Manual hole digging pile and construction method thereof

A technology of artificial digging piles and construction methods, applied in sheet pile walls, foundation structure engineering, construction and other directions, can solve the problems of popularization and application in difficult coastal soft soil areas, poor friction effect, single pile shape, etc., and achieve increased strength. and stiffness, increase side friction resistance, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

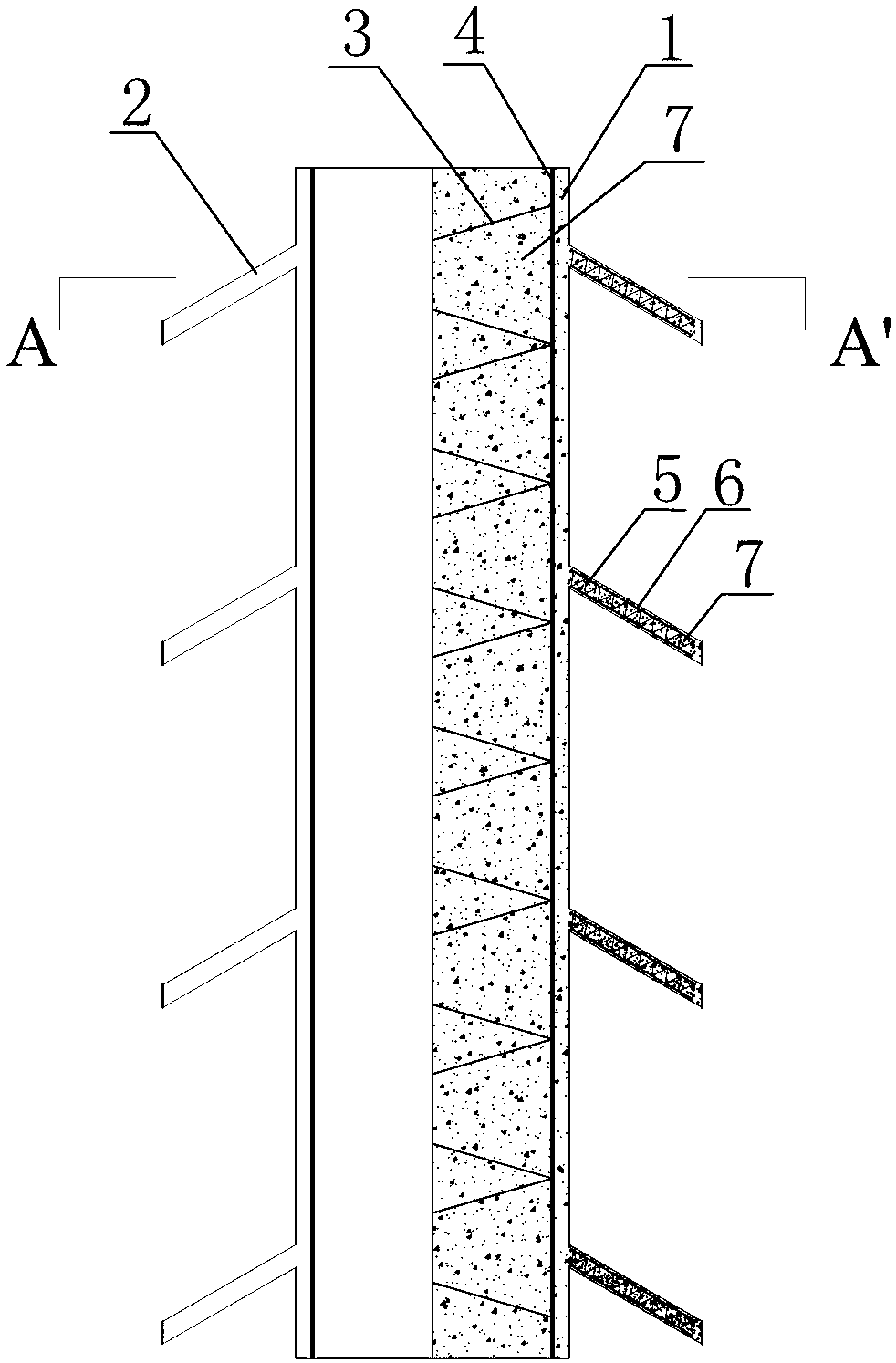

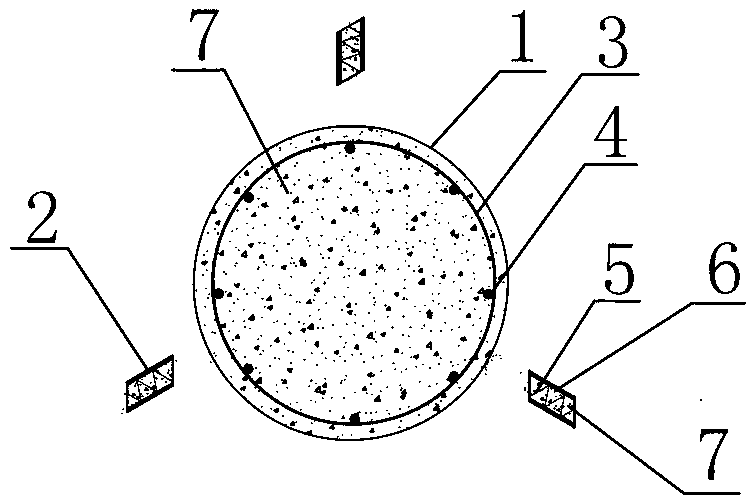

[0034] An artificial hole-digging pile of the present invention comprises a cylindrical trunk pile body 1 and several cylindrical branch pile bodies 2, and the branch pile bodies 2 are fixedly distributed on the outer wall of the trunk pile body 1.

[0035] In this specific embodiment, the branch piles 2 are distributed in an equilateral triangle on the circumferential section of the trunk pile 1. Considering the convenience of construction, and making the friction of the branch-shaped piles and the strength and stiffness of the surrounding soft soil reach the best The cooperation of branch pile body 2 and trunk pile body 1 is 15-25°, the diameter of trunk pile body 1 is 1.8-3.0m, the diameter of branch pile body 2 is 150-300mm, and the length of trunk pile body 1 is 15-3.0m. 20m, and the length of the branch pile body 2 is 1-2m.

