Patents

Literature

76results about How to "Prevent hole collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

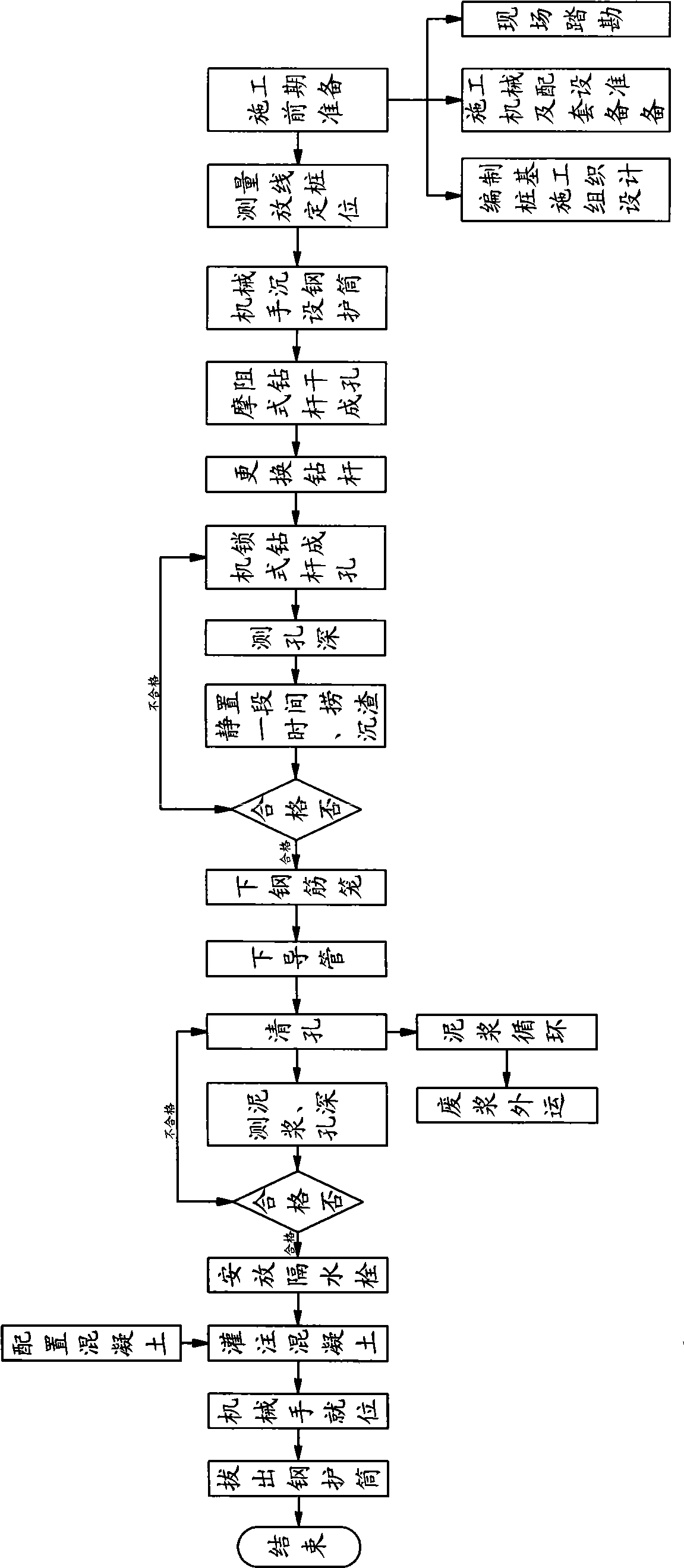

Construction process of cast-in-situ bored pile

The invention relates to a construction process for the pile foundation in the civil engineering, in particular to a construction process of a bored pouring pile. During the process, a steel casing is sunk on the upper surface of the dense soil layer at the soft soil layer section; the wall of the pile is protected by the steel casing; subsequently, a rotary excavation drilling machine with a friction-typed drilling rod is used for forming hole; at the dense soil layer section, the rotary excavation drilling machine with a lock-typed drilling rod is used for forming hole. Therefore, the boring deviation and diameter enlarging of the pile can be effectively avoided; the pile quality and the operation efficiency are improved; if the dense soil layer section contains the substance with plenty of underground water, the slurry is used for protecting the wall of the pile during the hole-forming process; after the hole is completed, the hole is arranged statically for certain a time; the sunk slag at the bottom of the pile is removed by a cylindrical drilling bucket; and if the dense soil layer contains the substance which has no underground water basically or has little underground, the dry hole-forming method is used. The construction process can avoid collapsing of the hole, reduces the displacement of the slurry and reduces the pollution to the environment.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

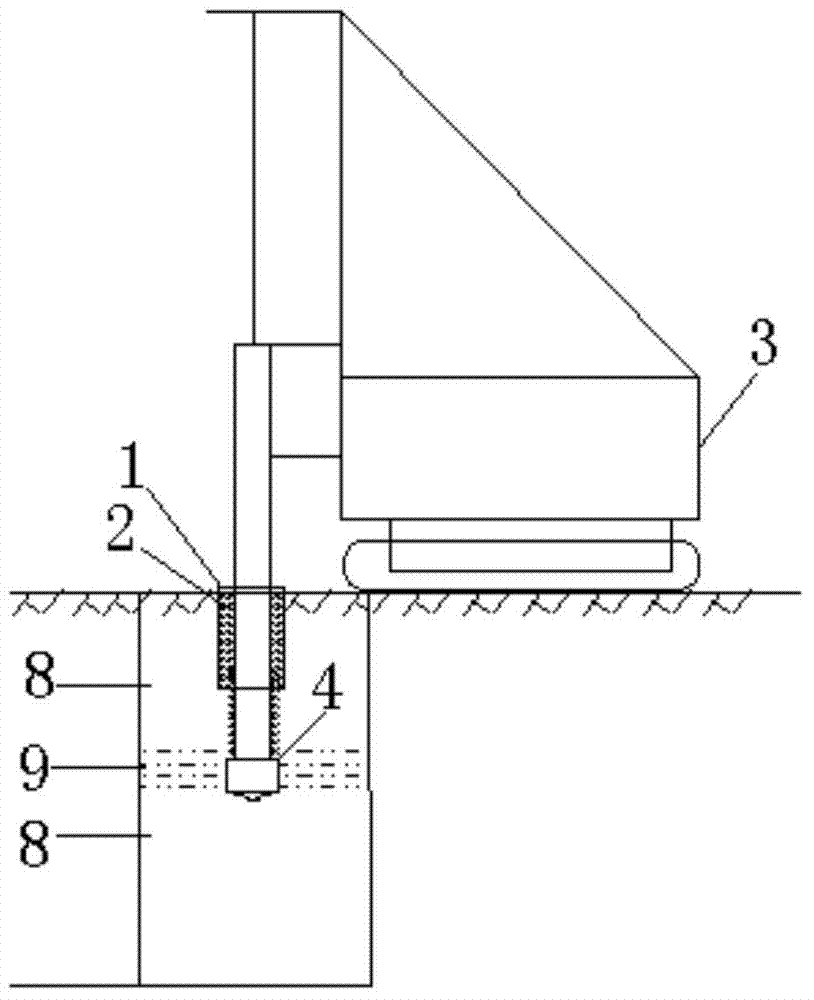

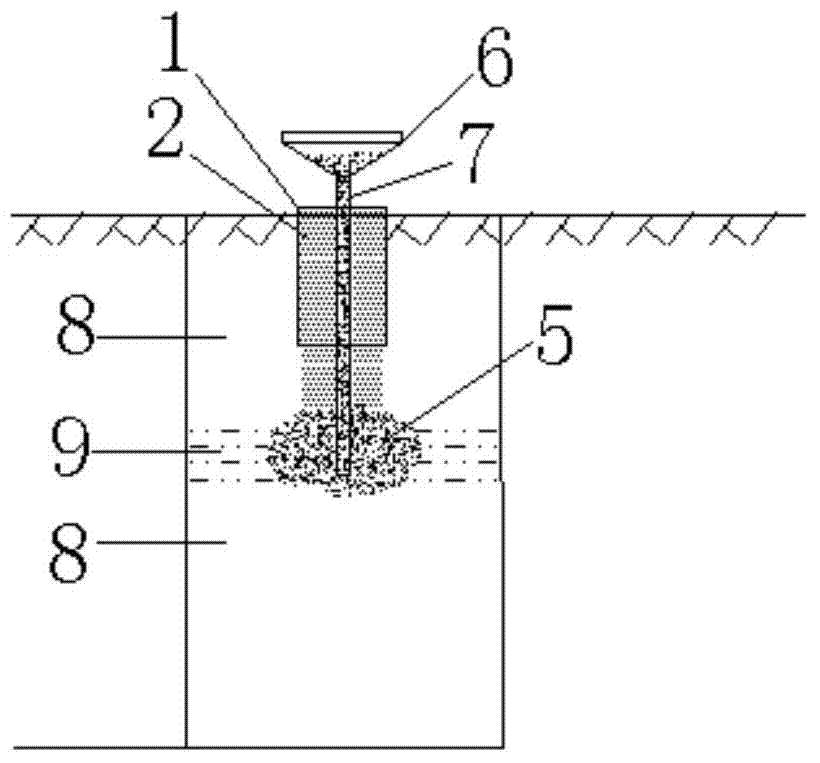

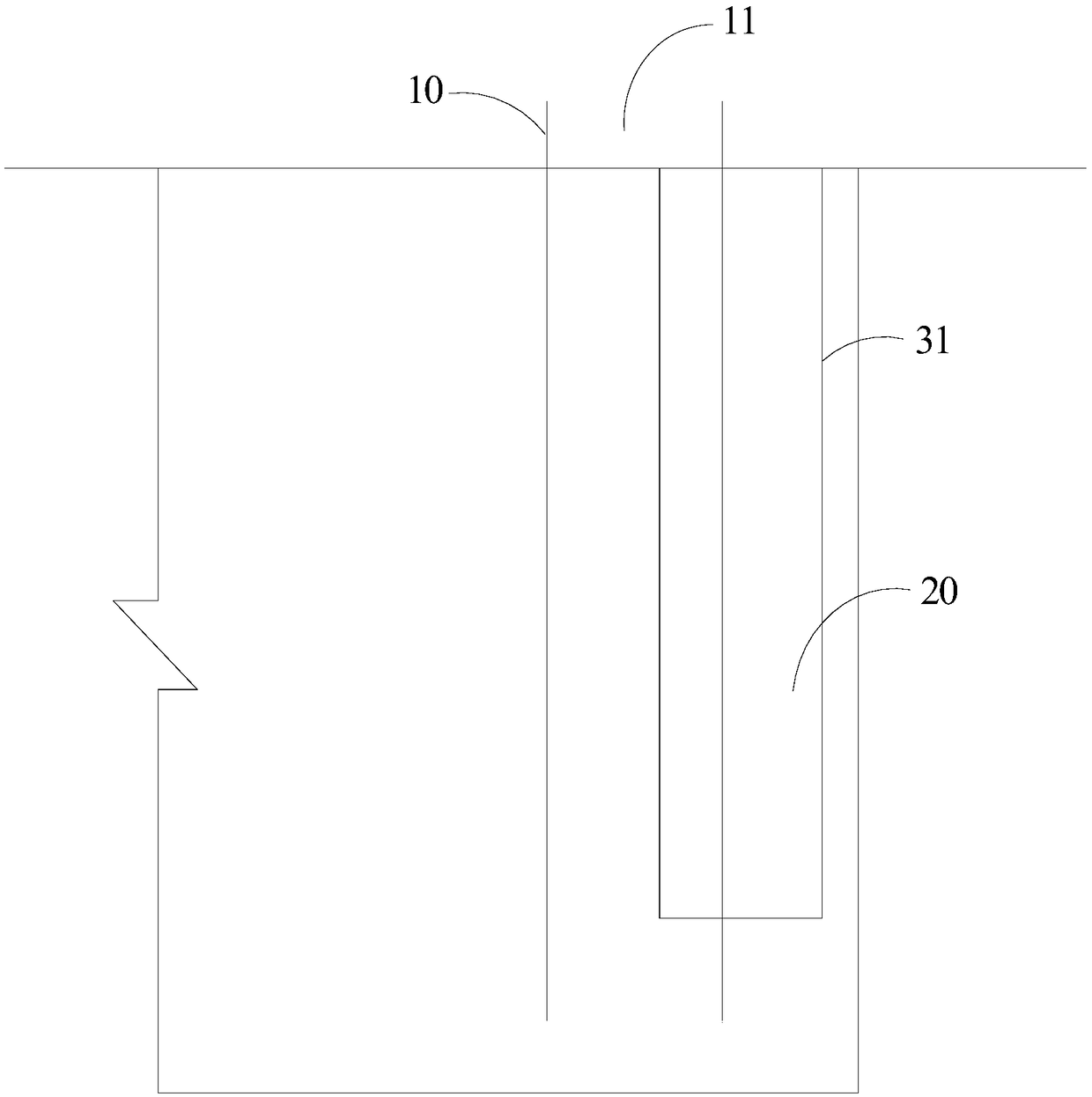

Coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method

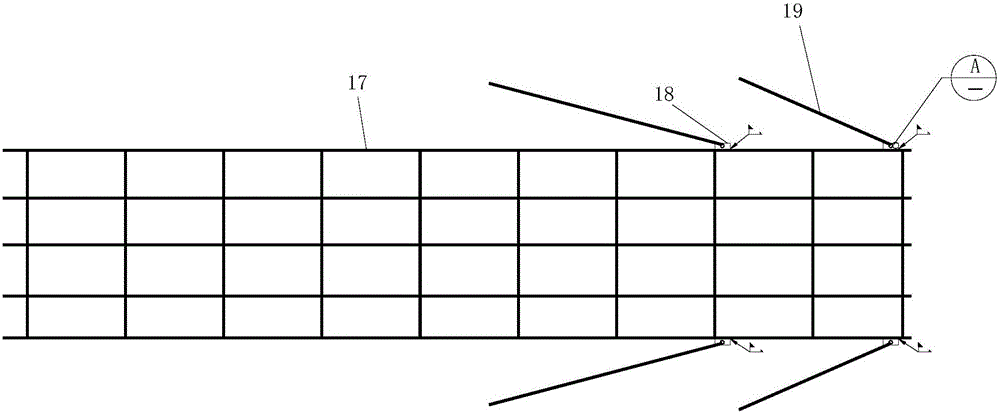

ActiveCN108643877AIncrease the scope of fracturing anti-reflectionEfficient extractionFluid removalGas removalUnderground tunnelCement paste

The invention discloses a coal mine underground coal seam long drill hole staged fracturing permeability increase and gas extraction method. The coal mine underground coal seam long drill hole stagedfracturing permeability increase and gas extraction method comprises the steps that a long drill hole with the length more than 100m are drilled into a coal seam using a underground tunnel drilling machine for a coal mine or a kilometer drilling machine; a rigid casing with an one-way valve is lowered into to protect the hole directly using the underground tunnel drilling machine or the kilometerdrilling machine, and casing centralizers are installed at regular intervals; after the casing is lowered, preset volumetric cement paste is injected into an annular space between the outer wall of the casing and a drill hole wall to carry out blocking and sealing; a rigid fracturing pipe with two or multiple packers is lowered into the casing to carry out coal seam staged fracturing step by stepor multistage staged fracturing; and the fracturing pipe and the packers are removed after staged fracturing permeability increase, the casing of coal seam long drill hole opening is accessed with a gas extraction pipeline after drainage finishes to carry out efficient extraction of gas. The engineering amount of a tunnel and hole-drilling can be greatly reduced, the coal seam gas extraction efficiency is improved, and the coal mine underground gas treatment cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

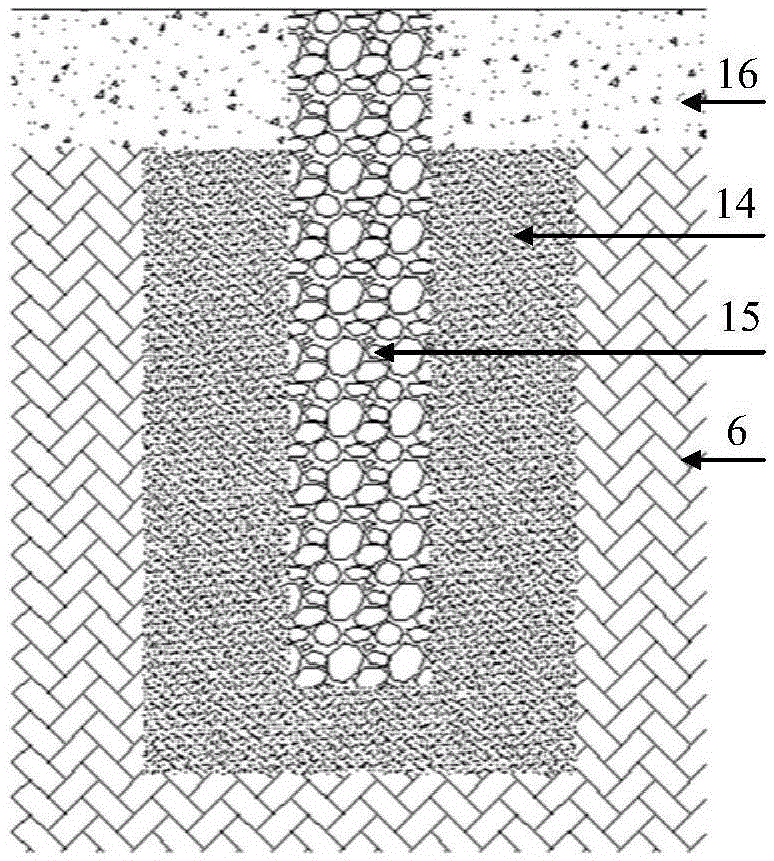

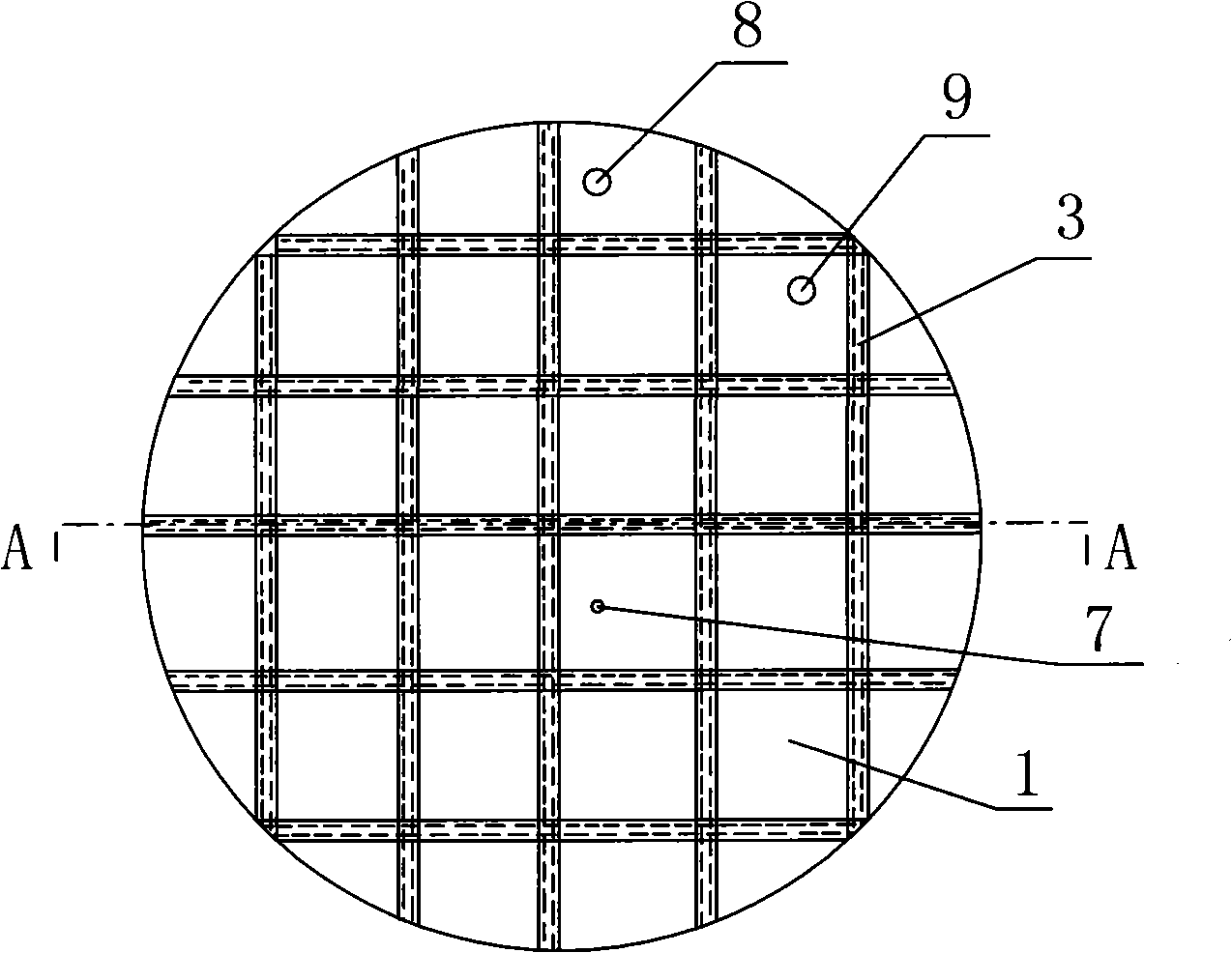

Composite foundation with discrete material pile restrained through microorganism soil solidification and construction method

ActiveCN105386436AImprove bearing capacityIncrease profitBuilding constructionsOrganic fertilisersMicroorganismSoil science

The invention relates to a composite foundation with a discrete material pile restrained through microorganism soil solidification and a construction method. The construction method includes the steps that a, a pile pipe is pressed into a foundation body; b, meanwhile, microorganism bacterium liquid is injected into a gap between an inner steel sleeve and an outer steel sleeve and diffused into the foundation body around the pile; c, the microorganism bacterium liquid is pumped out, a cementing solution is injected and diffused into the foundation body around the pile and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and loose sandy soil or floury soil is cemented; d, the step b and the step c are repeated until the soil around the pile meets reinforcement requirements; e, discrete materials are poured into a hole of the inner steel sleeve; and f, a bed course is laid, so that the composite foundation is formed. According to the composite foundation with the discrete material pile restrained through microorganism soil solidification, the microorganism bacterium liquid and the cementing solution react to generate calcium carbonate so as to solidify the soil around the pile, so that the strength of the soil around the pile is improved, and the discrete material pile is protected against the problems of different pile diameters, bulging damage, pile hole caving and the like; the microorganism solidified soil and the pile can be combined to bear loads, and thus the bearing capacity of the single pile is improved.

