Patents

Literature

30results about How to "Reduce drilling accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

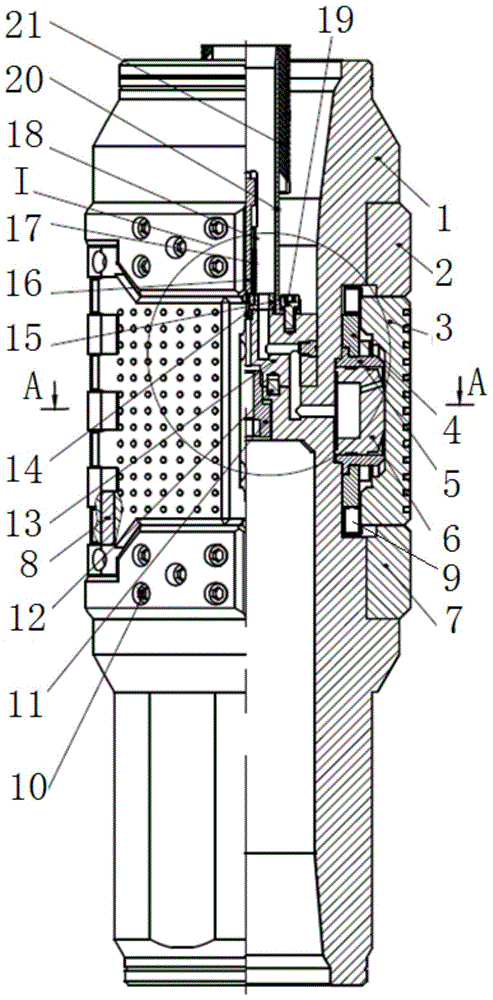

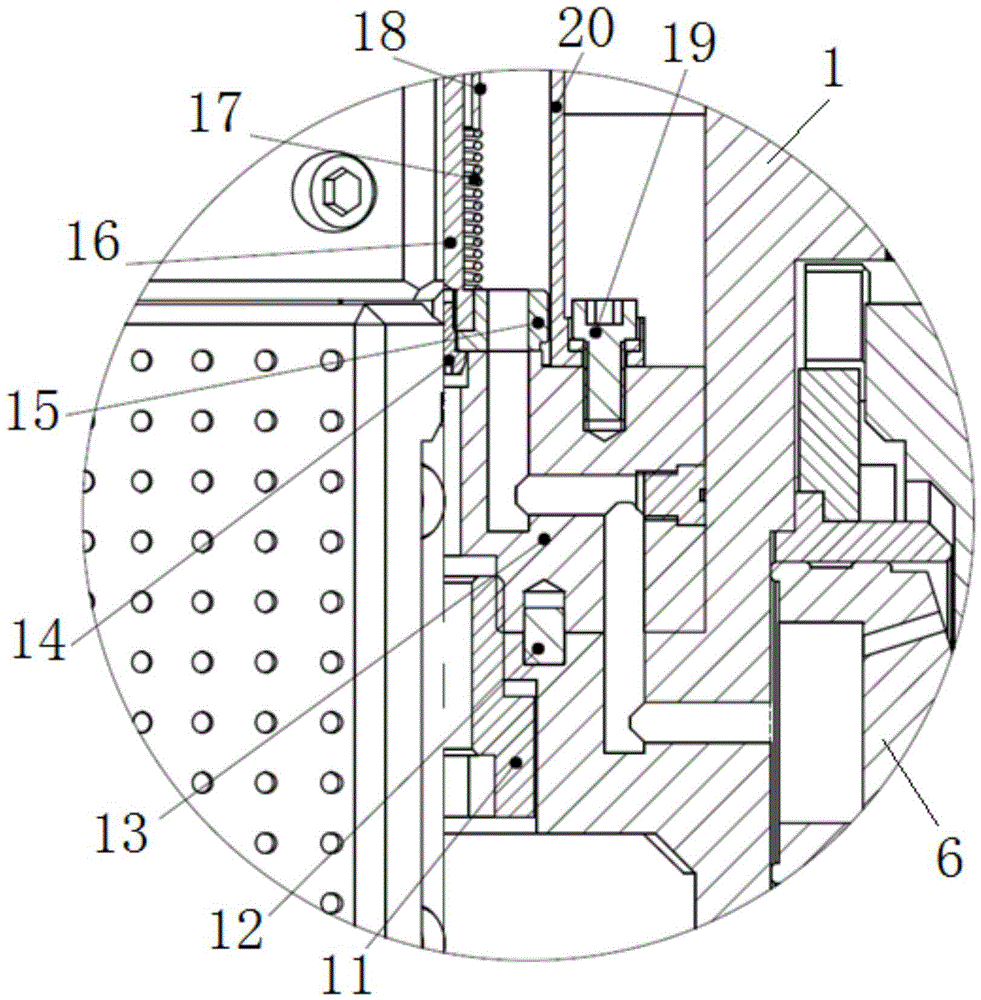

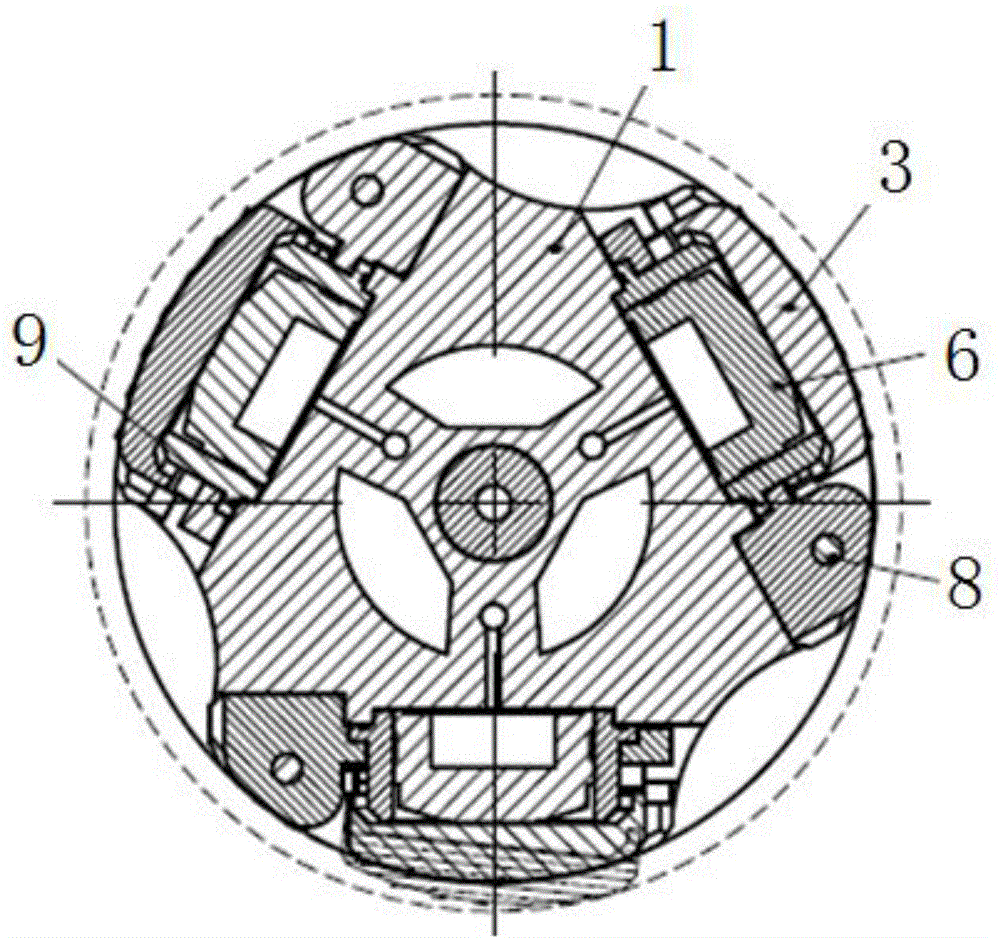

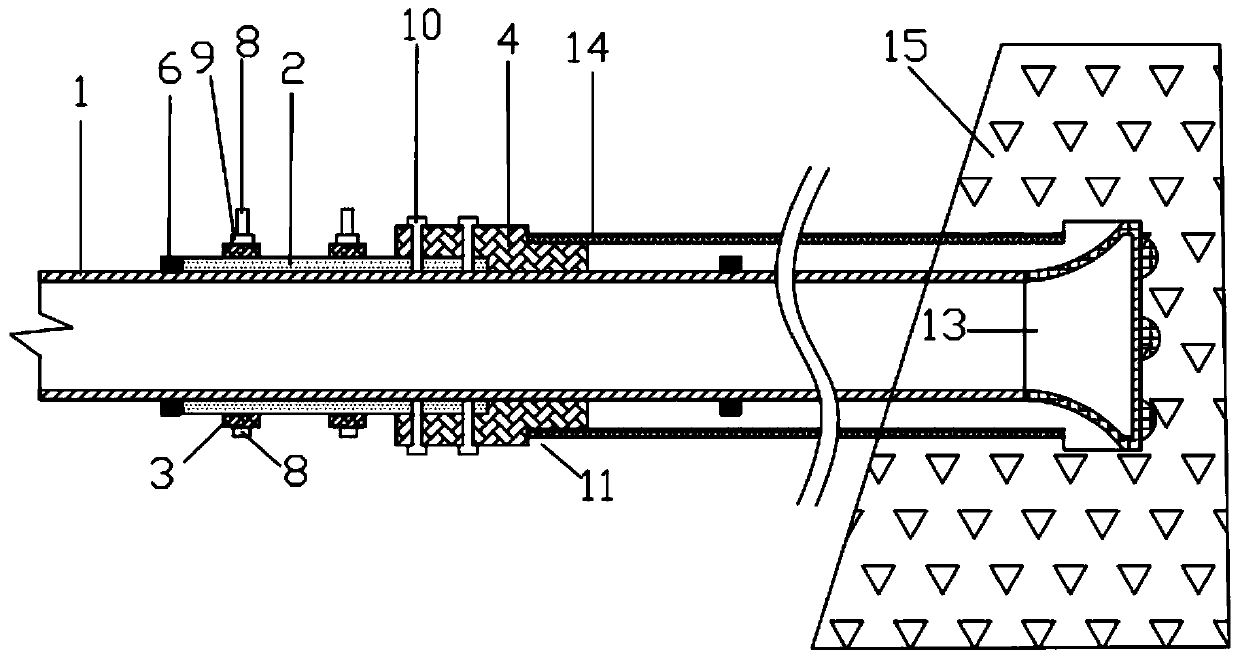

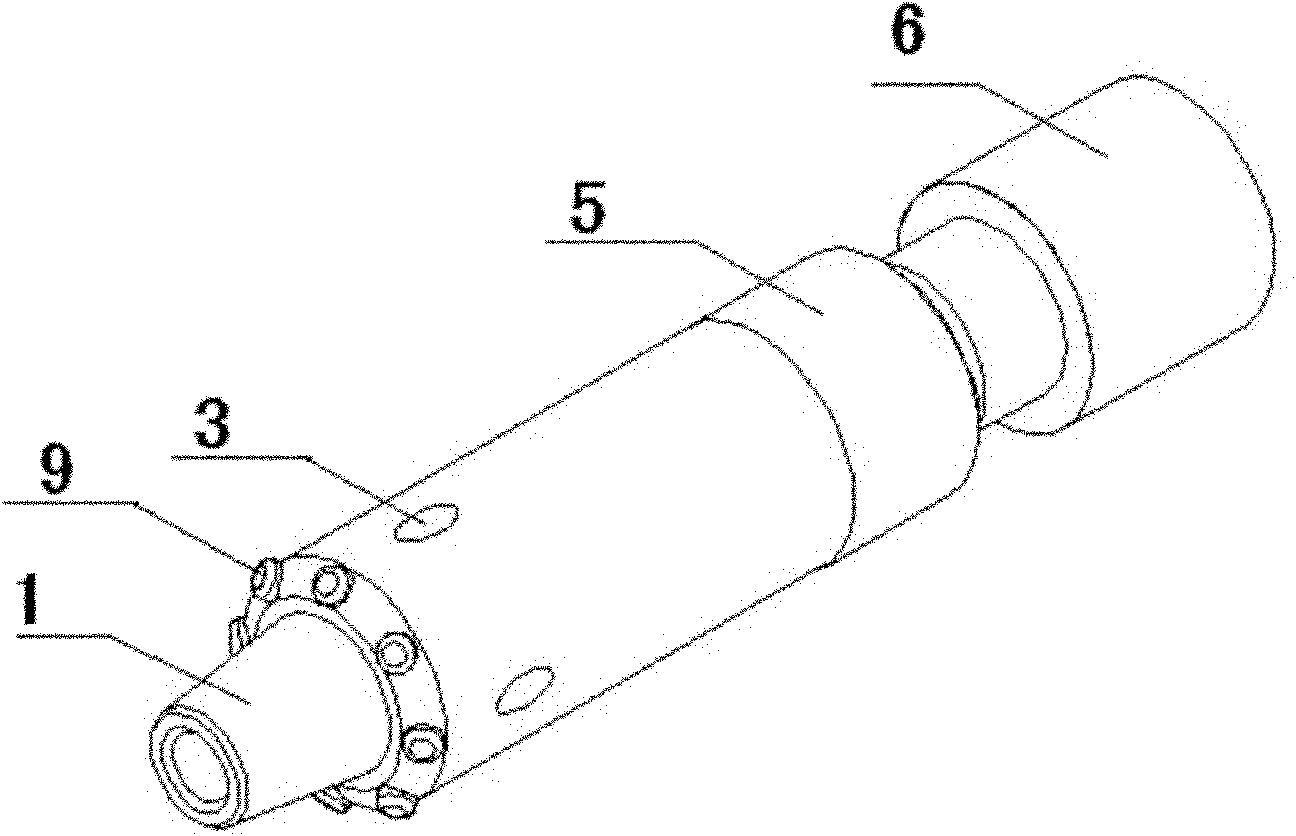

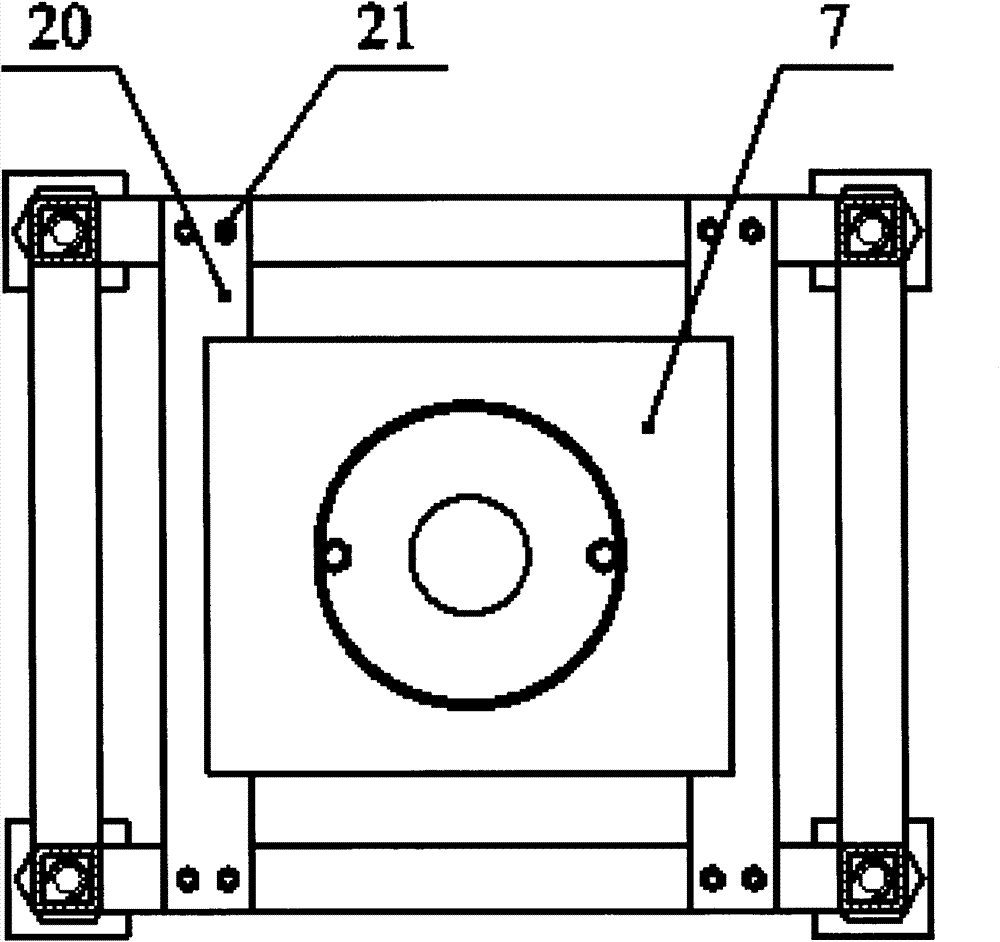

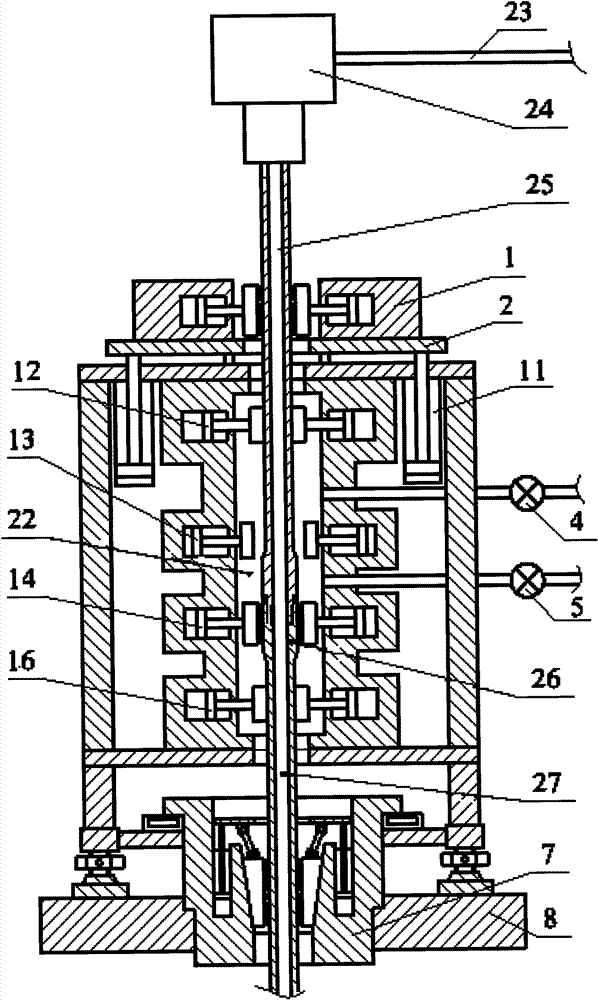

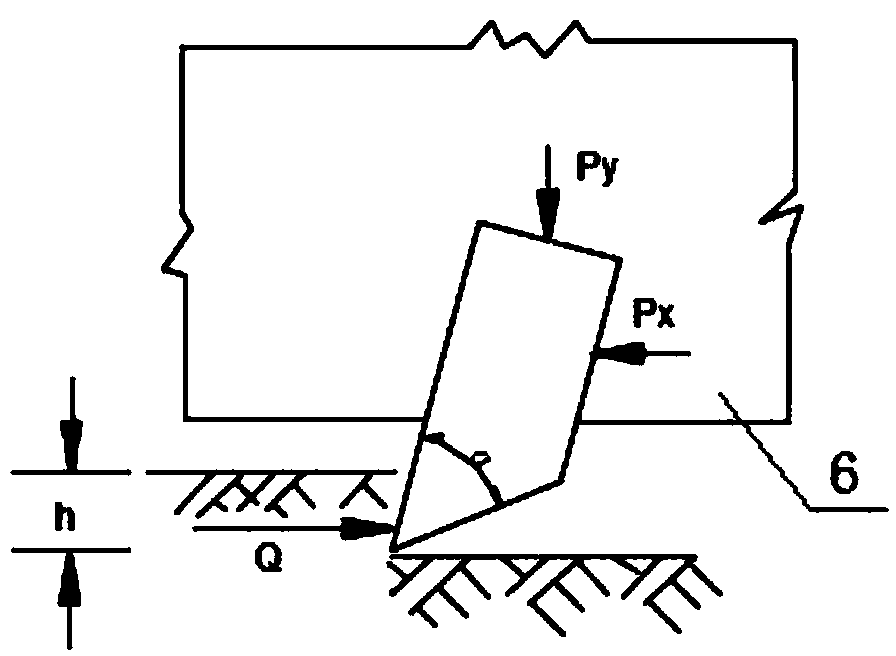

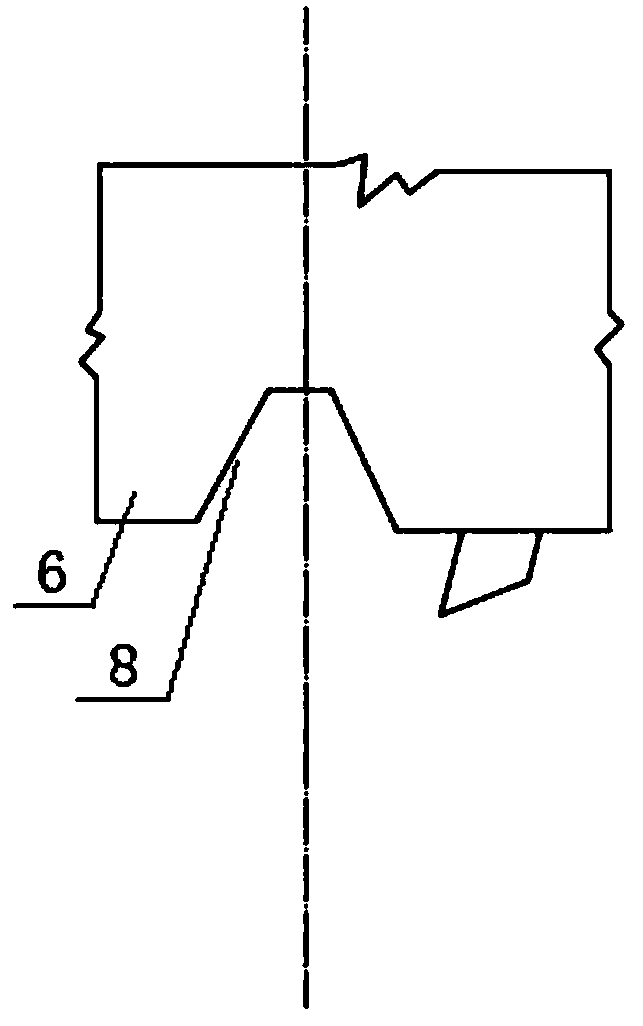

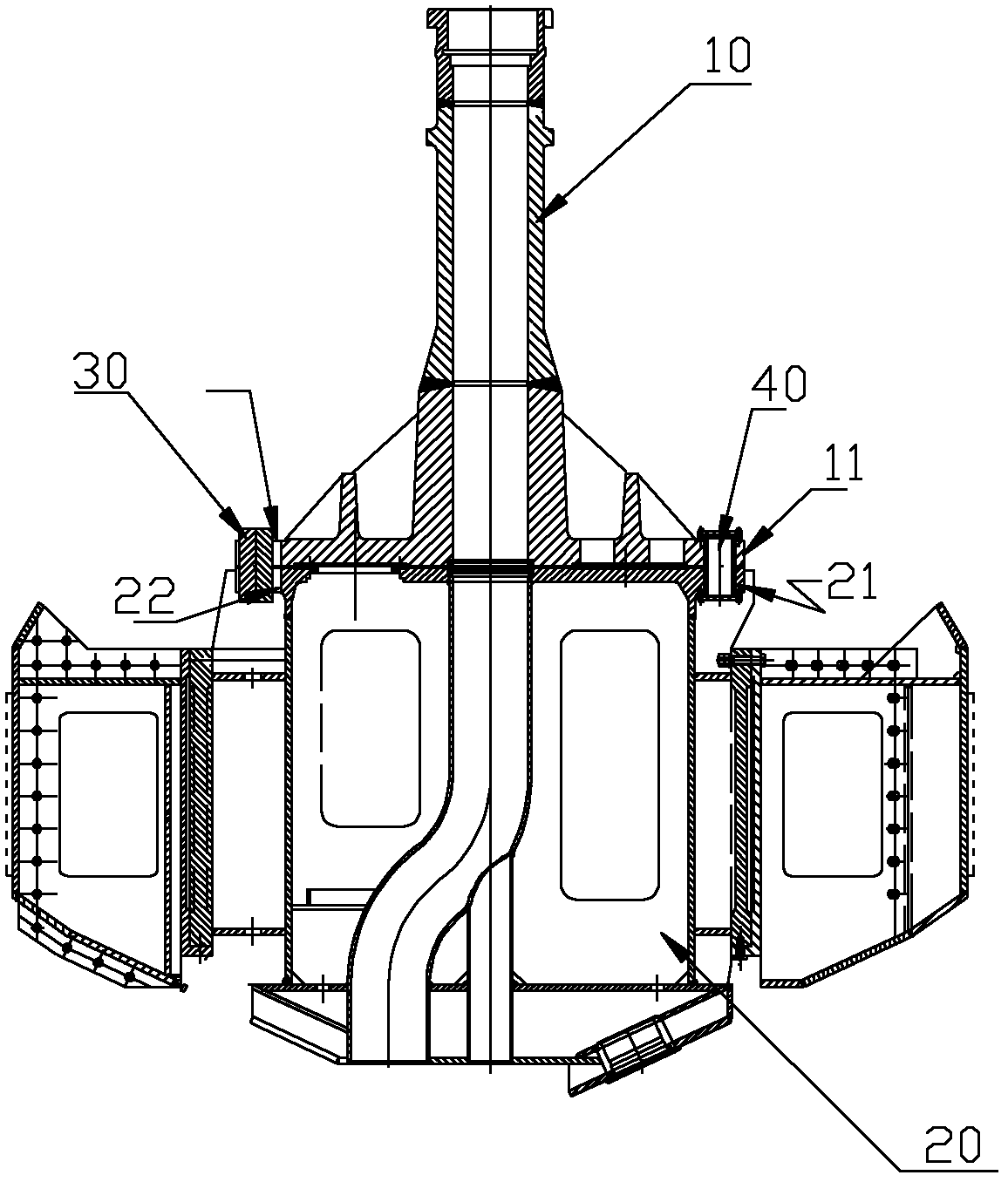

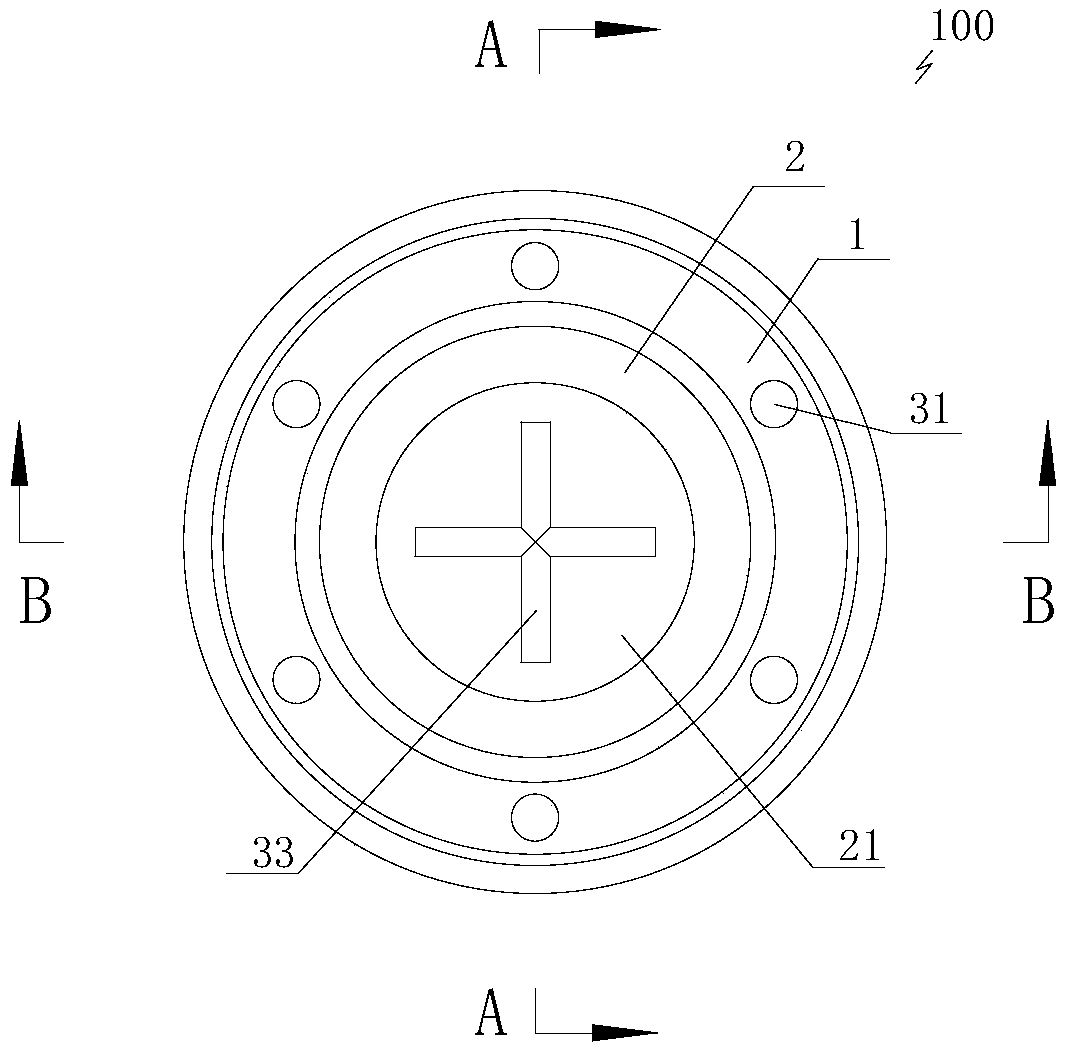

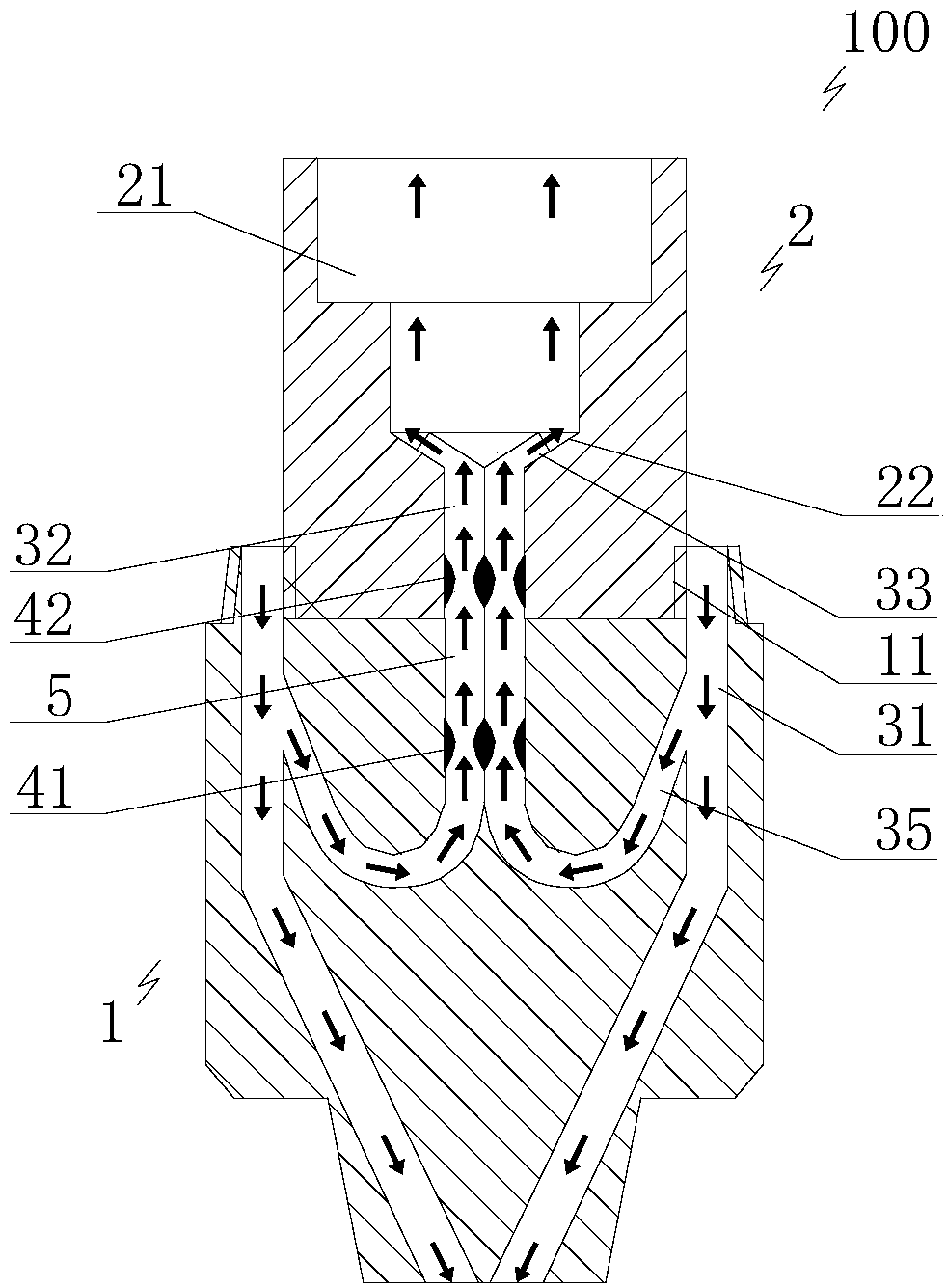

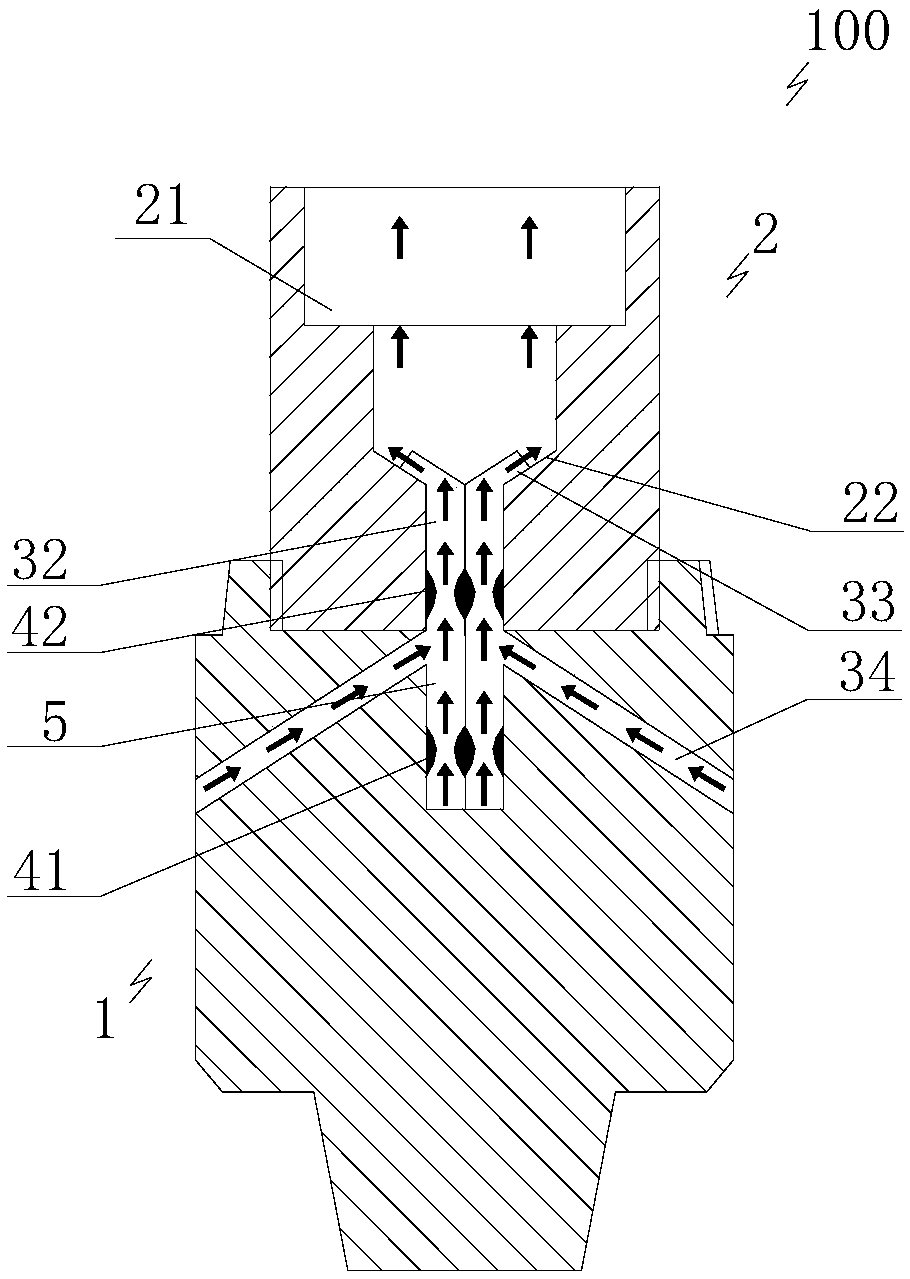

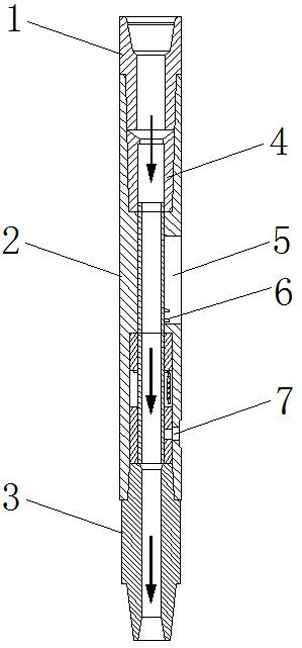

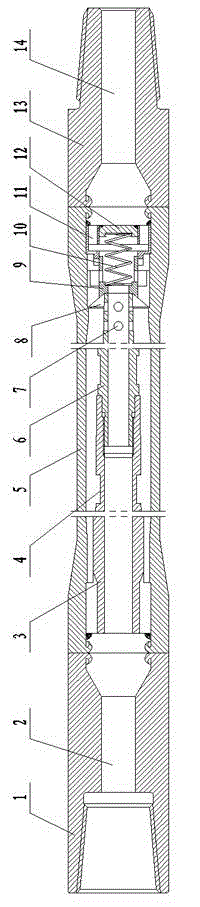

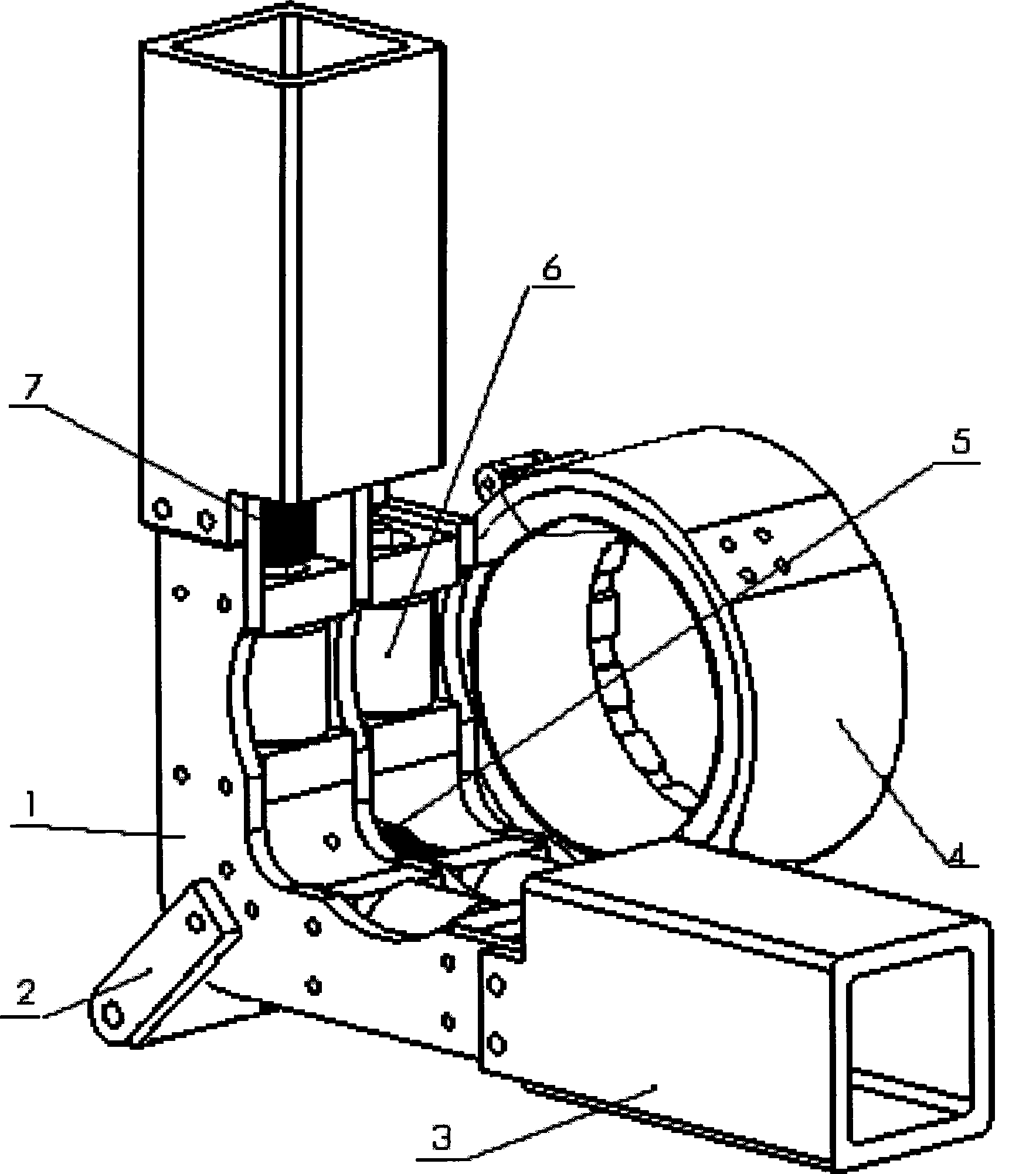

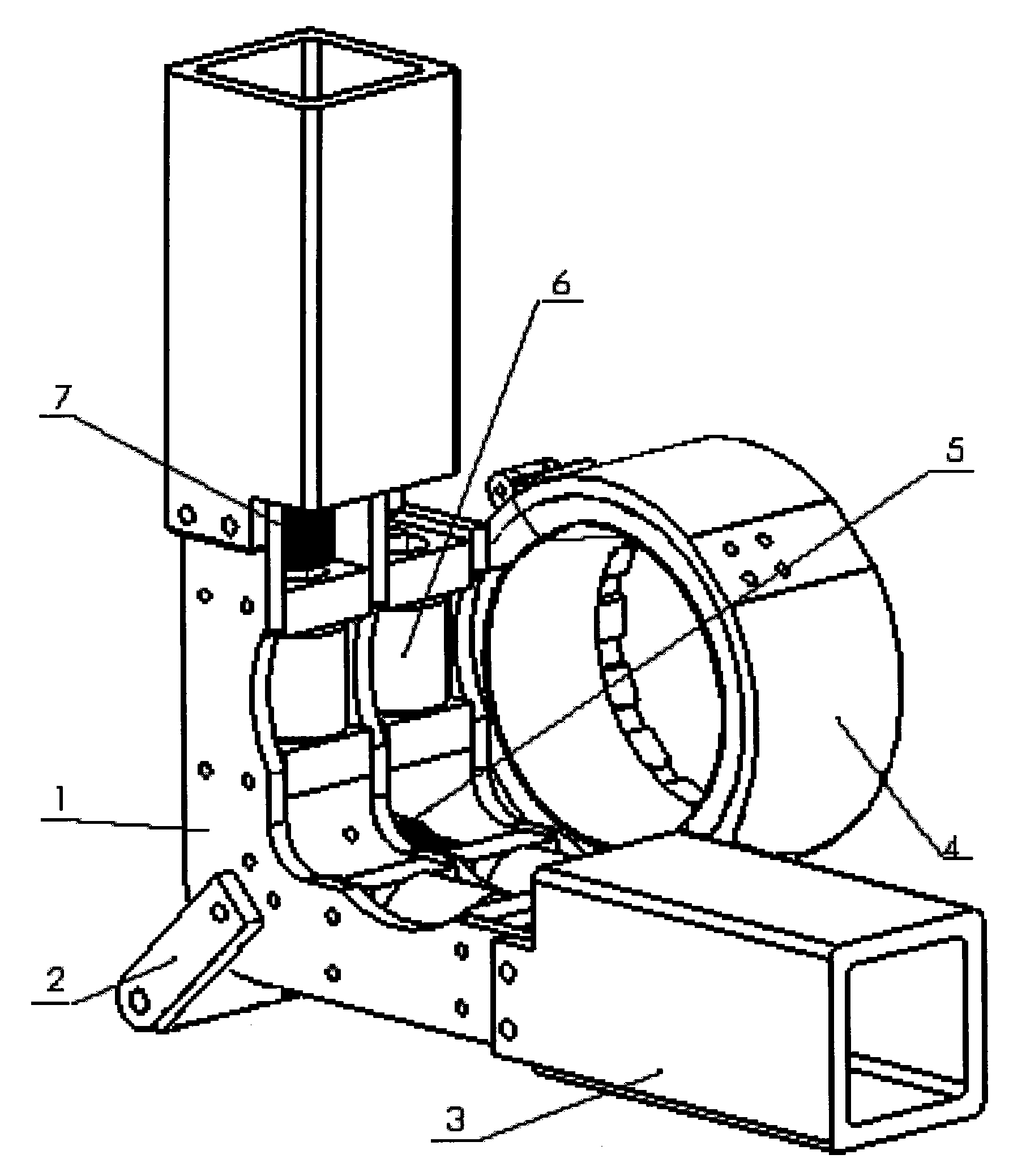

