Patents

Literature

72 results about "Di-tert-butylhydroquinone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin composition for insulation film

ActiveUS20130245161A1Low dielectric constantLow DfDomestic articlesThin material handlingPolymer sciencePtru catalyst

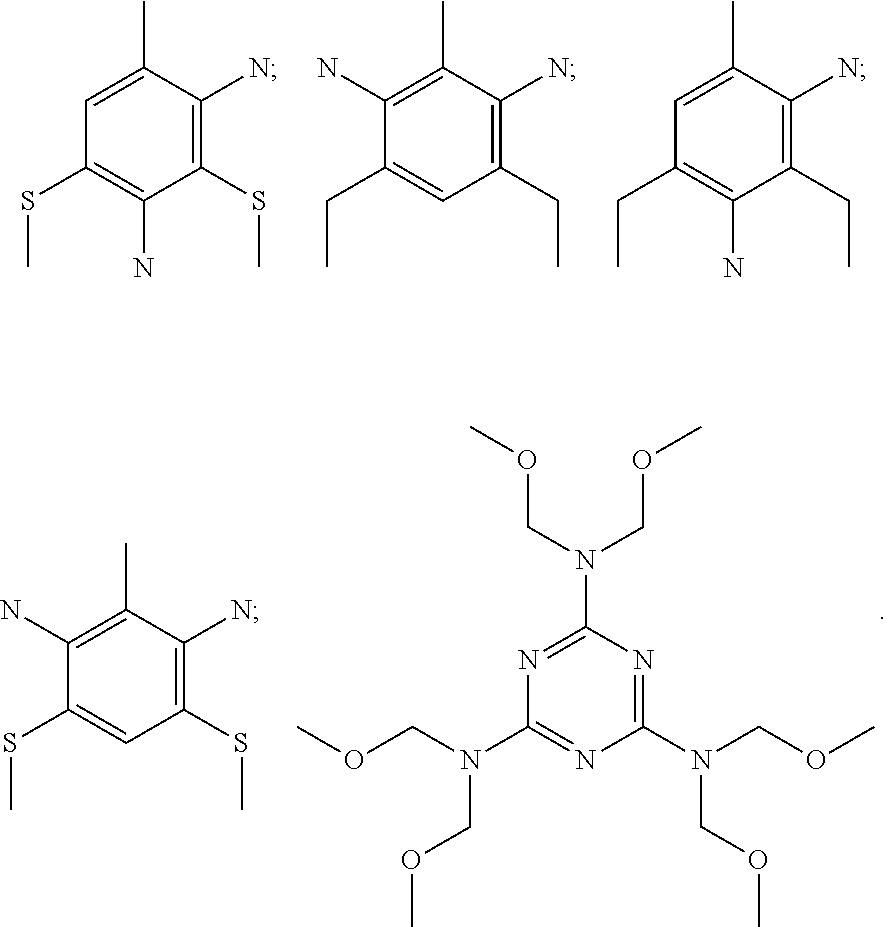

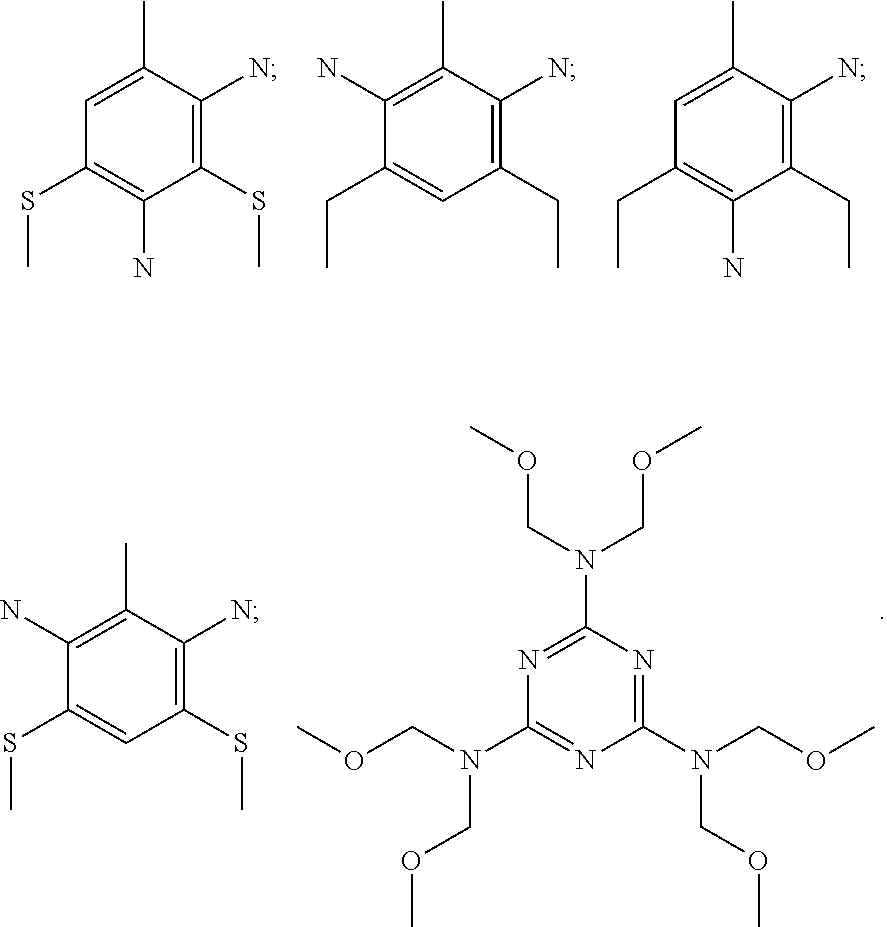

A resin composition includes (A) 100 parts by weight of epoxy resin; (B) 20 to 100 parts by weight of polybutadiene styrene divinylbenzene graft terpolymer resin; (C) 2 to 20 parts by weight of di-tert-butylhydroquinone (DTBHQ); (D) 5 to 50 parts by weight of polyphenyl ether modified cyanate ester resin; and at least one of (E) inorganic filler, (F) chain extending sealing agent, and (G) catalyst. The resin composition is characterized by specific ingredients and proportions thereof to attain high heat resistance, low dielectric constant Dk, and low dielectric dissipation factor Df, and being halogen-free, and therefore is applicable to protective film of printed circuit boards, insulating protective film of electronic components, and resin insulation film of leadframes.

Owner:ELITE MATERIAL