Owner:NANJING FORESTRY UNIV

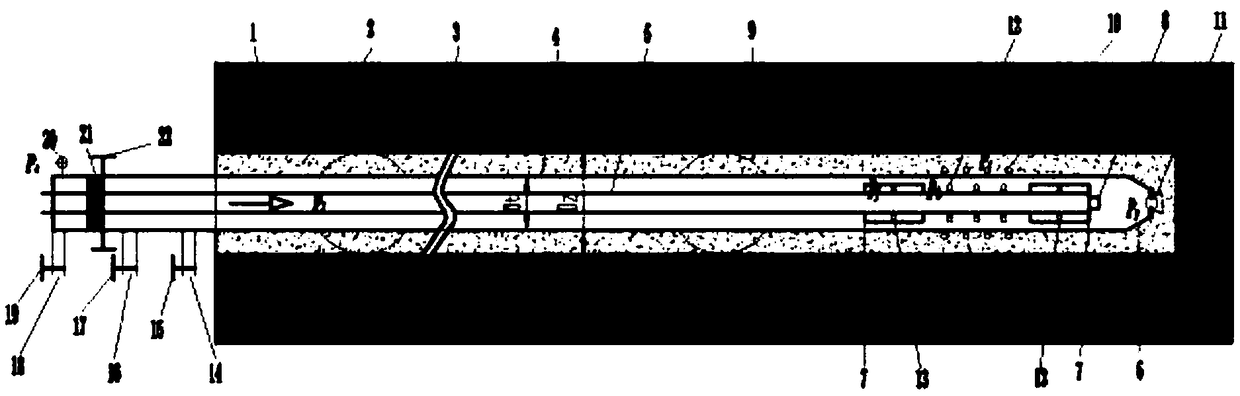

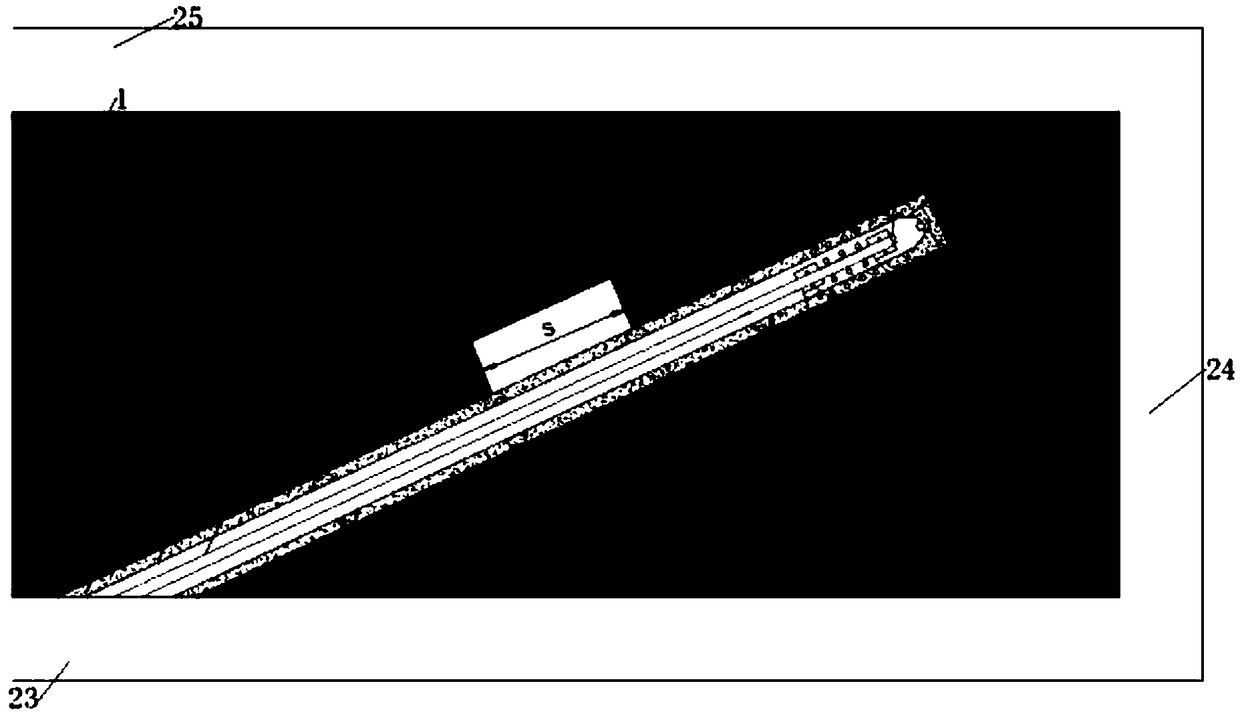

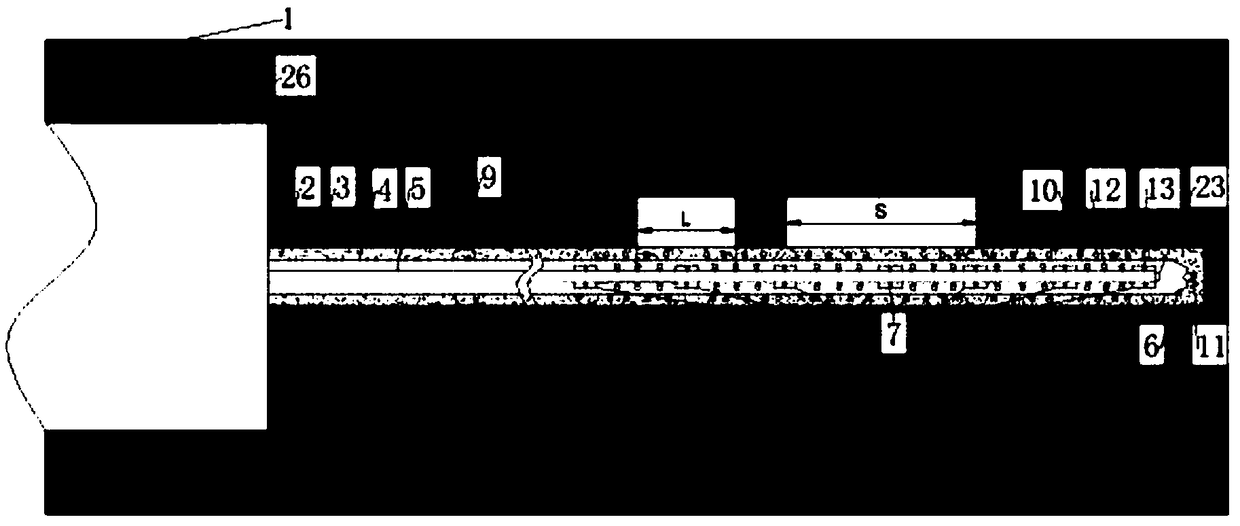

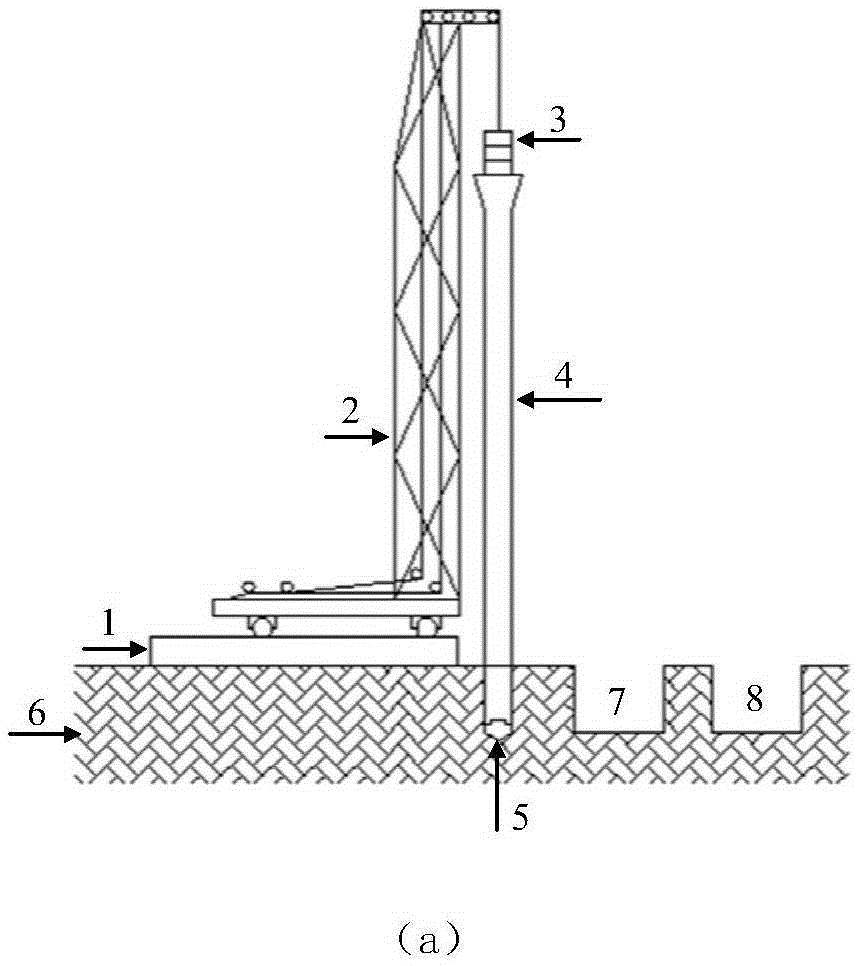

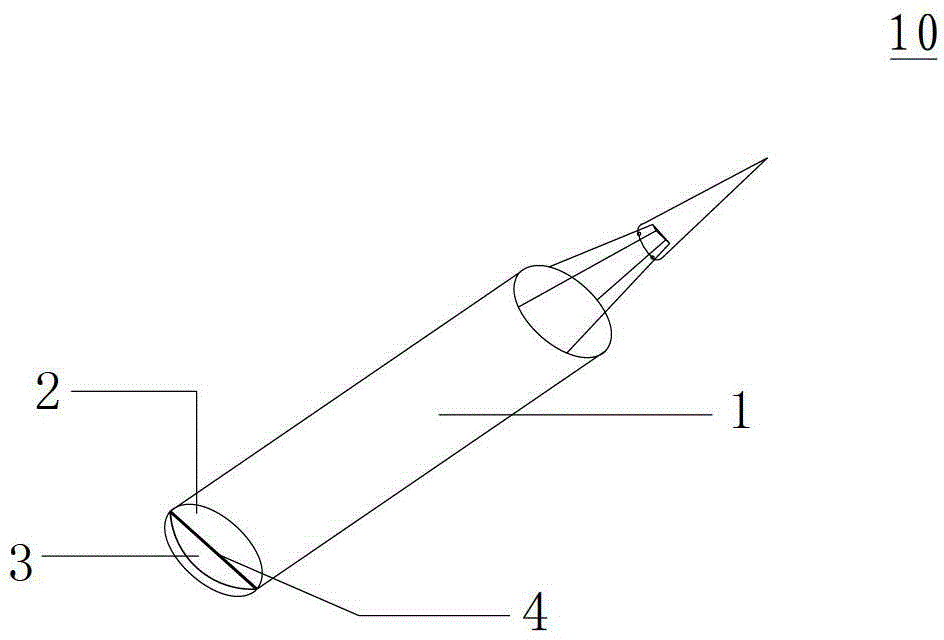

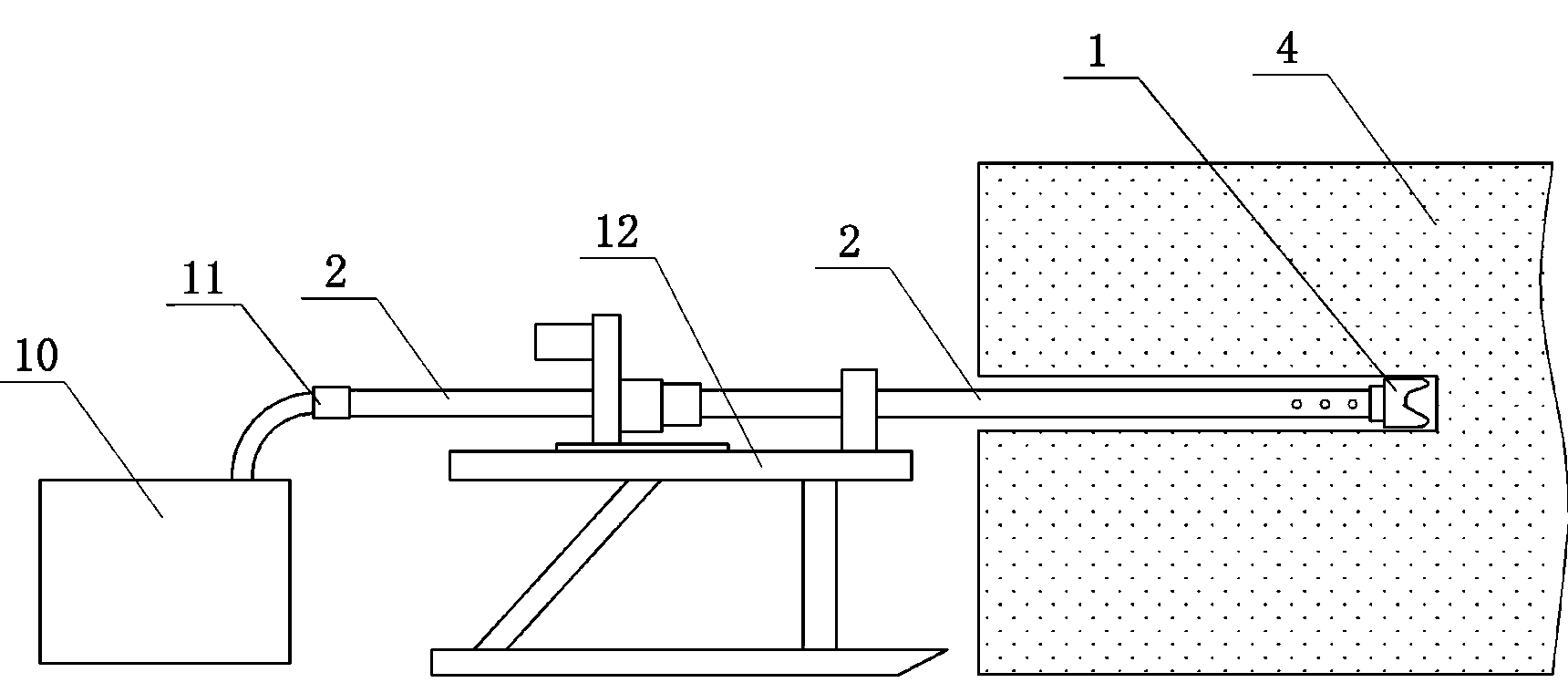

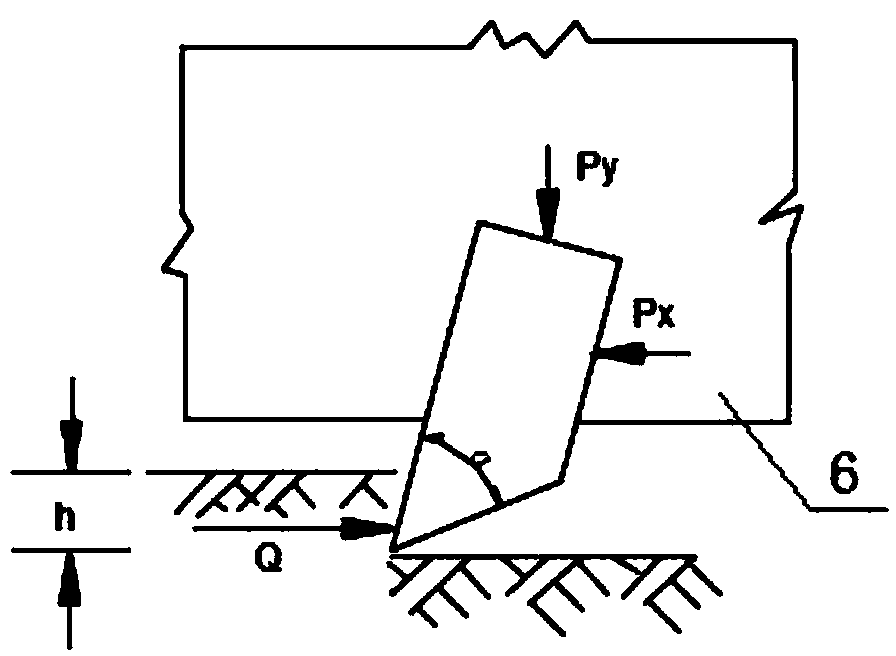

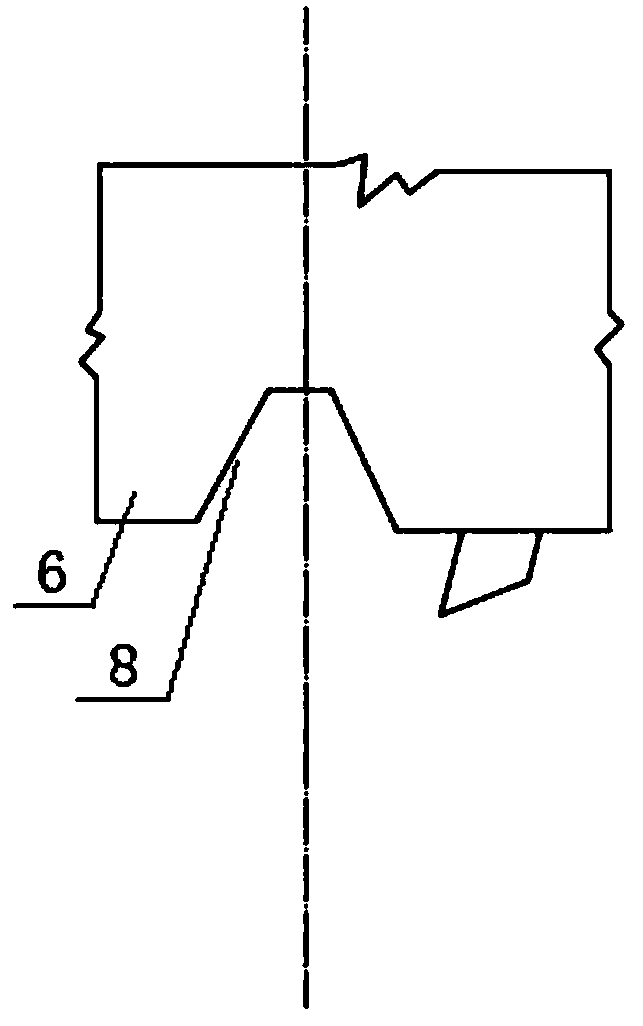

Soft rock and soil layer jet flow guiding hole forming-chamfering-hole collapse preventing integrated drilling method

InactiveCN104790873AImprove hole qualityImprove drilling efficiencyLiquid/gas jet drillingDirectional drillingDrill holeGeotechnical engineering

A soft rock and soil layer jet flow guiding hole forming-chamfering-hole collapse preventing integrated drilling method comprises the following steps that firstly, a soft rock and soil layer jet flow guiding hole forming-jet chamfering-hole collapse preventing guniting integrated drilling device is machined and tested; secondly, drilling technical parameters are designed; thirdly, guniting collapse preventing slurry fluid is prepared, and the solidification performance of the slurry fluid is tested; fourthly, the integrated drilling device is installed; fifthly, integrated drilling work is carried out; sixthly, after the design depth is achieved, drilling is stopped, clean water is used for cleaning a guniting pipeline and a slurry liquid nozzle, and a rod bit is pulled out; seventhly, the drilling effect is detected. The drilling efficiency and the hole forming quality of a horizontal or oblique long drill hole in the ground and an underground soft rock soil layer are greatly improved, the construction time for the horizontal or oblique long drill hole in the soft rock soil layer is shortened, and collapse destruction time of the horizontal or oblique long drill hole in the soft rock soil layer is greatly prolonged; the drilling track deviation of the horizontal or oblique long drill hole in the soft rock soil layer is reduced.

Owner:HENAN POLYTECHNIC UNIV

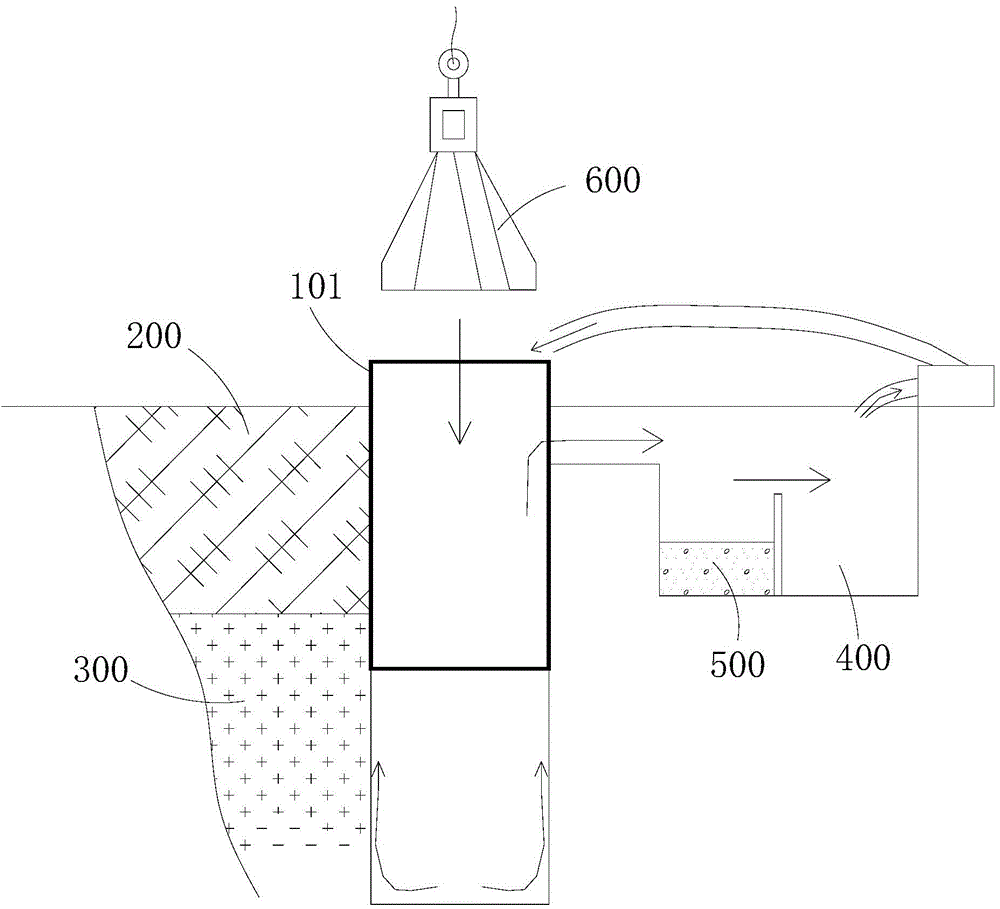

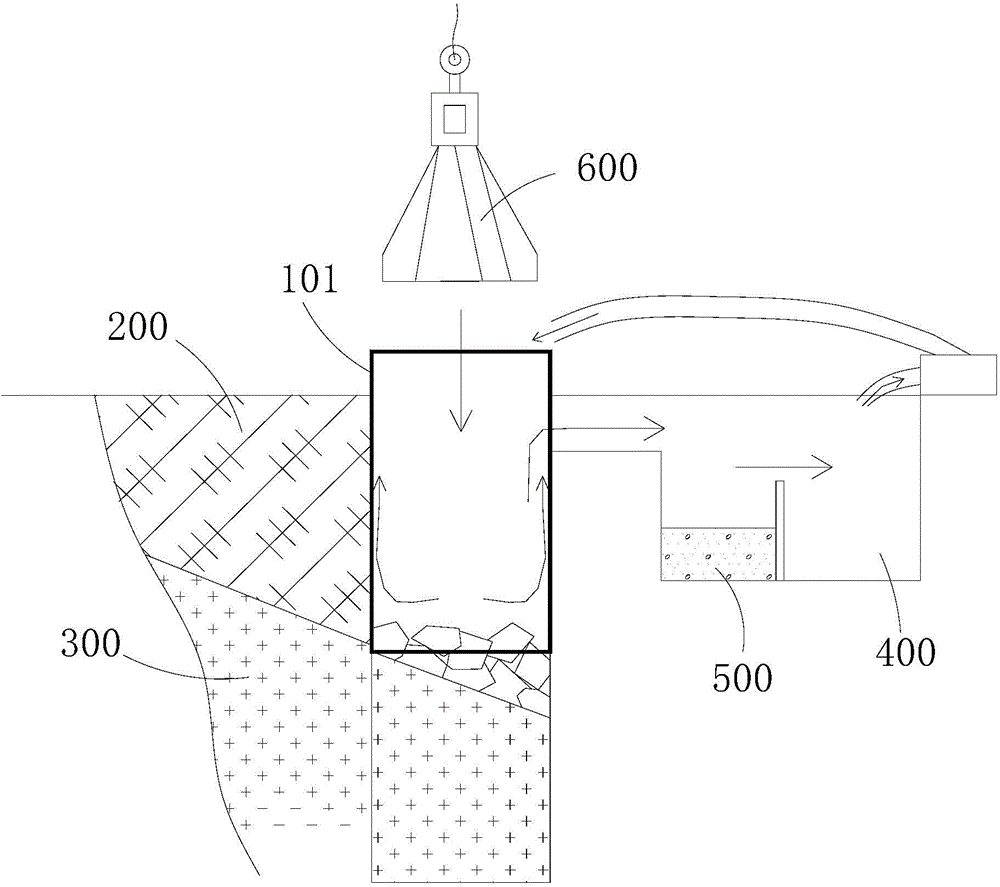

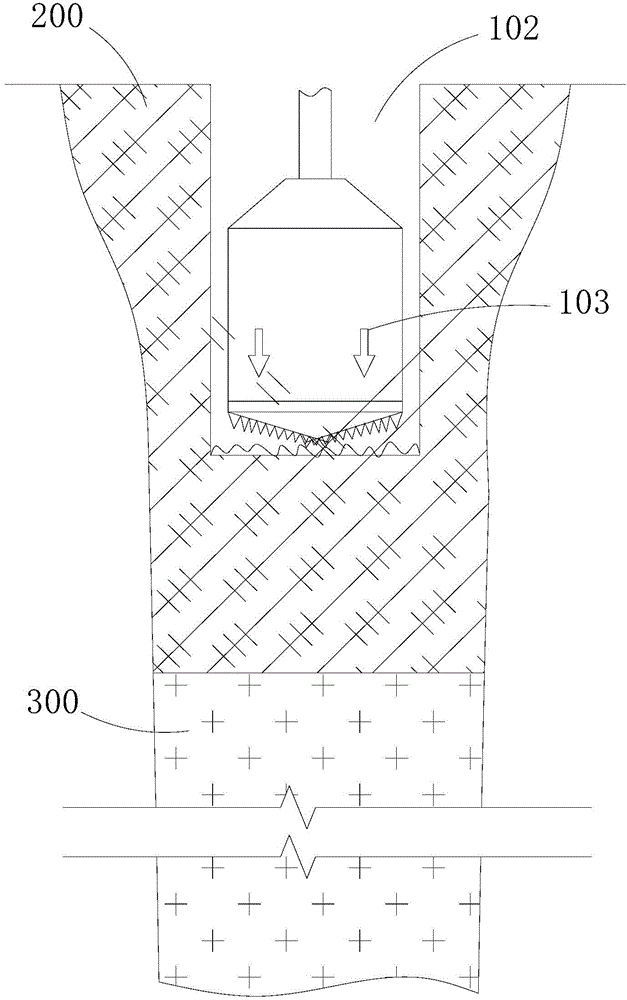

Foundation excavation retaining and protecting cast-in-situ bored pile construction method and equipment thereof