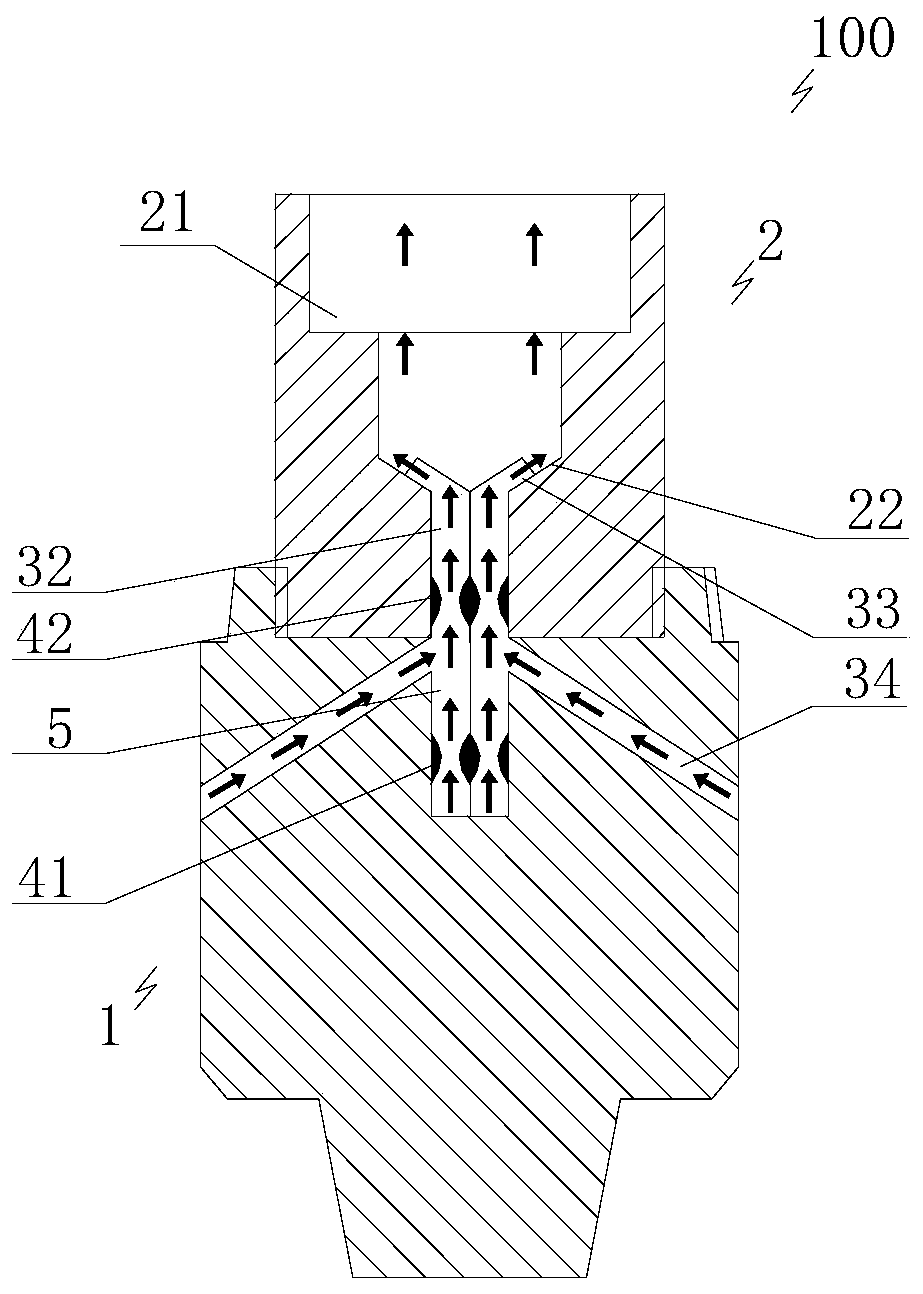

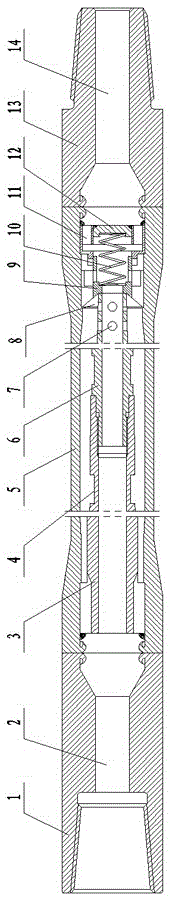

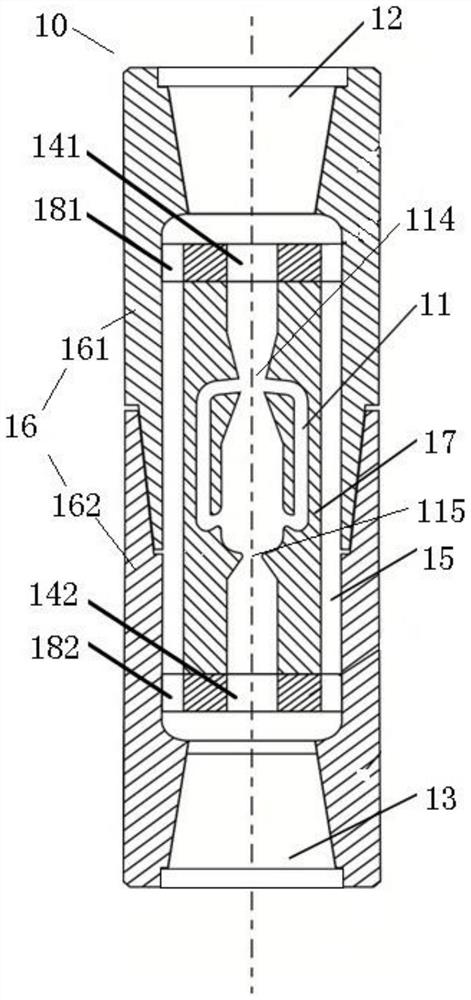

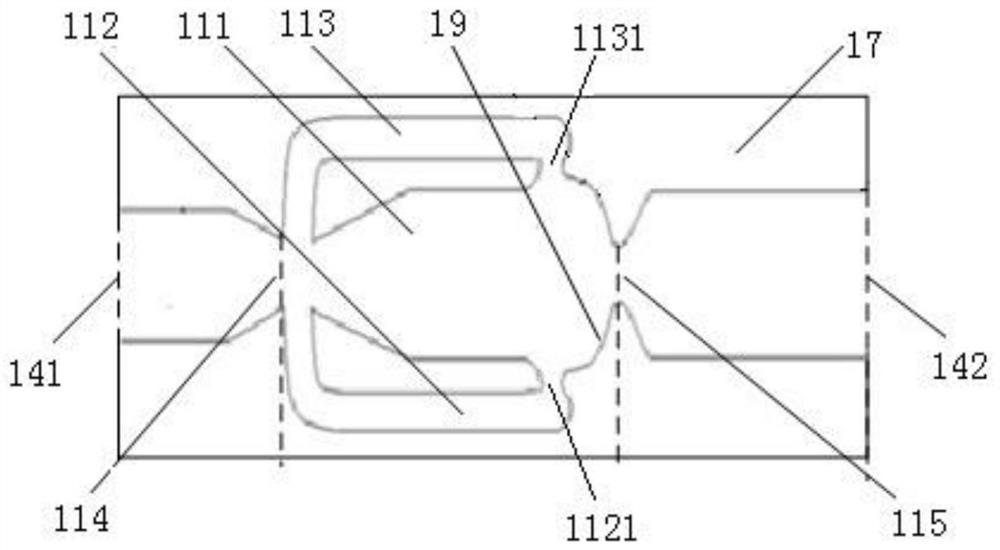

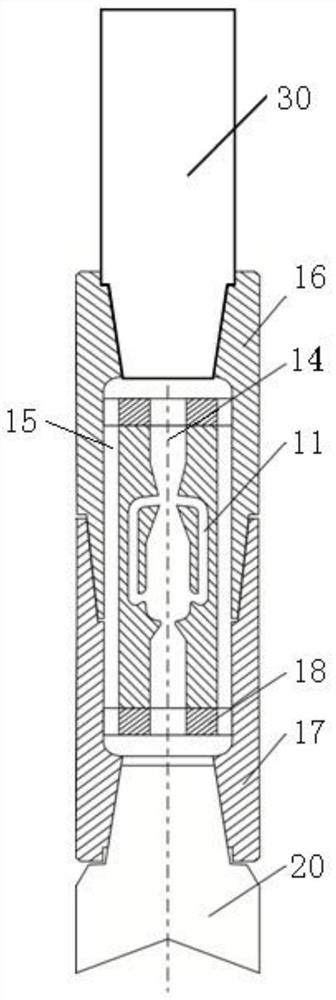

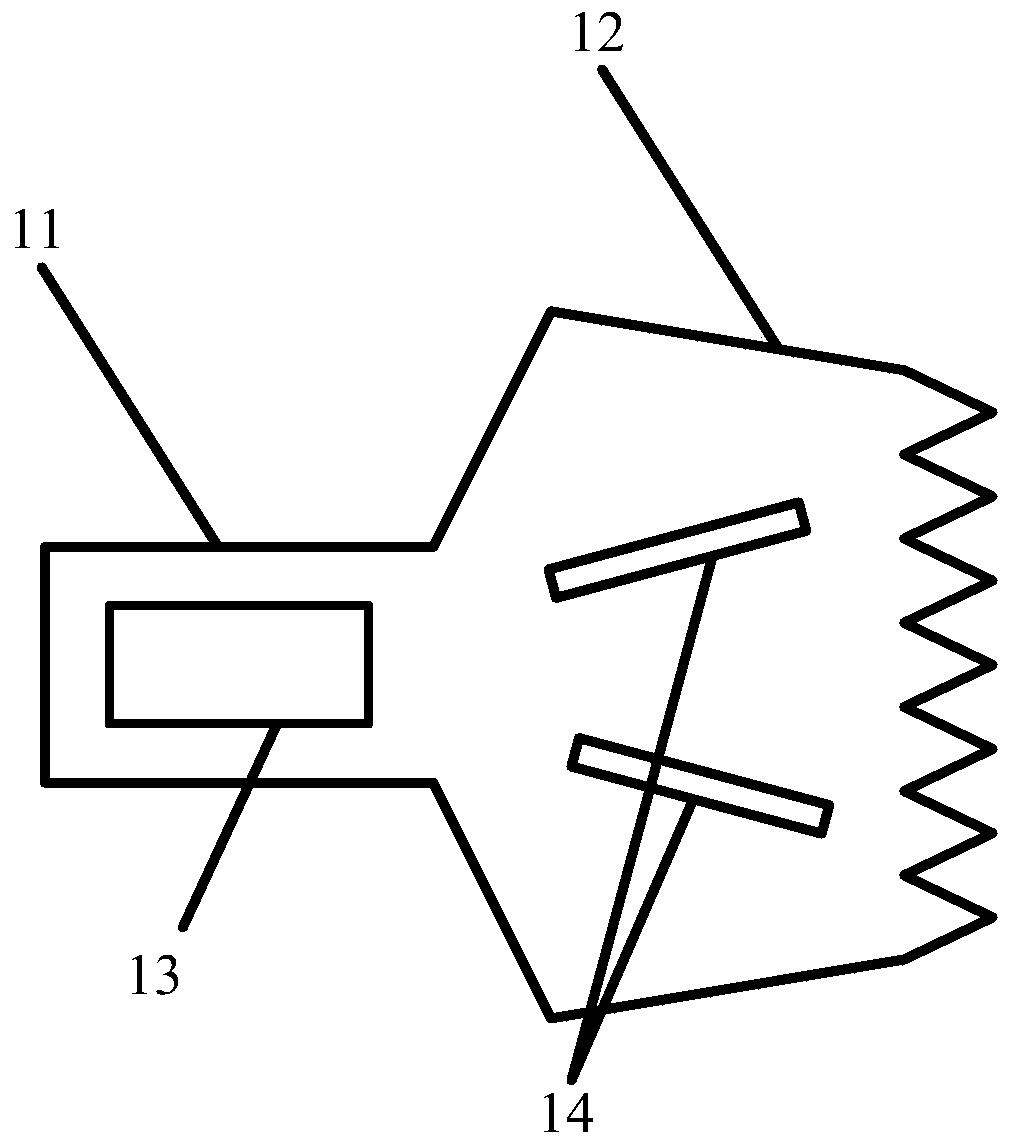

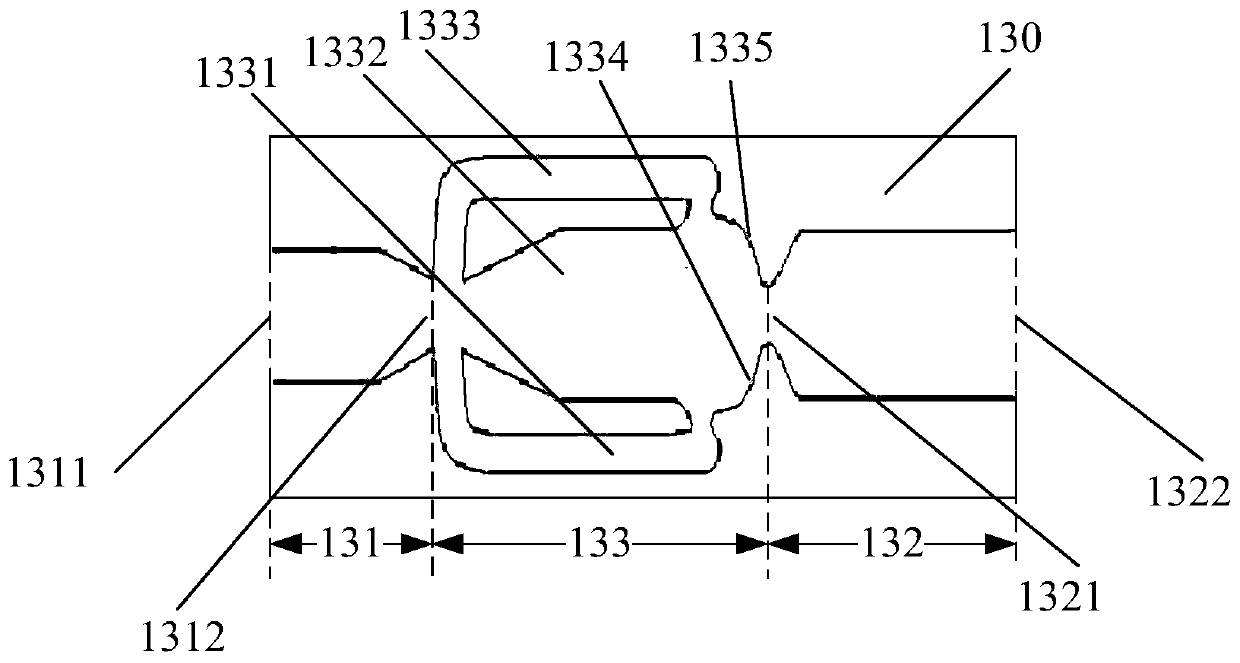

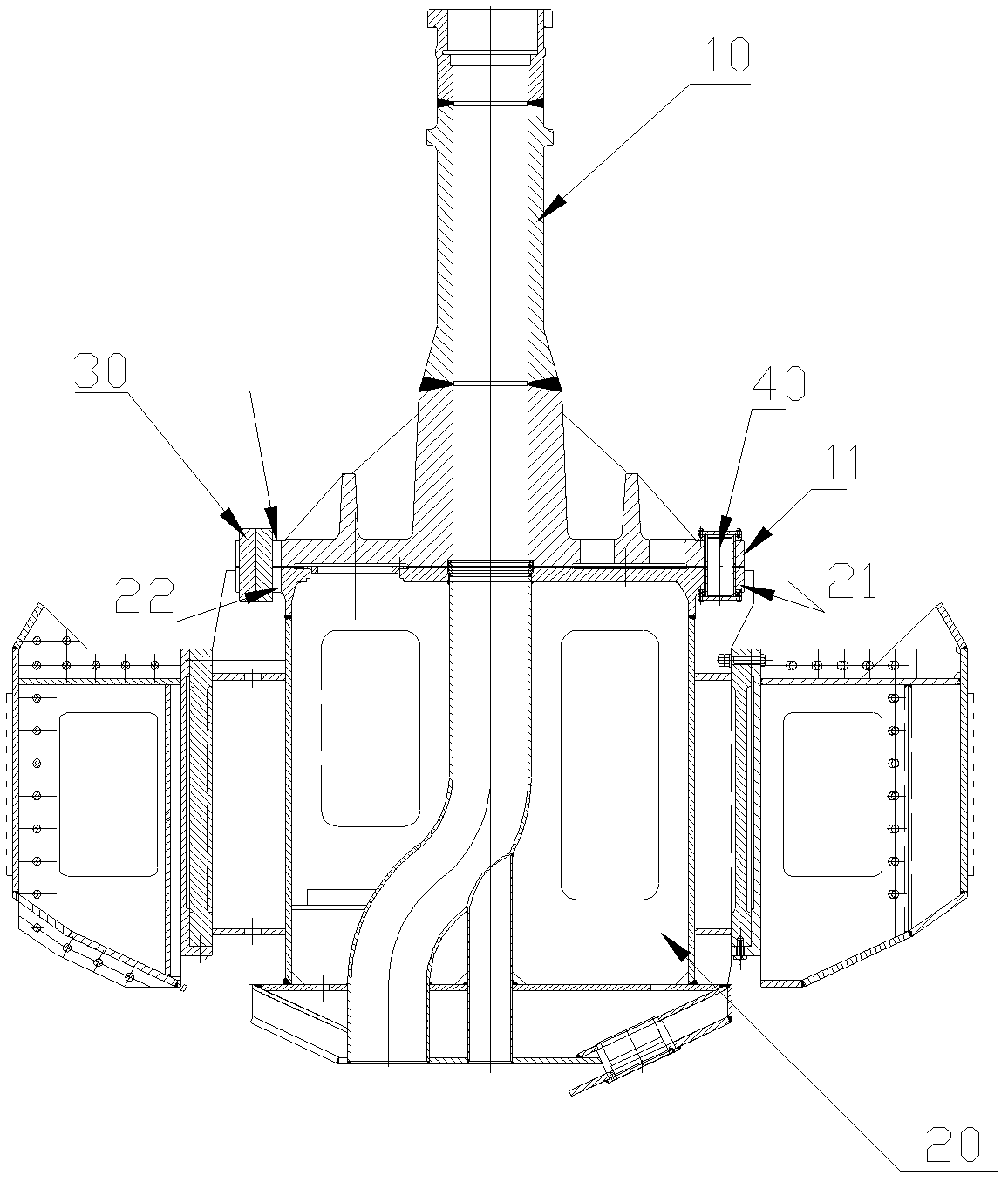

Performing mechanism for automatic vertical drilling tool

InactiveCN104563869AExtend your lifeAchieve the effect of stabilizingDirectional drillingFlushingEngineeringMechanical engineering

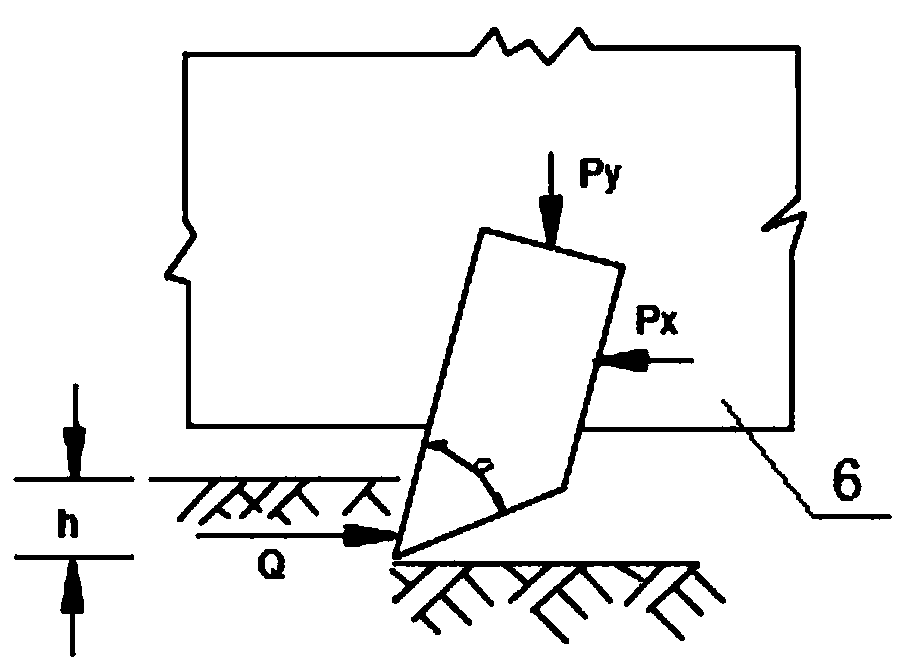

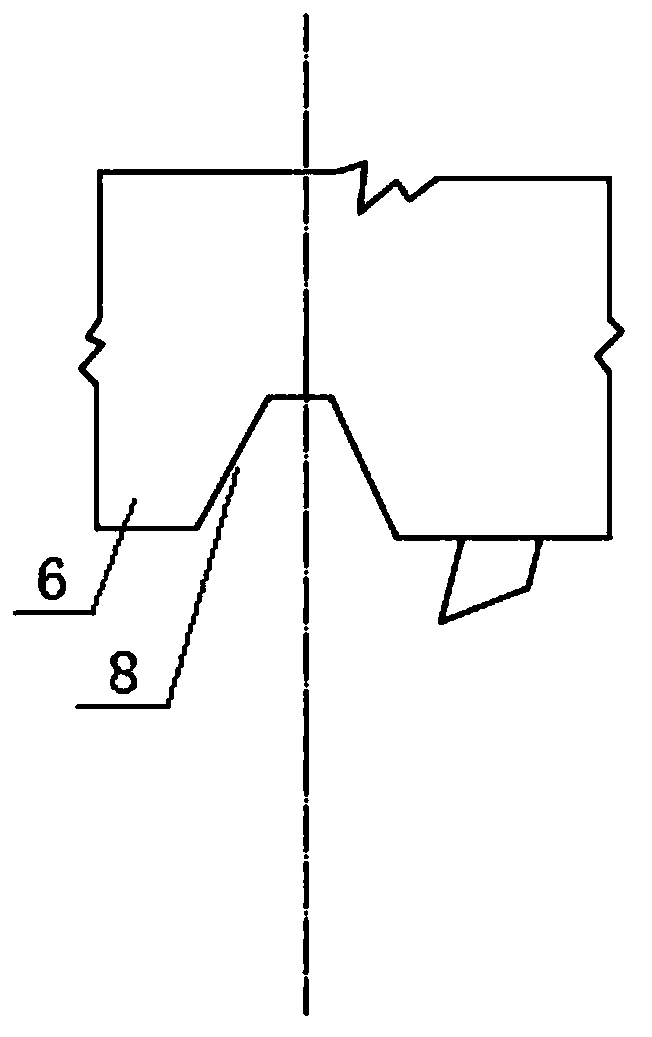

The invention discloses a performing mechanism for an automatic vertical drilling tool. The mechanism is that a slurry filtering mechanism, a liquid distributing mechanism and a thrust performing mechanism are respectively arranged on a mechanism body; the slurry filtering mechanism is used for filtering slurry entering a slurry branch runner to prevent the runner from being blocked; the liquid distributing mechanism is used for distributing the slurry flow according to a certain ratio in order to provide sufficient hydraulic pressure to push and prop a rectangular thrust plate through the slurry entering the slurry branch runner; a rectangular thrust plate of the thrust performing mechanism is pushed and propped to the side edge of the well wall under the effect of the slurry hydraulic pressure so as to apply a reverse acting force to the performing mechanism to generate an inclined lateral force to a drill bit, and as a result, the wellhead can be returned to be vertical to a track. The mechanism is simple in structure and reliable to work.

