Treatment device and method for mercury-containing wastewater in chlor-alkali industry

A treatment device and wastewater treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low overall efficiency and high operating cost of mercury-containing wastewater, and achieve automation High degree, easy to manage, advanced and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

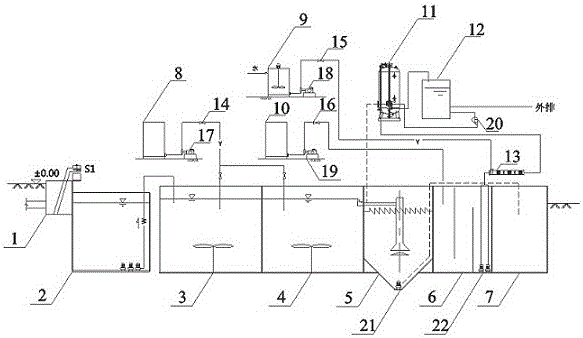

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

[0042] Such as figure 1 , a device for treating mercury-containing wastewater in the chlor-alkali industry, suitable for treating wastewater containing mercury and suspended solids in the chlor-alkali industry.

[0043] A treatment device for mercury-containing wastewater in the chlor-alkali industry. A grid pool 1, a regulating pool 2, a primary reaction tank 3, a secondary reaction tank 4, a sedimentation tank 5, a disinfection pool 6, and a sludge pool 7 are arranged in series in sequence, and a Nanometer zero-valent iron preparation pool 8, said nano-zero-valent iron preparation pool 8 is respectively connected with primary reaction tank 3 and secondary reaction tank 4 through pipelines, and a valve 14 and a metering pump 17 are arranged on the connecting pipelines.

[0044] The coagulant preparation tank 9 and the tank filter 11 are connected to the disinfection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com