The invention relates to the technical field of foundation excavation retaining and protecting cast-in-situ bored piles and discloses a foundation excavation retaining and protecting cast-in-situ bored pile construction method and equipment thereof. The method comprises the following steps: 1, adopting a rotary excavating drilling tool to guide a hole in advance; 2, adopting a vibratory hammer to convey a pile casing into the soil layer downward from a hole opening ; 3, adopting the rotary excavating drilling tool to drill to the elevation position at the bottom of the pile casing; 4, adopting an air compressor to supply air into the hole till the air comes out of an opening at the upper end of the hole, and then utilizing a down-the-hole hammer to drill on a bed rock layer; 5, after the down-the-hole hammer drills to a final hole, pulling out the down-the-hole hammer, and infusing slurry into the hole; 6, cleaning the interior of the hole, placing a steel reinforcement cage into the hole, and pouring concrete into the hole; 7, utilizing the vibratory hammer to pull out the pile casing. According to the construction method, a pile casing retaining wall is utilized, and the hole collapse and hole shrinkage can be prevented; the down-the-hole hammer is utilized for cooperating with the air compressor to supply the air, great rock breaking capability is achieved, a rotary drilling machine is adopted for cleaning the hole, the hole formation is made to be greatly accelerated, the construction progress is sped up, and the cost is saved.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

Construction technique for preventing hole collapse of bored cast-in-place pile

InactiveCN103498466APrevent hole collapseOvercoming the problem of insufficient lateral supportBulkheads/pilesStructural engineering

The invention discloses a construction technique for preventing hole collapse of a bored cast-in-place pile. The construction technique for preventing the hole collapse of the bored cast-in-place pile is characterized in that the construction technique comprises the steps that (1) a pile casing is buried in a soil layer according to a pile position control line, and a drilling machine is started to drill after a mud circulating system and the drilling machine are well prepared; (2) normal drilling is carried out in the soil layer, and drilling is stopped and a drill bit is lifted when the drill bit is located in a soft soil layer and it is difficult to continue to drill downwards for the drilling machine; (3) the drilling machine is moved after drilling is stopped, concrete is poured into a drill hole rapidly till the surface of the concrete is higher than the set upper surface of the soft soil layer, and a rigid protective wall is formed after the concrete is solidified; (4) the drill bit is replaced with a rock drill bit; (5) the rock drill bit is replaced with the original excavating drill bit after the rock drill bit penetrates through the concrete located in the soft soil layer to enable rapid drilling to be carried out continuously till a hole is formed. The construction technique for preventing the hole collapse of the bored cast-in-place pile has the advantages that the problem that the lateral supporting force, in the soft soil layer, of a protective wall which is formed only by slurry is insufficient is solved, the hole collapse of soil layers with strong flow plasticity is prevented, and drilling success rate is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for increasing gas extraction rate by permeability increasing of single thick coal seam

ActiveCN102678166AIncreased air permeability coefficientGuaranteed relief sizeGas removalCoal pillarTunneling length

Disclosed is a method for increasing gas extraction rate by permeability increasing of single thick coal seam. During a tunneling process of coal seam working face, gas extraction holes are drilled along coal seams and hole protecting tubes are inserted into the gas extraction holes after drilling and sealed so as to perform gas extraction. When tunneling length of a tunnel is less than 50m, a twist drill is used to drill on the bottom of the coal seam along an inclination at intervals of 0.3-0.5m of coal pillars, and drilling holes which are 1.0-1.5m in width and 0.1-0.2 time as high as the coal seam are formed. After the drilling holes are formed, curved sink from bottom to top occurs on the coal, a large quantity of gaps are generated, permeability coefficient of the coal is increased by more than 120 times on average, gas extraction flow is increased by more than 10 times on average, and average gas extraction concentration is larger than 55%. By the method, pressure relief of the single thick coal seam with high gas content and low permeability is achieved, permeability increasing range is wide, permeability increasing effect is fine, and the gas extraction rate is increased by 60%. In addition, the method is widely applicable.

Owner:CHINA UNIV OF MINING & TECH

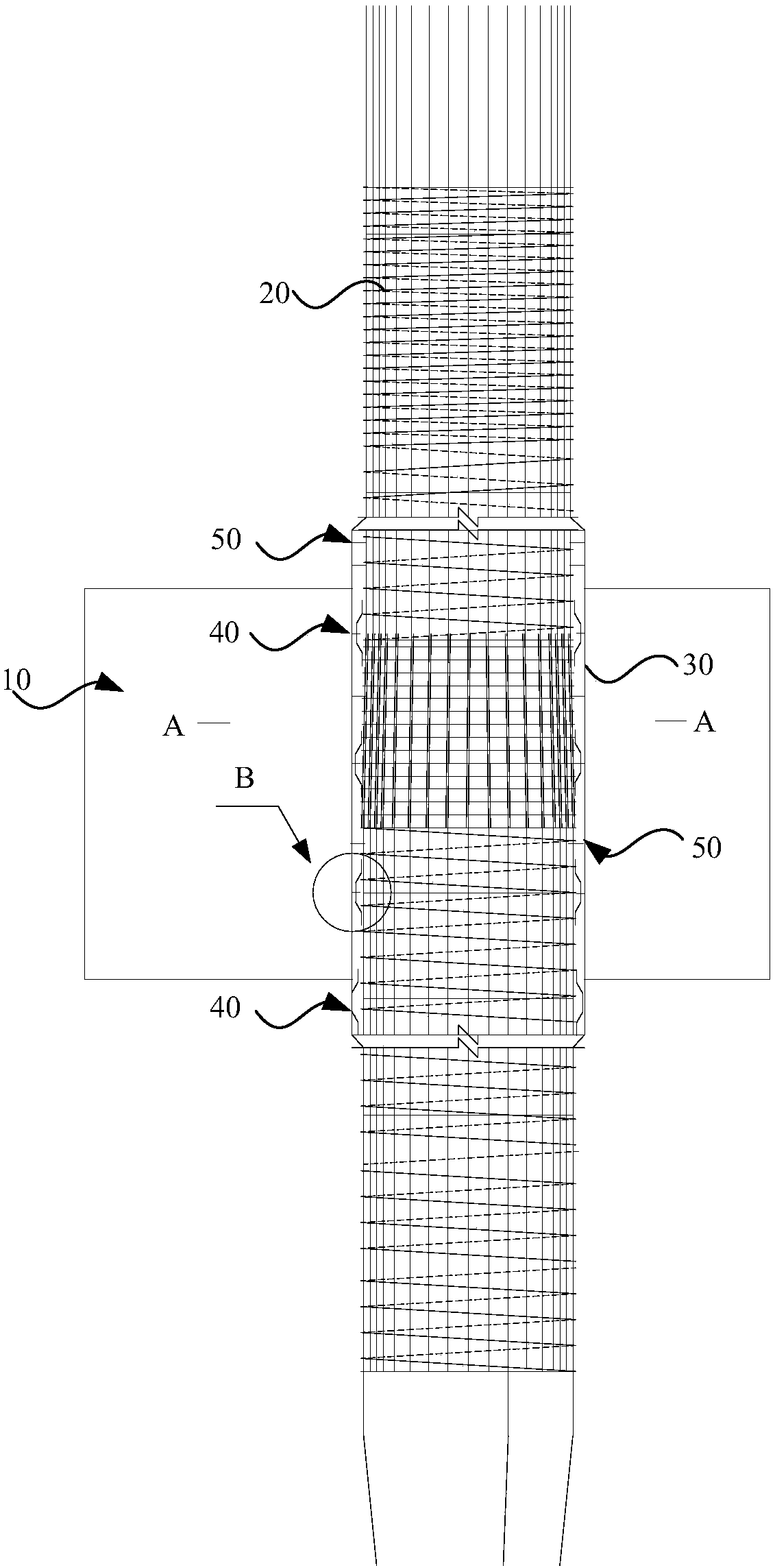

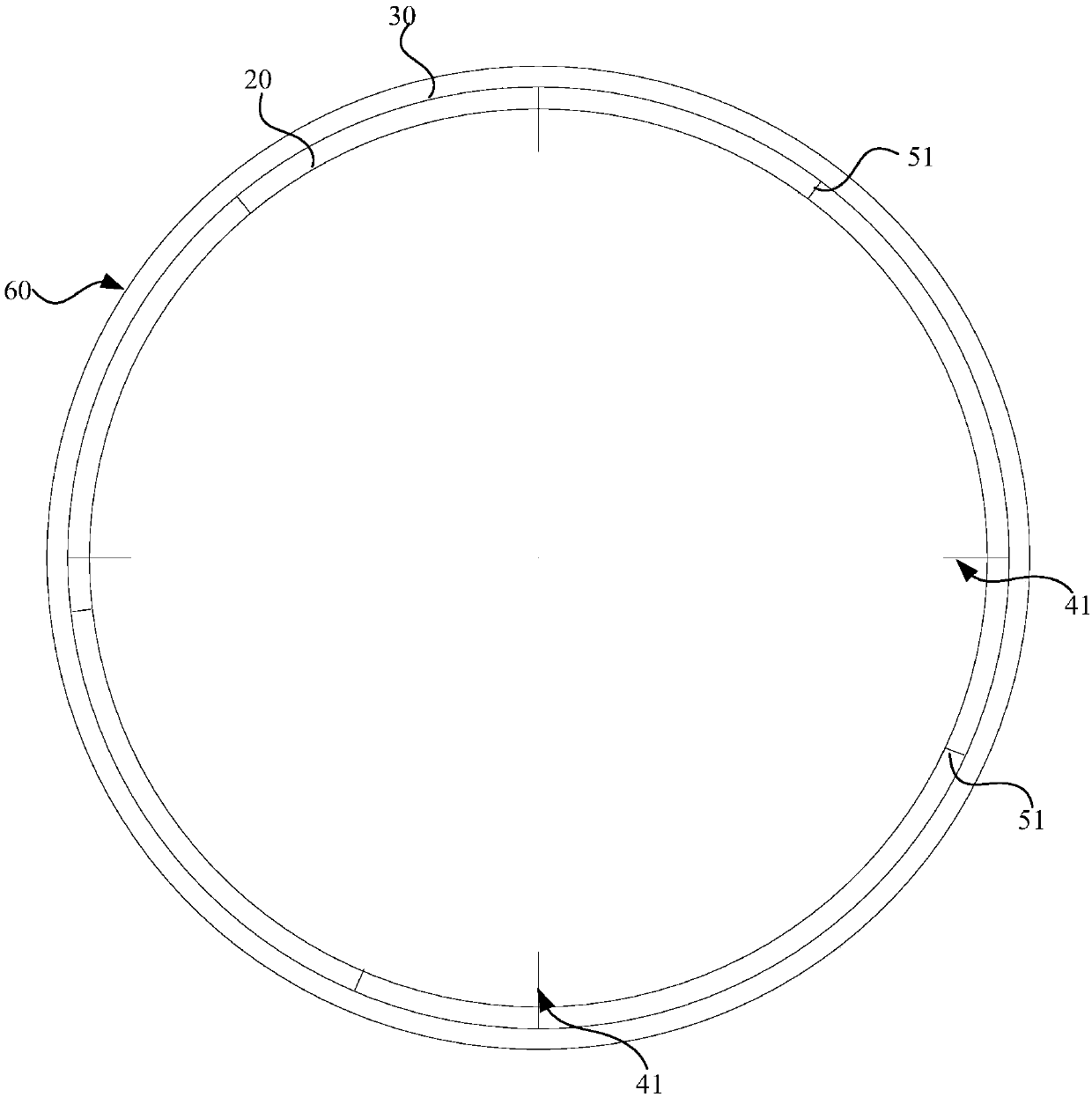

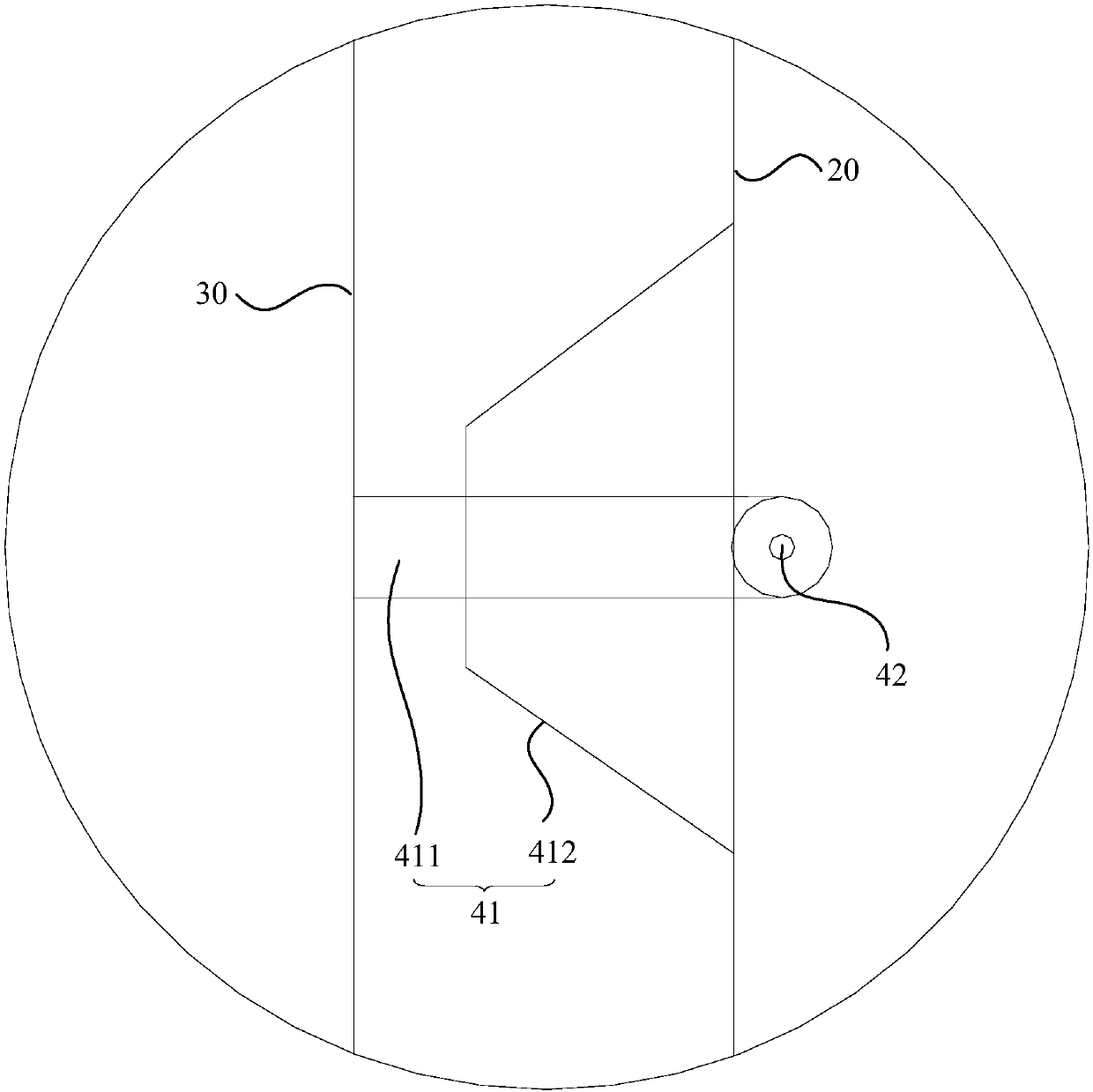

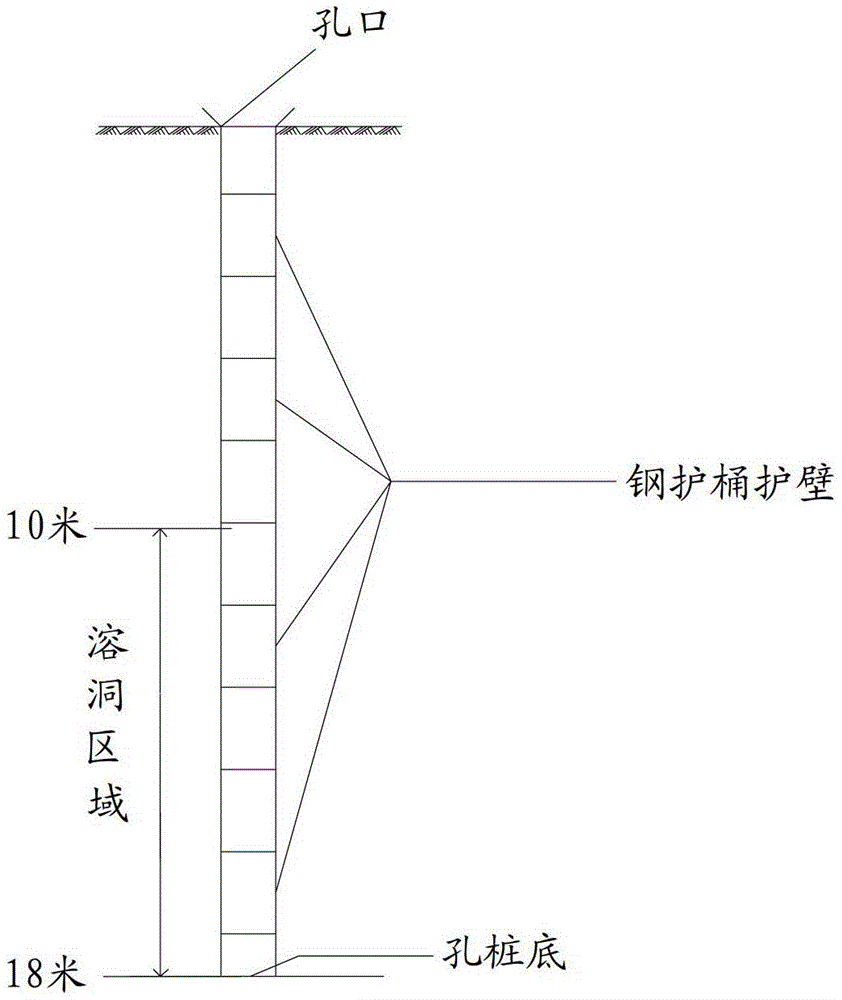

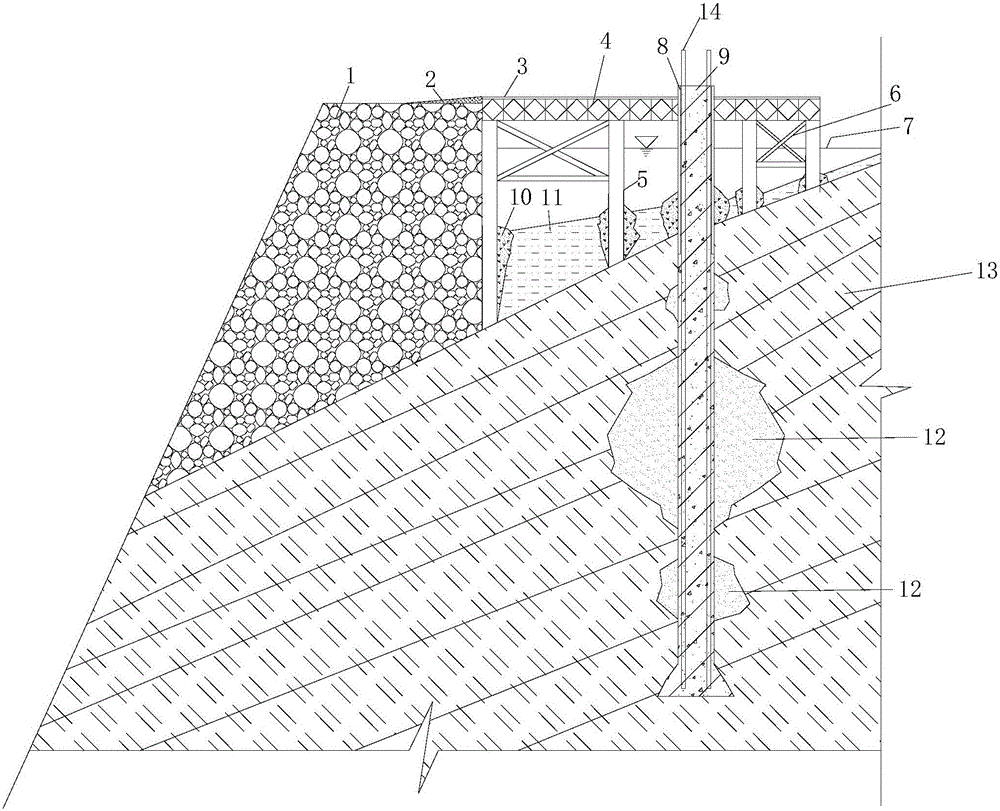

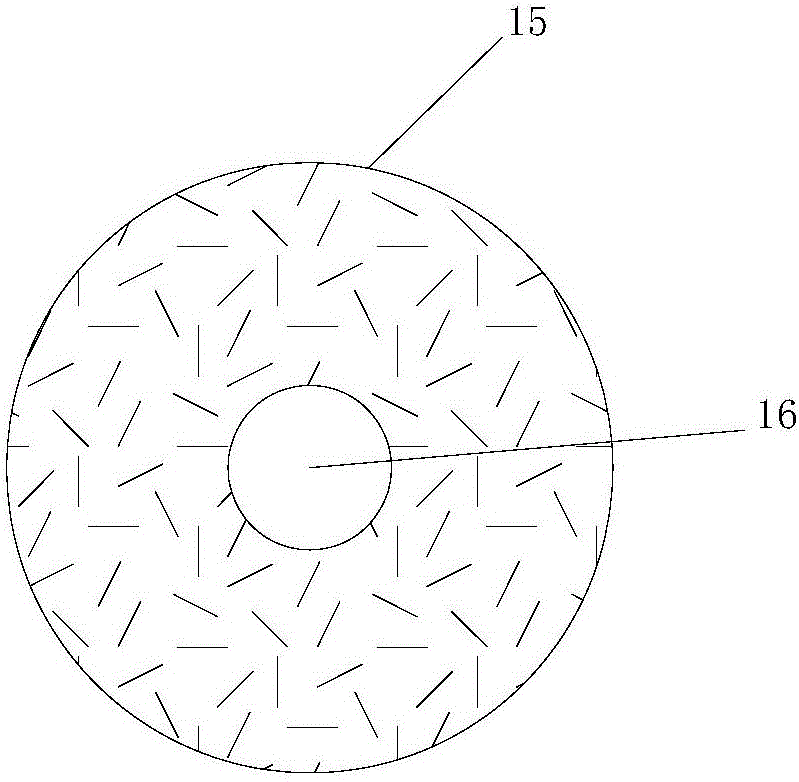

Karst area pile foundation protection device and construction method thereof

PendingCN107747309APrevent hole collapseGuarantee smooth constructionBulkheads/pilesKarstEngineering

The invention discloses a karst area pile foundation protection device and a construction method thereof. The karst area pile foundation protection device comprises a steel reinforcement cage, a protection cylinder and a connecting structure, the steel reinforcement cage and the protection cylinder are both arranged in a pre-dug pile hole, the pile hole penetrates through a karst cave, the bottomend of the steel reinforcement cage is arranged at the bottom of the pile hole in a supporting mode, the top end of the steel reinforcement cage is located over the karst cave, the protection cylinderis arranged on the outer side of the steel reinforcement cage in a sleeving mode and fixed to the steel reinforcement cage through the connecting structure, the bottom end of the protection cylinderis located under the karst cave, the bottom end of the protection cylinder and the bottom of the pile hole are arranged in a spaced mode, the top end of the protection cylinder is located over the karst cave, and the steel reinforcement cage and the protection cylinder are fixed to the interior of the pile hole through poured concrete. According to the karst area pile foundation protection deviceand the construction method thereof, on the condition of medium and large karst caves, the pile foundation construction quality can be guaranteed, the construction cost can be reduced, and destructionand pollution to the surrounding environment can be reduced.

