Coupling filler autotrophic denitrification biofilter and application

A technology of autotrophic denitrification and biological filter, which is applied in special compound water treatment, biological water/sewage treatment, anaerobic digestion treatment, etc. Efficiency improvement, increasing denitrification rate, and solving the effect of nitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The implementation steps of the preparation method and application of autotrophic denitrification biofilm filler in the following examples are:

[0047] Step (1), preparation and filling of filler: uniformly mix and couple pyrrhotite, sulfur, calcium carbonate / magnesium carbonate minerals according to a certain volume ratio, and then fill them into the reactor;

[0048] Step (2), inoculation of film formation: inoculate the reactor in step (1) with activated sludge or sulfur autotrophic denitrification bacteria, add nutrient solution and cultivate for several days until the completion of microbial film formation;

[0049] Step (3), operation: feed sewage to be treated into the reactor, flow through the reactor in an upflow manner, collect the overflow and discharge it through the outlet pipe, that is, the treatment of sewage nitrogen and phosphorus is completed.

Embodiment 1

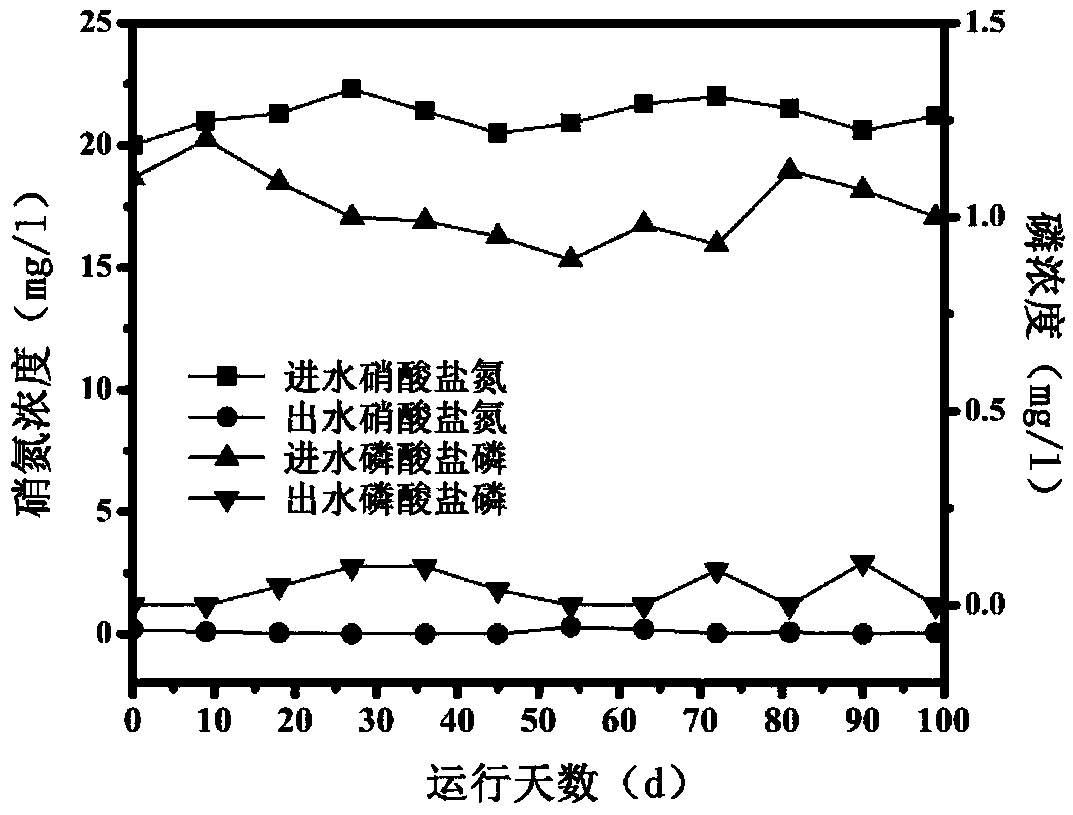

[0051] In this example, pyrrhotite, sulfur, and limestone were evenly mixed according to the volume ratio of 8:3:1 to prepare a filler with a total volume of 13L. The average particle sizes of the three minerals were 3mm, 2mm, and 2.7mm, respectively. Fill the filler into the reactor, inoculate the anaerobic sludge and add the culture solution, and complete the film formation after 8 days of cultivation. Feed water into the reactor, the hydraulic retention time is 2h, and the nitrogen and phosphorus in the water in and out during the 99d operation process are as follows: figure 1 shown.

