Pile forming method for submerged orifice impact jet grouting composite pile

A composite pile and pile-forming technology, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of weak adaptability of core piles and small ground range, so as to increase the ability to resist horizontal loads, improve seismic performance, The effect of increasing end resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

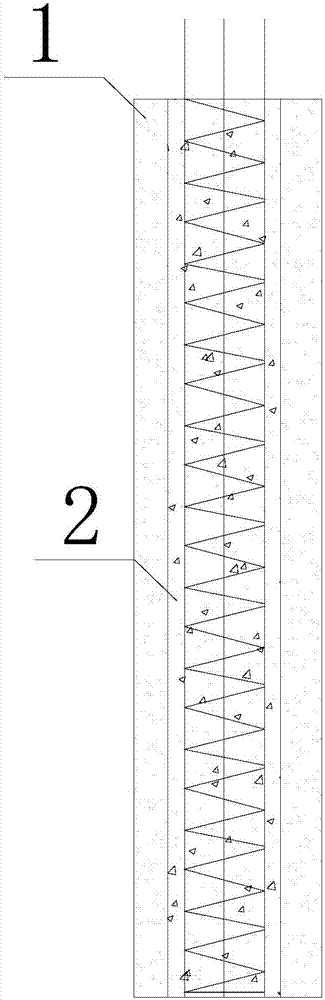

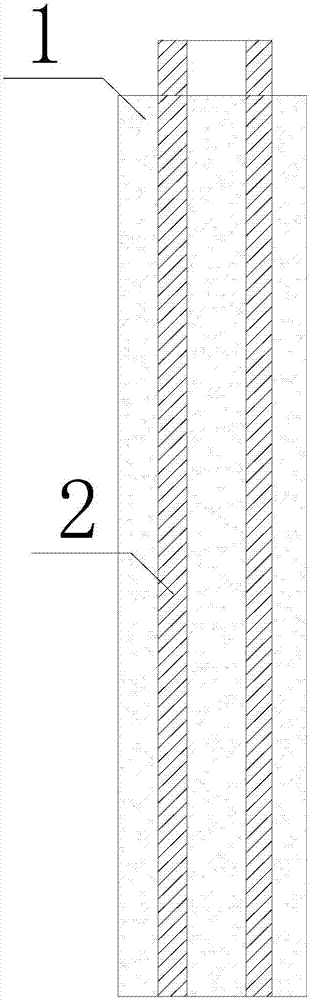

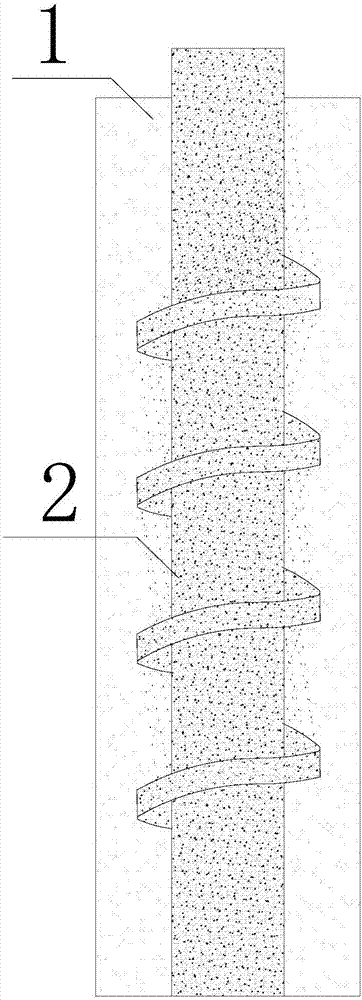

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0032] The invention discloses a pile-forming method of a submerged-hole impact rotary-grouting composite pile, which comprises the following steps:

[0033] Step A: first use the down-the-hole impact high-pressure rotary grouting pile construction technology to form the cement-soil outer pile 1; Spraying, that is, horizontal high-pressure spraying above the bottom of the down-the-hole impactor. While drilling, provide high-pressure water (slurry) with a pressure of not less than 15MPa to the injector to cut and soften the soil to ensure the radial aperture during drilling; In addition to the construction of rotary grouting piles in cohesive soil, silt and loose sand, large diameter rotary grouting piles can also be formed in dense sand layers, pebbles, gravels, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com