A kind of environment-friendly plugging agent for drilling fluid and preparation method thereof

An environmentally friendly, plugging agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of less environmentally friendly plugging agent products, achieve excellent plugging performance, improve heat resistance, reduce Effects of Drilling Accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

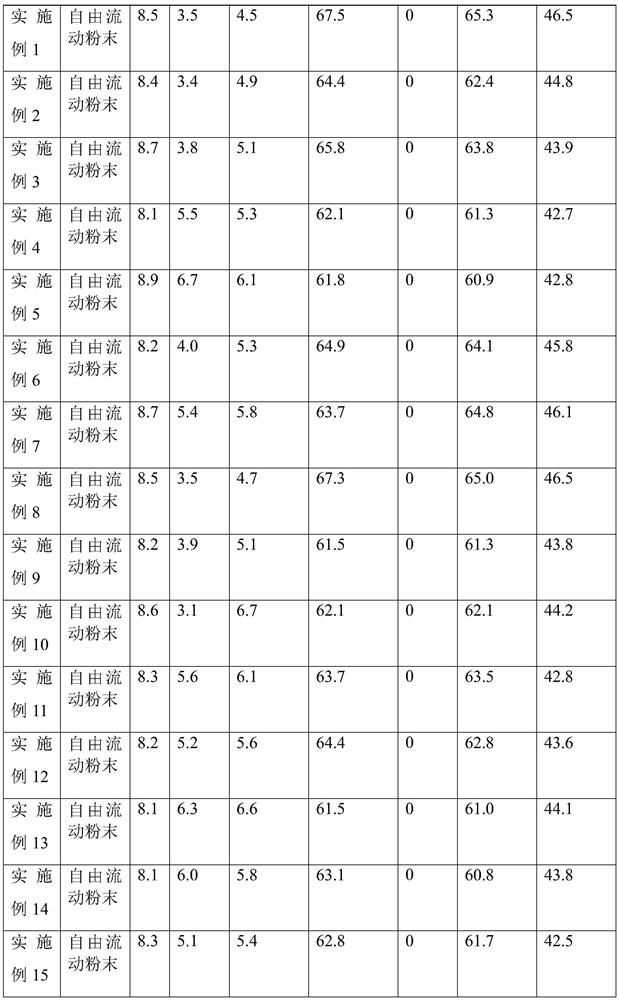

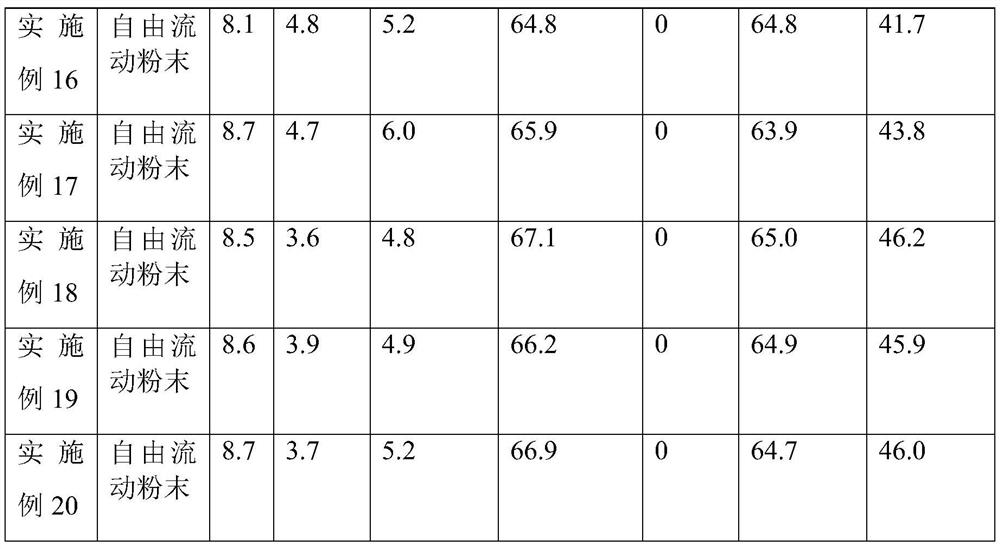

Examples

preparation example 1

[0027] The preparation method of the modified starch is as follows: in parts by weight, 110 parts of water are added to the reaction kettle, stirred and heated to 50°C, 25 parts of cornstarch are added, and then 4 parts of sodium hypochlorite solution is added, and after stirring at 50°C for 25min, Add 12 parts of sodium hydroxide solution;

[0028] Then add 250 parts of isopropanol and 330 parts of cationic etherification agent (purchased from Shandong Yifei Pharmaceutical Co., Ltd., model is yf-17), stir and react at 30°C for 4.5h, dry, pulverize and pass through a 90-mesh sieve, namely modified starch.

preparation example 2

[0030] The preparation method of modified starch is carried out according to the method in Preparation Example 1, the difference is that, in parts by weight, 100 parts of water are added to the reactor, the temperature is stirred to 45 ° C, 20 parts of cornstarch are added, and then 2 parts of cornstarch are added. 10 parts of sodium hypochlorite solution was stirred at 50°C for 20 minutes, and then 10 parts of sodium hydroxide solution were added;

[0031] Then add 200 parts of isopropanol and 300 parts of cationic etherification agent (purchased from Shandong Yifei Pharmaceutical Co., Ltd., model is yf-17), stir and react at 25°C for 4 hours, dry, crush and pass through a 80-mesh sieve to obtain modified starch.

preparation example 3

[0033] The preparation method of modified starch is carried out according to the method in Preparation Example 1, the difference is that, in parts by weight, 120 parts of water are added to the reaction kettle, stirred and heated to 60 °C, 30 parts of corn starch are added, and then 5 parts of Sodium hypochlorite solution, after stirring at 50°C for 30 minutes, add 15 parts of sodium hydroxide solution;

[0034] Then add 300 parts of isopropanol and 350 parts of cationic etherification agent (purchased from Shandong Yifei Pharmaceutical Co., Ltd., model is yf-17), stir and react at 35°C for 5 hours, dry, and crush through a 100-mesh sieve to obtain modified starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com