Owner:BAOJI PETROLEUM MASCH CO LTD

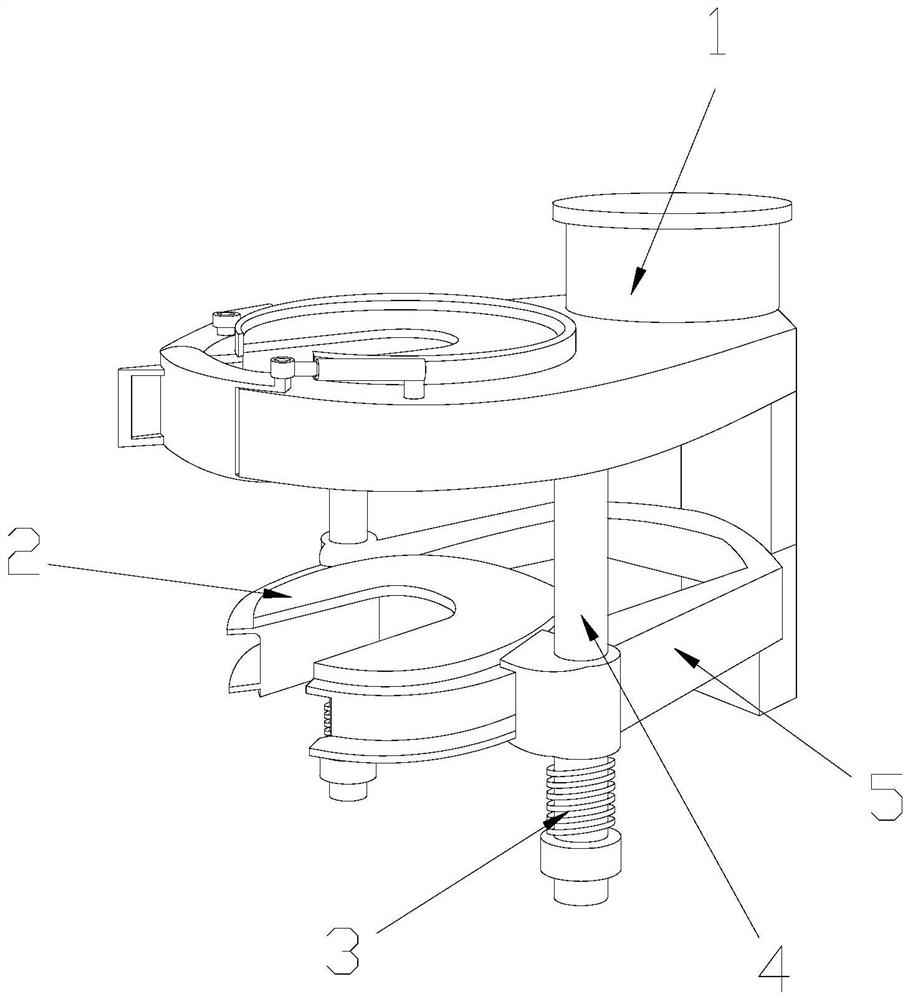

Device capable of conveniently drilling holes in fractured rock mass and drilling method thereof

ActiveCN111058762ASolve stuck drillSolve drilling accidentsDrilling rodsFlushingMining engineeringSlag

The invention provides a device capable of conveniently drilling holes in fractured rock mass and a drilling method thereof, and relates to the technical field of fractured rock mass drilling. The device comprises a drilling machine and a drill rod assembly provided with a protection casing follow-up device; the protection casing follow-up device is fixed to a drill rod through a lock fixing mechanism, the front end of the protection casing follow-up device is provided with a shoulder, and a protection casing is installed on the shoulder in a sleeving mode and can be in rotary fit with the shoulder; and the periphery of the interior of the protection casing follow-up device is provided with a plurality of through slag removal holes in the axial direction. According to the device, the problems that in the prior art, when the interior of loosened fractured rock is subjected to drilling operation, hole collapse is prone to occurring, thus, drill clamping and drill burying accidents are caused, the construction efficiency is low, in addition, in the prior art, construction is complex, the cost is high, construction is inconvenient, and the efficiency is low can be effectively solved; the device has the advantages of being high in construction quality and construction efficiency, safe and convenient to use and the like; and the device can be widely suitable for drilling of loosenedfragile rock mass, and especially suitable for drilling and casing following up inside the rock mass of which only the surface layer is loosened and broken.

Owner:NORTH CHINA ENG INVESTIGATION INST

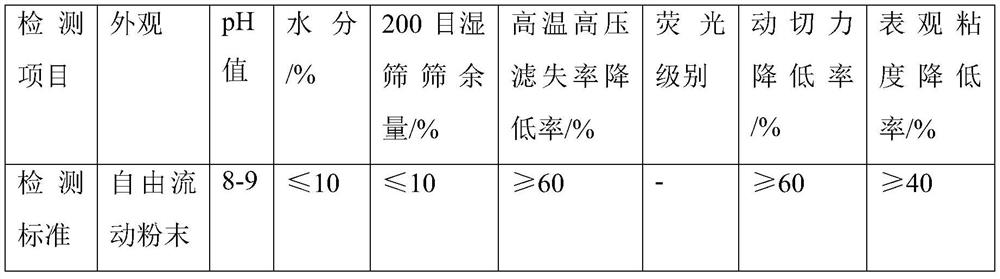

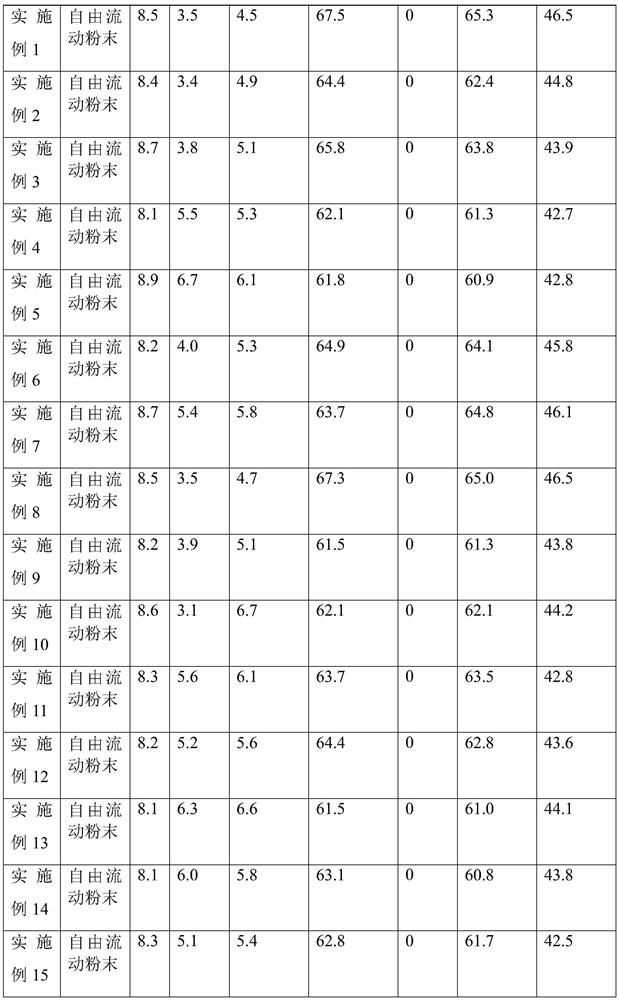

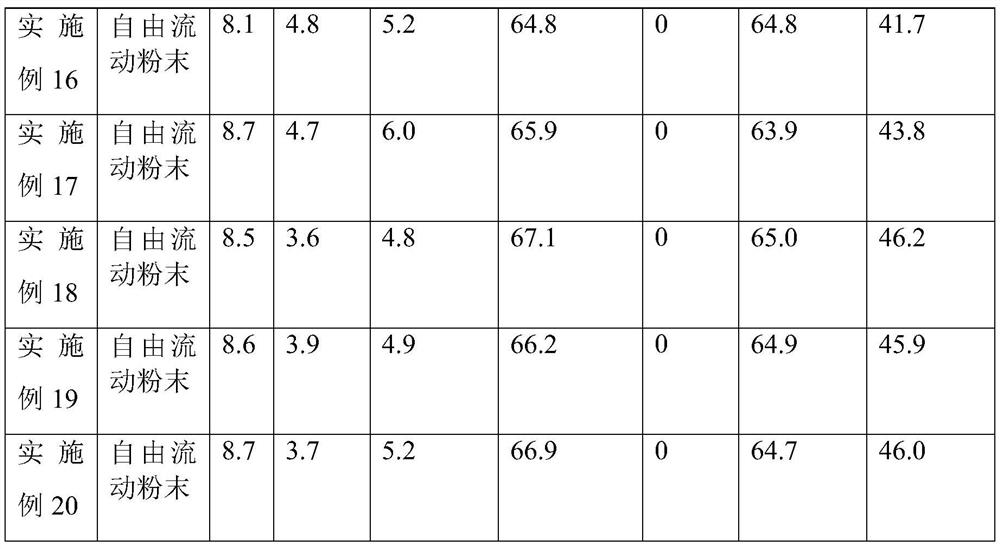

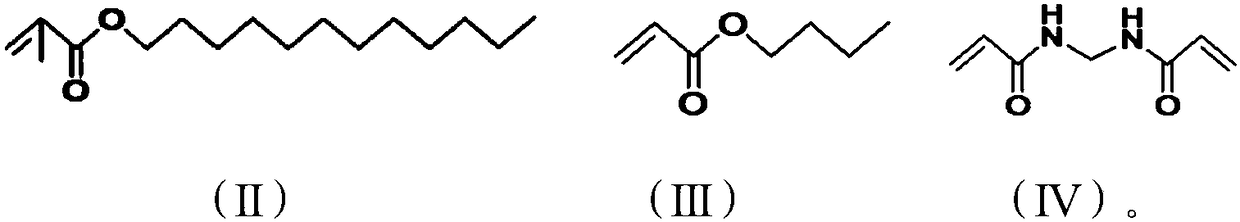

High-temperature hot dry rock flushing fluid and preparation method

The invention discloses a high-temperature hot dry rock flushing fluid and a preparation method. The flushing fluid comprises a normal-temperature well section flushing fluid and a high-temperature well section flushing liquid, wherein the normal-temperature well section flushing fluid is prepared from components as follows: bentonite, sodium carbonate (Na2CO3), hydrolyzed polyacrylamide and dry hydrolyzed polyacrylonitrile powder; the high-temperature well section flushing liquid is prepared from the components as follows: bentonite slurry, potassium polyacrylate, a liquid lubricant, sulfonated lignite, sulfonated phenolic resin, a high-temperature anti-salt filtrate reducer, an anti-sloughing lubricant and a viscosity-reducing filtrate reducer. A polymer drilling fluid is added on the basis of the sulfonated drilling fluid, the drilling fluid reserves advantages of the polymer drilling fluid, improves the filter cake quality and rheological property of polymers at the high temperature and under the high pressure and has the temperature resistance up to 200-250 DEG C, the drilling efficiency is improved, and drilling accidents are reduced.

Owner:青海九零六工程勘察设计院有限责任公司 +2

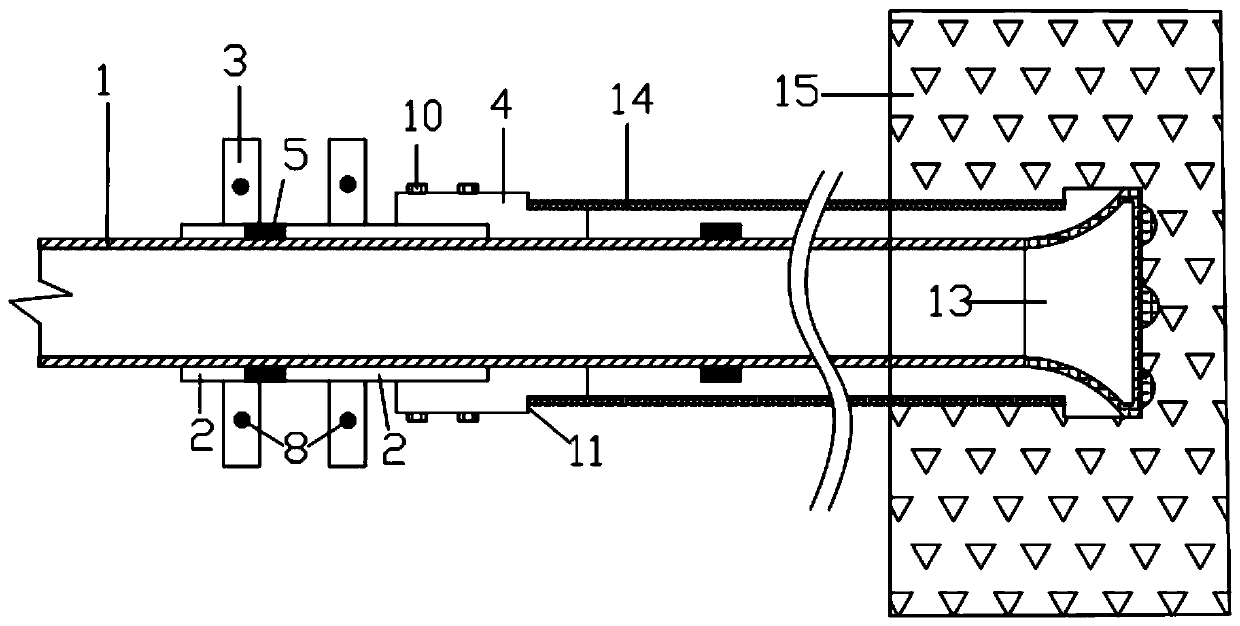

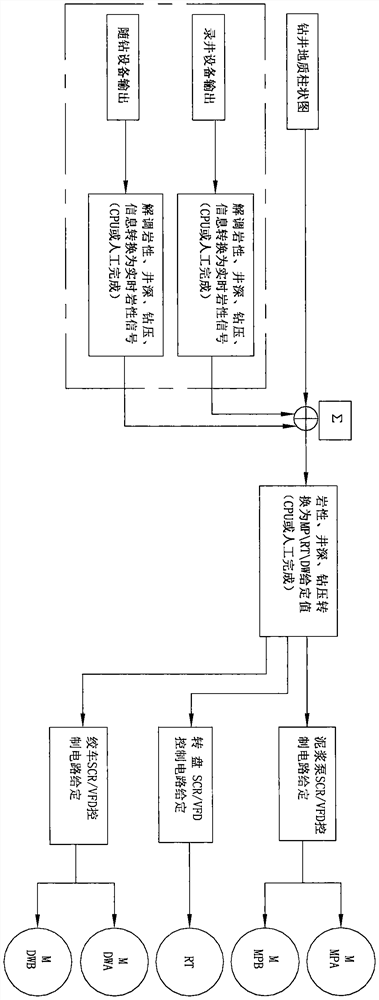

Real-time well drilling formation correction method and device

InactiveCN104727815AReduce drilling accidentsAvoid drilling abandoned wellsSurveyAutomatic control for drillingReal-time dataWell drilling

The invention discloses a real-time well drilling formation correction method and device and relates to the technical field of well drilling detection. The real-time well drilling formation correction device comprises a signal acquisition unit, a signal processing unit, a real-time data monitoring unit, a data storage unit, a first data correction unit and a second data correction unit, wherein the signal acquisition unit acquires well drilling parameter signals and transmits the well drilling parameter signals to the signal processing unit, signals processed by the signal processing unit are transmitted to the real-time data monitoring unit, the real-time data monitoring unit transmits the signals to the second data correction unit and the data storage unit respectively, the data storage unit transmits the signals to the first data correction unit for data correction, corrected data are transmitted from the first data correction unit to the second data correction unit for processing, and signals processed by the second data correction unit are transmitted to a drilling machine control unit. By means of the real-time well drilling formation correction method and device, real-time prediction and correction are achieved, well drilling accidents are deceased, abandoned well and useless well drilling is avoided, and well drilling success rate is improved.

Owner:河北百冠钻井设备有限公司

Combined drilling device

InactiveCN101949262ALimit Skew DirectionGuaranteed hole inclination controlDrilling rodsBorehole drivesPetroleum engineeringDrill pipe

The invention discloses a combined drilling device. The combined drilling device comprises a connectable drill rod and a downhole air hammer, wherein the downhole air hammer is sequentially connected with a back flushing grinding device and a centering device, and then connected with the drill rod; and a drill rod extension part connected after the downhole air hammer is sequentially connected with the back flushing grinding device and the centering device is at least connected with a group of centering devices. The combined drilling device grinds rock flour deposited in a back flushing hole, probe stones which fall on rock masses and are attached to a hole wall and large rock masses, so that the problems of drill clamping and drill burying of a large-diameter drilling tool are solved; and the centering device has the advantages of ensuring that the drilling tool is in the middle of a pore cannel, meeting the requirement on drilling accuracy, enhancing pore-forming quality and solving the problems of drill clamping and drill burying due to large outer diameter under the combination effect of the back flushing grinding device. Due to the combination effect of the device, drilling efficiency is improved and pore-forming quality is enhanced.

Owner:CHENGDU HYDRO ELECTRIC ENG CONSTR OF SINOHYDRO BUREAU 7

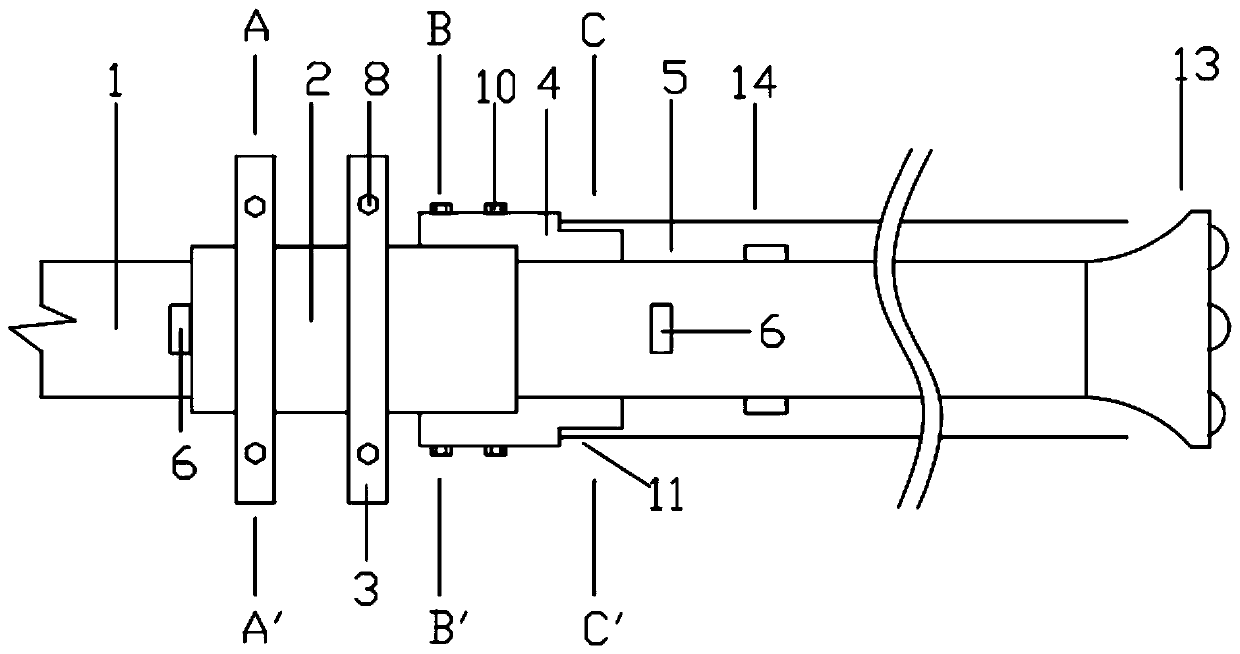

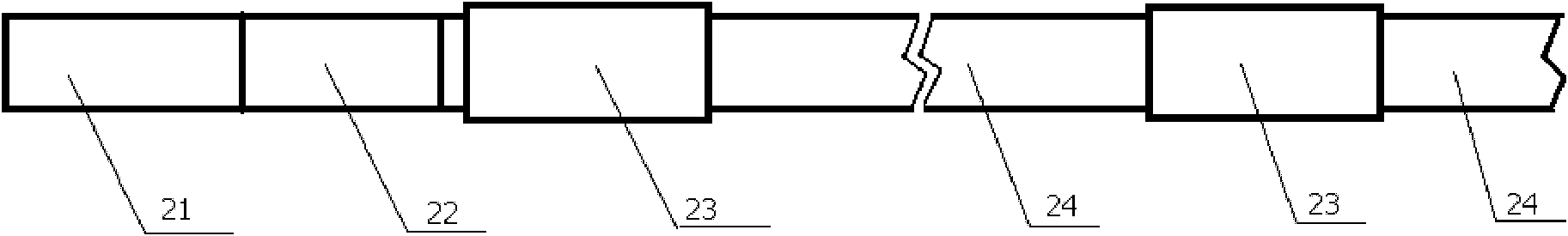

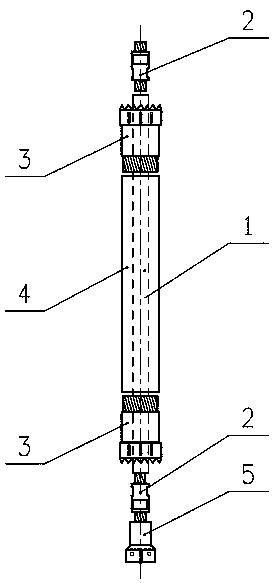

Two-way combined drilling rig

PendingCN109594917AAchieve joinImprove drilling efficiencyDrilling rodsDrilling casingsCouplingDrilling riser

The invention discloses a two-way combined drilling rig which comprises a drill rod (1) for intermediate support, drill rod couplings (2) disposed on ends of the drill rod (1), a small-diameter coreless drill bit (5) linked with one of the drill rod couplings (2), and a large-diameter coring drill bit (3) disposed on one of the drill rod couplings (2) and connected with the drill rod (1) in a sleeving manner; through the drill rod (1), the connection of the drill rod couplings (2) is realized; through the drill rod couplings (2), the connection of the large-diameter coring drill bit (3) and the small-diameter coreless drill bit (5) is realized, a drilling operation is implemented by the small-diameter coreless drill bit (5), and a reaming operation is implemented by the large-diameter coring drill bit (3), therefore, the two-way combined drilling rig is suitable for different geological drilling operations, and the drilling efficiency is improved.