Embodiment 2

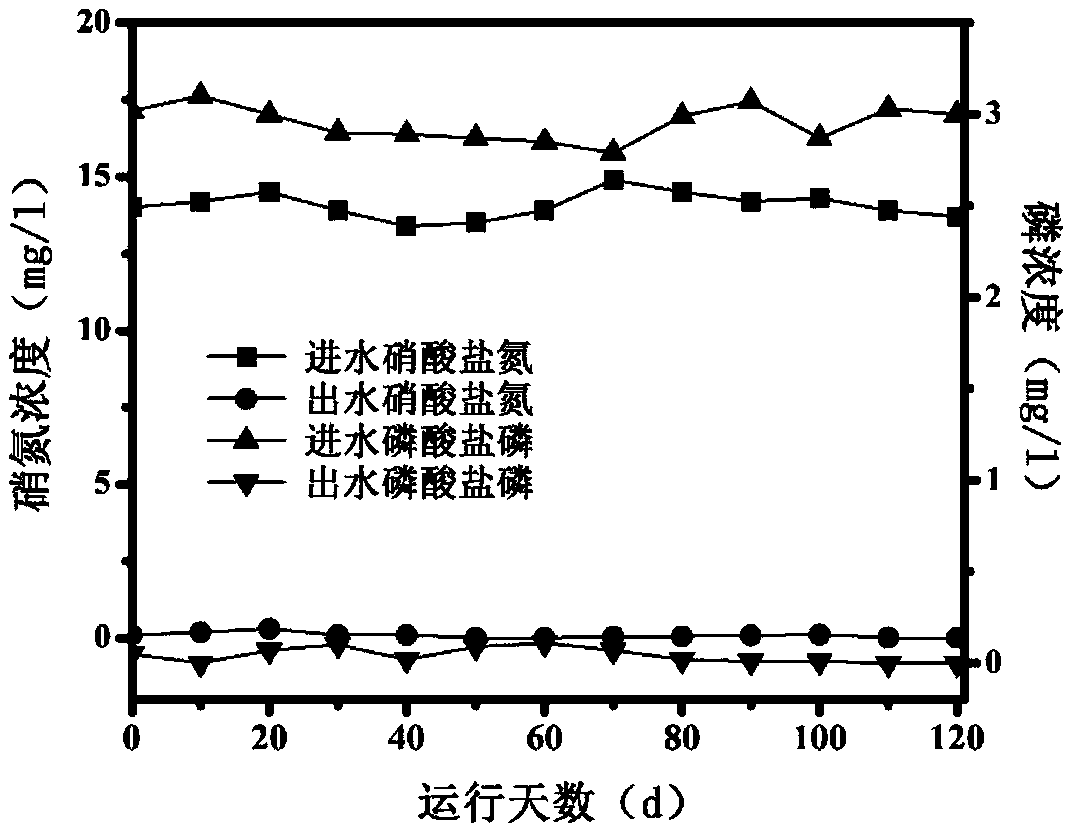

[0053] In this example, pyrrhotite, sulfur, and calcite were uniformly mixed at a volume ratio of 2:2:1 to prepare a filler with a total volume of 2L. The average particle sizes of the three minerals were 5mm, 3.5mm, and 3.3mm, respectively. Fill the filler into the reactor, inoculate the anaerobic sludge and add the culture solution, and complete the film formation after 5 days of cultivation. Feed water into the reactor, the hydraulic retention time is 1.6h, and the nitrogen and phosphorus in the water in and out during the 120d operation are as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com