Large-diameter cast-in-place concrete pile defect treatment reinforcing structure and construction method

A defect treatment and structural reinforcement technology, applied in the direction of foundation structure engineering, foundation structure repair, sheet pile wall, etc., can solve problems such as increased cost, construction period impact, and difficulty in achieving strength, so as to enhance lateral friction resistance and prevent collapse. Pore and water seepage, the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

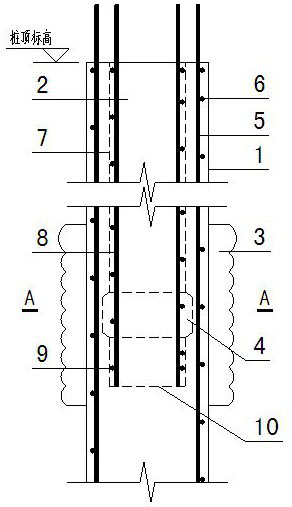

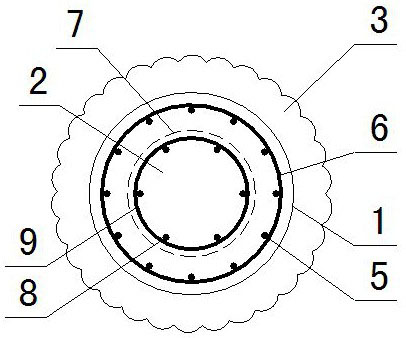

[0035] Such as figure 1 , figure 2 As shown, the reinforcement structure of large-diameter concrete cast-in-place pile defect treatment includes: defective large-diameter concrete cast-in-situ pile 1, defective large-diameter concrete cast-in-situ pile 1 contains pile body defect section 4 with quality problems such as mud inclusion and segregation, After the pile body is drilled and excavated, the core pile 2 after refilling treatment is installed. The core pile 2 is equipped with core pile longitudinal reinforcement 8 and core pile stirrup 9 according to the design requirements, and high-pressure rotary jet grouting is installed in a certain range around the defective section 4 of the pile body. Reinforcement section 3, according to the design requirements, determine the excavation side boundary 7 of the pile body and the bottom boundary 10 of the pile body, and the original pile longitudinal reinforcement 8 and the original pile stirrup 9 must be protected during the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com