Owner:山东龙元地质工程有限公司

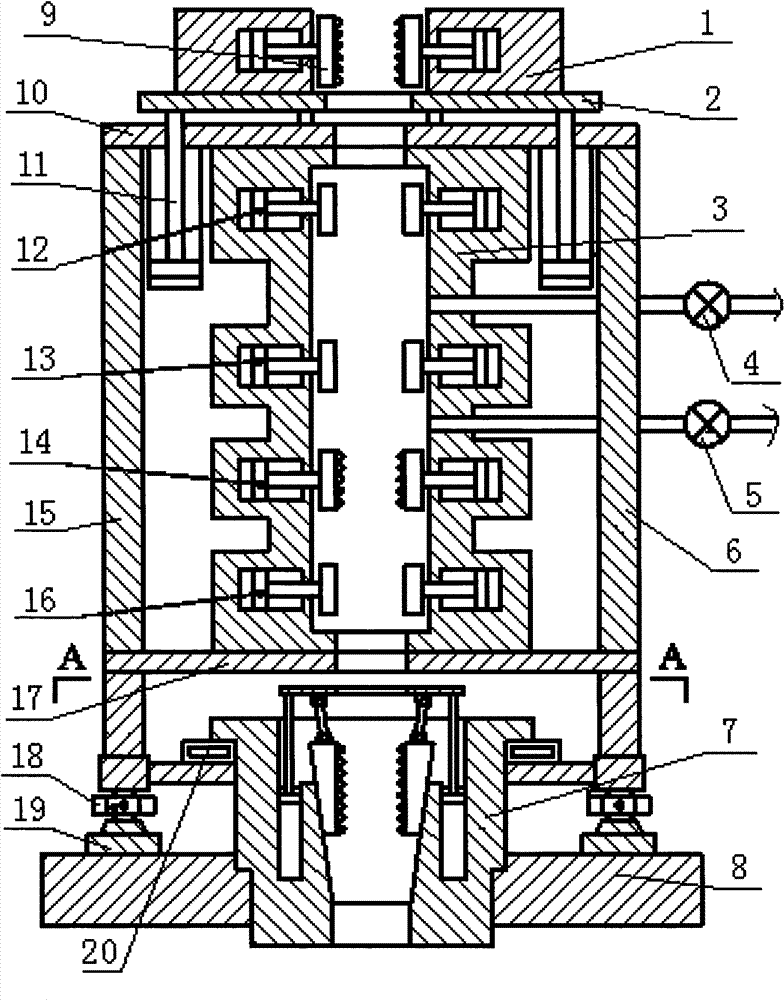

Continuous cyclic drilling device

The invention discloses a continuous cyclic drilling device used in the technical field of petroleum drilling. A drill pipe power tong is fixed on a power tong baseplate on the top of a balance compensation hydraulic cylinder, the balance compensation hydraulic cylinder is vertically fixed below the upper connection board of a support assembly, the piston rod of the balance compensation hydrauliccylinder passes through the upper connection board, and the top of the piston rod of the balance compensation hydraulic cylinder is fixedly provided with the power tong baseplate. A cavity assembly is fixed between the upper connection board and the lower connection board of the support assembly, the lower end of a drilling power slip is fixed in the bushing of a drilling turntable, the upper endof the drilling power slip is connected with the support assembly through a bearing beam, and the centers of the drill pipe power tong, the cavity assembly and the drilling power slip are coincident.The device has the effects of keeping the continuous cycling of the drilling fluid to discharge the drilling cuttings during the period of making a connection, avoiding the damage to the drill pipe caused by the up tong when screwing on and screwing off, eliminating the adverse effect of the slip holding capacity caused by the upset force of the drilling fluid, and improving the stress state between the slip and the drill string.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling coring equipment by adopting natural composite slurry to drill to achieve effect of rock core coated with mud

The invention discloses drilling coring equipment by adopting natural composite slurry to drill to achieve the effect of a rock core coated with mud. The drilling coring equipment comprises a drill pipe and a rock core pipe. A drill pipe joint located on the upper portion of the rock core pipe is a joint with a marble seat, the marble seat is arranged in the drill pipe joint, and when a water stopping marble is arranged in the marble seat, the upper portion of the rock core pipe is sealed; and the two ends of the rock core pipe are connected with a rock core pipe joint and an alloy drill bit,one end of the drill pipe is connected to the interior of the drill pipe joint, and the drill pipe joint is connected with the rock core pipe joint. The defects that in the prior art, the sandy soil rock core sample recovery is lower than 70%, and the undisturbed grain composition and structure of sandy soil cannot be maintained are overcome. The drilling coring equipment has the advantages that the sandy soil rock core sample recovery is sharply improved and can be as high as 100%, and the sampled sandy soil rock core sample is coated with mud, so that the undisturbed grain composition and structure of the sandy soil of the sandy soil rock core sample are maintained.

Owner:长江岩土工程有限公司 +1

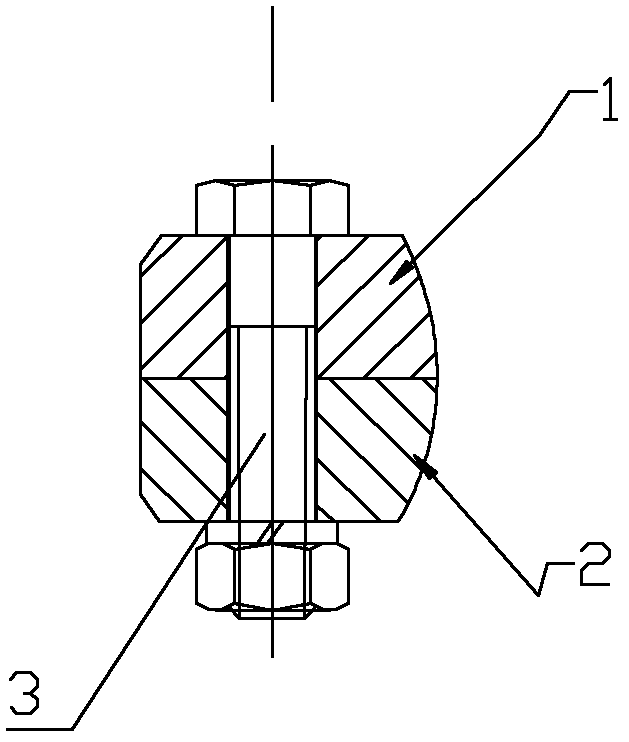

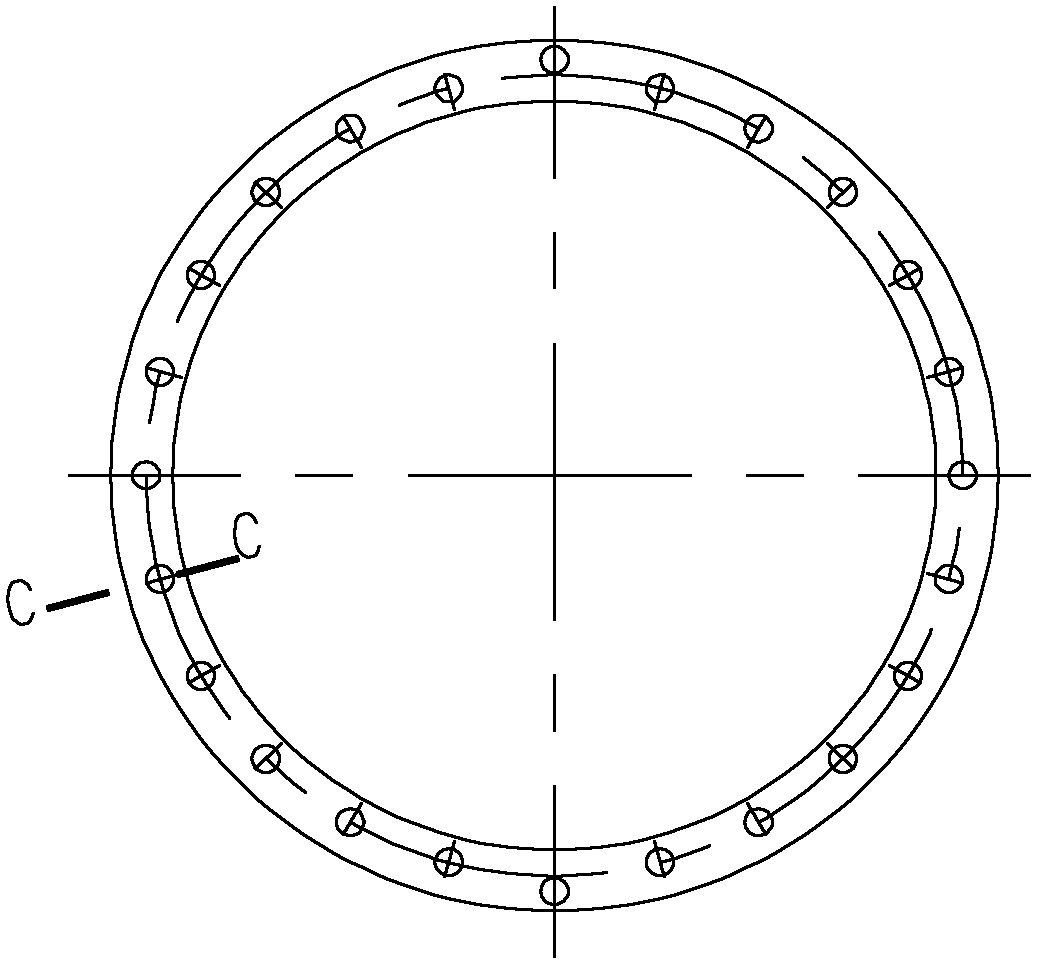

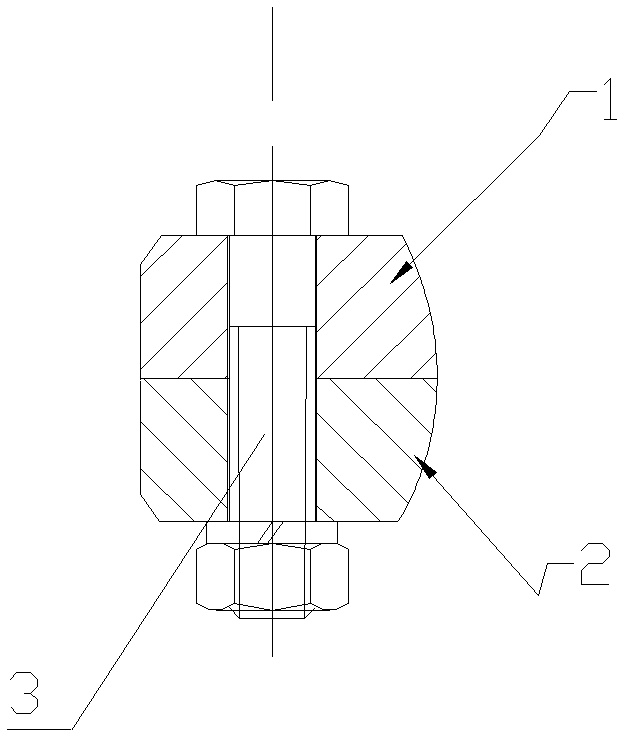

Drilling tool

InactiveCN102400650AFirmly connectedReduce drilling accidentsDrilling rodsDrilling casingsButt jointFlange

The invention discloses a drilling tool, and relates to the technical field of a drilling machine, aiming at solving the technical problems of realizing reliable connection and reducing drill fall-off accidents. The drilling tool comprises a drill rod and a drill bit connected with the drill rod, wherein flange connection plates of the drill rod and the drill bit are respectively provided with at least two openings and at least two pin holes; the flange connection plates of the drill rod and the drill bit are in butt joint; the openings and the pin holes which are arranged on the flange connection plate of the drill rod correspond to those arranged on the flange connection plate of the drill bit; the corresponding openings are respectively provided with an I-shaped block; the flange connection plates of the drill rod and the drill bit are connected with each other by the I-shaped blocks; and pin shafts used for transferring torque pass through the corresponding pin holes. The drilling tool is applicable to construction of large holes in large and medium-sized projects or other projects of mines.

Owner:CHINA COAL MINE CONSTR GRP

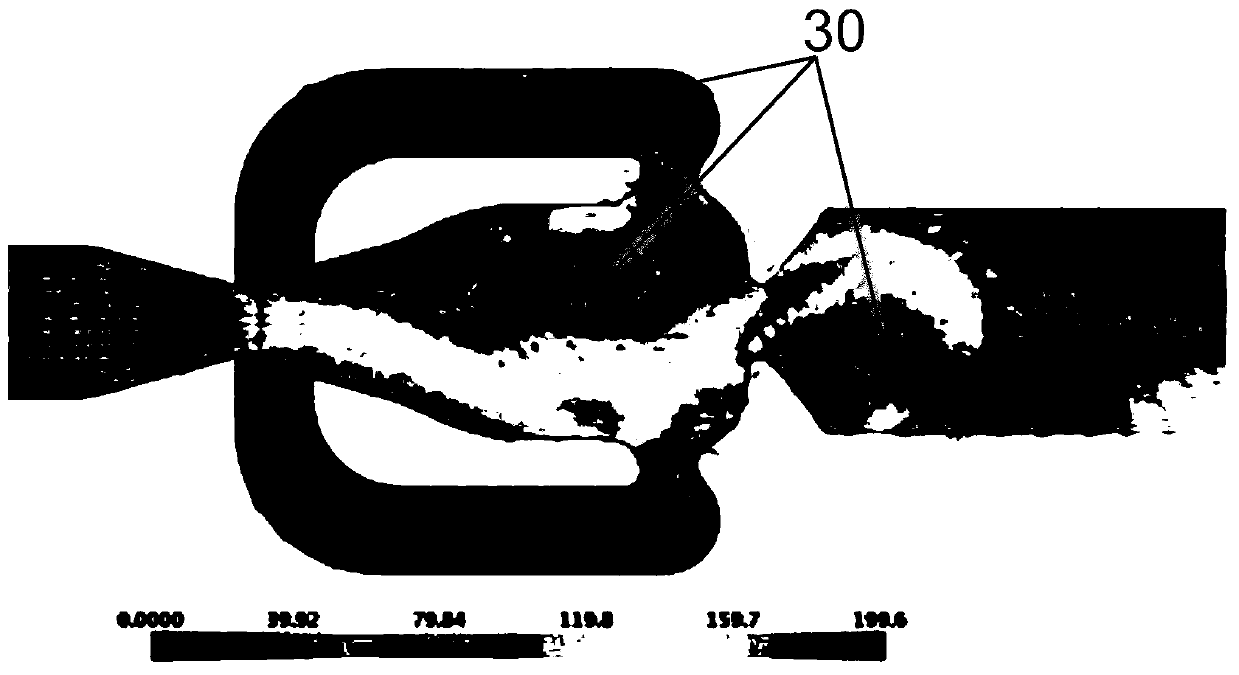

Concentric pipe rock debris sucking and crushing device suitable for dual-gradient drilling

ActiveCN108915619AUniform particle sizeCuttings carrying flowback is easyFlushingGrain treatmentsReturn channelDrilling fluid

The invention discloses a concentric pipe rock debris sucking and crushing device suitable for dual-gradient drilling. The device is internally provided with a drilling fluid flowing channel providedwith two open axial ends, wherein the drilling fluid flowing channel is in shunted communication with a drilling fluid flowback channel, the inlet end of the drilling fluid flowback channel is locatedin the device, the outlet end of the drilling fluid flowback channel is provided with a crushing portion, the drilling fluid flowback channel is provided with a first jet flow throat portion and a second jet flow throat portion, and a mixing cavity is formed in the position, located between the first jet flow throat portion and the second jet flow throat portion, of the drilling fluid flowback channel. The device is also internally provided with an annulus drilling fluid upward-returning channel capable of making the device outside and the mixing cavity communicated, and the annulus drillingfluid upward-returning channel and the drilling fluid flowing channel are peripherally arranged in a spaced way. The concentric pipe rock debris sucking and crushing device suitable for dual-gradientdrilling facilitates horizontal drilling rock debris carrying, decreases rock debris beds, reduces the drilling cost and ensures safe and efficient drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Composite well wall stabilizer

ActiveCN103013482BInhibits hydration swellingQuality improvementDrilling compositionParaffin waxWater based

The invention discloses a composite well wall stabilizer which is prepared from the following components in percentage by weight: 10-40% of trimethyl potassium silicate powder, 15-35% of nanmu powder, 20-45% of paraffin and 15-25% of graphite powder. The invention has the following beneficial effects: the trimethyl potassium silicate powder and the nanmu powder are used as mutually synergistic main components, and the paraffin and the graphite are used as auxiliary components; when being used in water-based mud (including brine water mud), the composite well wall stabilizer can effectively inhibit the hydration and expansion of shale, improve the quality of mud cakes, enable the mud cakes to be compact, tough and lubricating and stabilize the well wall on the mud shale layer; and meanwhile, the composite well wall stabilizer has plugging action on the microcrack-developing stratum, and enables the stratum to be stable and less prone to collapse, thus achieving the effect of protecting the well wall. By using the stabilizer, well drilling accidents are reduced, and the comprehensive well drilling cost is lowered.

Owner:库尔勒明洋工贸有限责任公司

Efficient uninterrupted circulating valve tool

The invention discloses an efficient uninterrupted circulating valve tool which comprises a bypass valve assembly, a cylinder assembly and a clamping mechanism. The bypass valve assembly comprises a driving pipe, an elastic hinge, a valve plate and a valve seat; a valve groove and a side hole are formed in the wall of the valve seat; the valve plate is located in the valve groove; one end of the valve plate is hinged to the top of the valve groove through the elastic hinge; the lower end of the driving pipe is in sliding sealing connection with the valve seat; a pump cylinder assembly comprises an upper connector, a middle cylinder, a lower connector and a lining; the valve seat is packaged in the middle cylinder through the lower connector; the lining is packaged in the middle cylinder through the upper connector; the upper end of the driving pipe is connected with the lining in a sliding and sealing mode; an opening communicated with the side hole is formed in the wall of the middle cylinder; the clamping mechanism comprises a hydraulic tong head and a lifter; and the lifter is connected with the upper end of the hydraulic tong head and used for pushing the driving pipe to move up and down. According to the efficient uninterrupted circulating valve tool, the driving pipe moves up and down to switch a main channel and a side channel, so that continuous circulation of drilling fluid can be kept during single connection, and stable equivalent circulation density is realized during the whole drilling period.

Owner:中石化石油工程技术服务有限公司 +2

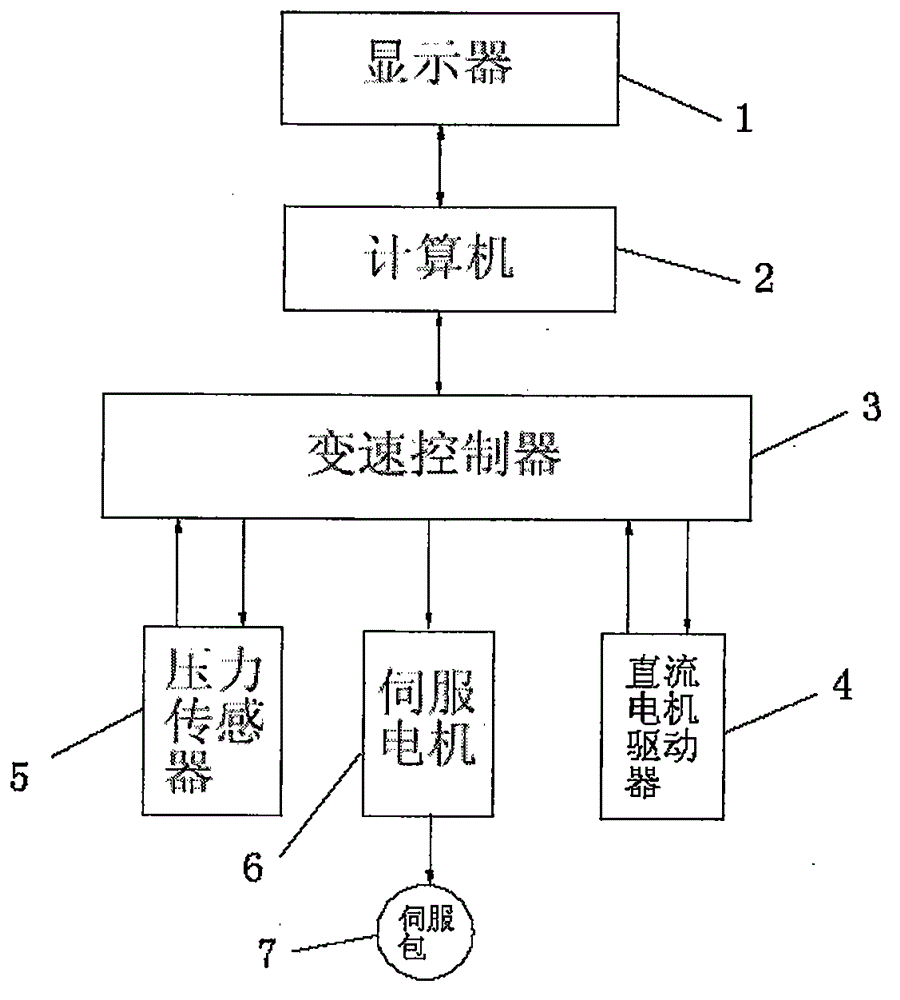

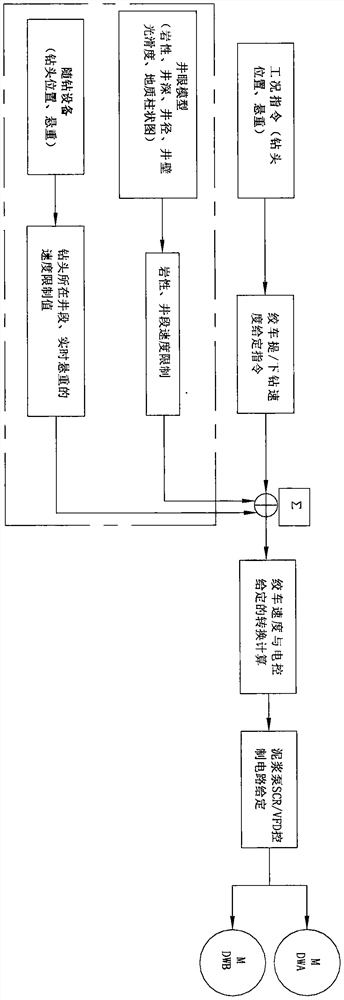

Intelligent rock drill control system

InactiveCN106703782AImprove work efficiencyReduce workloadAutomatic control for drillingControl systemEngineering

The invention provides an intelligent rock drill control system. The system comprises a displayer, a computer, a variable-speed controller, a direct-current motor driver, a pressure sensor, a servo motor and a servo package. The output end of the pressure sensor is connected to the same-name input end of the variable-speed controller, the input end of the servo motor is connected with the output end of the servo package through the output end of the pressure sensor, the output / input end of the direct-current motor driver is connected with the direct-current motor input / output end of the variable-speed controller, the output end of the direct-current motor driver is connected to the input end of the servo motor, the computer is in communication with the variable-speed controller through a transmission line, and the input / output end of the display screen is connected to the display output / input end of the computer.