Owner:GUANGZHOU EXPRESSWAY CO LTD +1

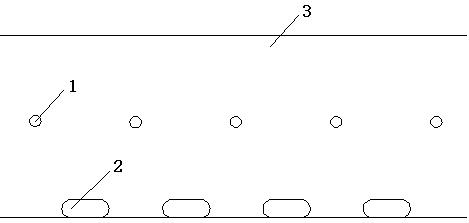

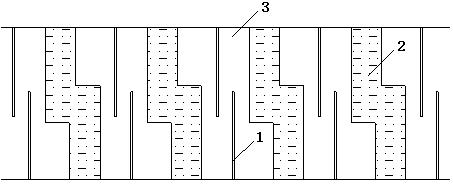

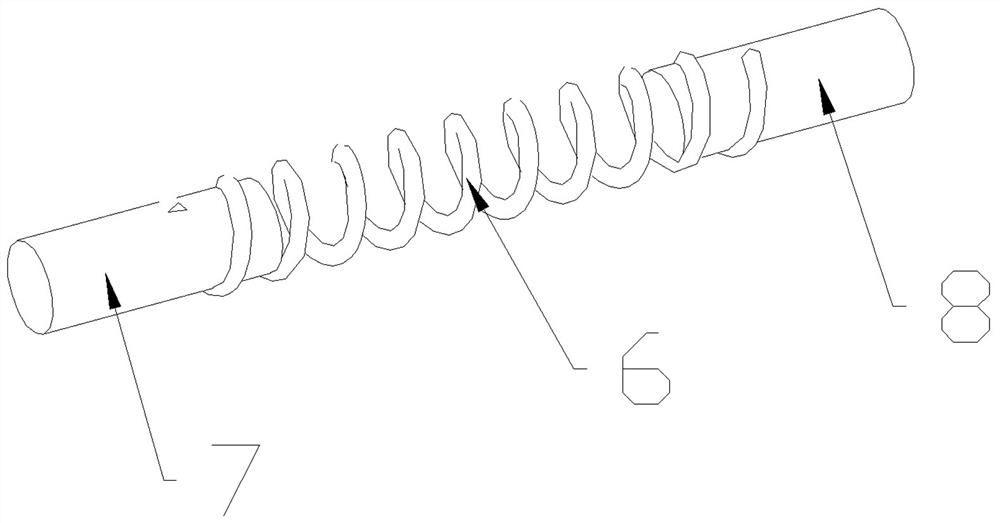

Reusable anti-hole collapse drilling apparatus and drilling method thereof

InactiveCN105113980AAchieve reusePrevent hole collapseDrilling machines and methodsScrew threadHole drilling method

The invention discloses a reusable anti-hole collapse drilling apparatus and a drilling method thereof, which apparatus comprises a drill bit, a screw drill pipe, a screw drill tube, a plug, a rotor and a pin. A shank portion of the screw drive pipe is cylindrical, and both head and tail thereof are square stems, a screw thread is welded on the shank portion, and the drill bit is connected with the head square stem of the screw drill pipe. The screw drill tube is a steel tube, alloy drill teeth are welded to the top of the screw drill tube, and a screw member is welded to the outer side of the drill tube. The screw drill tube, the screw drill pipe and the drill bit are integrated, the screw drill tube and the screw drill pipe synchronously advance during drilling, the screw drill pipe is removed after a borehole is formed, the screw drill tube is retained in the borehole, and the borehole is effectively protected; after the borehole is fully utilized, the screw drill tube can be removed for reuse.

Owner:SHANDONG UNIV OF SCI & TECH

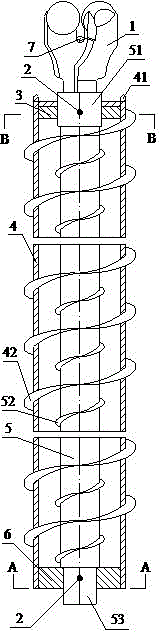

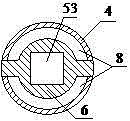

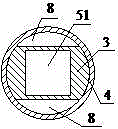

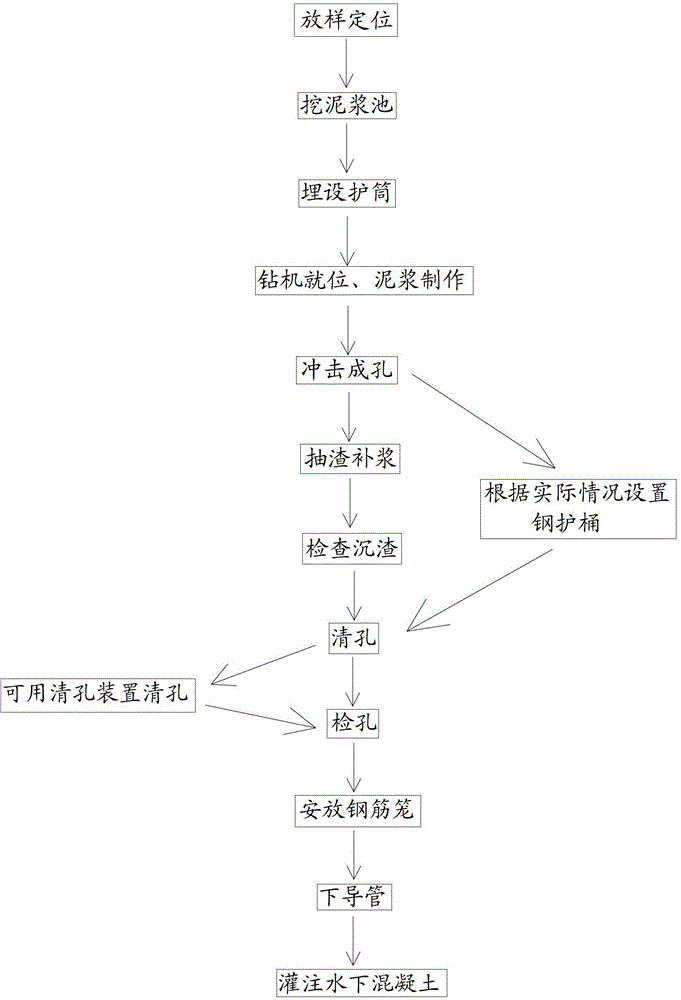

Mechanical hole forming technology applied to karst landform

The invention relates to a mechanical hole forming technology applied to karst landform. The technology comprises the following steps of: laying off and positioning; digging a mud pit; burying a pile casing; arranging a drill in place and making mud; forming holes by using an impact machine, wherein when a karst cave is greater than or equal to 3m in depth during construction, a steel pile casing dado is arranged; pumping out sediment and supplementing mud; checking the sediment; clearing off the holes by using a home-made hole cleaning device; checking the holes; arranging a steel reinforcement cage; arranging guide pipes; and pouring underwater concrete. By the mechanical hole forming technology, the probability of occurrence of hole collapse, overfilling of concrete and the like can be lowered, karst cave areas can be effectively protected, the effect of saving concrete is achieved and the cost is further reduced; moreover, by the mechanical hole forming technology, a unit in charge of construction can be effectively helped to clear off sediment from the bottoms of holes, hole piles in collapsed holes can be cleared quickly, the specific depth of a hole pipe can be measured by construction workers.

Owner:中色十二冶金建设有限公司

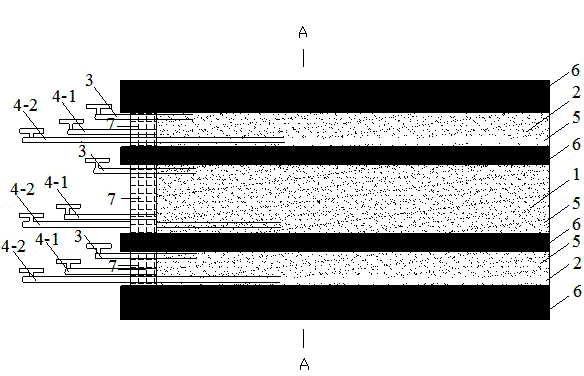

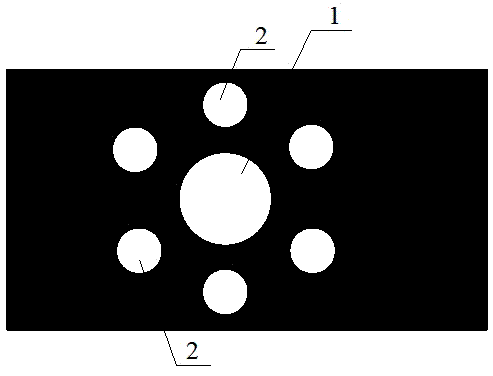

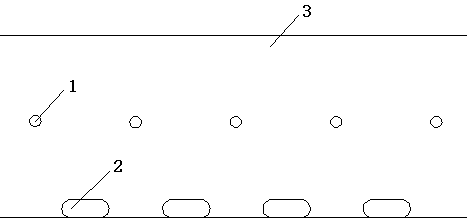

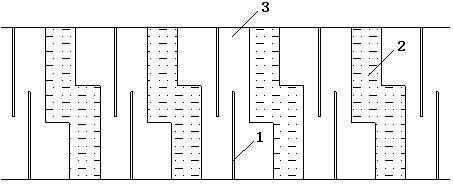

Method for forming easy-to-collapse drilled hole

ActiveCN102226375ASolve the technical problems of easy-to-collapse holesPrevent re-drilling hole collapseSealing/packingDrilling machines and methodsSlurryCement grout

The invention discloses a method for forming an easy-to-collapse drilled hole, and the method comprises the following steps: constructing a large-diameter main curing hole in a coal seam, and further placing a polyurethane grouting pipe, a cement grouting pipe and a slurry return pipe into the large-diameter main curing hole; and injecting a polyurethane layer with the thickness of 1-2m into the orifice of the large-diameter main curing hole via the polyurethane grouting pipe, further injecting cement slurry into the large-diameter main curing hole through the cement grouting pipe, curing thecement, and then implementing drilling operation in the axial center direction of the large-diameter main curing hole, thus completing the formation operation of one easy-to-collapse drilled hole; orfirstly constructing the large-diameter main curing hole, and constructing a plurality of small-diameter auxiliary curing holes which are distributed uniformly on the periphery of the large-diameter main curing hole; performing hole sealing and grouting on the large-diameter main curing hole and the small-diameter curing holes; and curing the cement slurry in the large-diameter main curing hole and the small-diameter curing holes, and then implementing the drilling operation in the axial center direction of the large-diameter main curing hole, thus completing the formation operation of one easy-to-collapse drilled hole. By adopting the method, the easy-to-collapse hole can be formed when the coal seam is drilled, the hole-forming probability is high, the operation is simple, convenient and practicable, and the cost is low.

Owner:CHINA UNIV OF MINING & TECH

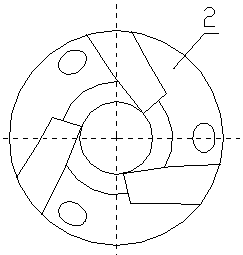

Earth auger of making concrete pile

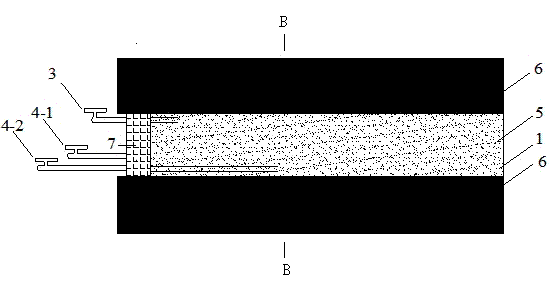

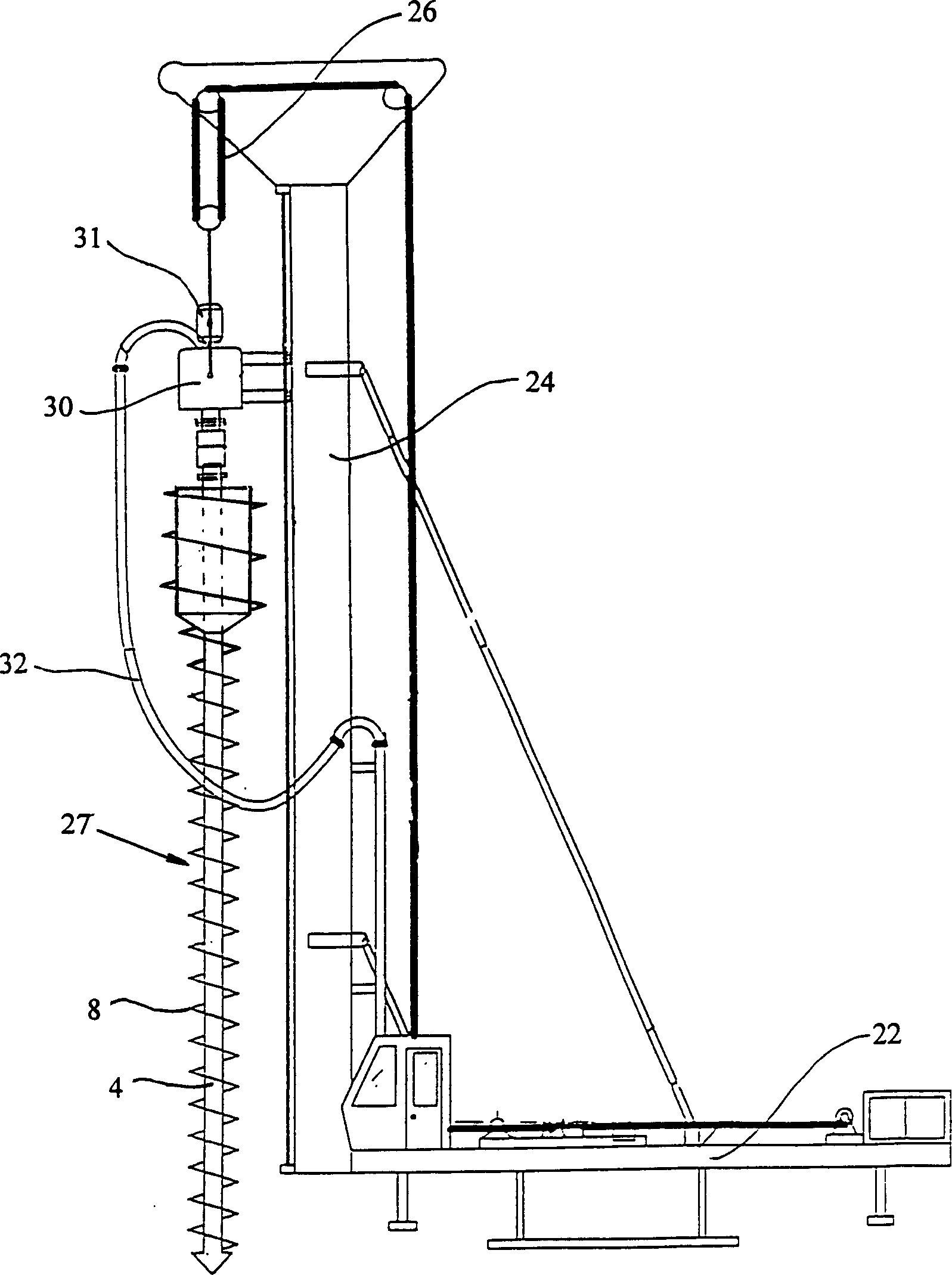

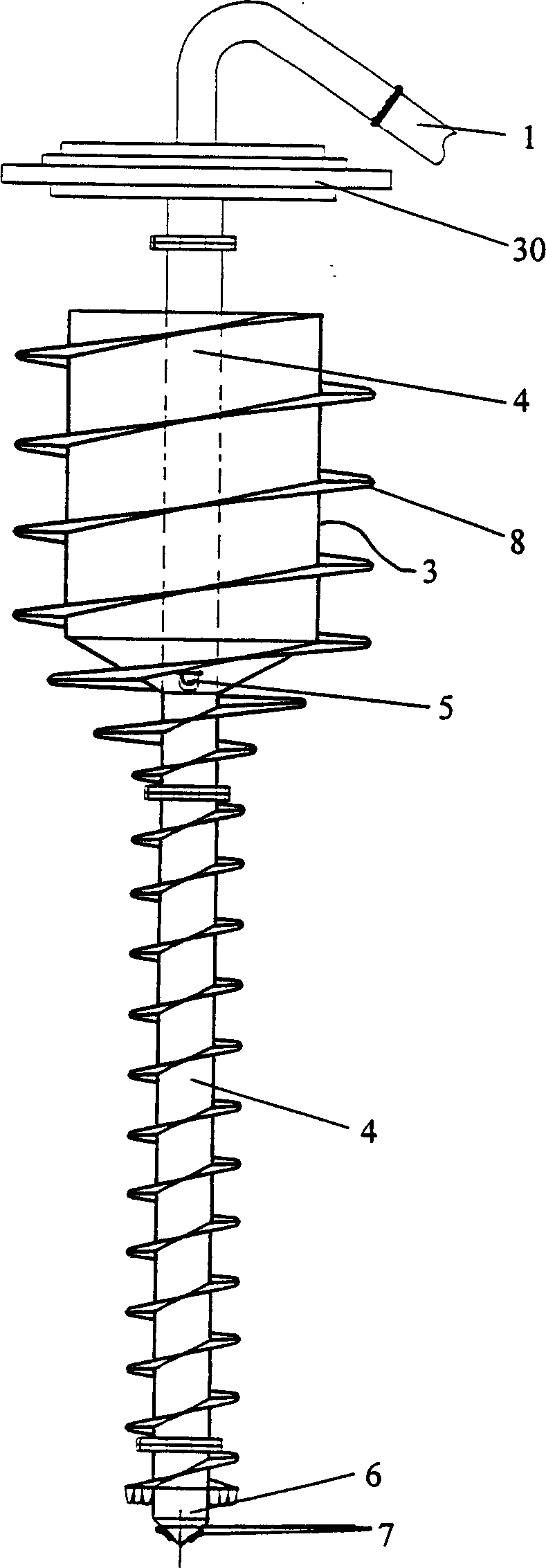

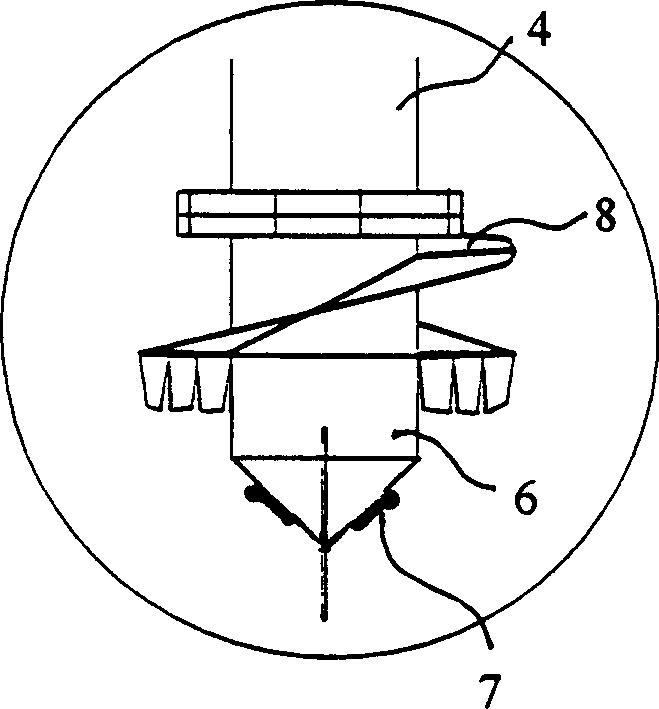

InactiveCN1540129AIncreased compactionAvoid collapsing holesRotary drillingRotary-drilling machinesGeotechnical engineeringDrill bit

A spiral drilling machine for forming concrete pile has a drilling tool, which is composed of a hollow drilling rod with spiral blades, a drill bit with discharge outlet and arranged at lower end of said hollow drilling rod, and an external pipe coaxially connected to the upper part of said hollow drilling rod in sealed mode. Said spiral blades are fixed to the external surface of said external pipe.

Owner:何庆林

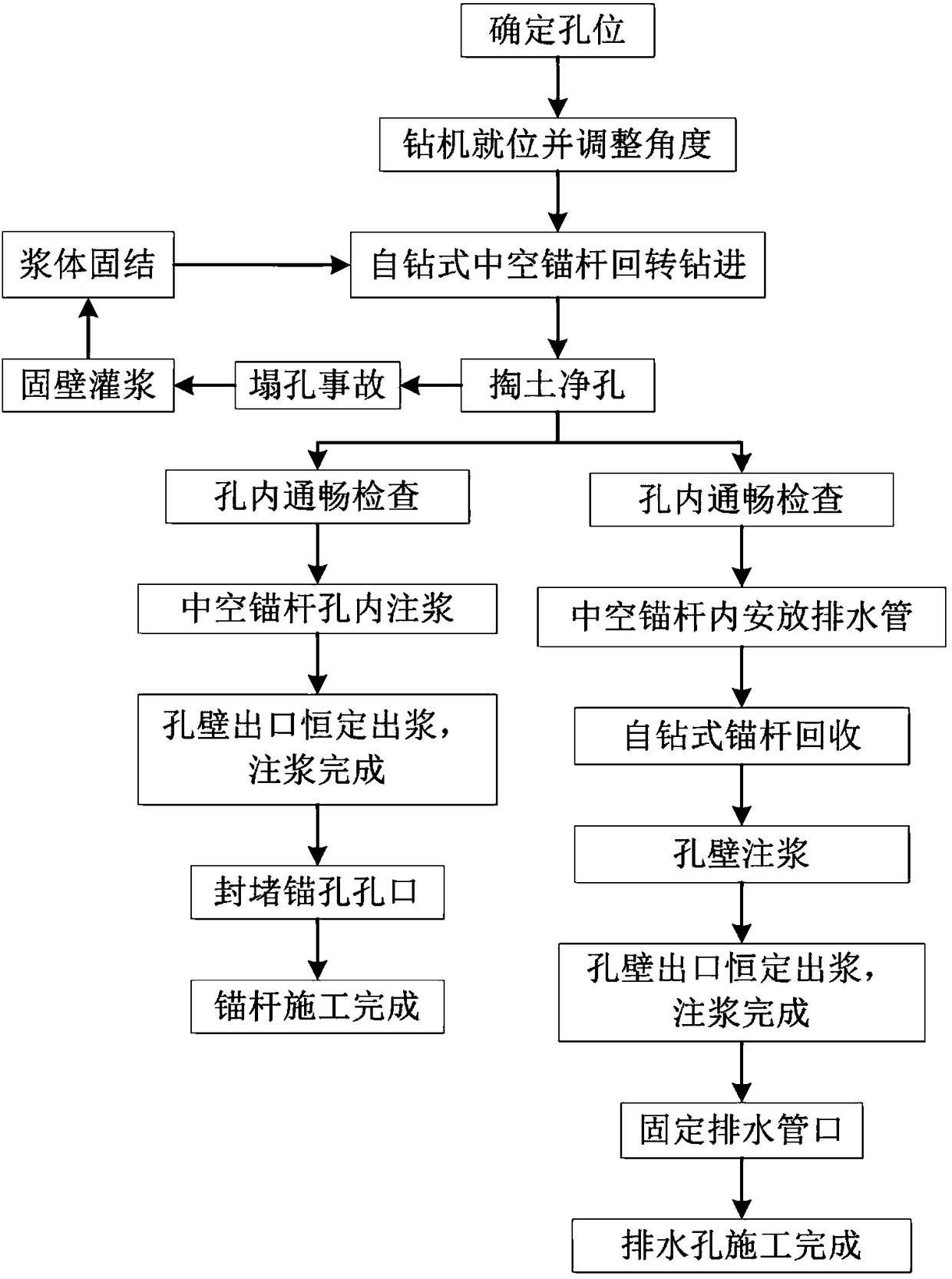

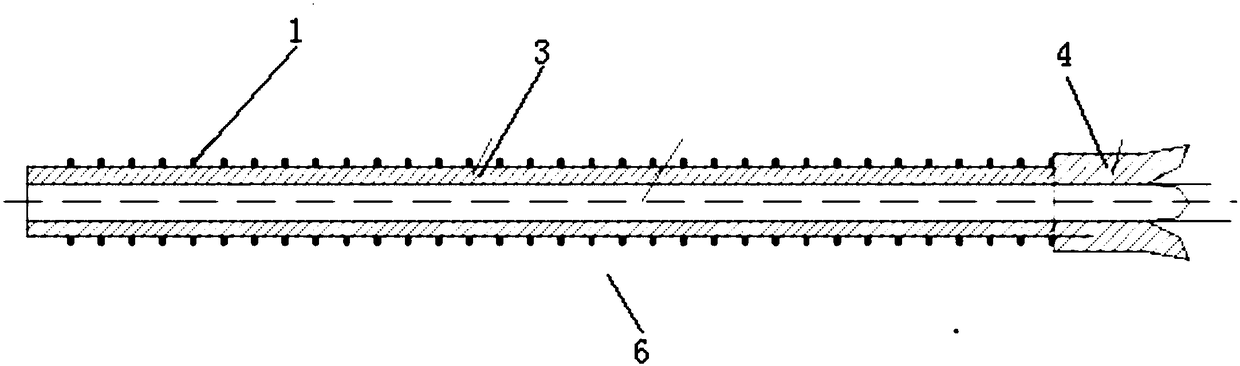

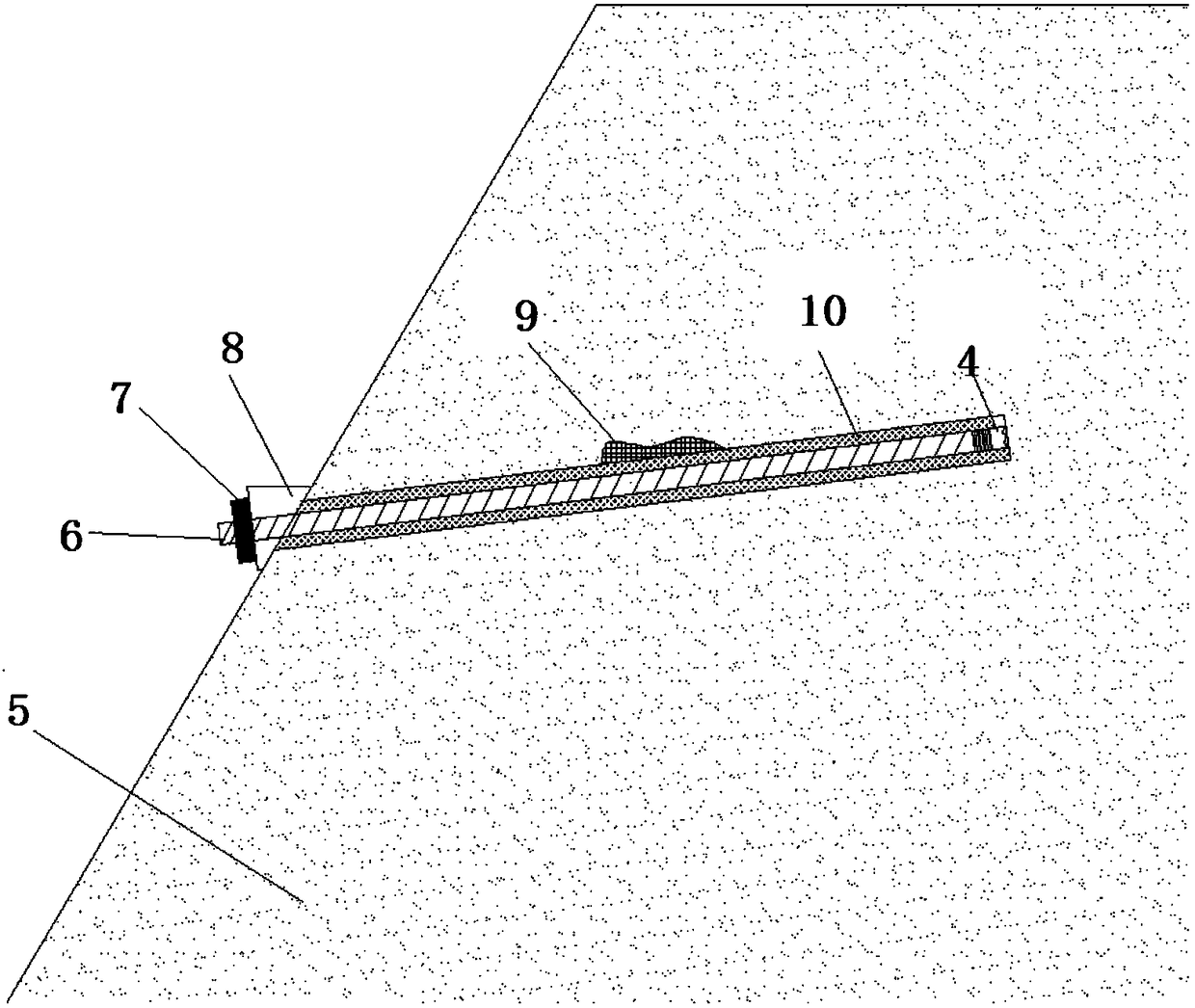

Hole forming process of dual-purpose hole of anchoring hole and drainage hole in muck side slope

