Cement-soil composite pile inserted into reinforced concrete core materials

A technology of reinforced concrete and cement-soil piles, which is applied in sheet pile walls, buildings, and foundation structure engineering. It can solve the problems of rammed and expanded piles disturbing residents, low strength, and increased construction costs, and achieves improved side friction resistance and pull-out resistance. Improvement, economy and environmental protection noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

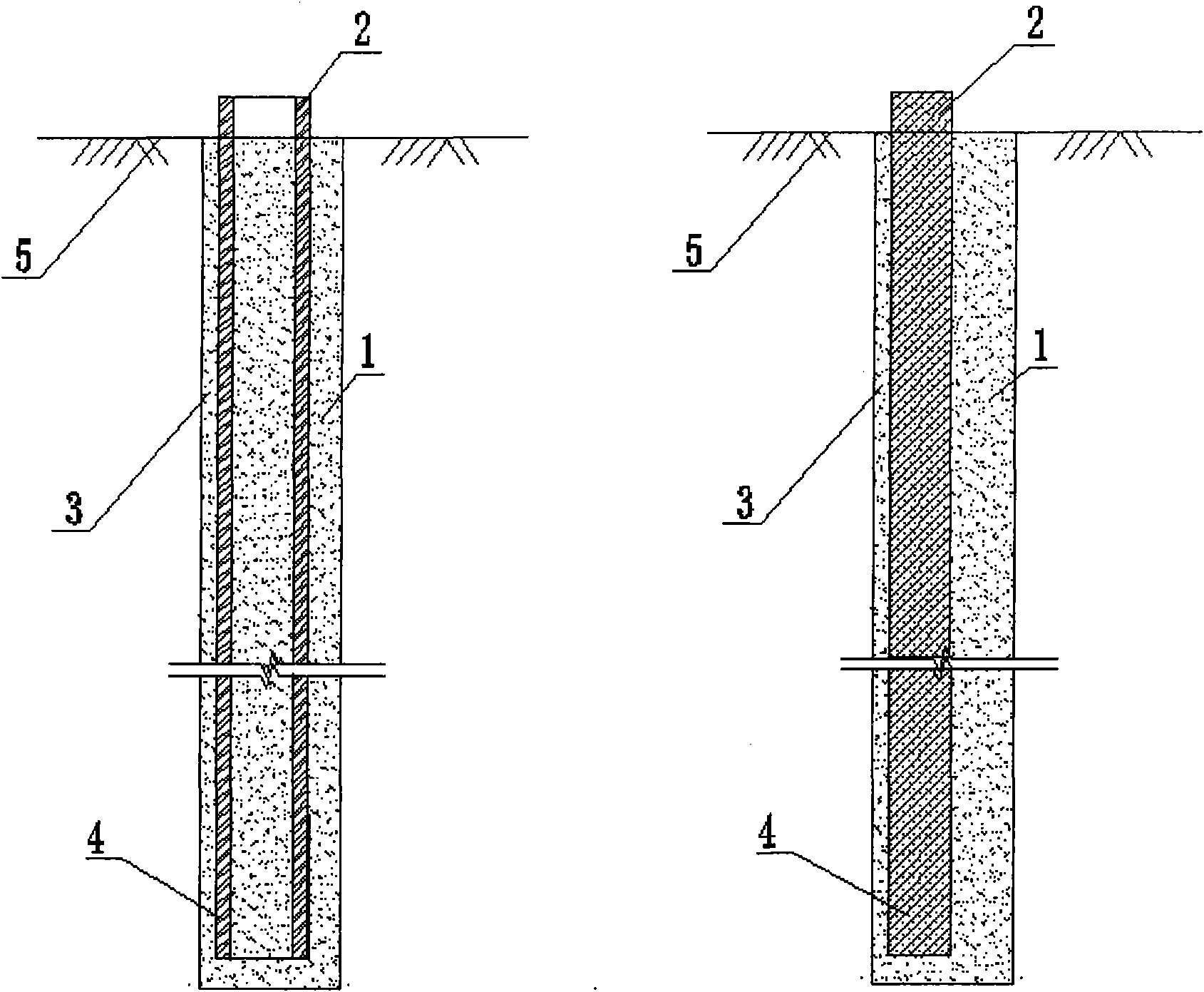

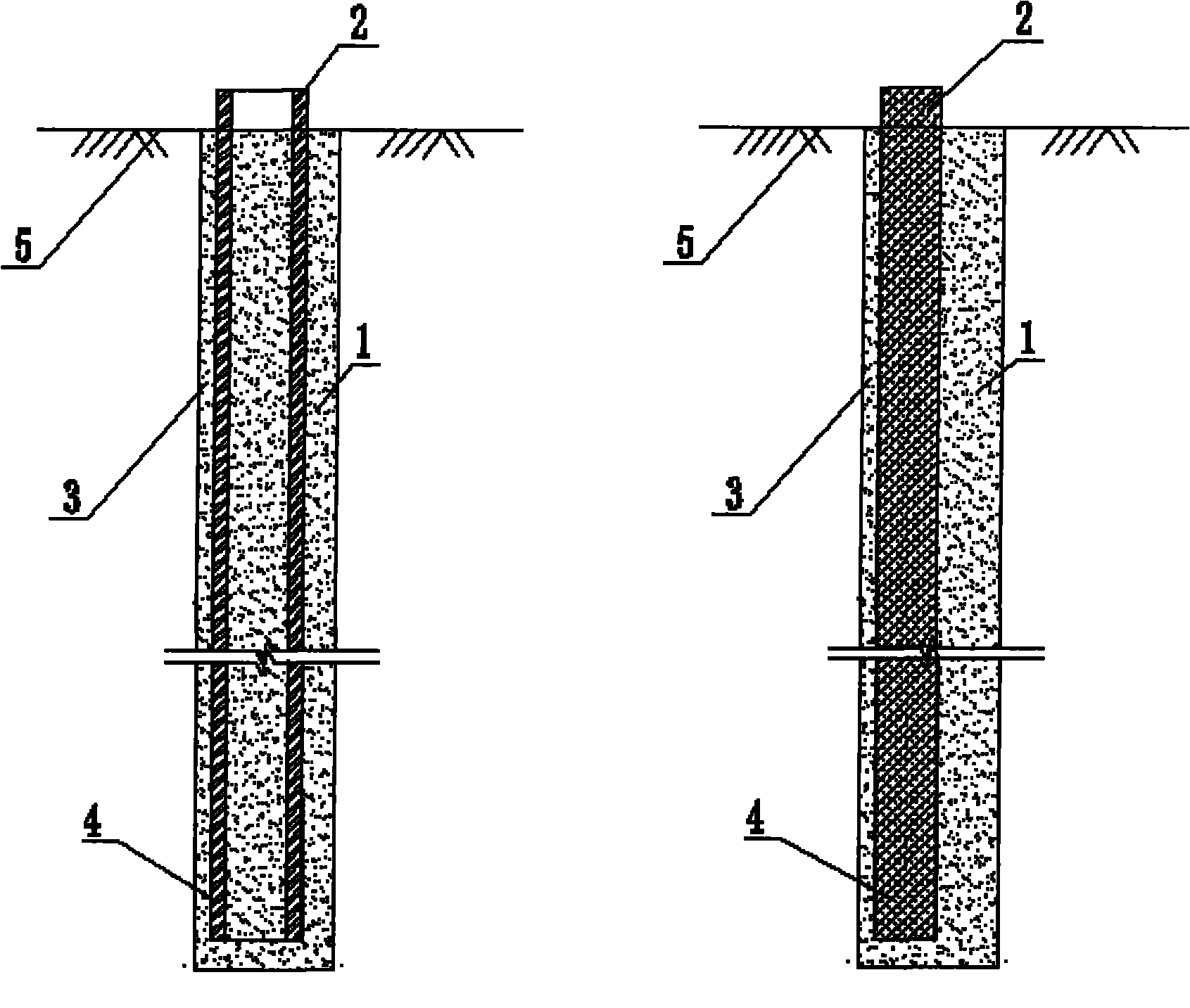

[0017] (1) First, use a single-axis, two-axis or three-axis mixing pile driver to mix the soil with the cement slurry to form cement soil

[0018] (2) Then vibrate or insert one (or several) core materials (prestressed concrete pipe piles, prestressed concrete pipe square piles, prefabricated reinforced concrete components, etc.) into a composite pile body.

[0019] (3) The insertion position is related to the requirements for the flexural strength of the composite pile. When higher flexural strength is required, the inserted core material should be close to the bending place; when higher vertical bearing capacity is required, then The inserted core material should coincide with the center of the stirring pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com