Owner:宁波高新区利威科技有限公司

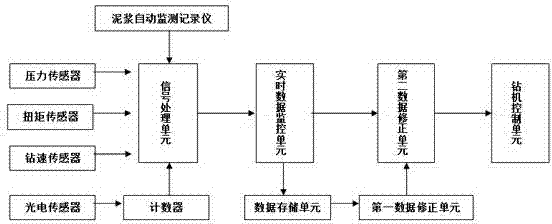

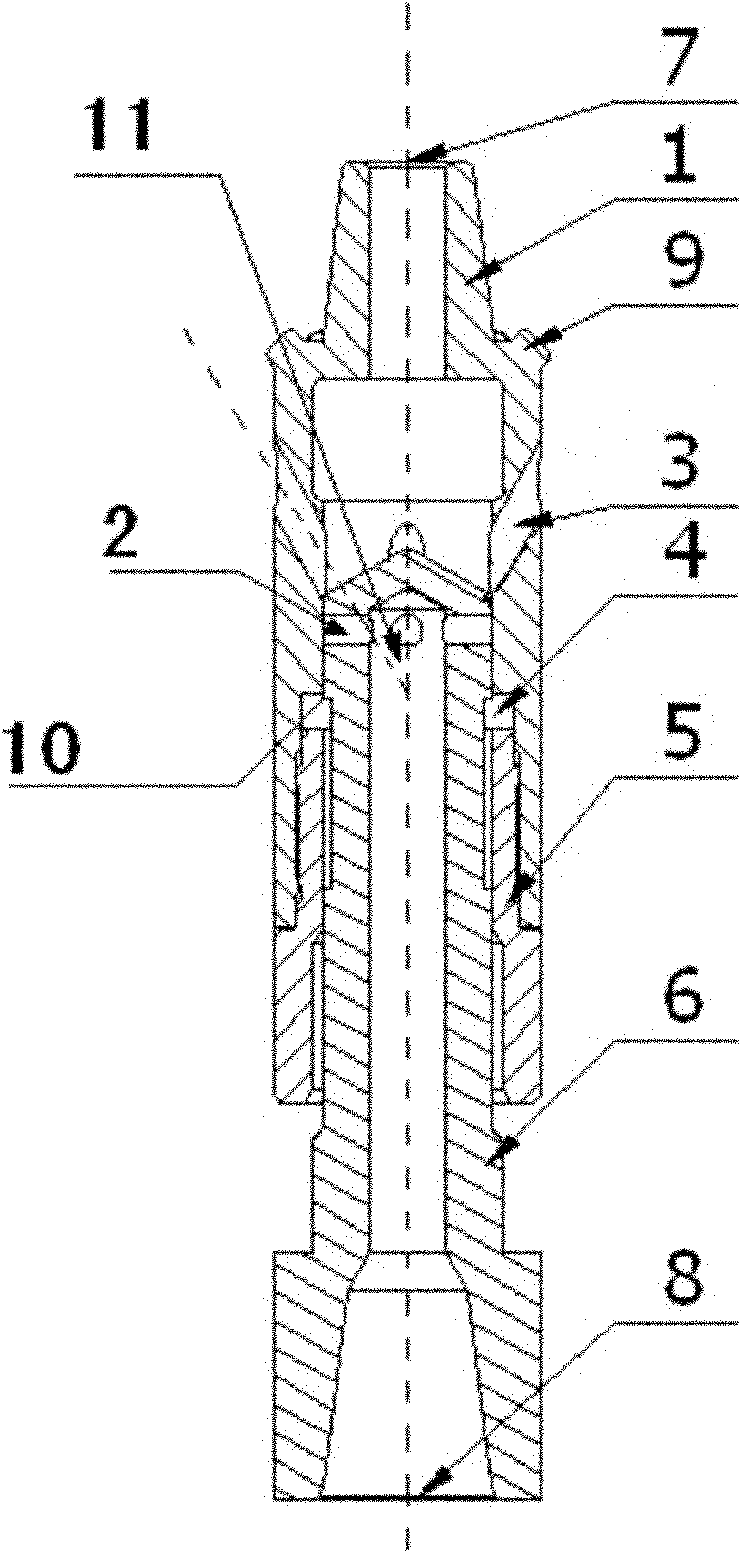

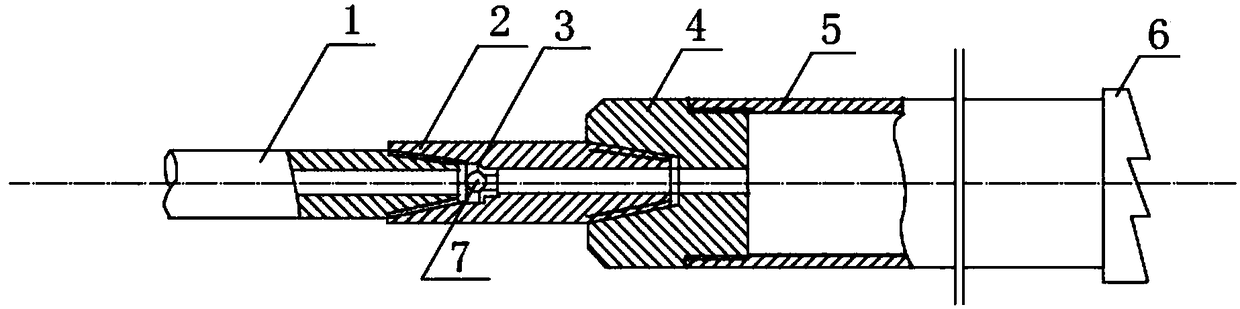

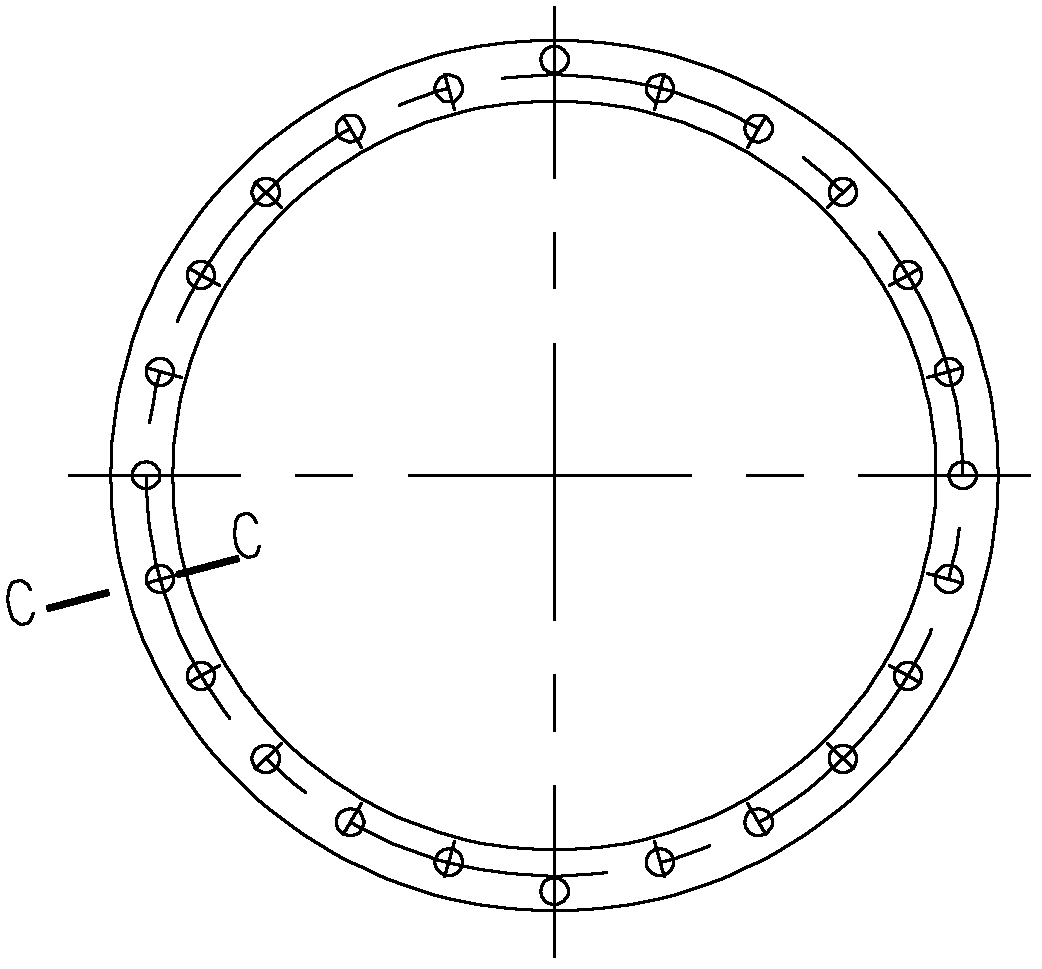

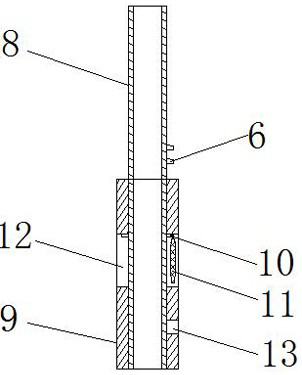

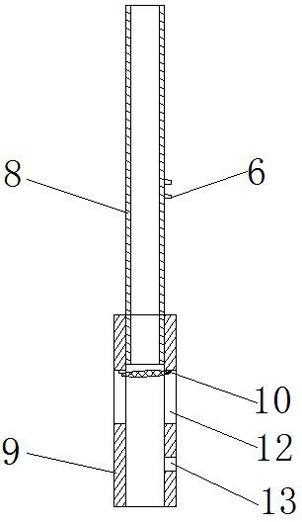

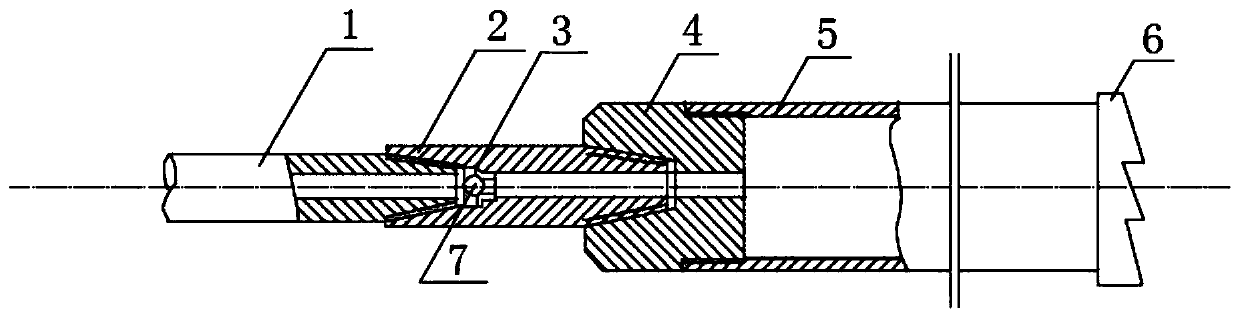

Alarming drill rod for drilling of horizontal directional drilling machine

ActiveCN104358528AReduce drilling accidentsAvoid excessive bending deformationDrilling rodsDirectional drillingFluid controlDrill

The invention discloses an alarming drill rod for the drilling of a horizontal directional drilling machine. The alarming drill rod comprises a drill rod body, wherein a female joint is fixedly arranged at the rear end of the drill rod body; a washing fluid inlet cavity is formed in the female joint; a male joint is fixedly arranged at the front end of the drill rod body; a washing fluid outlet cavity is formed in the male joint; a hollow straight rod body is arranged in the drill rod body; an inner cavity of the hollow straight rod body is set to be a washing fluid passage I communicated with the washing fluid inlet cavity and the washing fluid outlet cavity; a chamber between the outer wall of the hollow straight rod body and the inner wall of the drill rod body is a washing fluid passage II; a washing fluid control switch is arranged in front of the hollow straight rod body. According to the alarming drill rod, a valve element is forced by the hollow straight rod body to move forwards along a guide groove of a valve seat under the resistance of a compression spring so as to automatically close a washing fluid flow passage, then the indication of a pressure meter of a surface mud pump sharply increases, and an alarming prompt is given, so that the drill rod is protected from being excessively bent and deformed, and the service life of the drill rod is prolonged.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

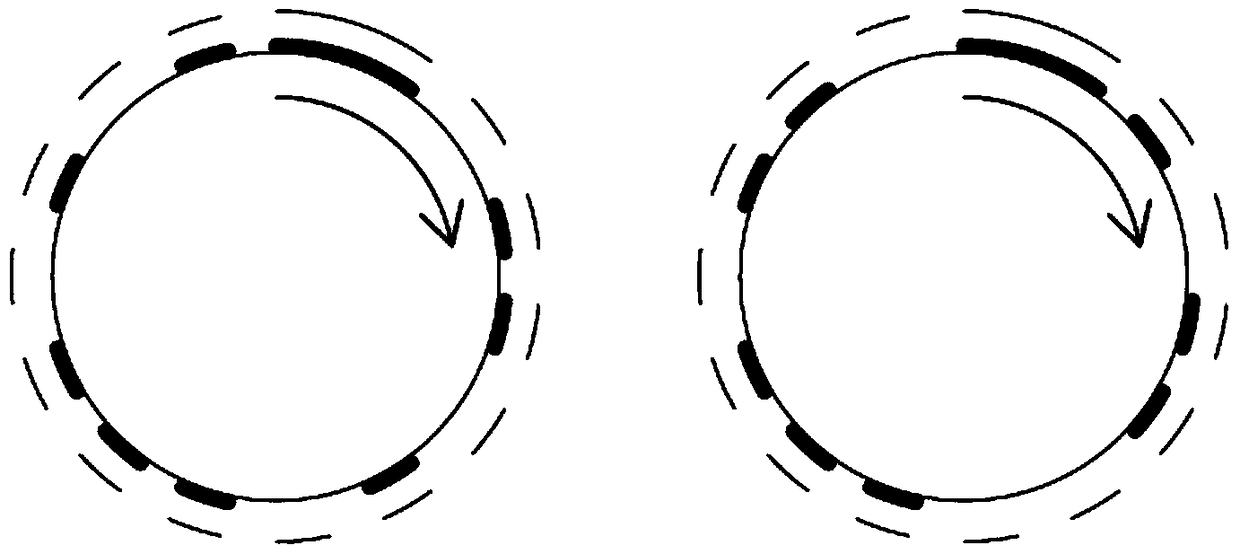

Portable drill rod magnetic memory detector

ActiveCN101419191BImprove distributionRealize full circumference measurementMaterial magnetic variablesSheet steelResidual magnetic field

Owner:PETROCHINA CO LTD

A concentric tube cuttings suction and crushing device suitable for dual-gradient drilling

ActiveCN108915619BRealize the reverse jetReduce formation rateFlushingGrain treatmentsWell drillingHorizontal wells

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

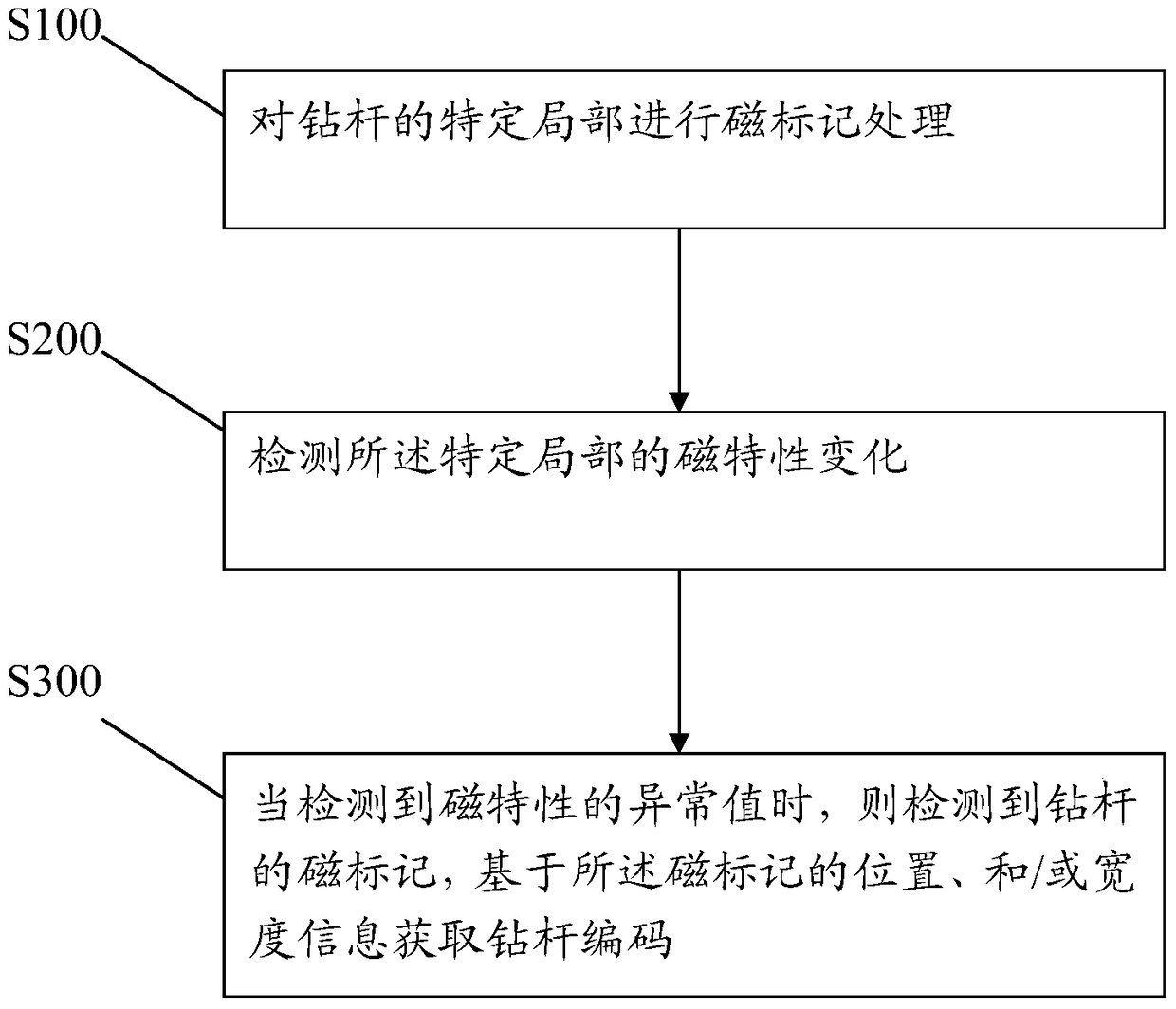

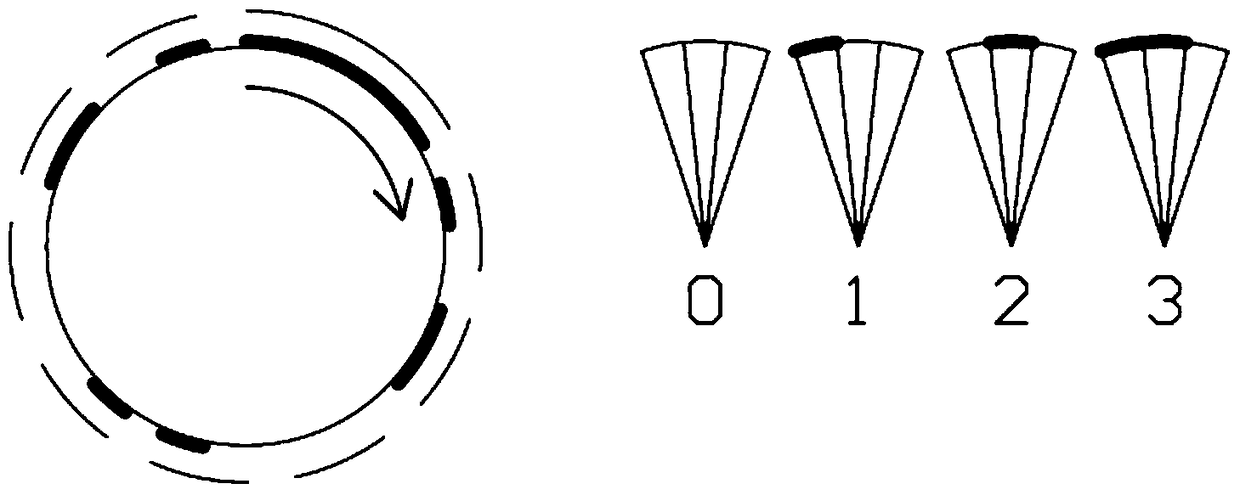

A Identification Method Applied to Petroleum Drill Pipe Operation

ActiveCN105787401BEasy to implementMagnetic changeSensing by electromagnetic radiationMagnetic markerWell drilling

Owner:梅士兵

Alarm Drill Pipe for Horizontal Directional Drilling Rig Drilling

ActiveCN104358528BReduce drilling accidentsAvoid excessive bending deformationDrilling rodsDirectional drillingFluid controlEngineering