ActiveCN108166513AImprove construction efficiencyReduce construction costsExcavationsBulkheads/pilesEngineeringForming processes

The invention relates to the technical field of side slope protection, in particular to a hole forming process of a dual-purpose hole of an anchoring hole and a drainage hole in a muck side slope. A rotary drilling machine is used as power to drill a hollow anchor rod body into a confirmed position, and the hollow anchor rod body rotates to the designed depth; during drilling of the hollow anchorrod body, soil excavation and slagging need to be carried out; and after it is ensured that drilling of the interior of the hollow anchor rod body and drilling of the outer side of the hollow anchor rod body are both smooth, fixing of the hollow anchor rod body and mounting of a drainage pipe are carried out at corresponding positions correspondingly. According to the hole forming process of the dual-purpose hole, the efficiency of construction is improved, the construction cost is reduced, and the engineering quality is improved.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

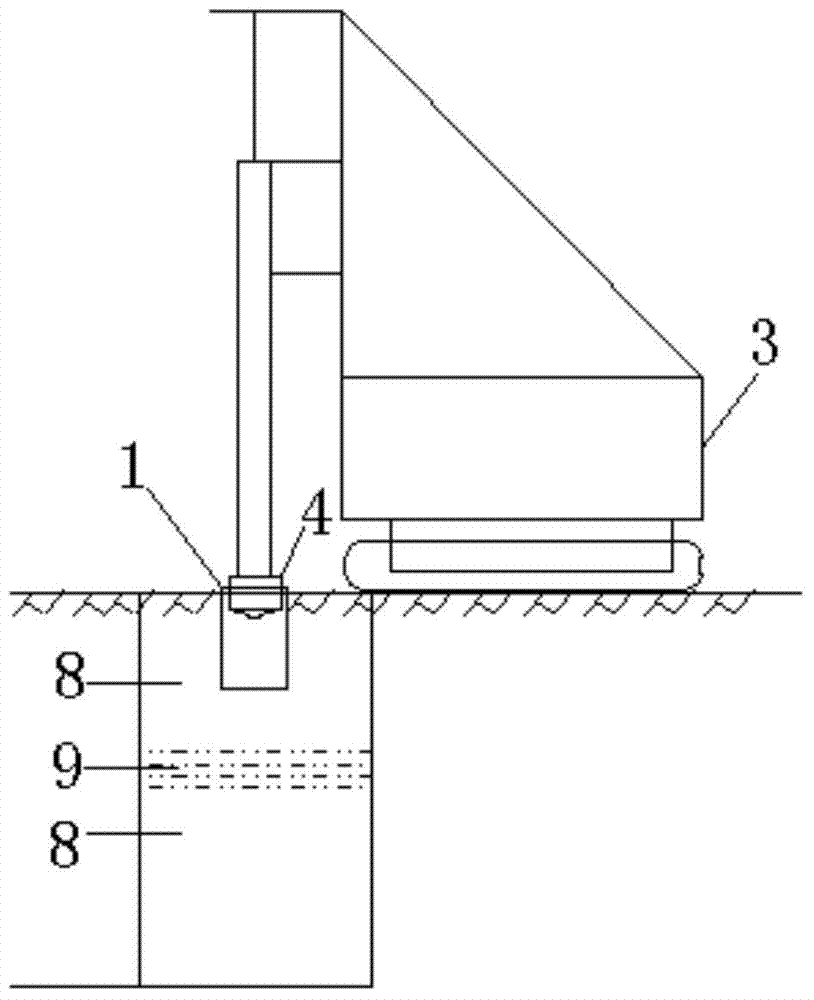

Method for accurately positioning impacting hole-drilling and pile grouting

InactiveCN107905221APrevent hole collapseNot easy to break piles and mudFoundation testingBulkheads/pilesEngineeringDrilling machines

The invention discloses a method for accurately positioning impacting hole-drilling and pile grouting. The method comprises the steps of measuring a hole position, burying a protective casing, preparing mud, drilling a hole, checking the hole, cleaning the hole for the first time, manufacturing and installing a reinforcing cage, installing a guide pipe, cleaning the hole for the second time and grouting concrete. According to the method for accurately positioning impacting hole-drilling and pile grouting, the pile hole can be accurately positioned through the design of guard piles, so that theconstruction of a drilling machine is facilitated; the protective casing is buried so that the hole opening can be protected and ground stones can be prevented from falling into the hole, meanwhile,the level of the mud can be ensured, and the collapse of the hole can be prevented; and the hole is cleaned twice so that the sediment at the bottom of the hole can be effectively removed, the groutedpile body is not prone to be broken and filled with the mud, and the quality of the pile body is guaranteed.

Owner:CHONGQING CONSTR ENG GRP +1

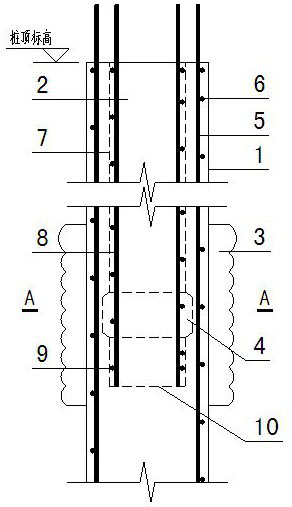

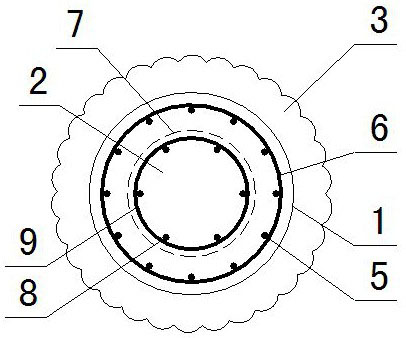

Large-diameter cast-in-place concrete pile defect treatment reinforcing structure and construction method

InactiveCN112411642AShort construction periodLittle impact on project progressFoundation repairBulkheads/pilesPunchingRebar

The invention relates to a large-diameter cast-in-place concrete pile defect treatment reinforcing structure and a construction method. The large-diameter cast-in-place concrete pile defect treatmentreinforcing structure comprises defective large-diameter cast-in-place concrete piles, the defective large-diameter cast-in-place concrete piles comprise pile body defect sections, pile body punchingexcavation side boundaries and pile body punching excavation bottom boundaries are determined according to design requirements, after pile bodies are punched and excavated, core piles subjected to refilling treatment are arranged, core pile longitudinal bars and core pile stirrups are arranged on the core piles according to design requirements, and high-pressure jet grouting reinforcement sectionsare arranged in a certain range of the periphery of the pile body defect sections to form a waterproof curtain and an enclosure structure. Compared with the prior art, the original pile does not needwaste treatment, the construction period is short, the influence on the overall engineering progress is small, and the treatment cost is controllable; on the basis that an annular reinforced concretestructure outside the original pile body is complete, a core pile processing mode is additionally adopted, the hooping effect can be formed, and the bearing capacity of the pile body is improved; andthe mode of thoroughly chiseling away part of concrete of the defect sections is obvious in treatment effect, and no defect risk is left.

Owner:ZHEJIANG JIEDI ARCHITECTURAL DESIGN

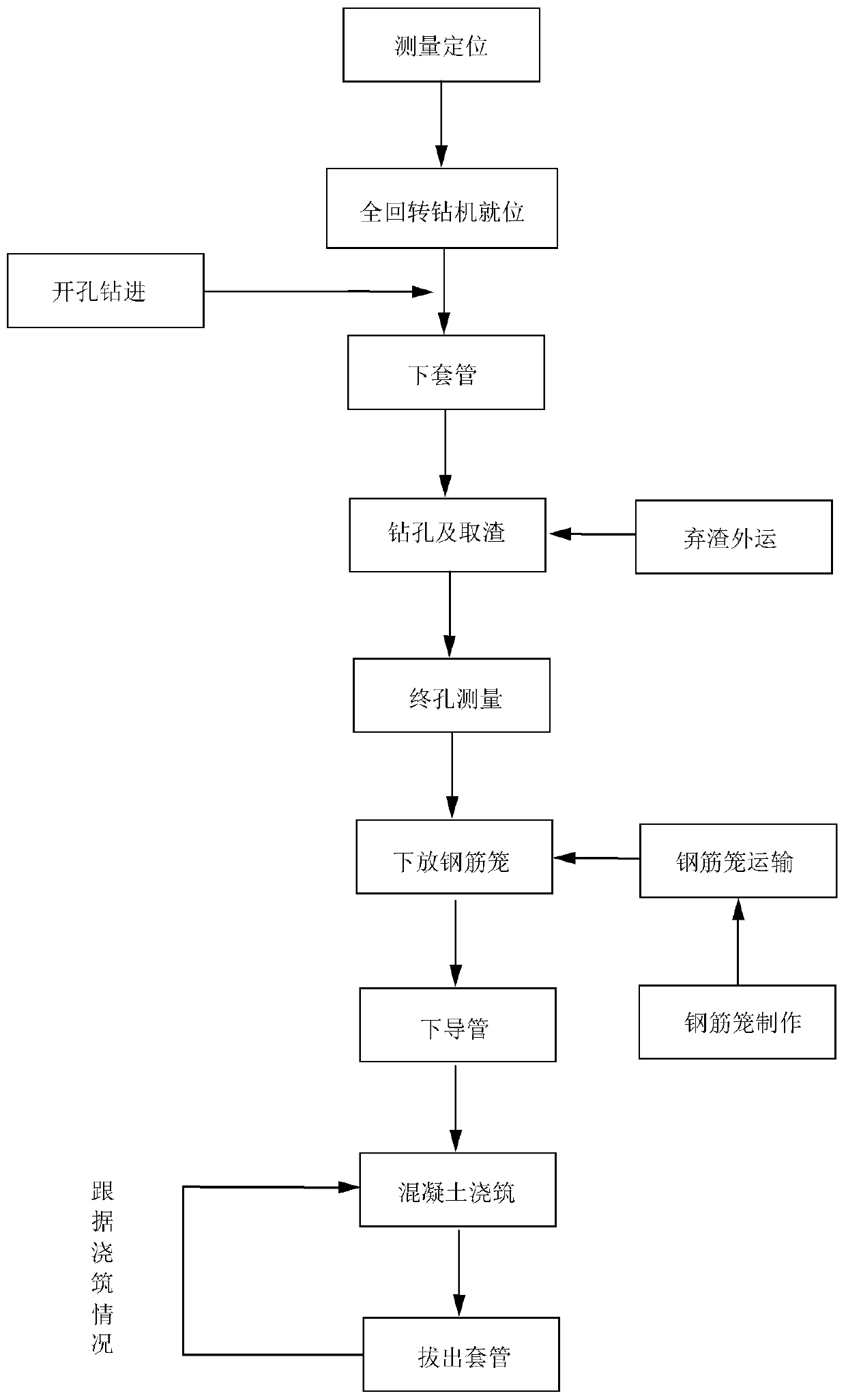

Pile foundation full-casing full-rotation construction process under complex geological conditions

The invention relates to a pile foundation full-casing full-rotation construction process under complex geological conditions. The pile foundation full-casing full-rotation construction process comprises the following steps: site preparation before drilling is conducted; casings with cutting edges are inserted in a drilling rig body, soil layers in the casings are dug through a grab, and then a self-rotation device of a drilling rig is utilized to rotate the casings and to be pressed into a formation simultaneously; the casings are spliced till drilling is completed; concrete is poured througha tremie method; and the casings are pulled out. According to a pile foundation construction method, mud does not need to be used, especially a full casing form is adopted in a strongly developed karst area, drilling and casing mounting are simultaneously conducted, and the phenomenon of hole collapse in the drilling process is avoided.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

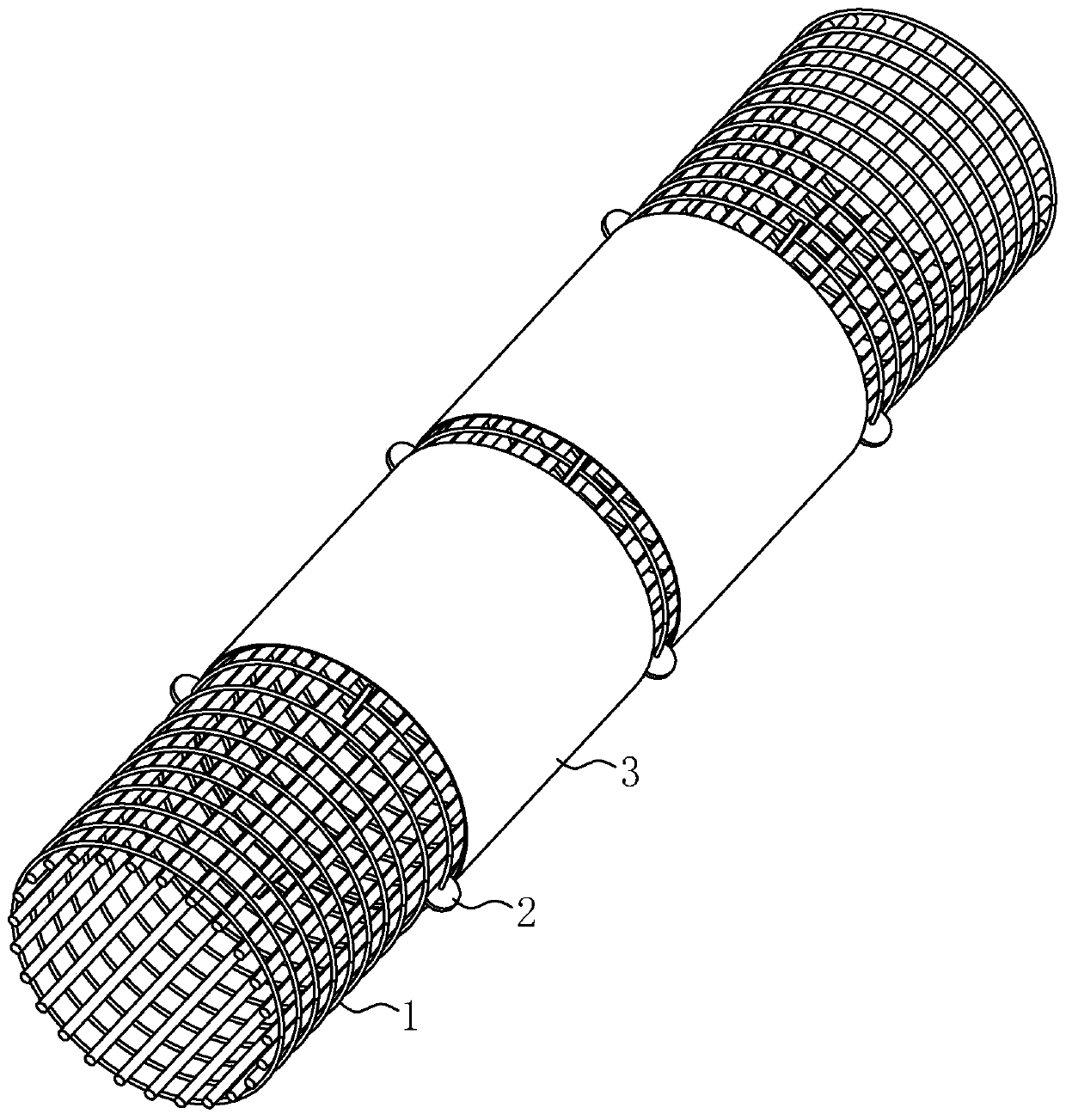

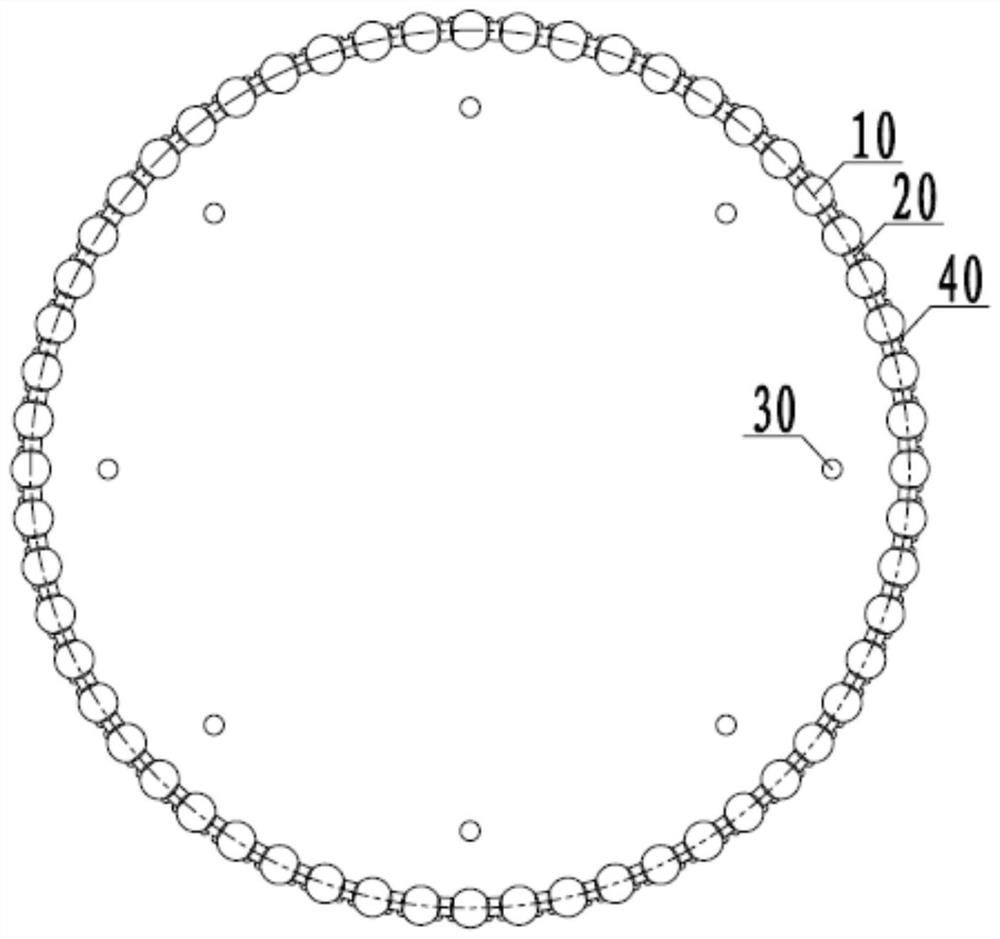

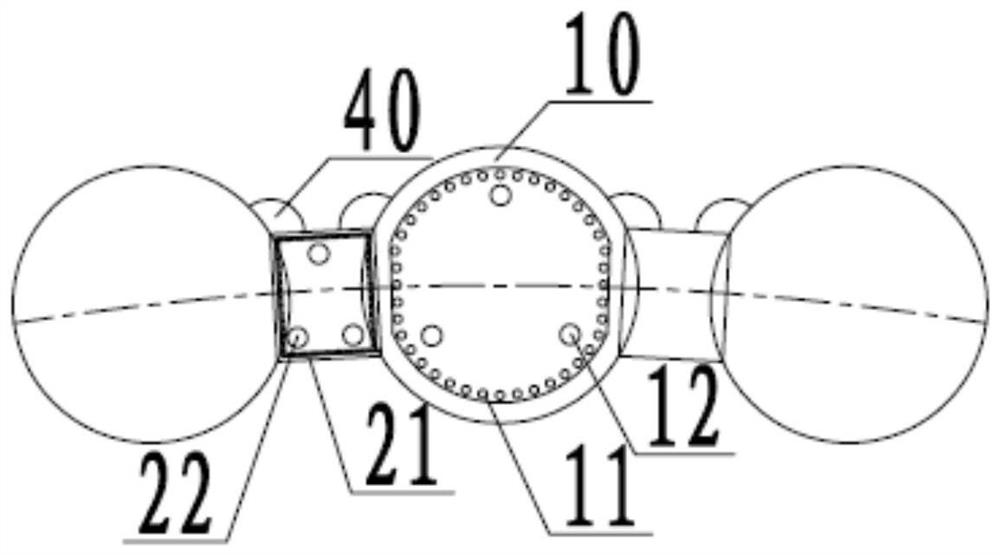

Suspension bridge large-diameter secant pile gravity type anchorage foundation enclosure structure and construction method

PendingCN112900264AReduce construction proceduresShorten the construction periodFoundation testingBridge structural detailsStructural engineeringArchitectural engineering

The invention discloses a suspension bridge large-diameter secant pile gravity type anchorage foundation enclosure structure and a construction method. The suspension bridge large-diameter secant pile gravity type anchorage foundation enclosure structure comprises a plurality of I-stage secant piles and a plurality of II-stage connecting piles, the I-stage secant piles and the II-stage connecting piles are sequentially and circularly connected and enclose to form a circular enclosure, and a plurality of dewatering wells are arranged in a foundation pit in the enclosure; and waterproof curtains are arranged at the joints of the outer walls of the I-stage secant piles and the II-stage connecting piles. According to the design, the structure is simple, the lining does not need to be constructed through a reverse construction method in the excavation process, therefore, construction procedures are reduced, the construction period is shortened, damage to the enclosure structure caused by lining construction is prevented, and the application range of the suspension bridge is widened. The invention further discloses a corresponding construction method of the suspension bridge large-diameter secant pile gravity type anchorage foundation enclosure.

