Multi-head minor-diameter long-spiral drilling machine and application thereof in construction of cast-in-situ major-diameter tubular pile

A technology of long auger drilling rig and large-diameter pipe, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of difficult construction of immersed pipe, significant soil squeeze effect, etc., and achieves clear construction process, good pile forming effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

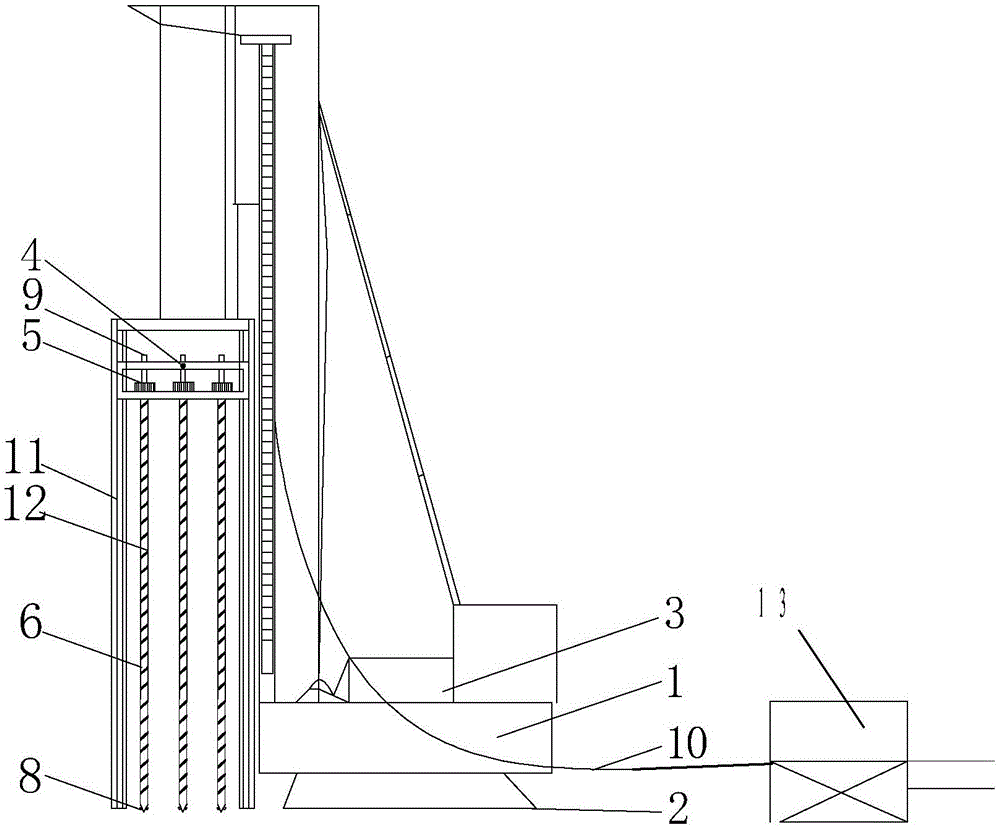

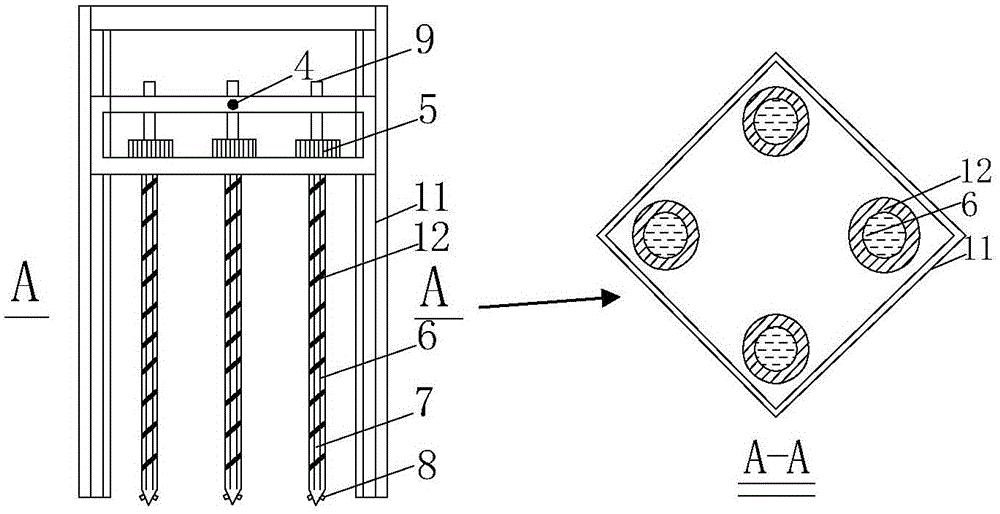

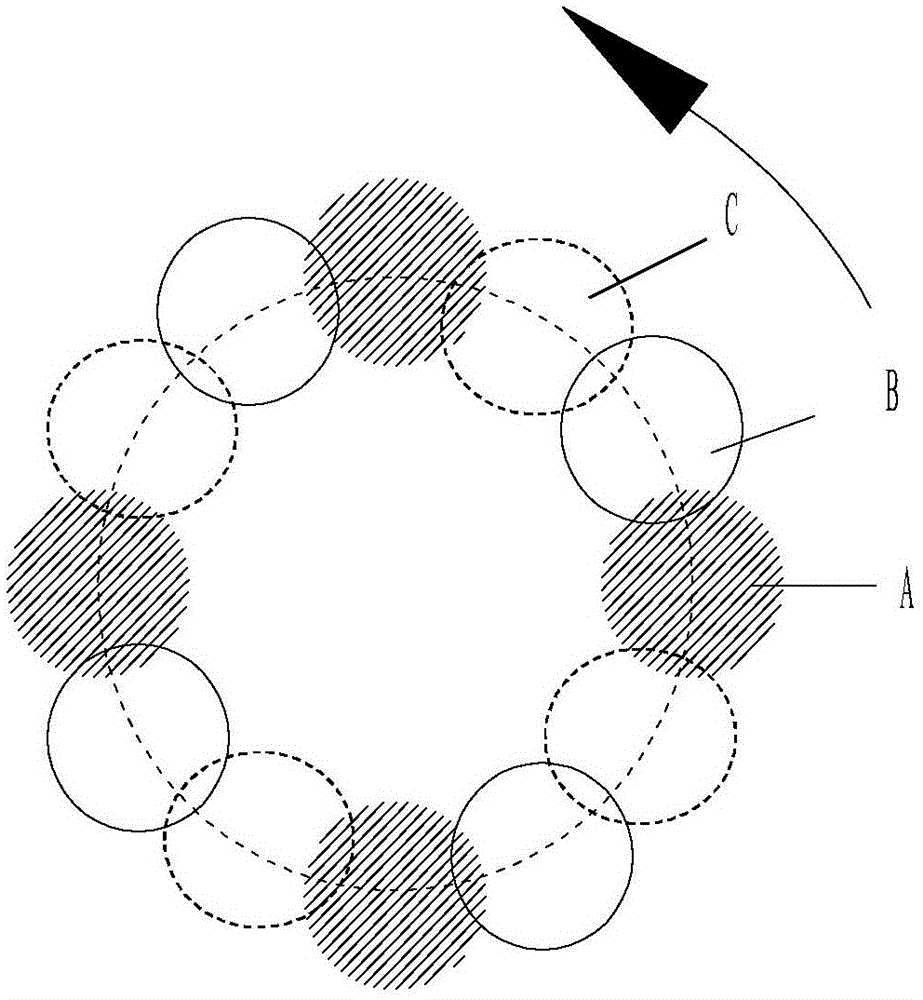

[0027] Such as figure 1 , 2 As shown in and 3, the winch 3 and the main engine 1 are located on the chassis 2, and the long auger rod 6 is fixed on the top of the positioning frame 11, and the positioning frame 11 is connected to the power unit 5 in rotation, and the positioning frame can be positioned after each construction. 11 rotation angles. The long auger rod 6 is a hollow structure, which is composed of a core pipe 7 and a helical blade 12. The top of the long auger rod 6 is provided with an exhaust valve 9, and the bottom is provided with a flap valve 8. Before the drilling tool cuts the soil, the flap valve 8. Close to prevent soil, sand or water from entering the auger core pipe 7, and open the flap valve 8 when pumping concrete. The arrangement of multi-axis drill pipes, the staggered side view of blades and the top view of A-A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com