The invention discloses an alarming drill rod for the drilling of a horizontal directional drilling machine. The alarming drill rod comprises a drill rod body, wherein a female joint is fixedly arranged at the rear end of the drill rod body; a washing fluid inlet cavity is formed in the female joint; a male joint is fixedly arranged at the front end of the drill rod body; a washing fluid outlet cavity is formed in the male joint; a hollow straight rod body is arranged in the drill rod body; an inner cavity of the hollow straight rod body is set to be a washing fluid passage I communicated with the washing fluid inlet cavity and the washing fluid outlet cavity; a chamber between the outer wall of the hollow straight rod body and the inner wall of the drill rod body is a washing fluid passage II; a washing fluid control switch is arranged in front of the hollow straight rod body. According to the alarming drill rod, a valve element is forced by the hollow straight rod body to move forwards along a guide groove of a valve seat under the resistance of a compression spring so as to automatically close a washing fluid flow passage, then the indication of a pressure meter of a surface mud pump sharply increases, and an alarming prompt is given, so that the drill rod is protected from being excessively bent and deformed, and the service life of the drill rod is prolonged.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

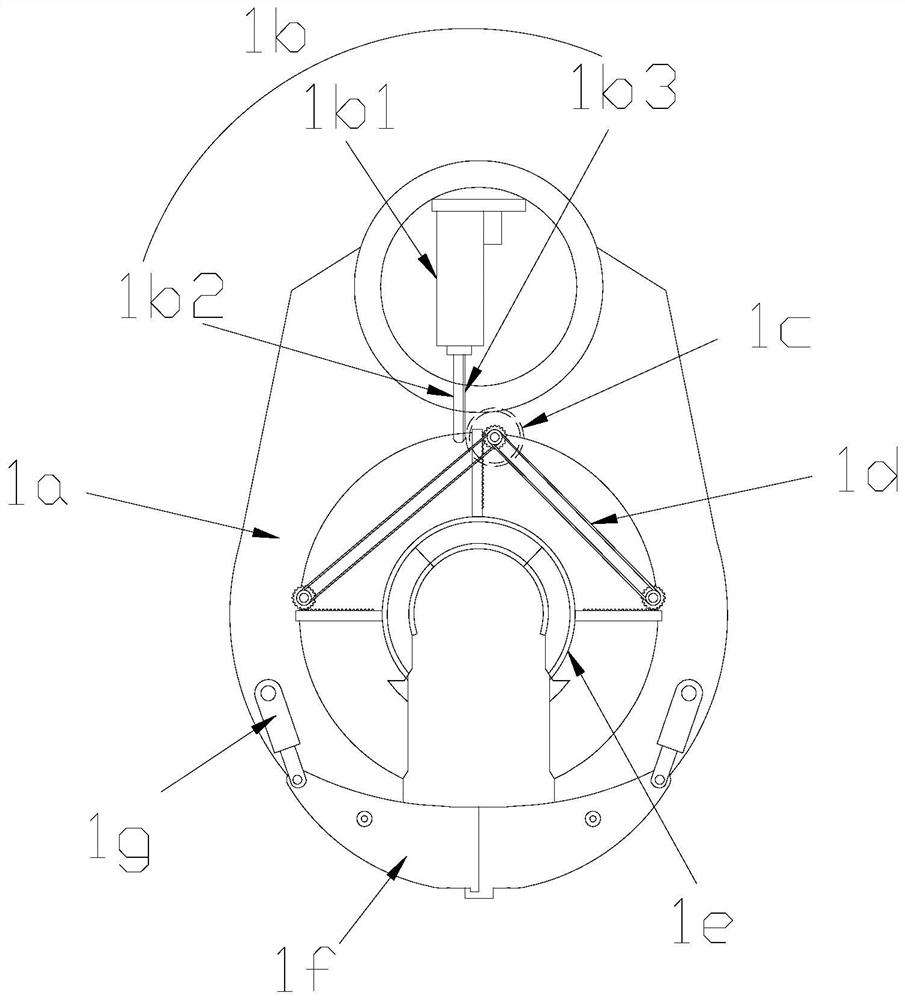

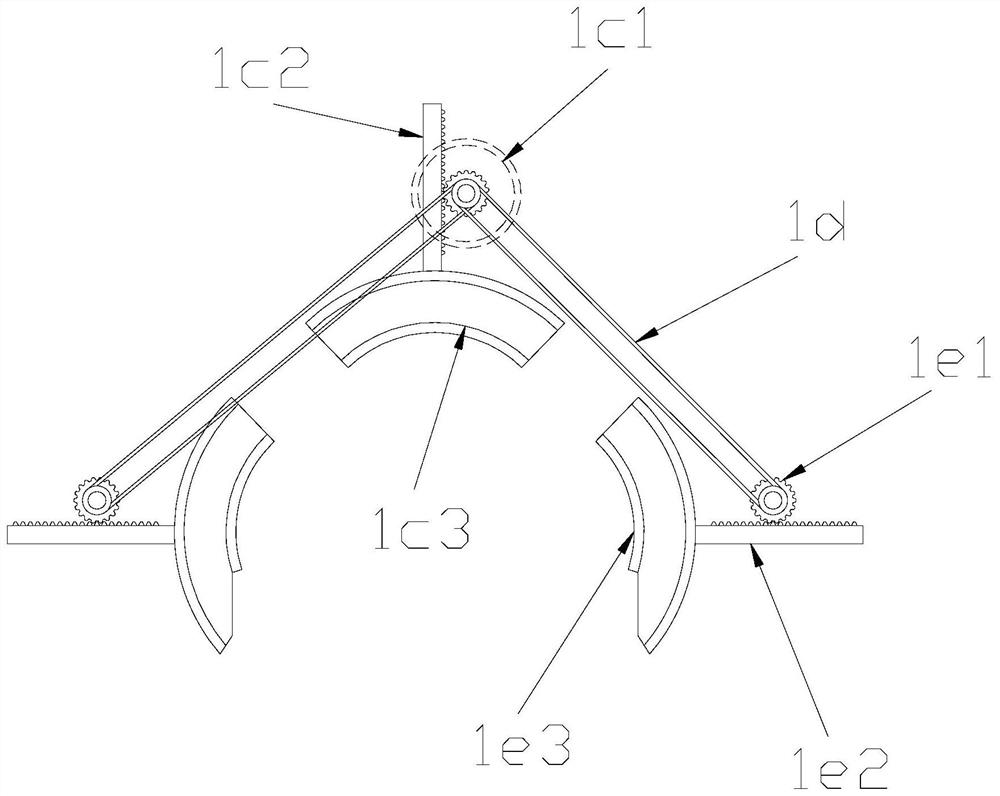

An oil drill adopts intelligent machinery

ActiveCN111271010BReduce friction in both directionsImprove work efficiencyEarth drilling toolsDrilling rodsHydraulic cylinderWell drilling

The invention discloses an intelligent machine for petroleum drilling, the structure of which includes a drill pipe stabilizing device, an auxiliary clamp, a shock absorber, a support column, and a supporting frame. The drill pipe stabilizing device consists of a machine body, a driving mechanism, a linkage mechanism, a transmission belt, The drill pipe stabilization device is composed of a spinner mechanism, a closing cover and a small hydraulic cylinder. The drill pipe stabilizing device controls the linkage mechanism and the spinner mechanism to fit and assist the drilling pipes of different diameters through the driving mechanism, so that when the drill pipe is drilling down to extract oil, Reduce rotation shaking and increase the safety performance of mining. The auxiliary gripper uses the cleaning mechanism to scrape off the garbage on the surface of the drill pipe, and then sprays water on the surface of the drill pipe to clean it through the spray head, which reduces the amount of manual labor and increases To improve the recovery efficiency, this technology can ensure that the well wall does not collapse to the greatest extent, avoid pipe sticking, reduce drilling accidents, increase the ROP, and balance the rotation of the drill pipe.

Owner:HEILONGJIANG JINGHONG PETROLEUM EQUIP MFG

A kind of environment-friendly plugging agent for drilling fluid and preparation method thereof

ActiveCN109735311BImprove the blocking effectDecreased fluorescence intensityDrilling compositionCelluloseDodecane

The invention discloses an environment-friendly plugging agent for drilling fluid, which is prepared from the following raw materials in parts by weight: 40-55 parts of modified starch, 20-30 parts of lignocellulose, and 5-15 parts of antioxidant , 3-10 parts of nano-calcium carbonate and 15-30 parts of dispersant, wherein the antioxidant is 2,5-di-tert-butyl hydroquinone, didodecyl thiodipropionate and hindered phenolic antioxidant One or more of the oxygen agents. The invention also discloses a method of an environment-friendly plugging agent for drilling fluid, which is characterized in that it comprises the following steps: stirring the modified starch and lignocellulose, mixing evenly, and then adding a dispersant, at 65-90°C Stir at high temperature for 90-120min, then add nano-calcium carbonate, stir for 30-50min, heat up to 85-115°C, add antioxidant, stir for 1-1.5h, then cool down to 80±5°C, and keep warm at this temperature React for 4-5 hours, pulverize, and pass through a 60-80 mesh sieve to obtain an environmentally friendly plugging agent for drilling fluid. The invention has the advantages of environmental protection, good plugging effect and low fluorescence intensity.

Owner:北京宏勤石油助剂有限公司

A kind of cleaning lubricating quick-drilling agent and preparation method thereof

ActiveCN104357029BEnhanced inhibitory effectGood compatibilityDrilling compositionOil and greaseWell drilling

The invention discloses a cleaning and lubricating fast drilling agent and a preparation method thereof. The cleaning and lubricating fast drilling agent comprises the following components in part by weight: 70-90 parts of waste grease, 2-7 parts of a fast penetrating agent, 2-5 parts of an emulsifying agent, 3-8 parts of a catalyst, 3-7 parts of a wetting agent and 5-9 parts of a surfactant. With the waste grease as a raw material, the prepared cleaning and lubricating fast drilling agent is good in compatibility, high in temperature resistance and wettability and low in surface tension, so that bit balling is effectively prevented; the cleaning and lubricating fast drilling agent is good in lubricating effect, strong in inhibition, resistant to salt and rock debris pollution, good in reservoir protection, environment-friendly, and extremely low in foaming rate before and after high temperature; the preparation method is simple in process and relatively low in cost; by the preparation method, key technical problems of deep well drilling and ultradeep well under complex geological conditions are solved; the cleaning and lubricating fast drilling agent protects an oil and gas reservoir, reduces drilling accidents, increases the drilling speed overall and reduces the drilling cost.

Owner:CHINA PETROCHEMICAL CORP +1

Pup joint and well drilling device

PendingCN113863872AExtend your lifeReduce intensityDrilling rodsVibration devicesWell drillingHelmholtz resonator

The invention provides a pup joint and a well drilling device. The pup joint is used for being connected with a drill bit, the pup joint comprises a pup joint body, an oscillation cavity is formed in the pup joint body, so that drilling fluid flowing into the oscillation cavity forms Helmholtz resonance in the oscillation cavity to drive the pup joint body and the drill bit connected with the pup joint body to generate ultrahigh-frequency vibration with preset frequency, and when the vibration frequency is close to the rock resonance frequency, rock resonance crushing is induced. The pup joint solves the problems that in the prior art, a drilling speed increasing device is low in drilling and rock breaking efficiency, low in drilling speed and long in drilling period in deep hard formation drilling.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

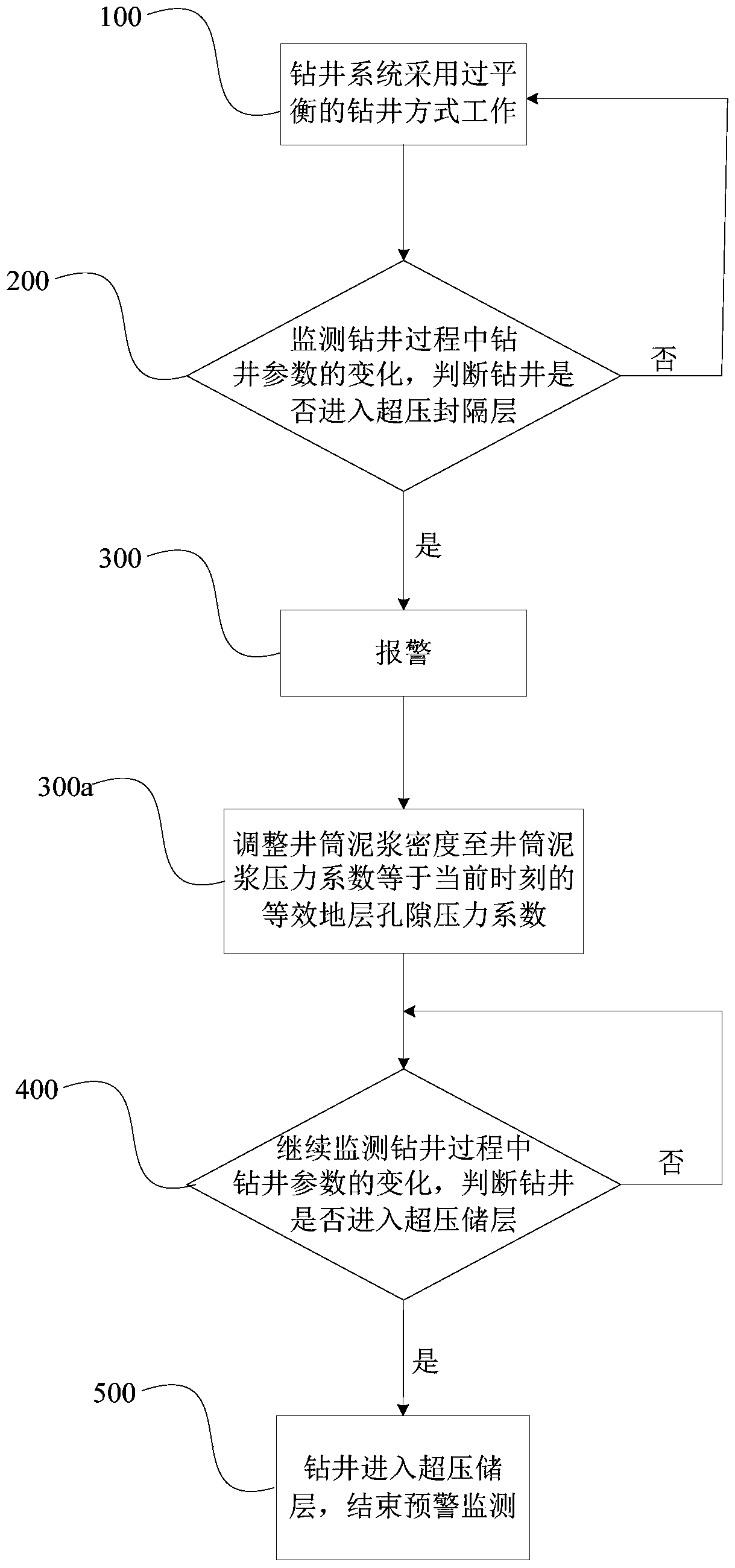

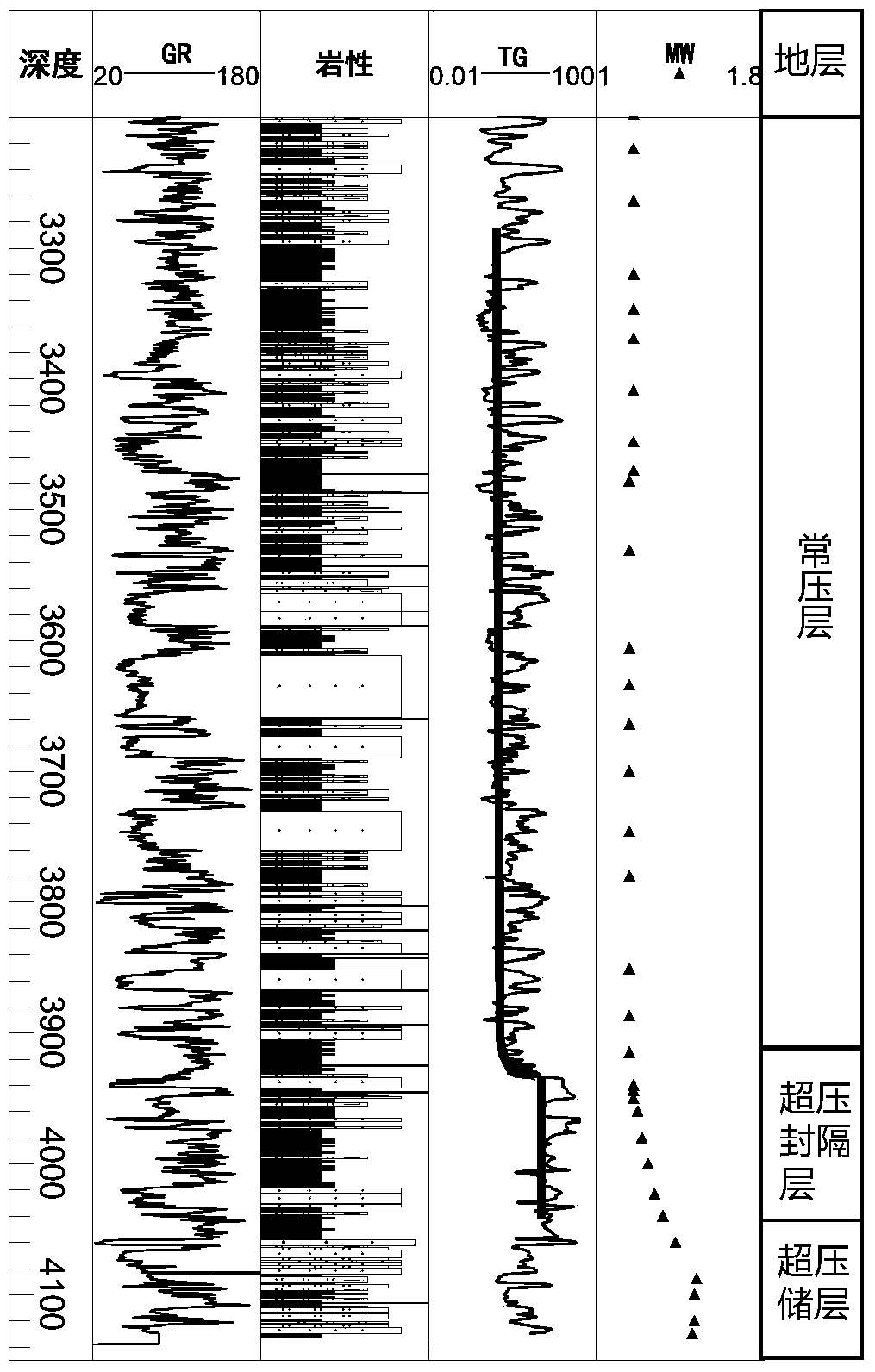

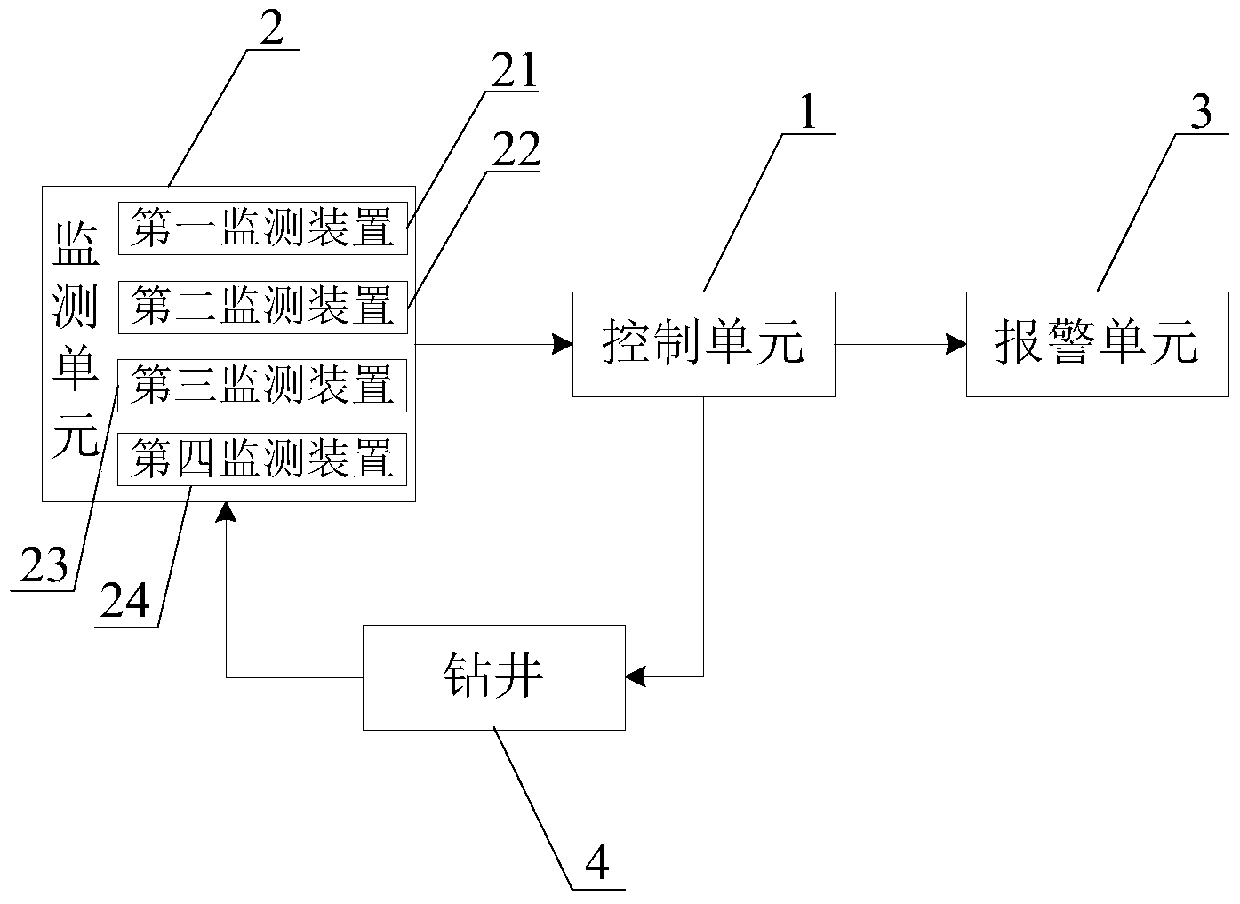

Formation Pressure Monitoring While Drilling Method and Monitoring Device

ActiveCN104453843BEliminate hidden dangers such as blowoutsReduce drilling accidentsSurveyAutomatic control for drillingWell drillingDrilling system

