Drilling coring equipment by adopting natural composite slurry to drill to achieve effect of rock core coated with mud

A mud and natural technology, applied in drilling equipment, drill pipes, drill pipes, etc., can solve the problem of difficulty in accurately determining the particle composition of sand core samples, affecting the accuracy of sand stratification and geological identification, and drilling sandy soil layers. The core removal rate is not high, which is conducive to wide popularization and application, easy to learn and master, and low equipment performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

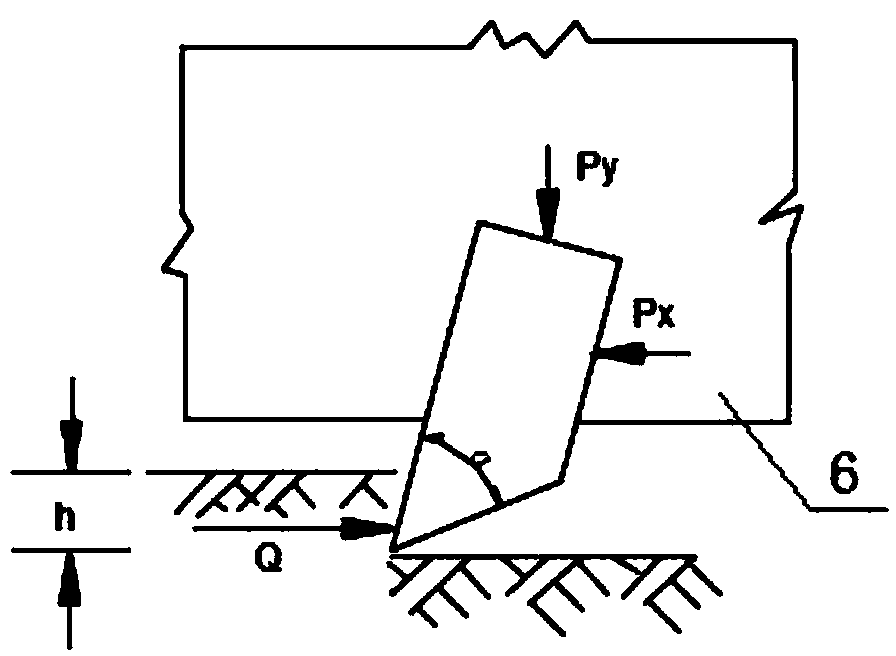

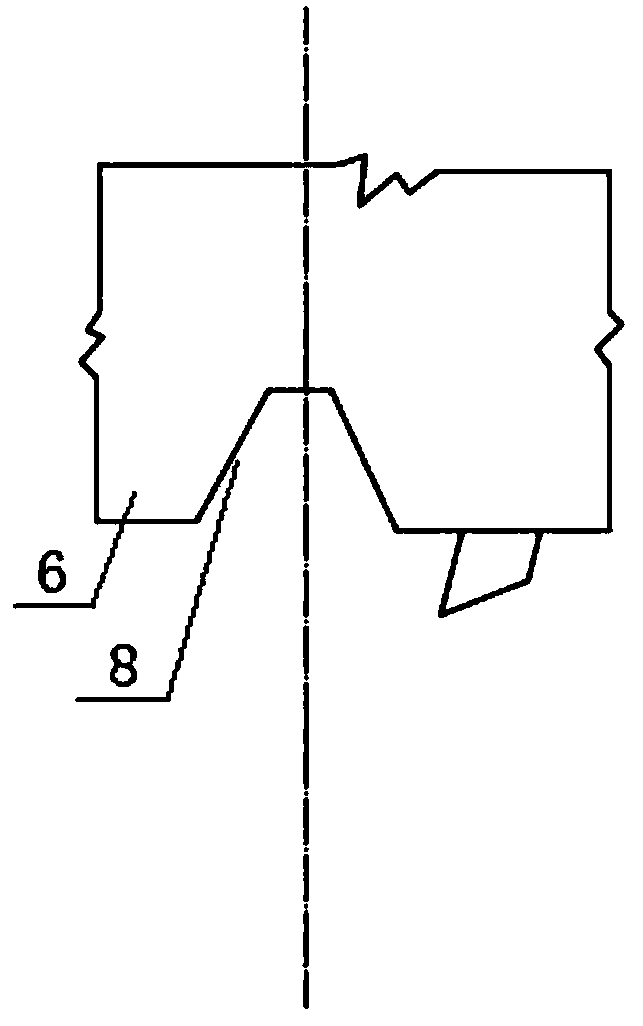

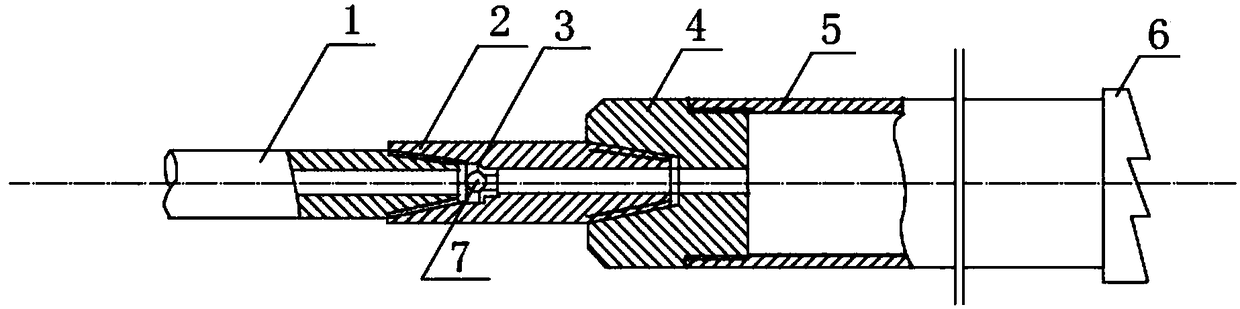

[0025] Referring to the accompanying drawings, it can be seen that the drilling and coring equipment that adopts natural composite mud drilling to achieve the mudcoat-wrapped rock core includes a drill pipe 1 and a core pipe 5, and the drill pipe joint 2 located on the upper part of the core pipe 5 is a joint with a pinball seat , the pinball seat 3 is set in the drill pipe joint 2; when the water-stop marble 7 is set in the pinball seat 3, the upper part of the core pipe 5 is closed, so that the mud pressure in the drill pipe cannot be transmitted to the sand core sample top surface, to avoid sandy soil core samples from falling; the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com