Real-time well drilling formation correction method and device

A prediction method and real-time monitoring technology, applied in drilling equipment, drilling automatic control system, measurement, etc., can solve problems such as low efficiency and low prediction accuracy, so as to avoid drilling abandoned wells, reduce drilling accidents, and improve drilling success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

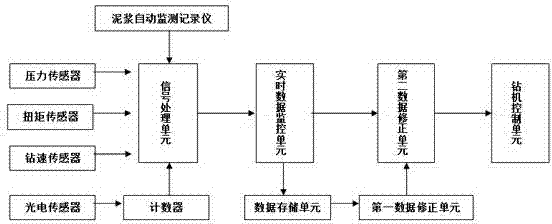

Image

Examples

Embodiment

[0022] Before drilling, geological analysis will be carried out, corresponding to the corresponding geology, mud viscosity, mud specific gravity will be estimated, the drilling pressure, rotational speed, and drilling speed of the corresponding bottom layer will be adjusted, and then the initial data value A will be recorded in the computer. At the same time, there are pressure sensors, torque sensors and drilling speed sensors at the joint of the power head, which will monitor and transmit data in real time, and record the real-time monitored drilling pressure, torque, and speed accordingly, and then the mud pool has an automatic recording monitor to monitor the mud. According to the flow meter below, the real-time mud flow is recorded. There is a counting sensor at the wellhead to record the number of pipes that have been run, so as to calculate the length of the drilling tool and the depth of the drilled well, such as the Drill the well to 200m, compare the 200m data B recor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com