Drilling and extracting integrated device

A drill pipe and drill bit technology, applied in the field of drilling and pumping integrated devices, can solve the problems of poor effect, complicated and slow operation process, affecting mining speed, etc., and achieve the effects of simple operation, high efficiency and reduction of mining cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

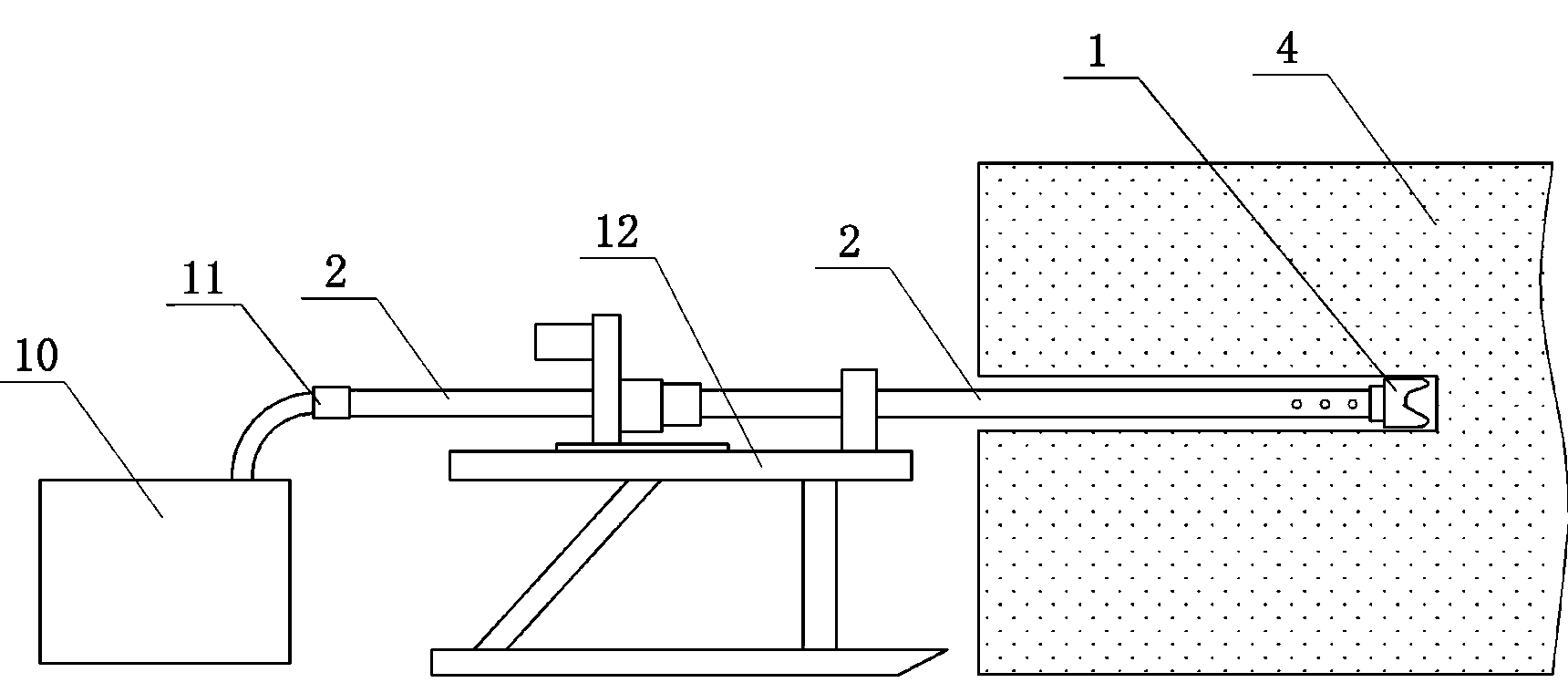

[0016] Embodiment 1: A kind of drilling and pumping integrated device, see figure 1 with figure 2 , the hollow PVC drill pipe 2 carries the PVC drill bit 1 to drill deep into the coal seam, and when the drill hole reaches the target position (for example, 60m), then the PVC drill pipe 2 is sealed. The PVC drill pipe is sealed.

[0017] The hollow PVC drill pipe 2 is used as a gas drainage pipe. The end of the PVC drill pipe 2 is sealed and connected to the air extraction device 10, and the air extraction device 10 is used to discharge the gas inside the borehole.