Owner:广西欣港交通投资有限公司 +2

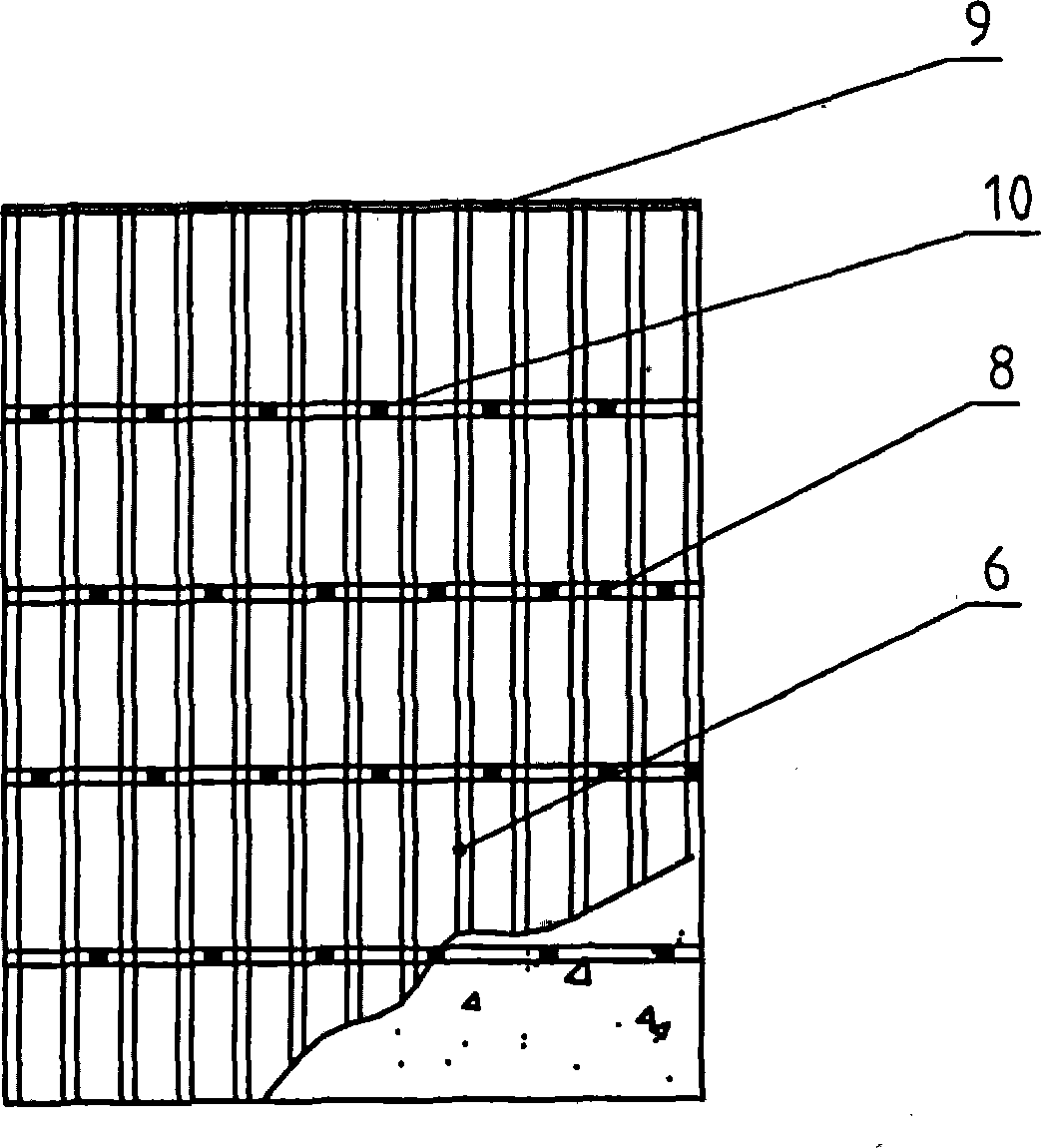

Large-diameter super-long bored pile construction method for steep dip stratified rock mass with alternative smashed parts and integral parts

InactiveCN105019431APrevent hole collapseImprove construction efficiencyBulkheads/pilesRebarDrill bit

The invention discloses a large-diameter super-long bored pile construction method for steep dip stratified rock mass with alternative smashed parts and integral parts. The method mainly includes the steps that firstly, a construction platform is reinforced; secondly, the periphery of a steel protection cylinder is reinforced; thirdly, surveying and sampling are conducted; fourthly, a smashed zone is reinforced; fifthly, the bottom is expanded through explosions; sixthly, drilling is conducted; seventhly, rotatable head-expanded reinforcing steel bars are placed; eighthly, a reinforcement cage is placed; and ninthly, concrete is poured. The smashed zone is reinforced in advance so that hole collapse and hole shift can be prevented, drill bit replacement is avoided by expanding the bottom in advance, and therefore the construction efficiency is greatly improved. The large-diameter super-long bored pile construction method has the beneficial effects of being high in construction speed and good in construction effect and is obvious in technical and economical benefit.

Owner:SHANDONG GOLDENCITY CONSTR

Post-grouting bored pile construction method

The invention discloses a post-grouting bored pile construction method. The post-grouting bored pile construction method comprises the following steps of hole forming: measuring a pile position first,and then vertically burying a pile aligning the center of a steel protective cylinder with the center of a pile hole, and finally, drilling to form a hole; after the hole is drilled to a designed depth, using a hole cleaning drill bit to clean the hole once; transporting a made steel reinforcement cage to the site through a cage transporting vehicle; lowering the steel reinforcement cage in place; after a guide pipe is lowered, carrying out secondary hole cleaning; pouring concrete to the pile depth within half an hour of secondary hole cleaning; when the pouring is performed to the top of the pile, measuring the elevation of the top of the pile by using a heavy hammer or a measuring rod in real time; and finally, carrying out post-grouting construction, wherein in post-grouting construction, grouting is carried out on the pile side first; and after a grouting liquid is initially set, the grouting liquid is grouted to the bottom of the pile. By using the post-grouting bored pile construction method to construct, harmful effects on adjacent buildings and surrounding environments are small, the length and diameter of the pile can be freely changed according to design requirements, the end of the pile can enter a supporting layer or can be embedded into a rock stratum; and the bearing capacity of a single pile is large.

Owner:POWER CHINA HENAN ENG CO LTD

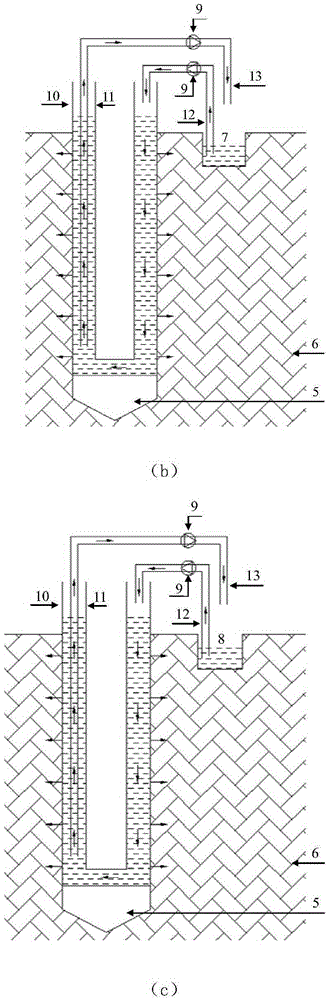

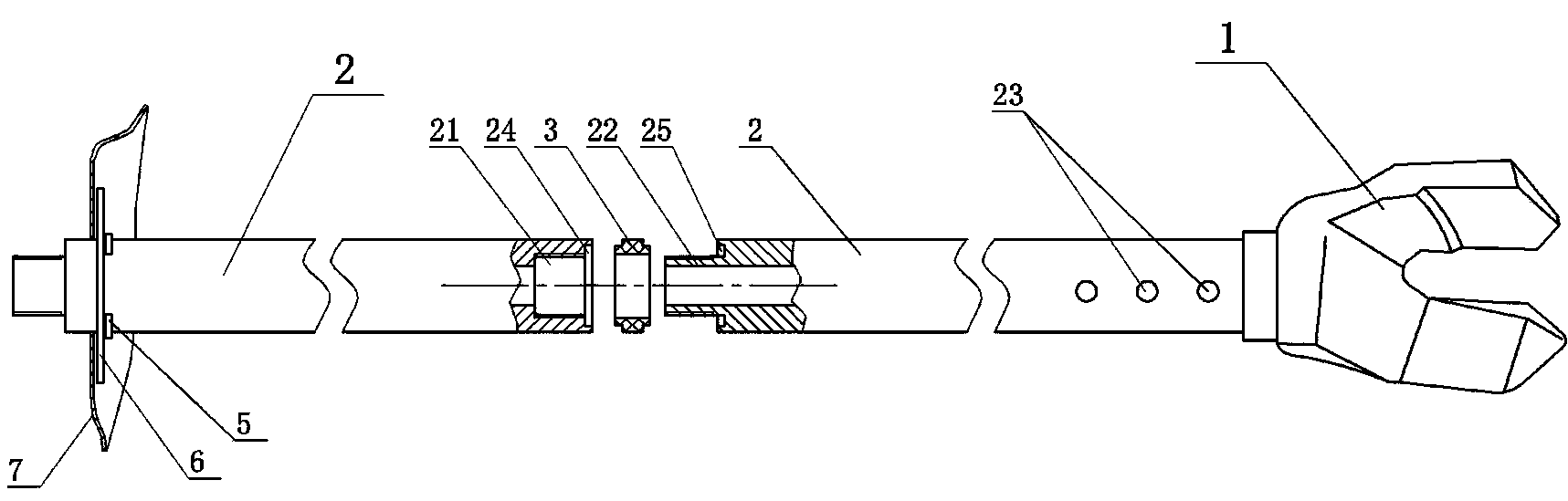

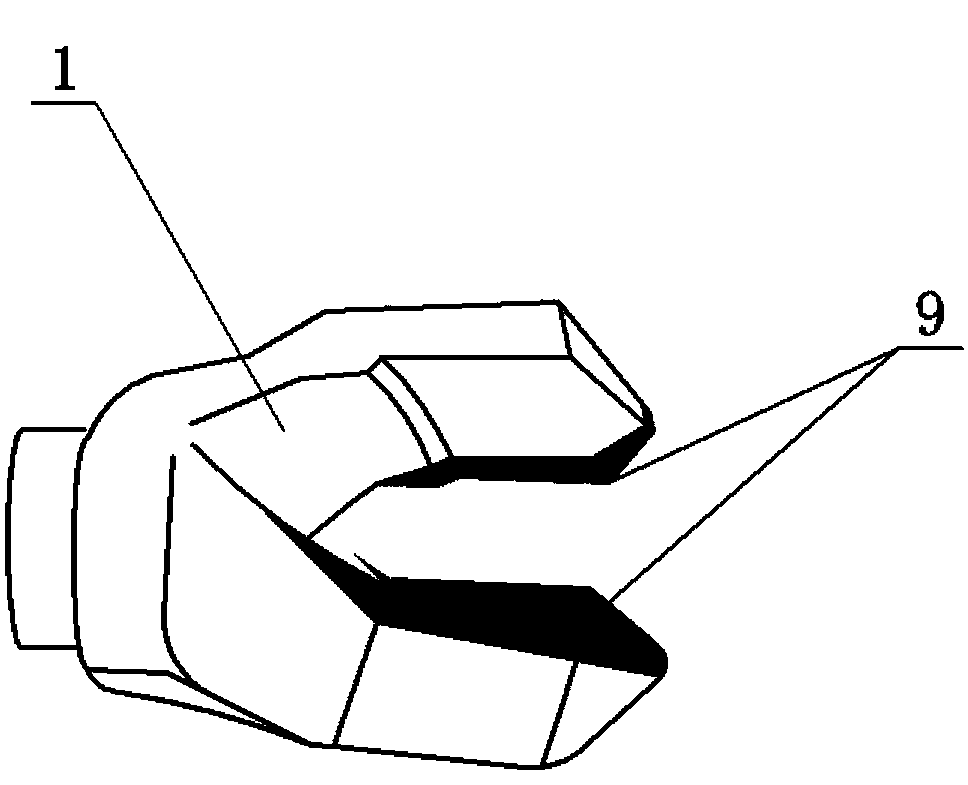

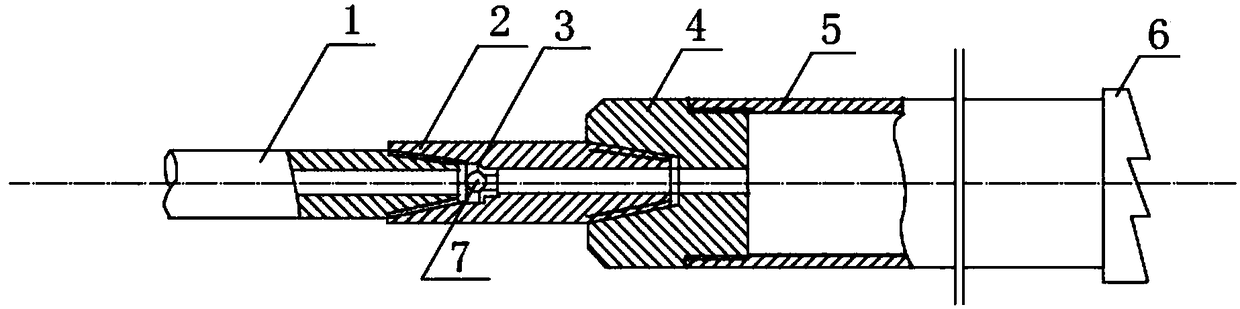

Drilling and extracting integrated device

InactiveCN103939129ASimplify the pumping processPrevent hole collapseFlushingGas removalPetroleum engineeringIntegrated devices

The invention discloses a drilling and extracting integrated device. The drilling and extracting integrated device comprises a dill pipe, a drill bit and a drilling rig and is characterized in that the drill pipe is a hollow PVC drill pipe, the drill bit is a PVC drill bit, segments of the PVC drill pipe are in butt connection in a sealed mode one by one, and the tail end of the PVC drill pipe is connected to an air extractor in a sealed mode. After work of the drill pipe and the drill bit of the device is finished, the drill pipe and the drill bit are directly left in a dilled hole to serve as a gas extraction pipe, and therefore the device not only is favorable for gas blowing or gas extracting in the hole drilling process but also can better serve as a gas inlet for gas extraction. The drilling and extracting integrated device is easy and convenient to operate, high in efficiency, good in effect and very favorable for being popularized and implemented, and exploiting cost can be reduced, and exploiting speed is not affected.

Owner:HENAN POLYTECHNIC UNIV

Self-advancing recyclable steel pipe pile and construction method

ActiveCN103643673AEasy to recycleSave steel and cementExcavationsBulkheads/pilesSteel tubeStructural rigidity

The invention relates to a steel pipe pile for the construction industry, in particular to a self-advancing recyclable steel pipe pile and a construction method. The self-advancing recyclable steel pipe pile comprises a self-advancing connector, a male adapter, a steel pipe and a female adapter. The male adapter and the female adapter are firmly welded to the two ends of the steel pipe to form one section of steel pipe pile, the self-advancing connector is connected with the steel pipe pile, the steel pipe pile with the self-advancing connector is taken as a beginning end, all steel pipe piles are connected in a two-two connection mode through female adapters and male adapters, and an eccentric bit and an impacter drive the steel pipe piles to advance automatically through the pressure of compressed air. A supporting structure is adopted in the steel pipe pile supporting system, wherein the supporting structure is formed by arranging the steel pipe piles and anchor ropes alternatively, locking the steel pipe piles and the anchor ropes through crown beams and waist beams and hanging nets among the steel pipe piles. According to the self-advancing recyclable steel pipe pile and the construction method, hole forming and piling are completed at one time, the hole collapse phenomenon of a cobblestone or miscellaneous fill geologic structure is eliminated, structural rigidity is large, stability is strong, the supporting effect is good, the steel pipe piles are easy to recycle, construction efficiency is high, and cost is saved.

Owner:TAIAN DAIZHONG ELECTROMECHANICAL TECH DEV CO LTD

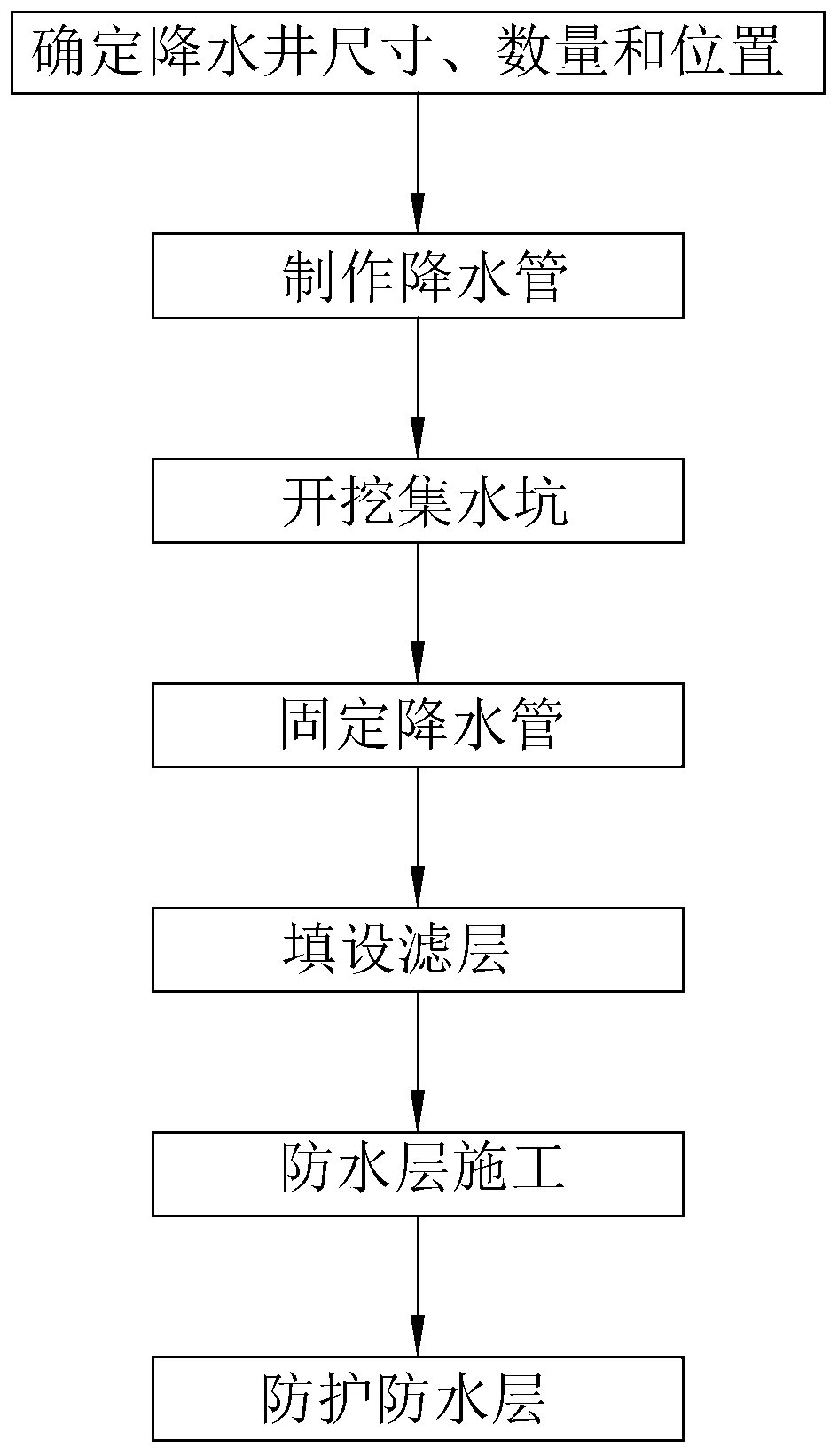

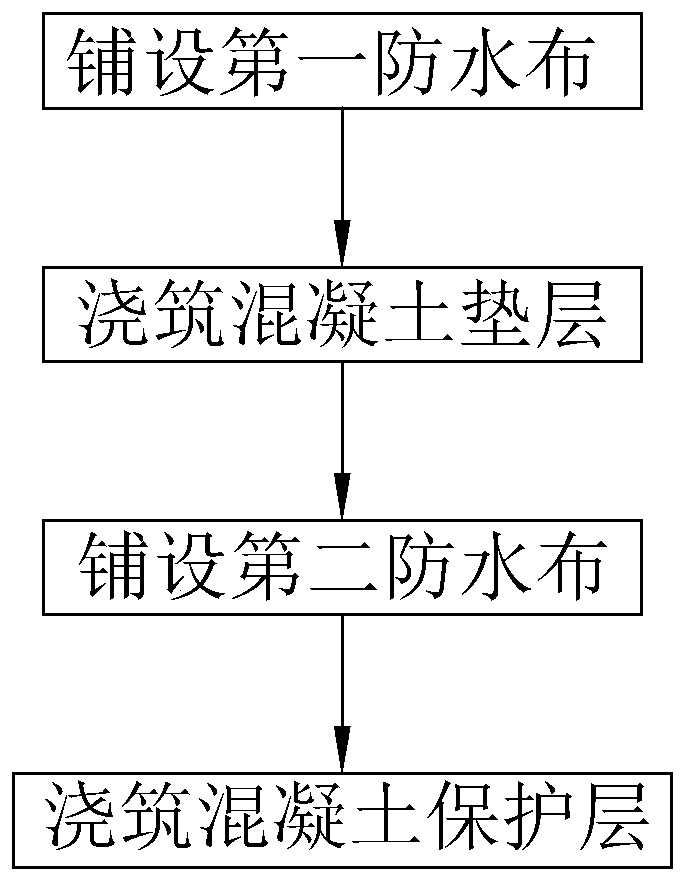

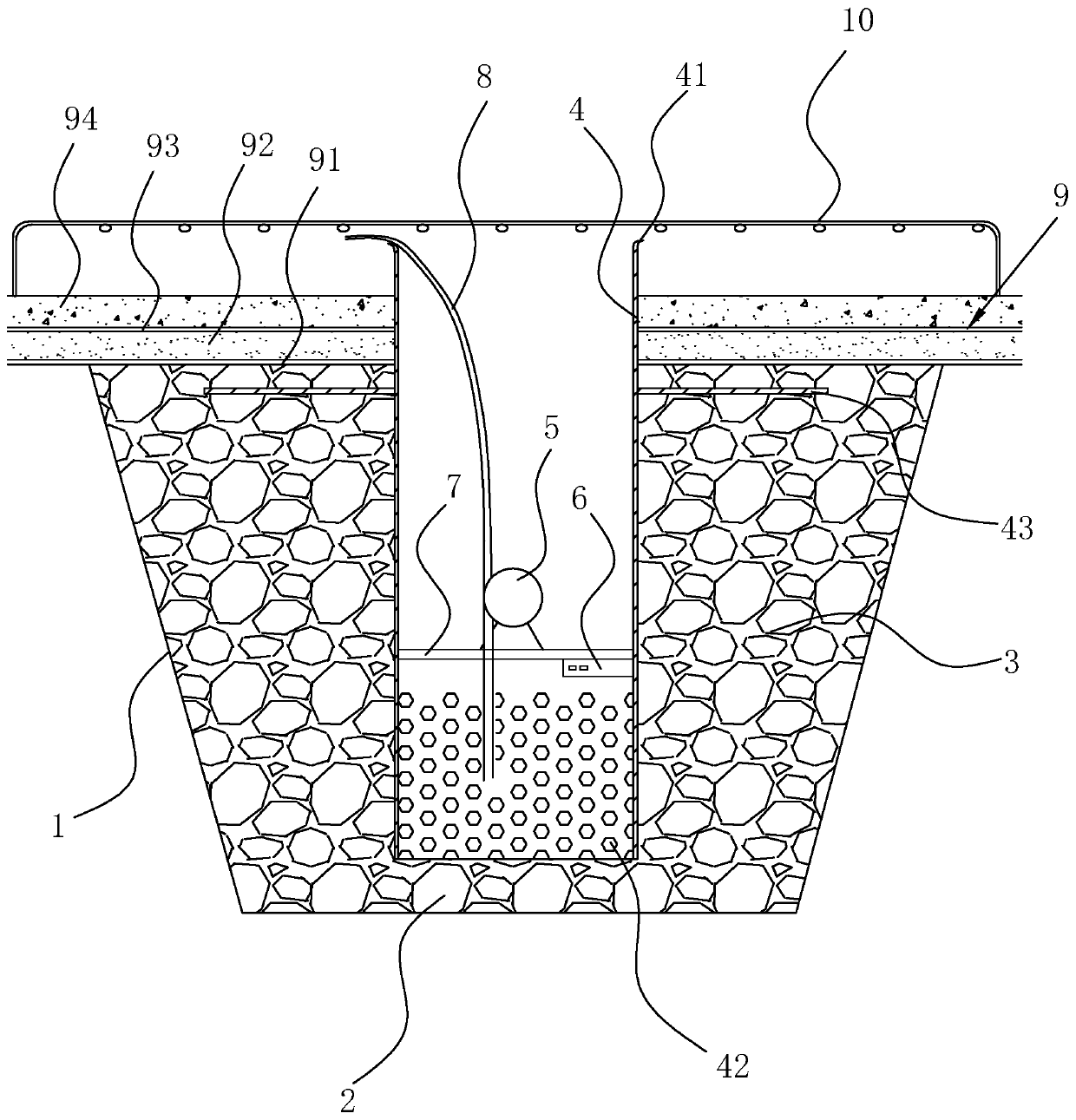

Foundation pit local dewatering construction method

InactiveCN110820778APrevent hole collapseAvoid cloggingExcavationsWater dischargeArchitectural engineering

The invention relates to a foundation pit local dewatering construction method, relates to the technical field of foundation pit dewatering, and aims at solving the problems that an existing dewatering well easily receives impact of underground water, and easily generates the hole collapse condition, or even well wall slurry collapsing can occur, and a water discharging pump is blocked. The methodcomprises the following steps of Step 1, determining the dimension, quantity and positions of dewatering wells; Step 2, manufacturing dewatering pipes; Step 3, digging water collecting pits; Step 4,fixing the dewatering pipes; Step 5, filling and installing filtering layers; and Step 6, constructing waterproof layers. The foundation pit local dewatering construction method has the beneficial effect that a hole collapsing phenomenon of the dewatering wells can be reduced.

