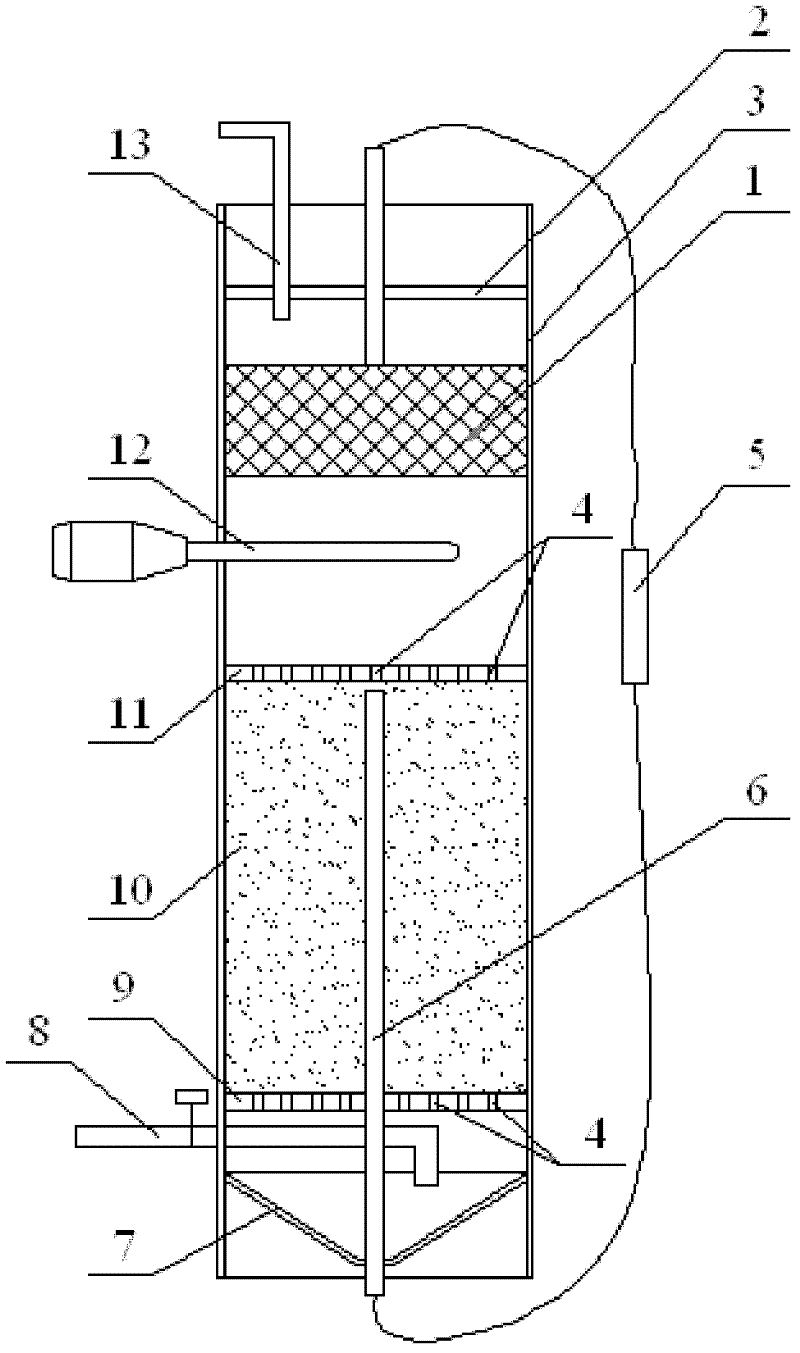

[0012] Specific implementation mode one: combine figure 1 To illustrate, the non-diaphragm upflow continuous flow bioelectrochemical device for treating refractory wastewater includes an anode 1, a top plate 2, a casing 3, a graphite rod 6, a bottom plate 7, an inlet pipe 8, a lower separator 9, and a cathode Material 10, an upper partition 11, a reference electrode 12 and a liquid outlet pipe 13, the housing 3 is fixedly connected with a bottom plate 7, a lower partition 9, an upper partition 11, an anode 1 and a top plate 2 from bottom to top, The outlet of the liquid inlet pipe 8 is located between the bottom plate 7 and the lower partition 9, the reference electrode 12 is located between the upper partition 11 and the anode 3, the liquid outlet pipe 13 is installed on the top plate 2 and the inlet is located above the anode 1, and the cathode The material 10 is installed between the upper partition 11 and the lower partition 9, the graphite rod 6 passes through the lower p...

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment is different from Embodiment 1 in that: the anode 1 is a carbon fiber brush. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the cathode material 10 is graphite particles. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com