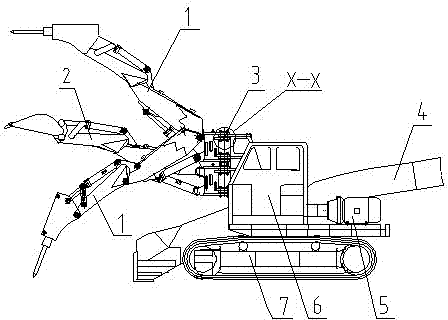

Multi-arm breaking excavation-type heading machine

A technology of excavation and roadheader, which is applied in the directions of slitting machinery, earthwork drilling and mining, etc., can solve problems such as shortening time, and achieve the effect of reducing labor hours, reducing construction costs, improving construction efficiency and safety production technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

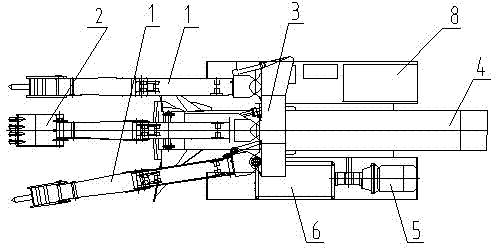

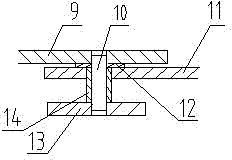

[0011] exist figure 1 , figure 2 and image 3 Among them, the multi-arm crushing and excavating roadheader includes a frame, a traveling mechanism 7, a transport mechanism 4, a hydraulic system 8, an electrical system 5, an operating driving mechanism 6 and an excavating mechanism 2, and the hydraulic system 8 includes hydraulic pumps, manual Reversing valve, manual pilot valve, plunger pump, coupling, radiator and oil tank, the hydraulic system is provided with a cross-link hydraulic control multi-way reversing valve; the walking mechanism 7 includes guide wheels, crawlers, expansion Tightening devices, track beams, supporting wheels, driving wheels, supporting wheels and travel motors, supporting rollers matching the track are arranged at intervals below the track beams, and supporting weights matching the bureau length are arranged at intervals above the necessary belt beams Wheel, on the track beam is provided with a tensioning device that can change the relative positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com