Owner:CHINA NAT OFFSHORE OIL CORP +1

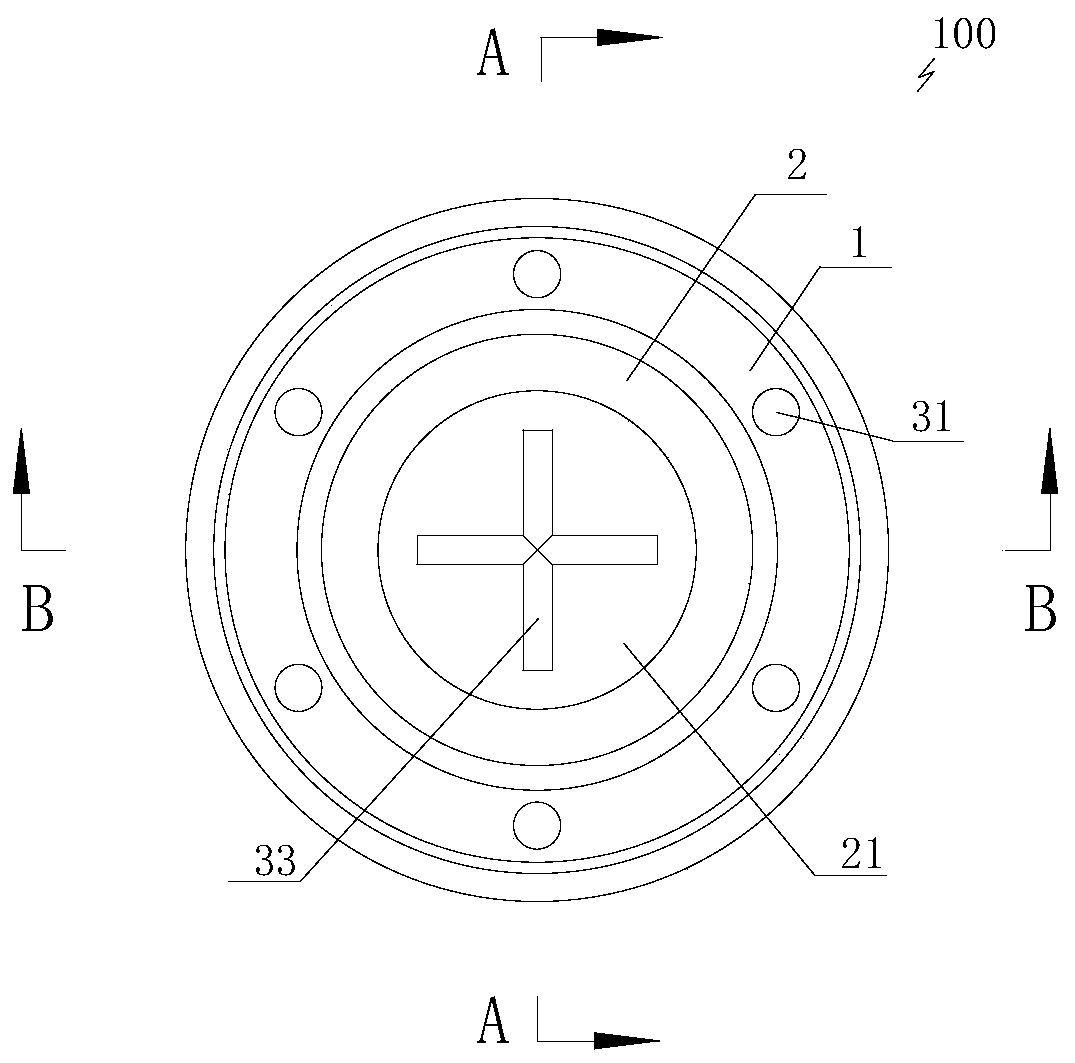

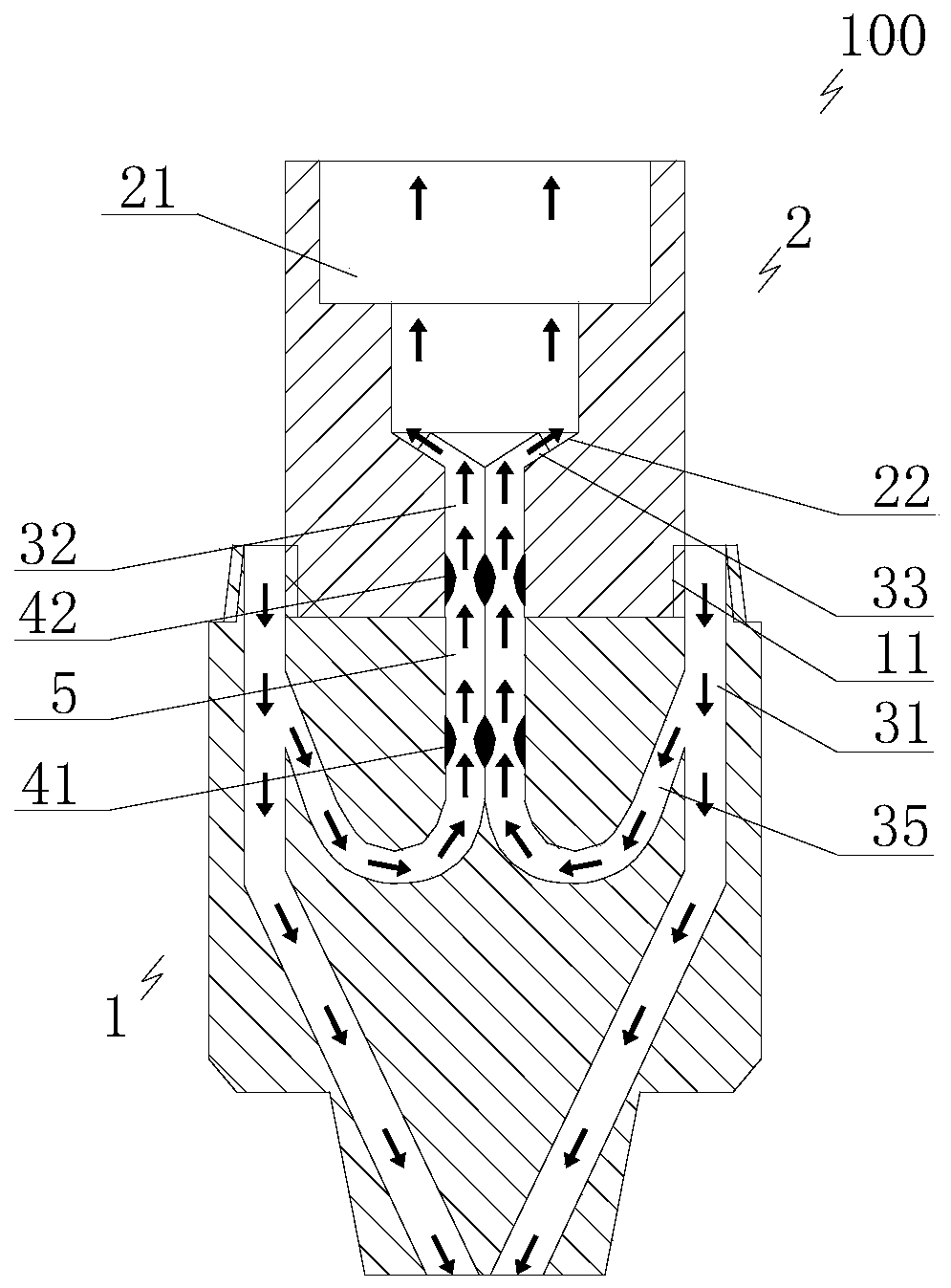

Drill bit and drilling device

PendingCN111485827AExtend your lifeReduce intensityDrill bitsConstructionsWell drillingClassical mechanics

The invention discloses a drill bit and a drilling device. The drill bit comprises a joint and a drill bit body; a hydraulic oscillation cavity is formed in the joint, and used for making drilling fluid flowing into the hydraulic oscillation cavity form a self-excited oscillation effect in the hydraulic oscillation cavity, pressure fluctuation is generated, the longitudinal vibration of the drillbit is driven, the drill bit transmits high-frequency vibration to rocks in contact, and thus inducing the rocks to undergo resonance failure and assisting the drill bit to break the rocks; and a nozzle is arranged in a drill bit body, an outlet of the hydraulic oscillation cavity communicates with the nozzle, and the nozzle is used for ejecting the drilling fluid flowing out of the hydraulic oscillation cavity out the drill bit. According to the technical scheme, the rock breaking speed can be increased, the service life of drilling tools is prolonged, a smooth and stable borehole is advantageously formed, and the drilling efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

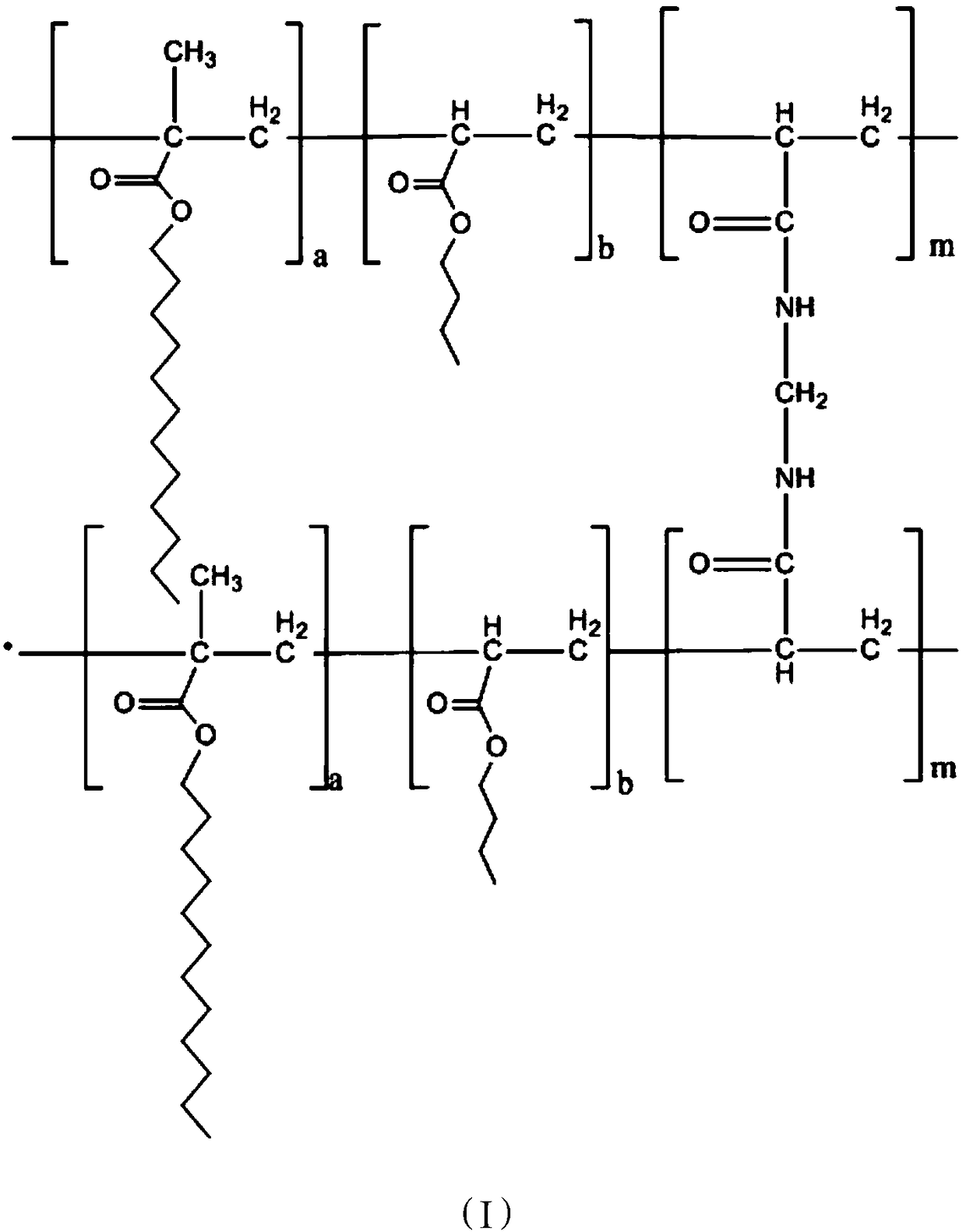

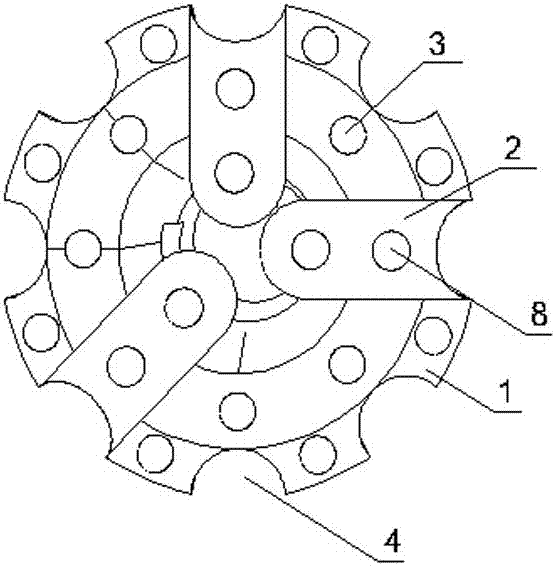

A kind of oil-absorbing resin material and preparation method thereof

ActiveCN106366240BImprove lipophilicityImprove oil absorption efficiencyDrilling compositionOrganic chemistryExpansion rate

The invention discloses oil-absorption resin. The oil-absorption resin is a compound expressed as formula (I), wherein a is 100000-150000, b is 400000-500000, and m is 30000-35000. The oil-absorption resin is high in expansion rate in an oil-based drilling liquid system, excellent in oil absorption effect and high in plugging capability. The formula is shown in the description.

Owner:SICHUAN KUINENG ENVIRONMENTAL PROTECTION TECH CO LTD

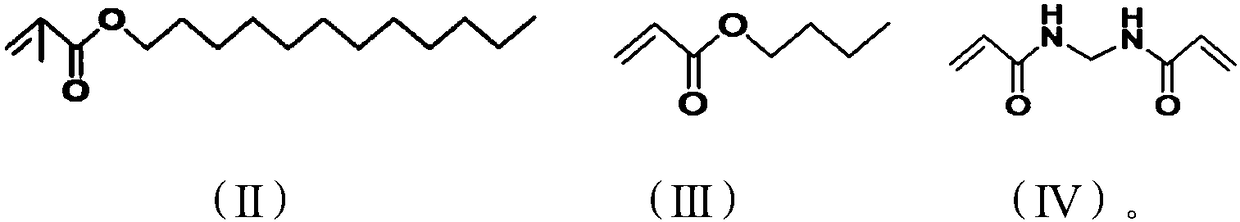

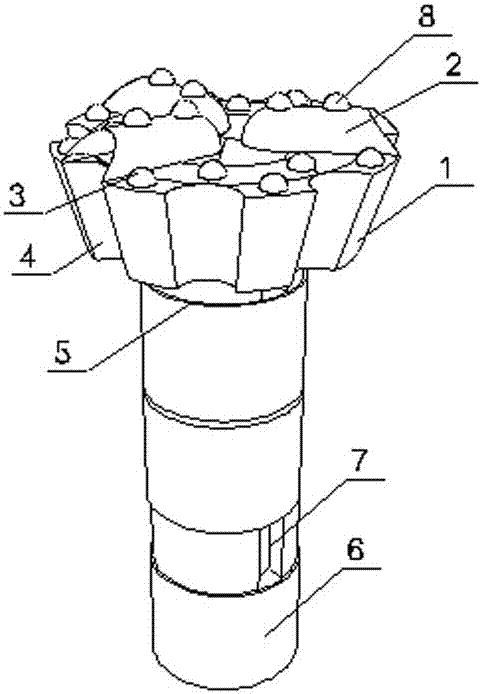

A type of round lip impregnated diamond bit automatic rock removal device

ActiveCN104763350BIncrease the amount of rock breakingImprove rock breaking abilityDrill bitsConstructionsMaterials scienceDrill bit

The invention provides an automatic rock removing device with a triangulated round lip diamond-impregnated drill bit. The device comprises a hollow diamond drill bit and a hollow drilling rod which are connected through a connecting ring; the inner hole diameter of the hollow diamond drill bit is not greater than the inner hole diameter of the hollow drilling rod; the blades and a first diamond layer are arranged on the upper surface of the hollow diamond drill bit; a second diamond layer is arranged on the surface of each blade; at least one chipping removing guide groove is formed around the hollow diamond drill bit; the three blades are arranged like a triangle; axes of the chipping removing guide grooves are inclined toward the inside of the hollow diamond drill bit; at least one chipping removing opening groove is formed in the middle of the hollow drilling rod. The device is fast to drill, long in service life of the drill bit, quick to remove chippings, high in adaptability, and particularly applied to the core drilling industry.

Owner:CHENGDU HUILINGFENG DIAMOND BIT

In the sand soil, the core method of drilling the core of the rocky core is used in the sand soil

The invention discloses a drilling coring method enwrapping a rock core by using a mud coating in sandy soil. The drilling coring method comprises the following steps of putting a drilling apparatus in position and assembling; preparing natural compound mud according to the distribution condition of a stratum; drilling coring: according to the category of the stratum, drilling, by the drilling apparatus, until a drilling depth of 1.50m according to a corresponding drilling parameter; stopping a pump, stopping circulating the natural compound mud in a hole of a drill pipe and a drilled hole, opening a mud return valve, and putting a water-stop marble into the drill pipe; burning a bit, carrying out dry drilling after stopping the pump, drilling by adopting a low rotational speed and low drilling pressure in the beginning, when a rock core barrel is filled with the rock core, drilling by adopting high drilling pressure and a high rotational speed, generating a higher temperature betweenthe bottom of an alloy bit and a rock core sample of the sandy soil within a short time, and slightly sintering the bottom of the alloy bit and the rock core together; lifting the bit; withdrawing thecore by the pressure of the mud. The drilling coring method has the advantages that the recovery rate of the rock core sample of the sandy soil is improved by a wide margin, and can reach 100 percent; the rock core sample of the sandy soil is enwrapped by the mud coating, and the rock core sample of the sandy soil is enabled to maintain the undisturbed grain composition and structure of the sandysoil.

Owner:长江岩土工程有限公司 +1

Drilling tool

InactiveCN102400650BFirmly connectedReduce drilling accidentsDrilling rodsDrilling casingsButt jointFlange

The invention discloses a drilling tool, and relates to the technical field of a drilling machine, aiming at solving the technical problems of realizing reliable connection and reducing drill fall-off accidents. The drilling tool comprises a drill rod and a drill bit connected with the drill rod, wherein flange connection plates of the drill rod and the drill bit are respectively provided with at least two openings and at least two pin holes; the flange connection plates of the drill rod and the drill bit are in butt joint; the openings and the pin holes which are arranged on the flange connection plate of the drill rod correspond to those arranged on the flange connection plate of the drill bit; the corresponding openings are respectively provided with an I-shaped block; the flange connection plates of the drill rod and the drill bit are connected with each other by the I-shaped blocks; and pin shafts used for transferring torque pass through the corresponding pin holes. The drilling tool is applicable to construction of large holes in large and medium-sized projects or other projects of mines.

Owner:CHINA COAL MINE CONSTR GRP

Mining method of high stress soft outburst coal seam

InactiveCN103806933BConducive to strong rowReduce frictionDrilling rodsDust removalReturn currentGas release

The invention discloses a high-stress soft outburst coal seam mining method which comprises a coal seam gas extraction method, wherein the coal seam gas extraction method comprises the steps of drilling with an arc-shaped three-edge drill rod matched with the air compressing and slagging drill technique, extracting gas at the position close to a drilled hole, and conducting dedusting on the hole, average drilling depth is 75 m - 80 m, the gas releasing rate of a great coal working surface reaches over 60%, the content of residue gas of a protected coal seam is below 7 m<3> / t, and during tunneling of the great coal working surface, the absolute gas discharge is 2.0 m<3> / min - 2.5 m<3> / min, and the maximum gas density of a return current is about 0.3 percent; during stoping of a stope working surface, the absolute gas discharge is 3.5 m<3> / min - 4.5 m<3> / min, the maximum gas density of a return current is about 0.4 percent, and the gas density on a corner of the stope working surface is 0.6 percent at most; a hole deduster is used for dedusting during drilling, and then dust concentration of the working surfaces is reduced.

Owner:冀中能源峰峰集团有限公司大淑村矿

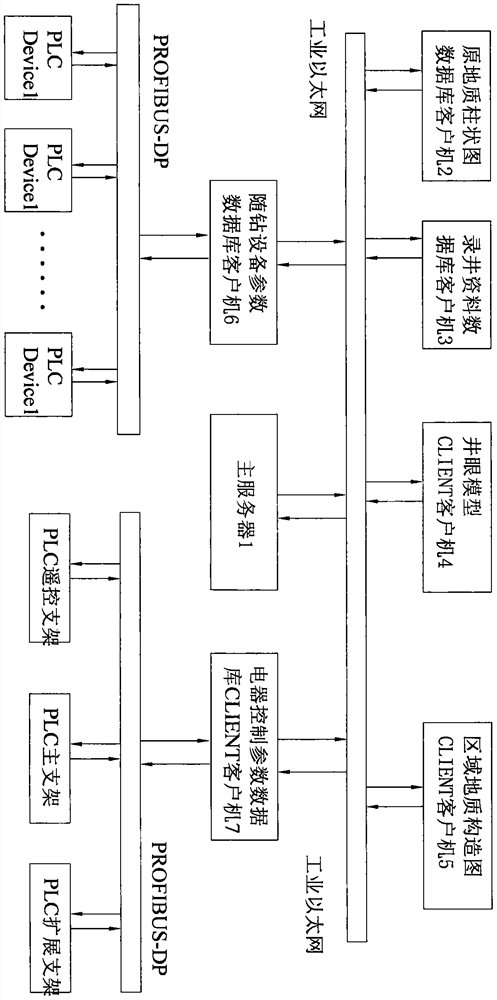

Intelligent drilling machine operation control system

PendingCN112302617AImprove drilling efficiencyLower Drilling CostsAutomatic control for drillingLoop controlWell logging

The invention discloses an intelligent drilling machine operation control system, and belongs to the technical field of drilling machine control systems. The intelligent drilling machine operation control system comprises a main server, an original geological histogram database client, a logging data database client, a borehole model CLIENT client, a regional geological structure map CLIENT client, a while-drilling equipment parameter database client and an electric appliance control parameter database CLIENT client. The main server is provided with an Internet platform of the industrial Ethernet and browsers of a plurality of databases, and converts the browsers into an automatic data interaction system. A static well position geological columnar database, well logging data, dynamic real-time changing while-drilling parameters and electrical control parameters are integrated and managed to form static and dynamic complementary double closed-loop control, so that the drilling efficiency is improved, the drilling cost is reduced, and drilling accidents are reduced.

Owner:陕西鼎晟石油电气控制技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com