Concrete pile construction equipment and construction method thereof

A technology for concrete piles and construction equipment, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of insufficient utilization of the original soil, inability to carry out the next construction, and extension of the construction period, and achieve transportation costs and entry and exit. The effect of low cost, strong construction continuity and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

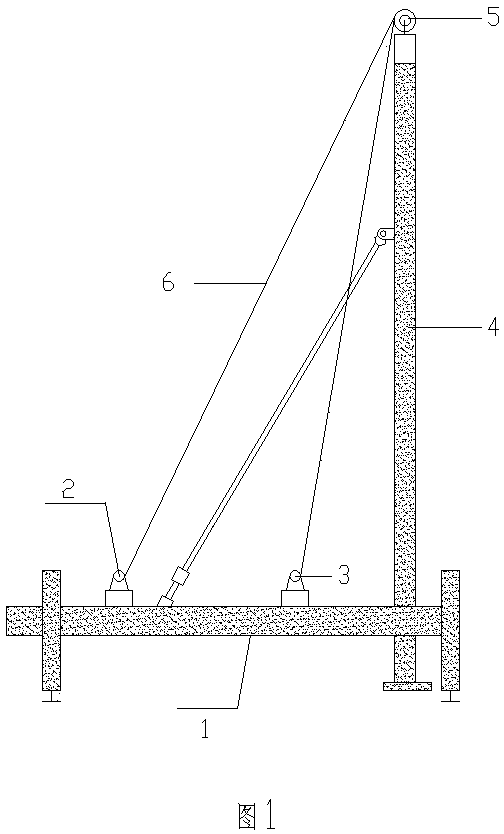

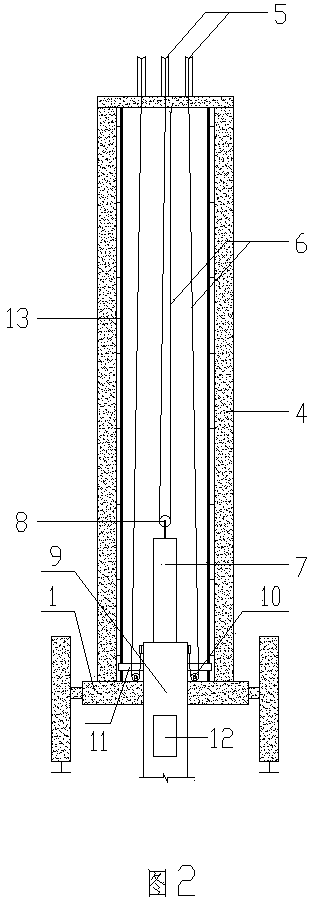

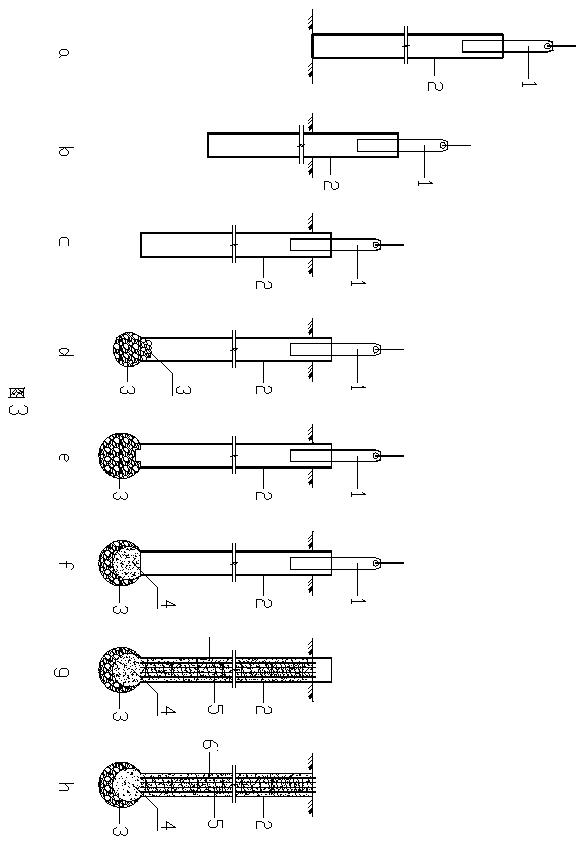

[0039] figure 1 is the front view of the construction equipment of the concrete pile of the present invention, figure 2 is a side view of the construction equipment of the concrete pile of the present invention, as figure 1 with figure 2 As shown, a high-power hoist 2 and a low-power hoist 3 are fixed on the chassis 1, a bracket 4 perpendicular to the chassis is provided at the front end of the chassis 1, and a pulley 5 is arranged at the upper end of the bracket; the rated load of the high-power hoist 2 is 40kN~80kN, from The protruding wire rope 6 in the high-power winch 2 passes through the pulley 5 on the upper end of the support 4 and then passes through the pulley 8 set on the top of the weight 7, and the other end of the wire rope 6 is connected and fixed on the top of the support 4, thereby realizing high-power hoisting. The hoist 2 drives the weight 7 to lift; the weight 7 is a slender steel weight that can penetrate the casing 9, the bottom of the weight 7 is point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com