External water channel evaporative cooling horizontal motor

An evaporative cooling, horizontal motor technology, used in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of large temperature gradient of the stator core, difficult heat dissipation, uneven cooling, etc., to achieve obvious cooling effect, The effect of stable chemical properties and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Further illustrate the present invention below in conjunction with accompanying drawing.

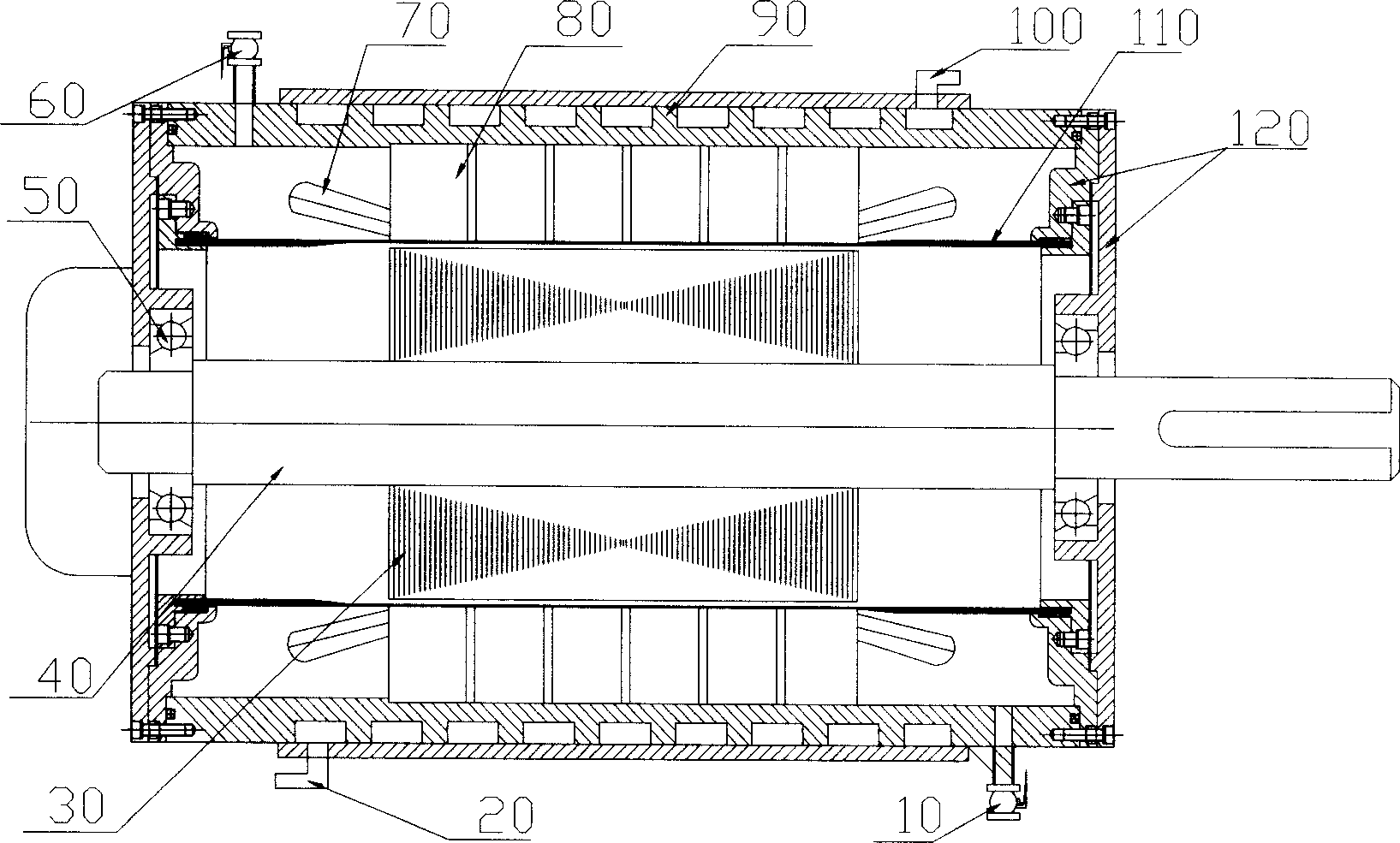

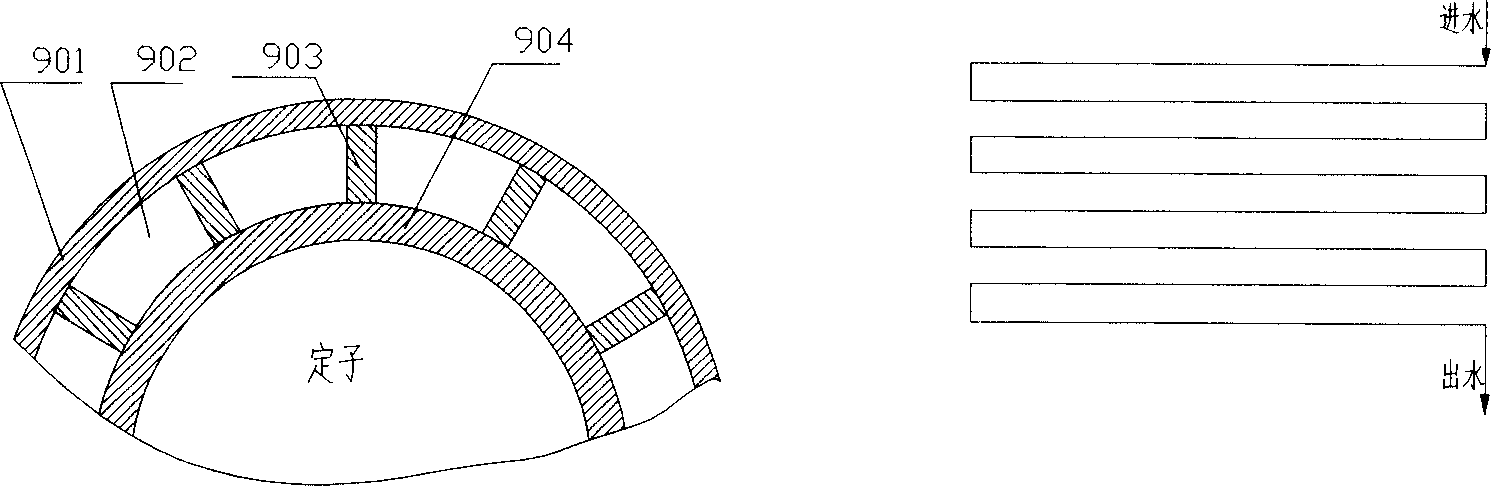

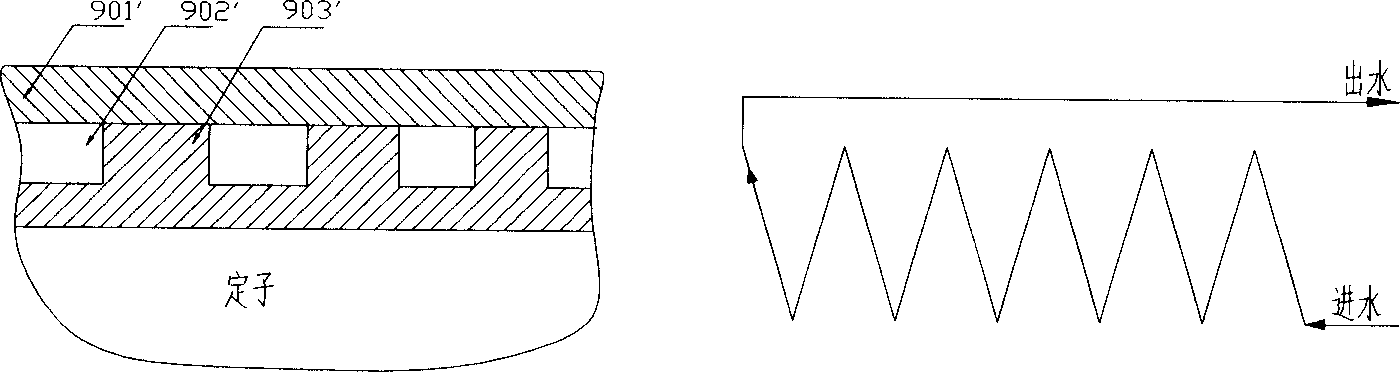

[0034] One of the specific embodiments of the present invention is as figure 1 as shown, figure 1 It is a schematic diagram of the structure of the outer channel type evaporative cooling motor. The outermost part in the figure is the motor casing, which includes the stator casing and the motor end cover 120 . The stator casing is mainly composed of an outer water channel 90, the outer water channel 90 is composed of an inner water jacket cylinder 903' and an outer water jacket cylinder 901', etc., the lower left end is provided with a water inlet 20, and the lower right end is provided with a cooling medium outlet 10, The left end of the upper part is provided with a cooling medium inlet 60, and the right end of the upper part is provided with a water outlet 100; a stator core 80 is installed in the middle of the stator casing, and the outer circle of the stator core 80 is an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com