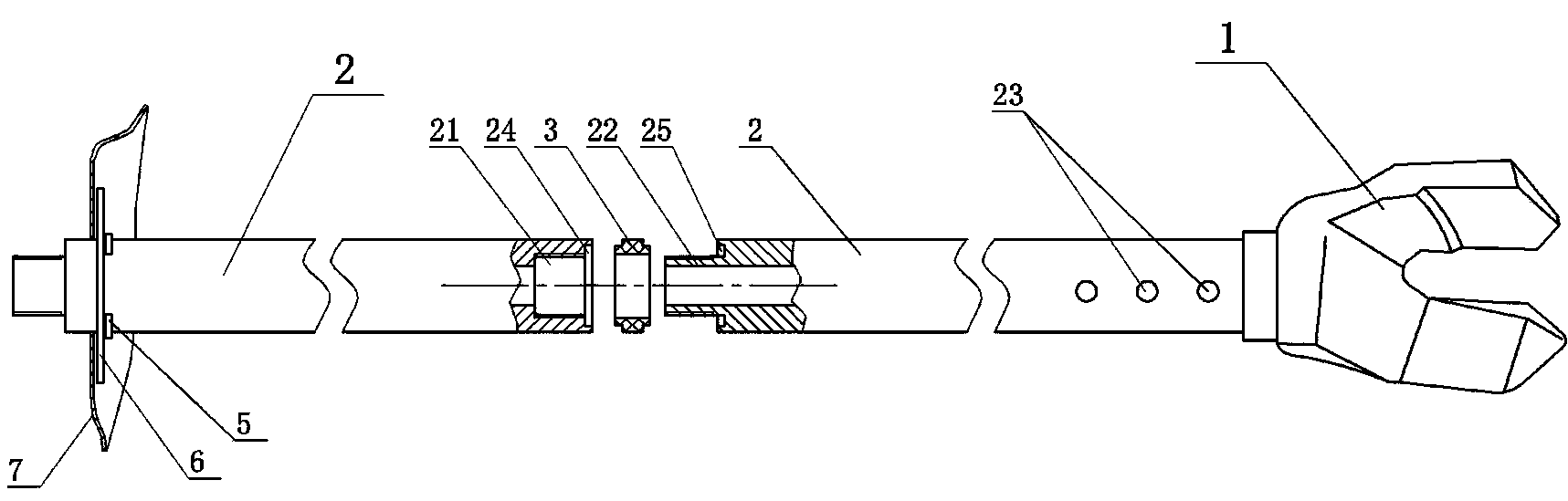

[0018] The PVC drill pipe 2 can be sealed and butted section by section, so that it can be continuously extended until it is drilled into a suitable position. The butt joint surface of the adjacent PVC drill pipe 2 is preferably provided with a sealing layer, such as a sleeve sealing ring 3, the sealing surface of the adjacent drill pipe can be provided with annular grooves 24 and 25, and the sealing ring 3 is m...

Embodiment 2

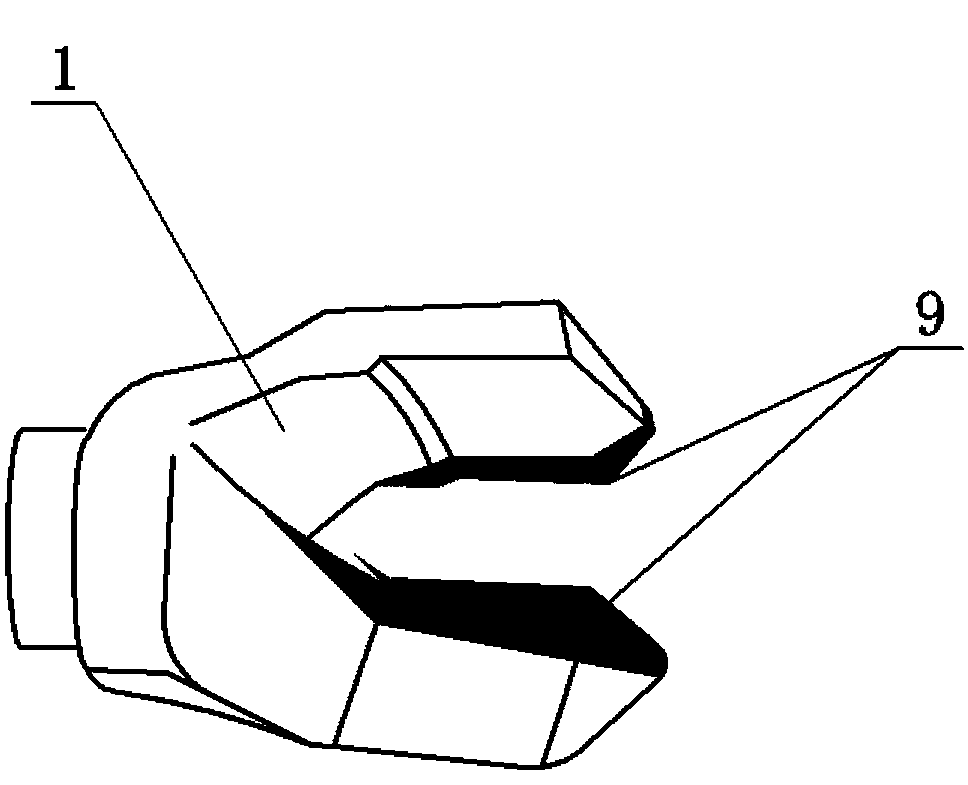

[0021] Embodiment 2: On the basis of the method of embodiment 1, the PVC drill bit is improved, see image 3 , Embedding the metal edge portion 9 at the drill edge position to form a composite drill bit. For example, protruding ribs can be provided at the root of the metal blade, and matching grooves can be provided on the base of the drill bit, and the protruding ribs can be embedded in the grooves to form a composite body through a heat sealing process.

Embodiment 3

[0022] Embodiment 3: see figure 2 , on the basis of Embodiment 1, a sealing structure that can be installed is provided, that is, a hole sealing device is movably installed on the end of the drill rod, and a clamping table is movably installed at the end of the drill rod according to actual needs. 5. A circular support plate 6 is set on the outside of the card table, and a circular flexible sealing sheet 7 is set on the outside of the circular support plate. The circular support plate is equivalent to or larger than the drilled hole, and the outer diameter of the circular flexible sealing sheet is larger than The outer diameter of the circular support plate is larger than the outer diameter of the drilled hole, so that when the PVC drill pipe is pumped, the internal air pressure is lower than the external air pressure, and the circular flexible sealing sheet is sucked inward, and it fits and seals near the drilled hole .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com