Ultrahigh large-span concrete cast-in-place beam bailey truss framework construction method

A construction method and concrete technology, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., can solve the problems of erecting frame body length and height restrictions, and achieve reduced labor intensity, high rigidity, Guaranteed weld seam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

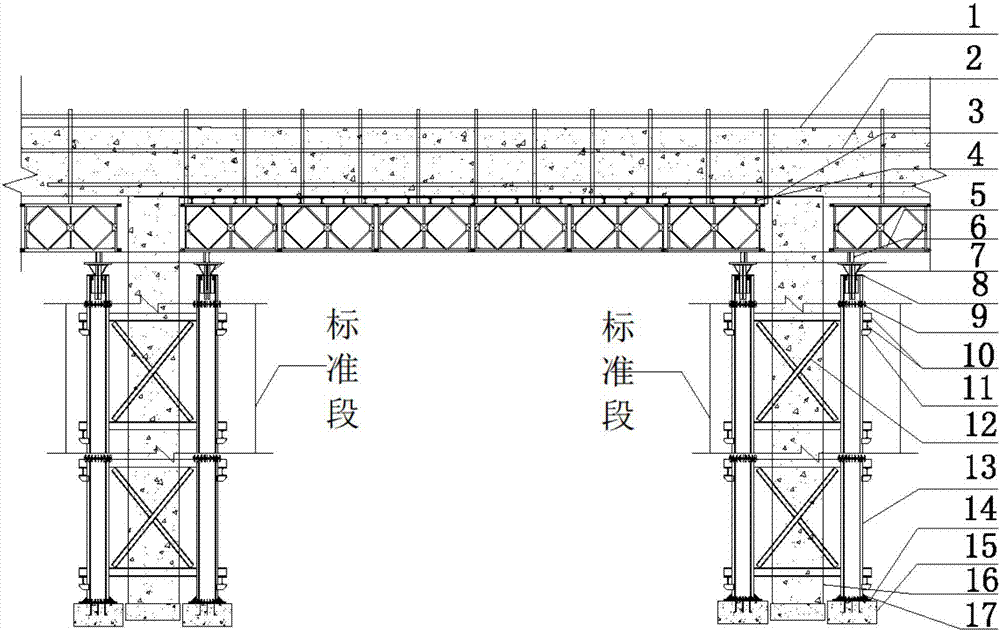

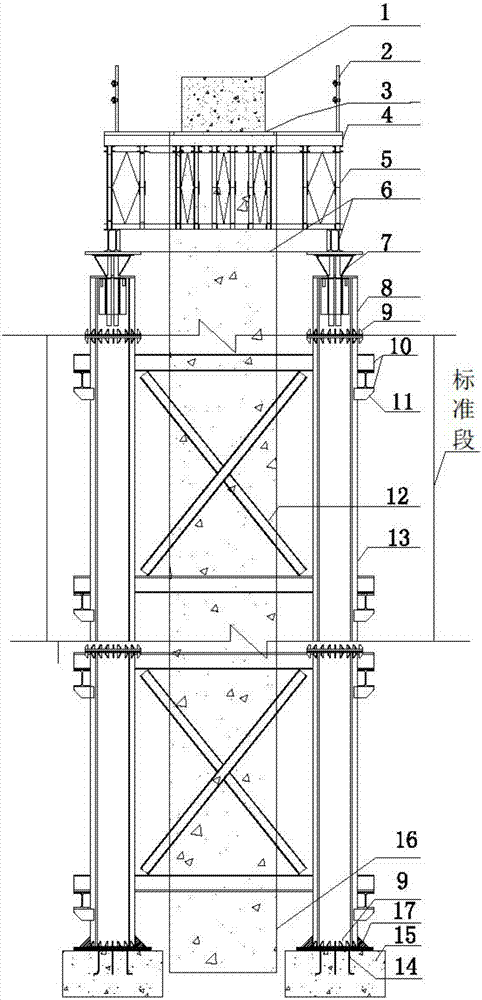

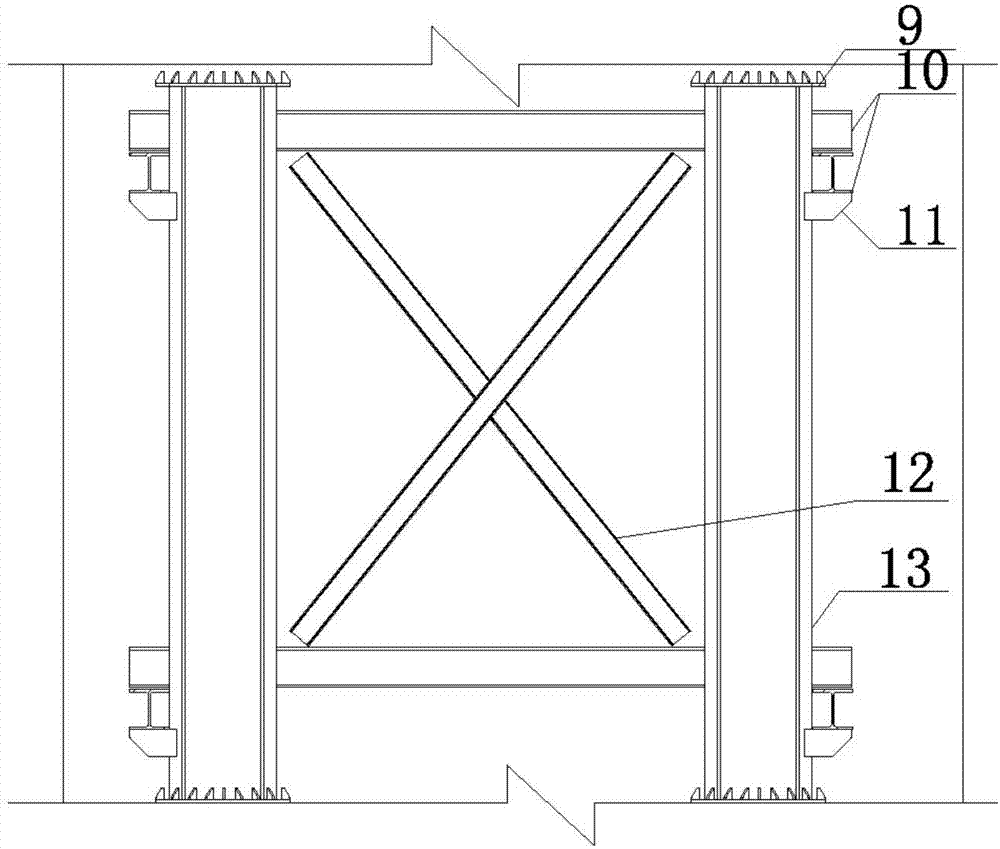

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] Figure 1-Figure 5 Shown is the implementation drawing of the high formwork installation construction method of the present invention, and it comprises the steps:

[0034] (1), lattice column foundation construction,

[0035] see figure 1 According to the design drawings of the lattice column foundation, the steel column embedded parts 14 are processed in advance, the setting-out and positioning are carried out on site, the foundation is excavated, and the foundation groove is inspected to ensure that the foundation meets the requirements of the foundation bearing capacity. After pouring a 100mm cushion, and then Support the formwork on the foundation, bind the steel bars, install the embedded parts, and pour concrete. During the construction of the concrete foundation 15, pre-embed the embedded parts 14 on the concrete foundation, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com