Owner:陕西神州实业有限公司

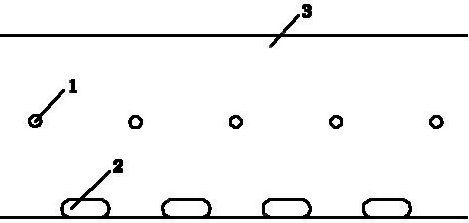

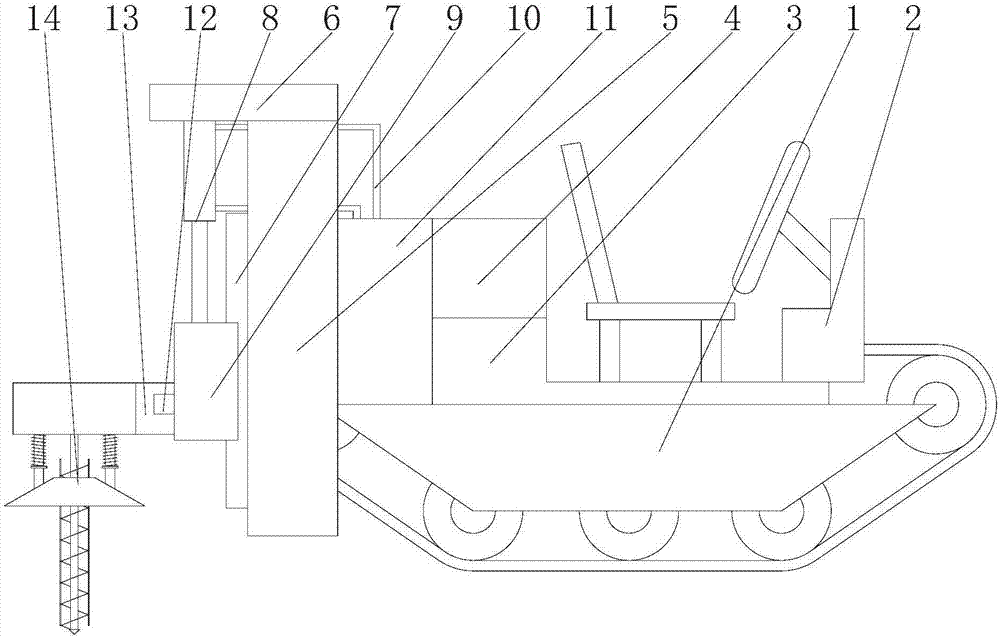

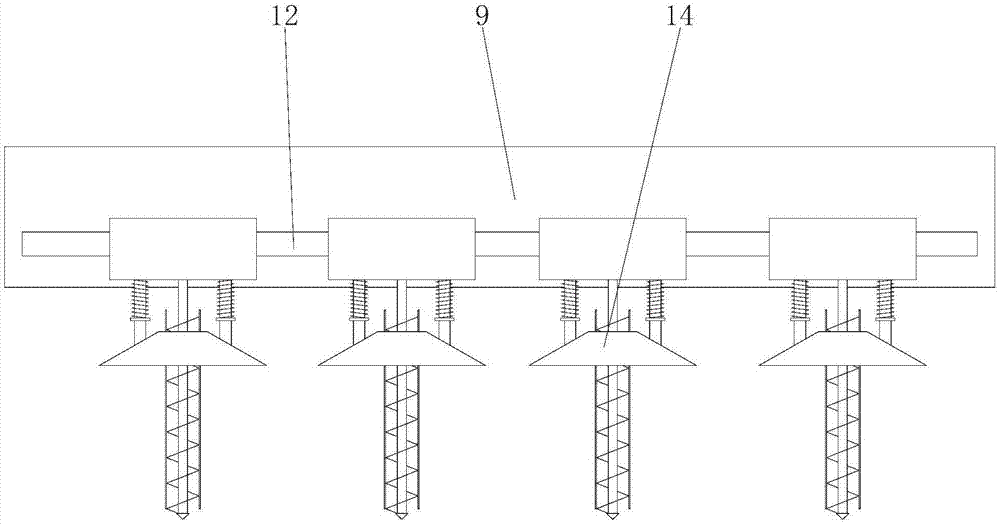

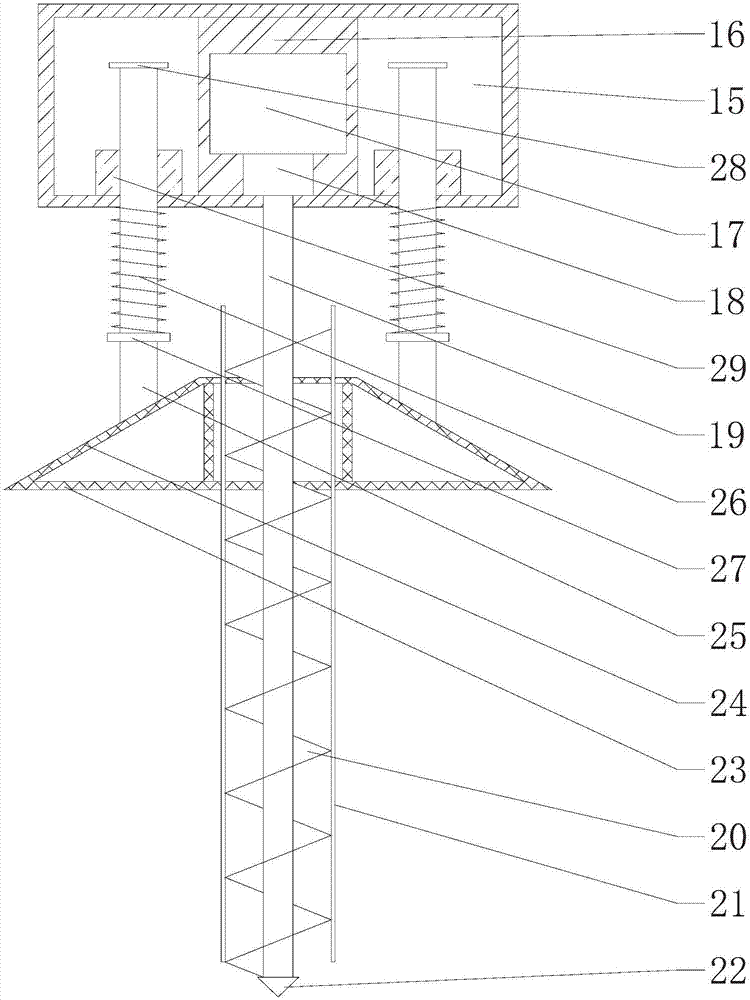

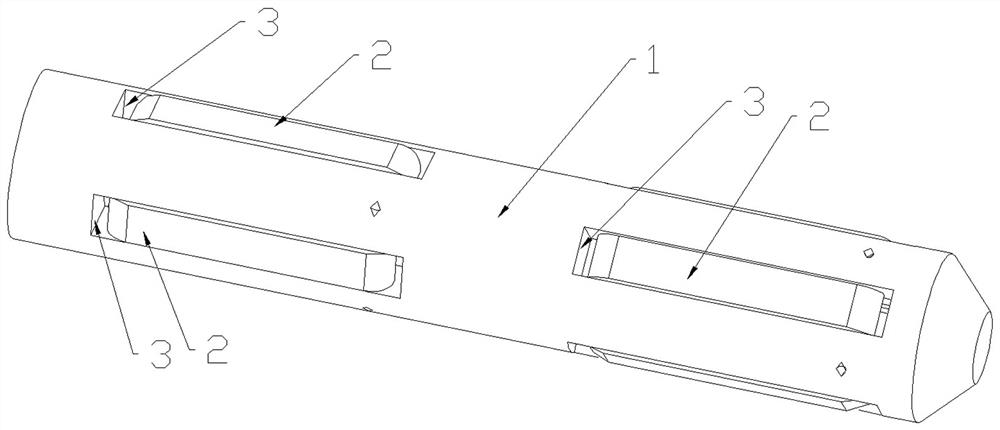

Earth boring machine for fresh ginger cultivation

InactiveCN107371474APrevent hole collapseImprove cleanlinessPlantingFurrow making/coveringDrill bitEngineering

The invention discloses an earth boring machine for fresh ginger cultivation. The earth boring machine for fresh ginger cultivation comprises a walking mechanism. A power mechanism is arranged on the lower side of a control mechanism, a control box is arranged on the back side of the control mechanism, a column is arranged on the back side of the power mechanism, a cross beam is arranged on the upper end of the column, a guide rail is arranged on the back side of the column, the guide rail is movably connected to a mounting seat, a plurality of earth boring mechanisms are connected to the back side of the mounting seat, a power box is arranged in each of the earth boring mechanisms, an electric base is arranged in the power box, the electric base is fixedly connected to a motor, the lower end of the motor is connected to a transmission, the lower end of the transmission is connected to a rotary shaft, a spiral blade is arranged on the outer side of the rotary shaft, and a drill is arranged on the lower end of the rotary shaft. By arranging the rotary shaft and the spiral blade, the earth boring machine can perform mechanical boring, and meanwhile, a stick and a press are arranged, so that the bored holes are neat inside and the holes can be effectively prevented from collapsing. The holes can be also prevented from being covered as soil fails. The line spacing and row spacing as well as the depth of the bored holes can be precisely adjusted and controlled at the same time.

Owner:CHONGQING UNIV OF ARTS & SCI

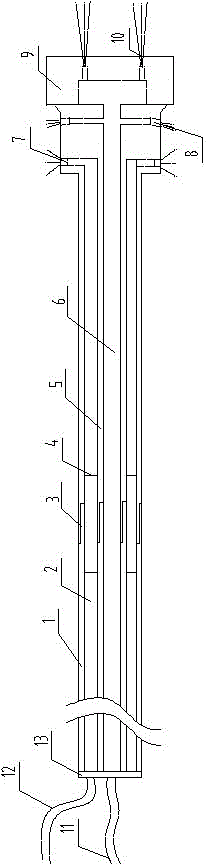

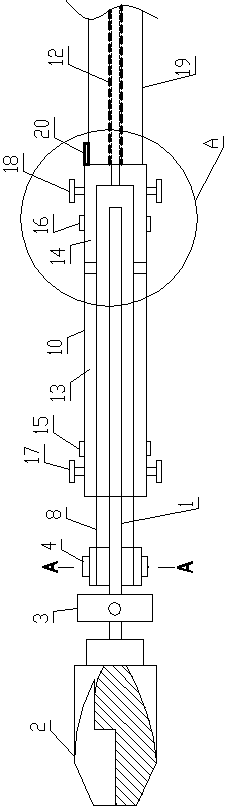

Supporting device for coal seam gas extraction drilling and using method thereof

PendingCN112682094AStable supportDrainage works smoothlyGas removalBorehole/well accessoriesStructural engineeringMechanical engineering

The invention discloses a supporting device for coal seam gas extraction drilling and a using method thereof. The supporting device for coal seam gas extraction drilling comprises a support body and an elastic supporting foot mechanism, wherein the elastic supporting foot mechanism comprises at least two supporting feet hinged to the support body; the support body is provided with a containing groove for containing the supporting feet; and each supporting foot is provided with an elastic piece for controlling the supporting foot to pop out of the containing groove to support a drilled hole and a non-return assembly for preventing the supporting foot from retracting into the containing groove after the supporting foot pops out. The using method of the supporting device for coal seam gas extraction drilling comprises the following steps that the supporting feet retract into the containing groove, the support body is pushed to advance in an opening and closing type drill bit till the support body descends into the drilled hole from the opening and closing type drill bit, the supporting feet pop out of the containing groove outwards to support the drilled hole, and the non-return assemblies are arranged outside the containing groove. The drilled hole can be effectively supported, and hole collapse is prevented. The supporting device is suitable for being used in coal seam gas extraction drilling and used for supporting the drilled hole.

Owner:XIAN UNIV OF SCI & TECH

Gas pumping-exhaust directional drilling tool and drilling method

PendingCN110685735AReduce vibrationReduce the chance of collapsing holesFluid removalDirectional drillingThermodynamicsPneumatic motor

The invention discloses a gas pumping-exhaust directional drilling tool which comprises a hollow drill rod and a drill bit; a high-pressure gas path is connected to the hollow drill rod backwards; a pneumatic motor is connected to the front end of the hollow drill rod; an output shaft of the pneumatic motor is connected with the drill bit forwards; the position, behind the pneumatic motor, of thehollow drill rod is uniformly provided with more than three front pneumatic jacks in a circumferential direction; each front pneumatic jack is connected with the high-pressure gas path, and the connecting part of each front pneumatic jack and the high-pressure gas path is provided with a front electromagnetic valve used for controlling the working state of the corresponding front pneumatic jack; ajacking direction of each front pneumatic jack is perpendicular to an axis of the hollow drill rod; and the high-pressure gas path extends backwards to a high-pressure gas source outsides a drilled hole. The invention further discloses a corresponding drilling method. By adopting the gas pumping-exhaust directional drilling tool and the drilling method, self-propelled drilling is realized, a pipeis put down while drilling is performed, the drilled hole is timely supported, and operation of separately inserting a gas pumping-exhaust pipe does not need to be performed after drilling, so that the whole drilling process is safer, time-saving and efficient, lowers the operation difficulty and improves the working efficiency.

Owner:HENAN POLYTECHNIC UNIV

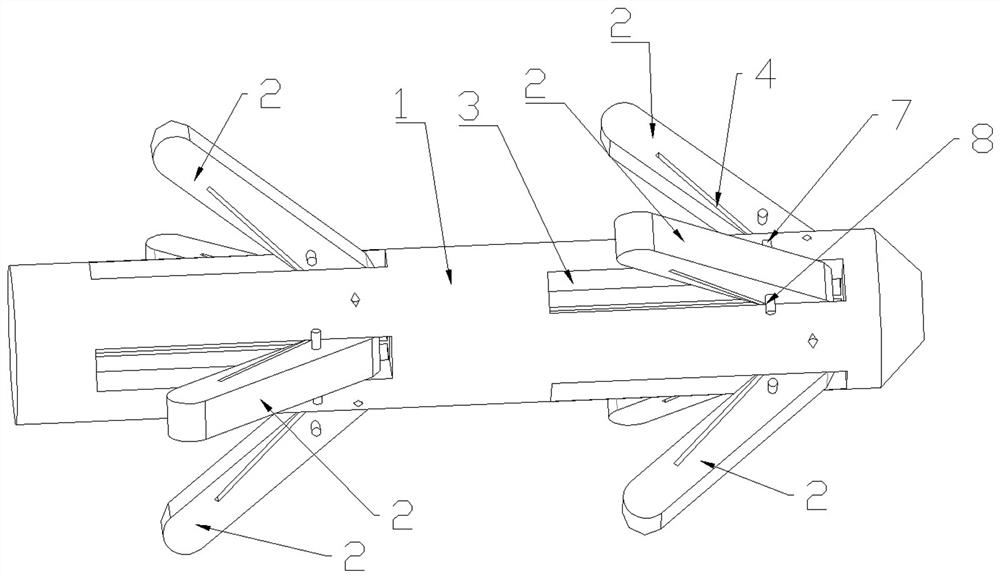

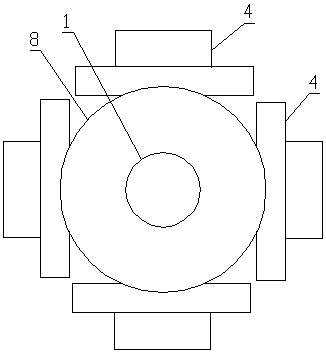

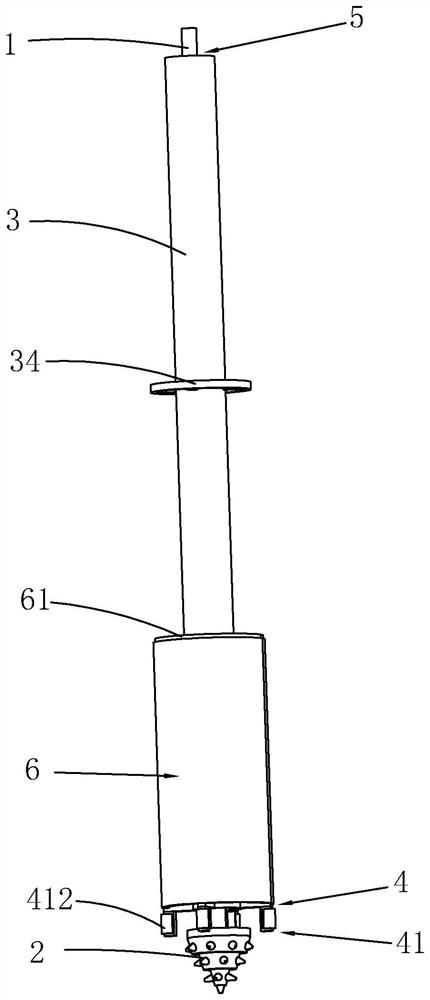

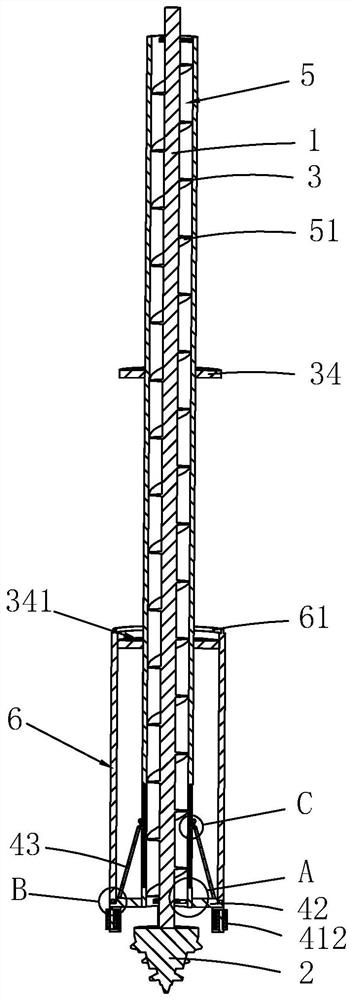

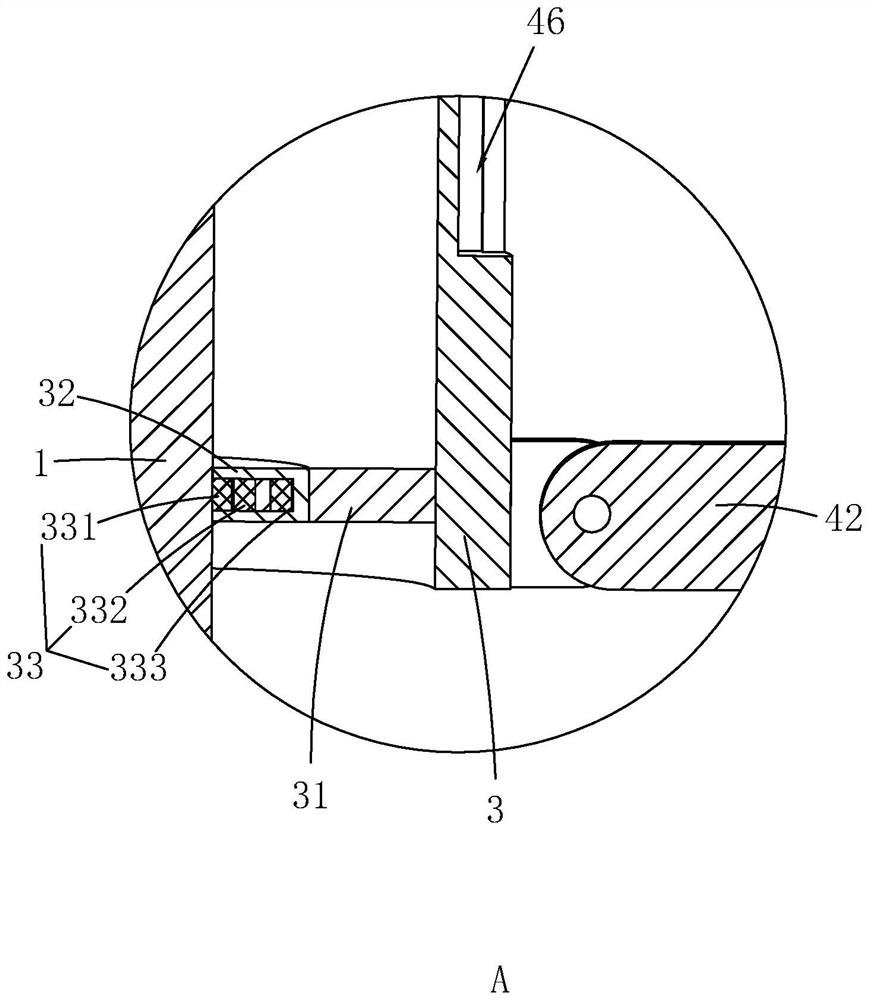

Hole collapse prevention construction device and cast-in-place pile construction technology

PendingCN114370236AAchieve supportImprove rotary drilling efficiencyDrilling with mechanical conveyingExcavationsStructural engineeringLantern

The invention relates to the technical field of highway construction, in particular to a hole collapse prevention construction device and a cast-in-place pile construction technology.The hole collapse prevention construction device comprises a drill rod and a rotary excavating drill bit, the rotary excavating drill bit is fixedly connected with the suspended end of the drill rod, and the hole collapse prevention construction device further comprises a sleeve, at least two sets of connecting rods, a lifting assembly and a supporting assembly; one end of the connecting rod is connected with the inner wall of the sleeve, the other end of the connecting rod is rotatably connected with the drill rod, the supporting assembly comprises a lantern ring, a plurality of pull rods, a plurality of supporting rods and diameter expanding pieces, one end of each supporting rod is rotatably connected with the sleeve, one end of each pull rod is rotatably connected with the supporting rod, and the other end of each pull rod is rotatably connected with the lantern ring; the horizontal projection diameter of the rotary drilling bit is smaller than the inner diameter of the pile casing. The pile hole wall is supported by the pile casing through synchronous movement of the rotary excavating drill bit and the pile casing, so that the pile hole wall is in a protection state, meanwhile, the rotary excavating efficiency of the pile hole is improved through the synchronous action of the lifting assembly and the rotary excavating drill bit, and then the construction efficiency of a cast-in-place pile is improved.