[0036] In this specific embodiment, the trunk pile body 1 is provided with a trunk reinforcement skeleton, which includes a trunk spiral stir...

specific Embodiment 2

[0037] A kind of construction method of manual hole-digging pile of the present invention specifically comprises the following steps:

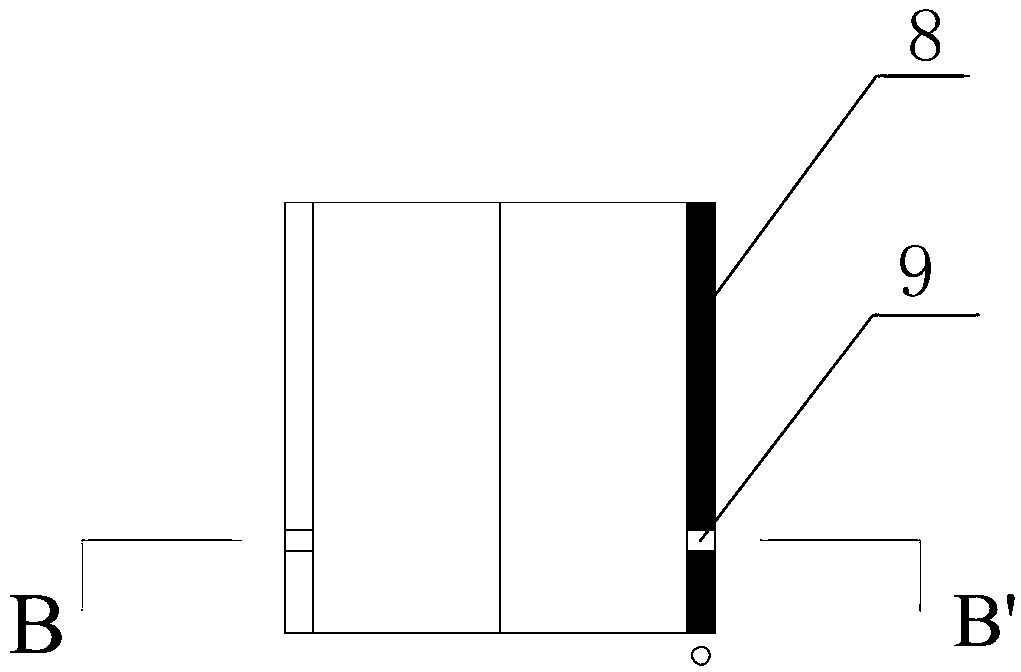

[0038] (1) Buried steel casing

[0039] Excavate the hole of the casing, press the first-level main steel casing 8 by the static pressure method, manually excavate the soft soil in the first-level main steel casing 8, and pump water while excavating until the first-level predetermined depth;

[0040] (2) Press the branch casing 10 into the cutout 9 of the first-level trunk steel casing 8, use Luoyang shovel to dig out the soil in the branch casing 10, and pump out the internal seepage;

[0041] (3) Weld the second-level main steel casing 8 on the top of the first-level main steel casing 8, and statically press it into the soil, and manually excavate the soft soil in the second-level main steel casing 8, while excavating pumping until the second predetermined depth is reached;

[0042] (4) Press the branch casing 10 into the cutout 9 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com