Construction Method of Cast-in-situ Reinforced Concrete Large Diameter Pipe Pile

A technology of reinforced concrete and large-diameter pipes, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of prefabricated pile tips not being airtight, prefabricated pile tips not reusable, and reinforcement cages that cannot be lowered directly. Achieve the effects of increased horizontal bearing capacity, good sealing, and large side friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

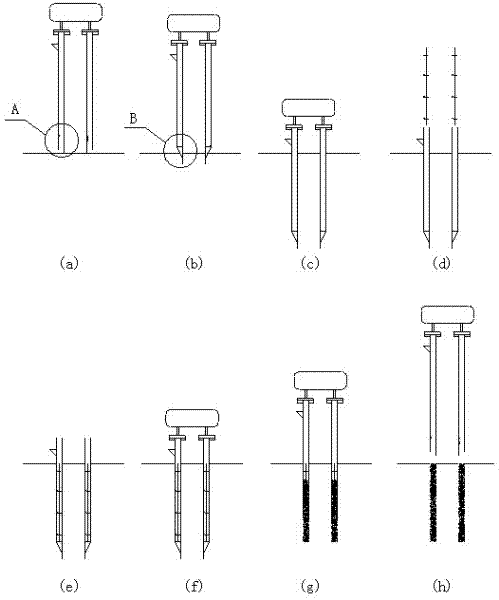

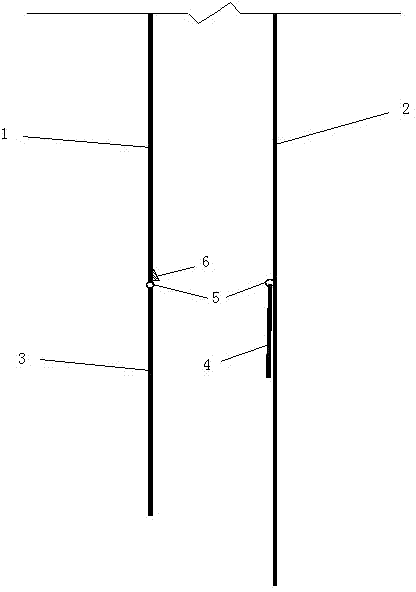

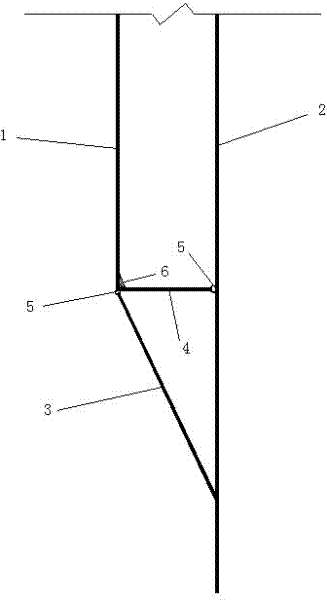

[0035] Such as Figure 1~Figure 5 As shown, the pile formwork used in the construction method of cast-in-place reinforced concrete large-diameter pipe piles is composed of an outer pipe 1 and an inner pipe 2 to form a double-layer concentric casing. 3. A movable inner support 4 is set between the outer pipe 1 and the inner pipe 2, the movable inner support 4 is connected to the wall of the inner pipe 2 through the movable shaft 5, the movable shaft 5 is flush with the bottom end of the outer pipe 2, and the movable inner support 4 rotates to the horizontal , the limiter 6 just limits its continued rotation, so that the movable inner support 4 just supports the outer tube 1 and the inner tube 2, ensuring that the formed annular cavity is uniform. The movable inner support 4 can be a short steel bar, requiring high rigidity and small deformation, and three or more can be evenly arranged along the annular cavity. The limiter 6 is a right-angled triangular steel plate, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com