Owner:中交二公局萌兴工程有限公司

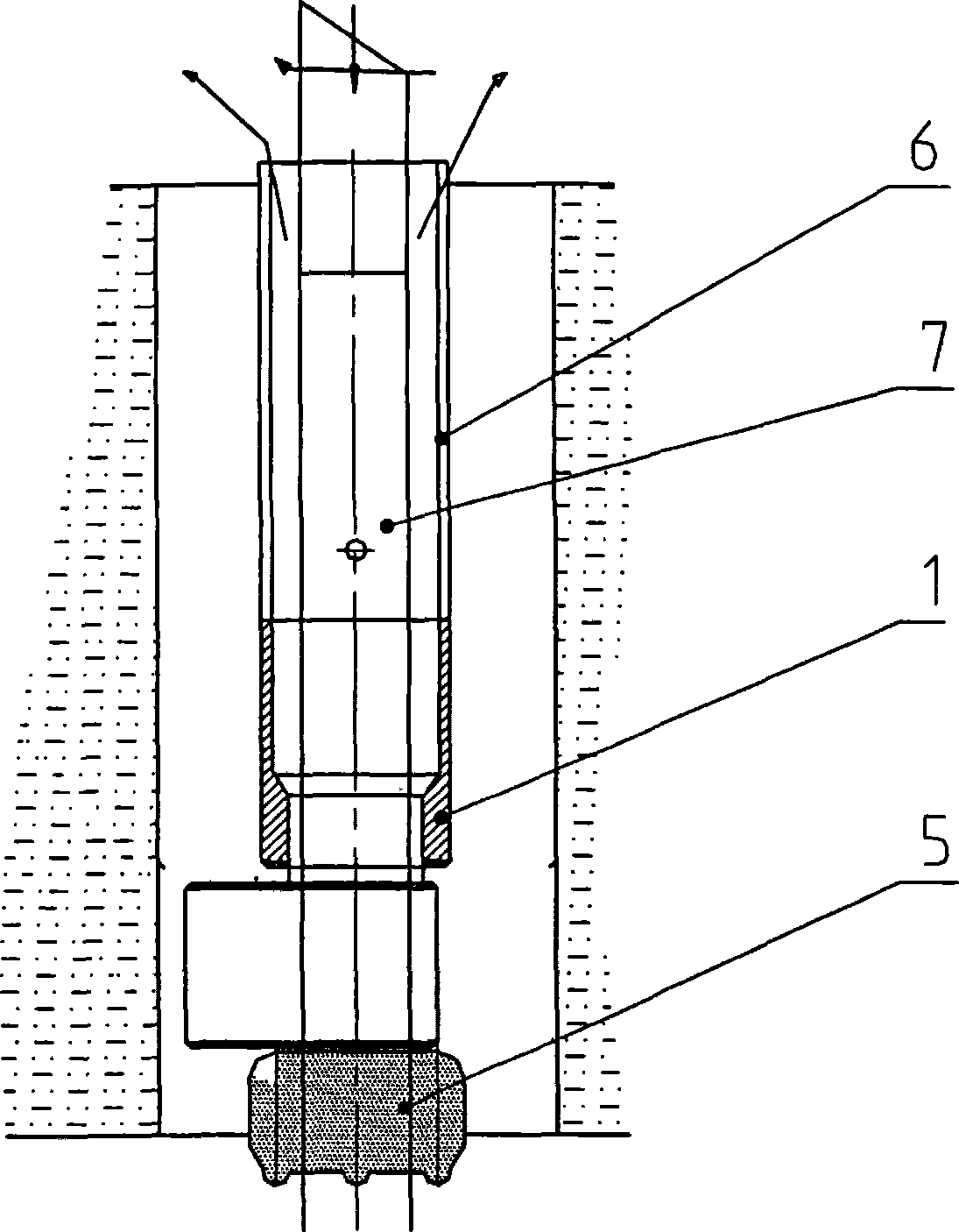

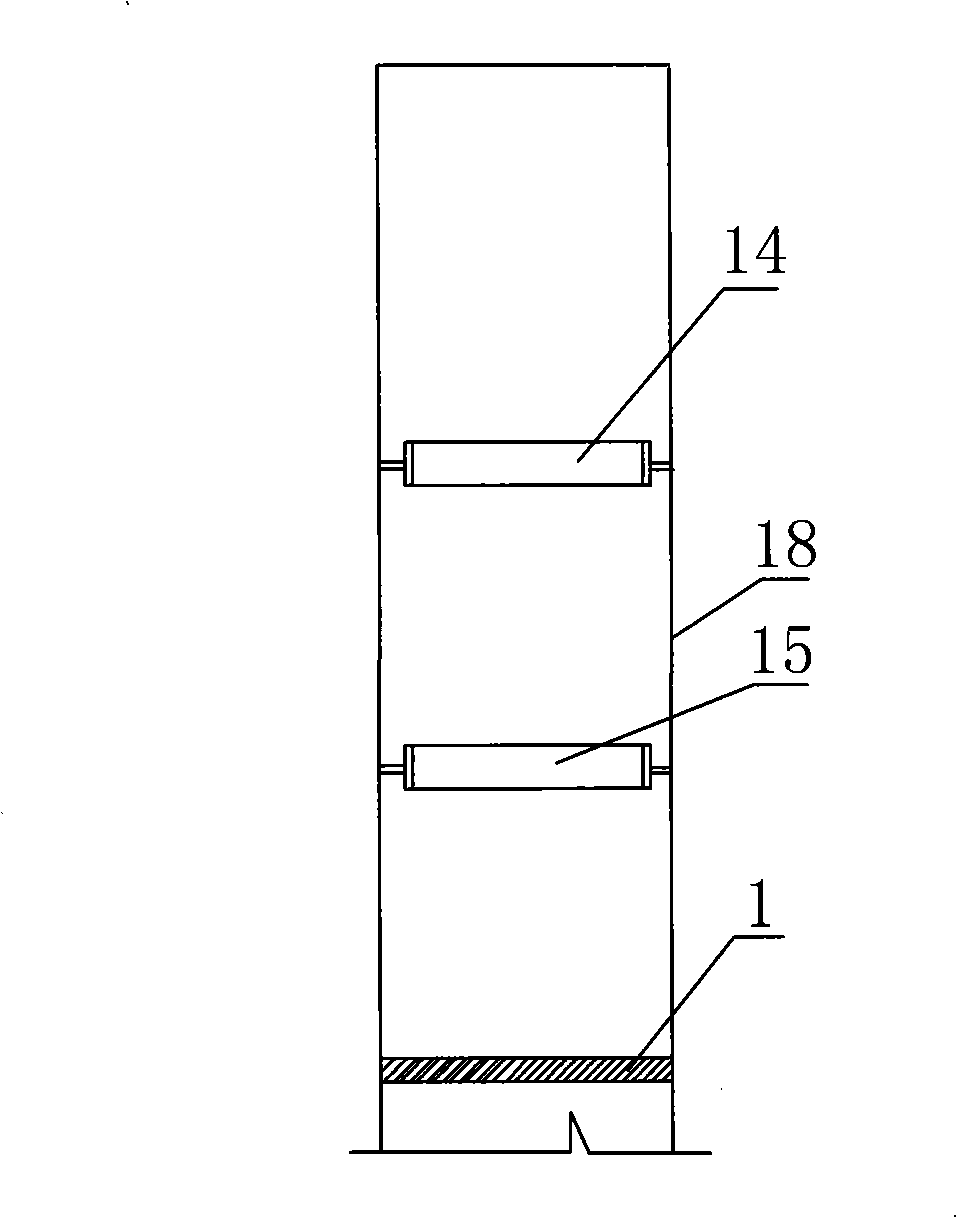

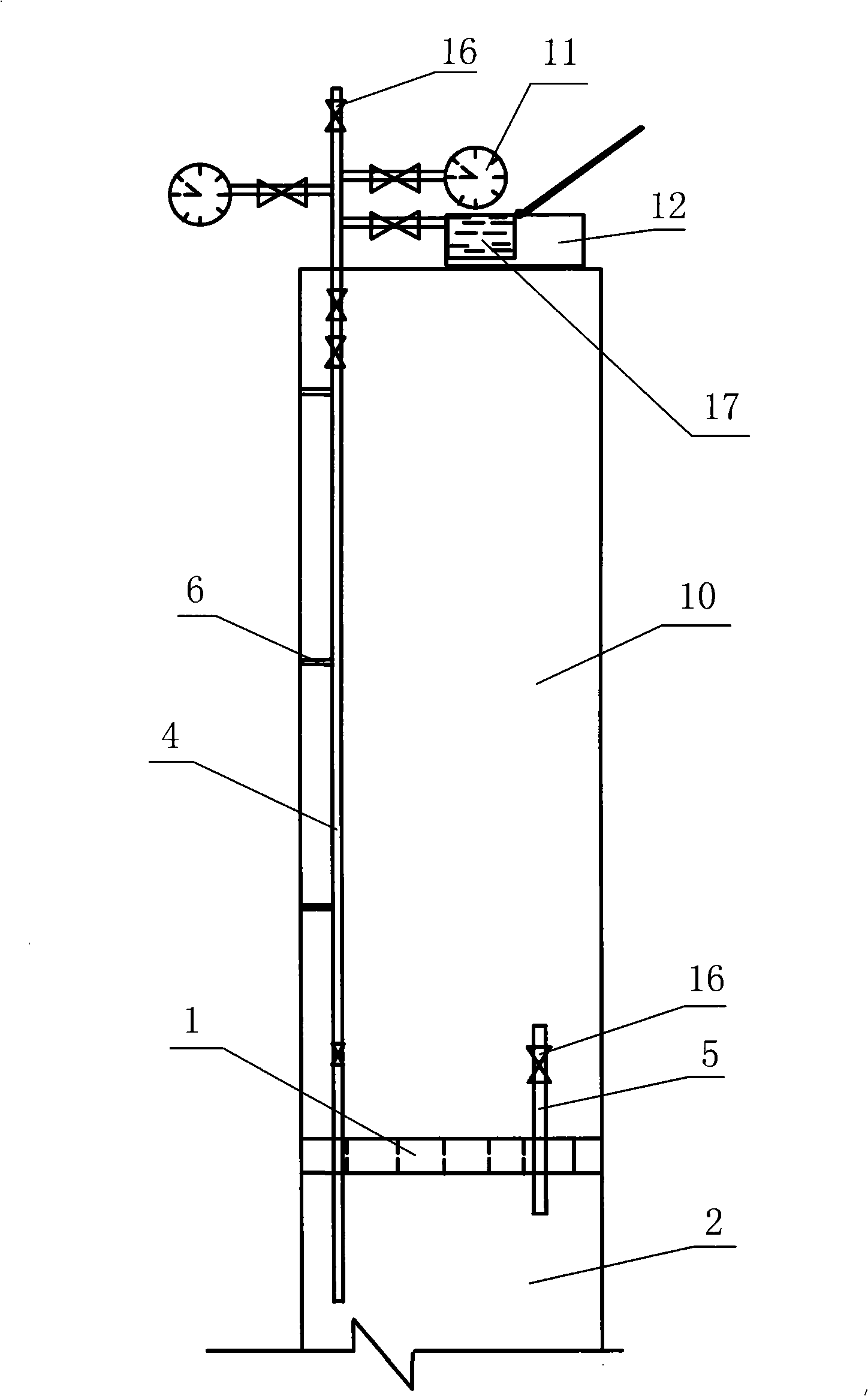

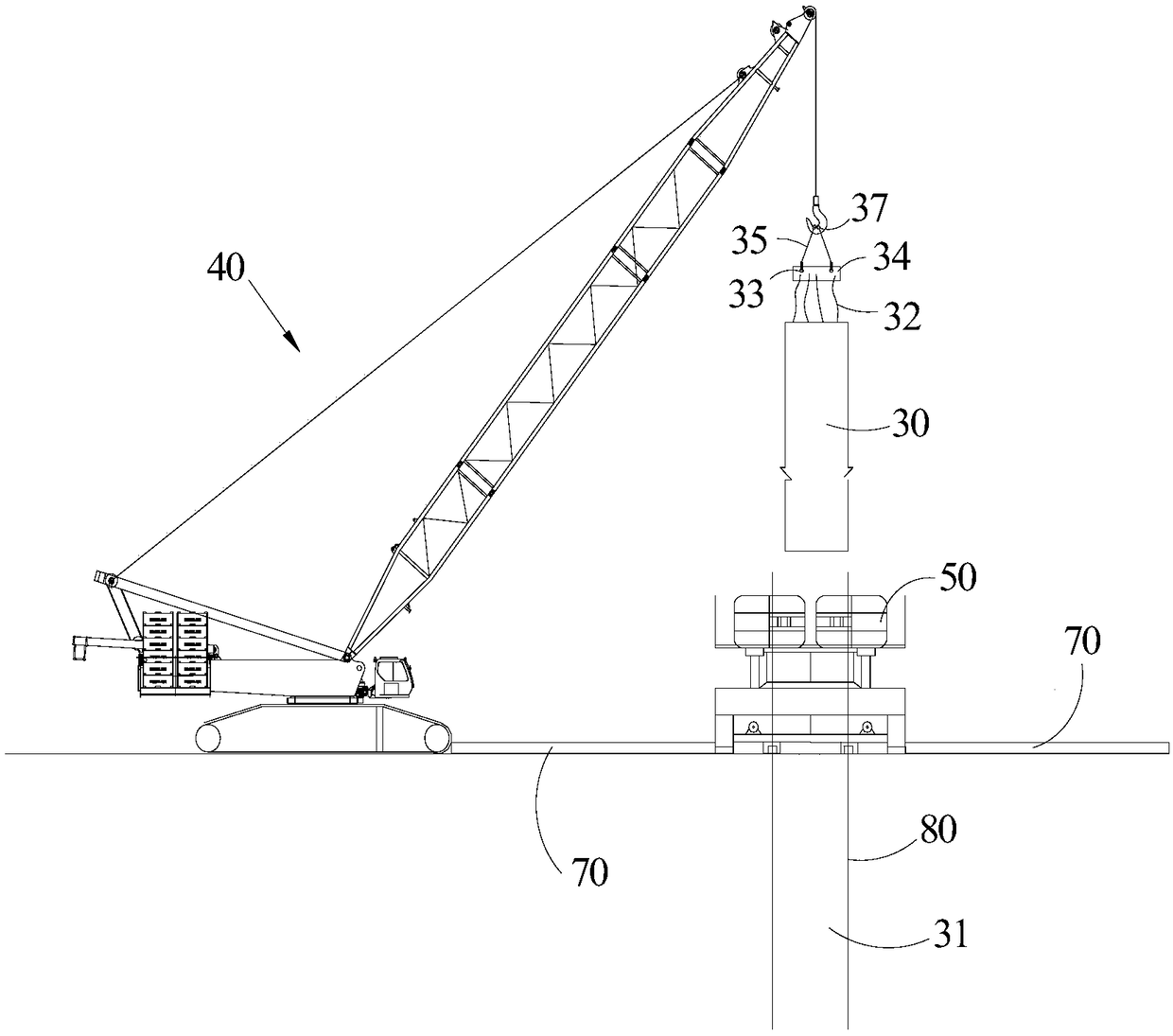

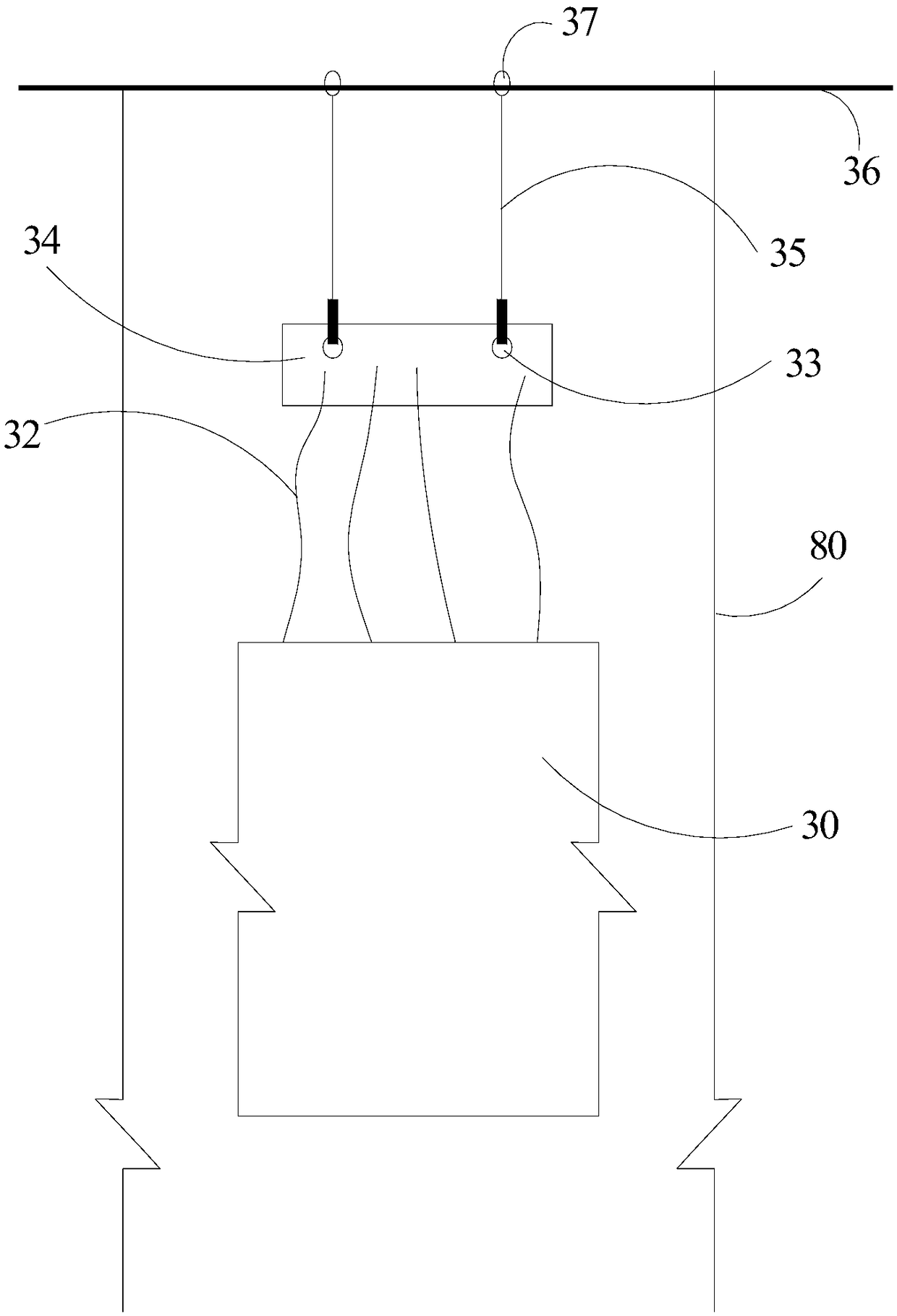

Mounting method of deep well high pressure aeration reactor steel drum

InactiveCN101344004AReduce lifting weightPrevent hole collapseFlow mixersMixing methodsInstabilityEngineering

The invention discloses an installation method for a steel cylinder of a high-pressure aeration reactor of a deep well, comprising the following steps of: processing and manufacturing an inner baffle; determining the installation position of the inner baffle: the steel cylinder consists of a plurality of groups of steel cylinder sections from bottom to top, the inner baffle is arranged on the steel cylinder section with the number of M and the length ratio of the upper part and the lower part of the inner baffle is 2.5 to 4.0 : 6.0 to 7.5; installing a plurality of groups of steel cylinder sections of the lower part of the inner baffle in sequence from bottom to top; installing the inner baffle; sinking and temporarily fixing the steel cylinder section with the number of M+1; sinking and installing the steel cylinder section with the number of M+2 after the pressure in the cylinder is transmitted up uniformly and installing a plurality of groups of steel cylinder sections of the upper part in sequence according to the installation method thereof; pouring concrete or mortar to the outside of the steel cylinder; releasing the pressure and carrying out cutting recovery of the inner baffle. The invention can solve the lifting problem of the steel cylinder and the instability and distortion problem of the steel cylinder under the effect of the side pressure of the slurry outside of the cylinder, can ensure that the steel cylinder sinks to the designed elevation safely and smoothly and can save the construction cost.

Owner:陈定平

Construction method for replacing cast-in-place pile

InactiveCN108775036AEasy to recycleEasy to manageFoundation repairBulkheads/pilesEngineeringDrilling machines

The invention relates to the technical field of rotary excavating cast-in-place piles, and discloses a construction method for replacing cast-in-place piles. The construction method comprises the following steps that (1), a full rotary drilling machine sinks a sleeve around an old pile body to the bottom of the old pile body to isolate the old pile body from a soil body and pull out the old pile body to form an old pile hole; (2), the old pile hole is backfilled with cement soil, and the sleeve is pulled out while backfilling; (3), cement-mixed soil is tamped and stand for a week; (4), an outer retaining cylinder is embedded, then an inner retaining cylinder is embedded, the inner retaining cylinder is located in the outer retaining cylinder, and the outer retaining cylinder is provided with positioning structure; and the lower part of the inner retaining cylinder sinks to the lower part of the bottom of the old pile hole; (5), the soil body inside the inner retaining cylinder is excavated to form a new pile hole; and (6), a steel cage is lowered, concrete is poured, and a new pile body is formed. The old pile body is removed integrally, the work efficiency is higher, and recoveryand management are facilitated; the backfilling of old pile hole reduces the quality hidden trouble of the new pile hole; and through the construction method, old pile bodies and new pile bodies can be replaced in the urban project renewal.

Owner:深圳市工勘基础工程有限公司 +1

Method for increasing gas extraction rate by permeability increasing of single thick coal seam

ActiveCN102678166BIncreased air permeability coefficientGuaranteed relief sizeGas removalCoal pillarTunneling length

Disclosed is a method for increasing gas extraction rate by permeability increasing of single thick coal seam. During a tunneling process of coal seam working face, gas extraction holes are drilled along coal seams and hole protecting tubes are inserted into the gas extraction holes after drilling and sealed so as to perform gas extraction. When tunneling length of a tunnel is less than 50m, a twist drill is used to drill on the bottom of the coal seam along an inclination at intervals of 0.3-0.5m of coal pillars, and drilling holes which are 1.0-1.5m in width and 0.1-0.2 time as high as the coal seam are formed. After the drilling holes are formed, curved sink from bottom to top occurs on the coal, a large quantity of gaps are generated, permeability coefficient of the coal is increased by more than 120 times on average, gas extraction flow is increased by more than 10 times on average, and average gas extraction concentration is larger than 55%. By the method, pressure relief of the single thick coal seam with high gas content and low permeability is achieved, permeability increasing range is wide, permeability increasing effect is fine, and the gas extraction rate is increased by 60%. In addition, the method is widely applicable.

Owner:CHINA UNIV OF MINING & TECH

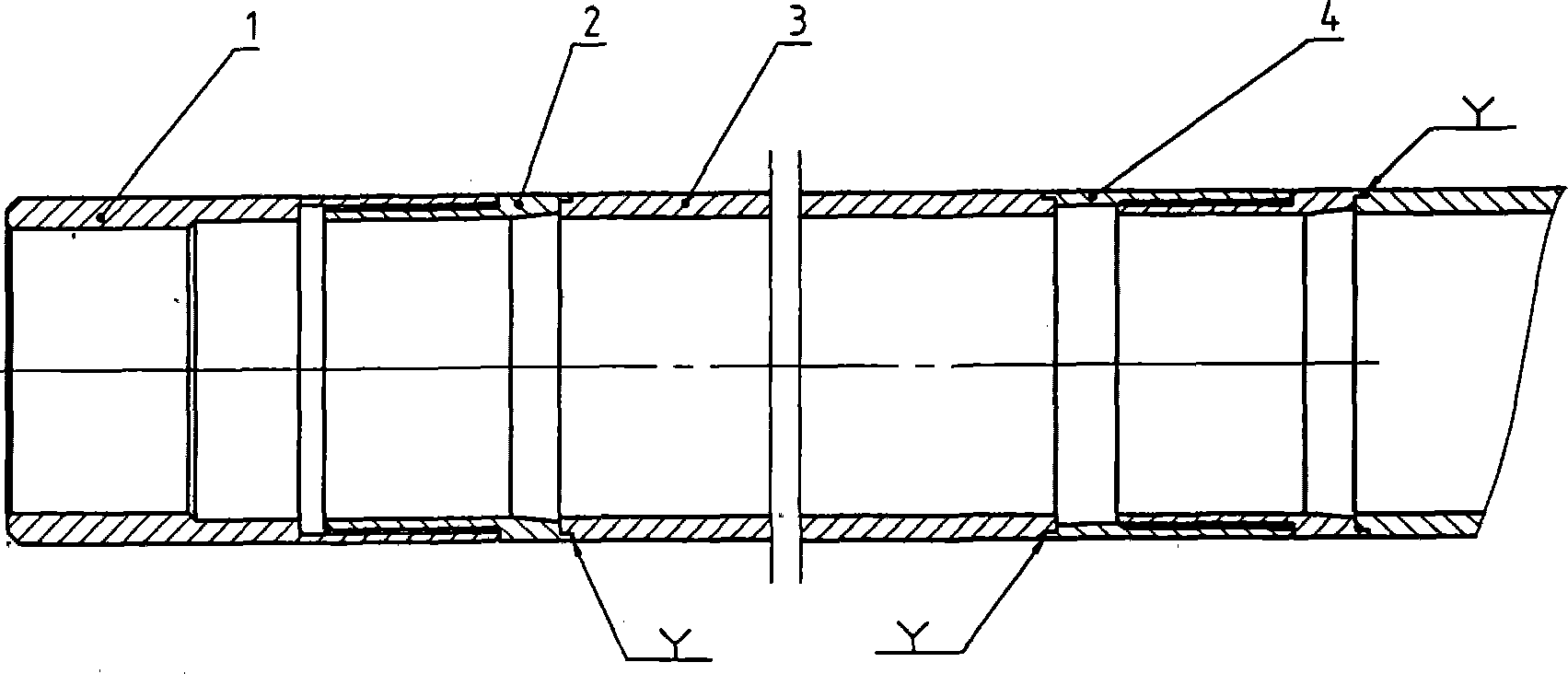

Drilling coring equipment by adopting natural composite slurry to drill to achieve effect of rock core coated with mud

The invention discloses drilling coring equipment by adopting natural composite slurry to drill to achieve the effect of a rock core coated with mud. The drilling coring equipment comprises a drill pipe and a rock core pipe. A drill pipe joint located on the upper portion of the rock core pipe is a joint with a marble seat, the marble seat is arranged in the drill pipe joint, and when a water stopping marble is arranged in the marble seat, the upper portion of the rock core pipe is sealed; and the two ends of the rock core pipe are connected with a rock core pipe joint and an alloy drill bit,one end of the drill pipe is connected to the interior of the drill pipe joint, and the drill pipe joint is connected with the rock core pipe joint. The defects that in the prior art, the sandy soil rock core sample recovery is lower than 70%, and the undisturbed grain composition and structure of sandy soil cannot be maintained are overcome. The drilling coring equipment has the advantages that the sandy soil rock core sample recovery is sharply improved and can be as high as 100%, and the sampled sandy soil rock core sample is coated with mud, so that the undisturbed grain composition and structure of the sandy soil of the sandy soil rock core sample are maintained.

Owner:长江岩土工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com