Method of preparing exo-dicyclopentadiene from endo-dicyclopentadiene or cyclopentadiene

InactiveCN1907927ALiquid phase reaction conditions are mildHigh yieldHydrocarbon by isomerisationBENZYL ALCOHOL/WATERHeptane

The invention discloses a preparation method for exo-dicyclopentadiene from bridge-type dicyclopentadiene or cyclopentadiene, belonging to the exo-dicyclopentadiene preparation technology. The method includes preparing a solution composed of bridge-type dicyclopentadiene or cyclopentadiene, and benzene, or toluene, or benzyl alcohol, or decalin, or cyclohexane, or heptane, or hexane at a certain quality ratio, adding p-tert-butylcatechol, or 2, 5-di-tert-butylhydroquinone, or 2,6-di-tertbutyl-4-methylphenol, or hydroquinone, or 2-methyl-1,4-dihydroxybenzene, or o-hydroquinone inhibitor and carrying out reaction at a certain temperature and pressure, distilling and separating to obtain the exo-dicyclopentadiene. The invention has the advantages of one-step synthesis without catalyst, mild reaction conditions and high yield, and is suitable for industrial production.

Owner:TIANJIN UNIV

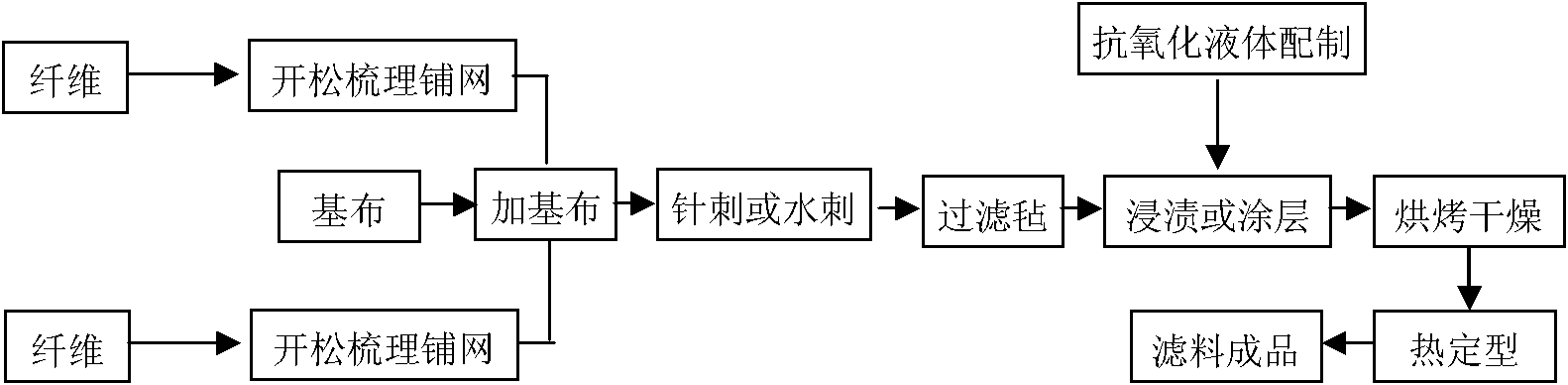

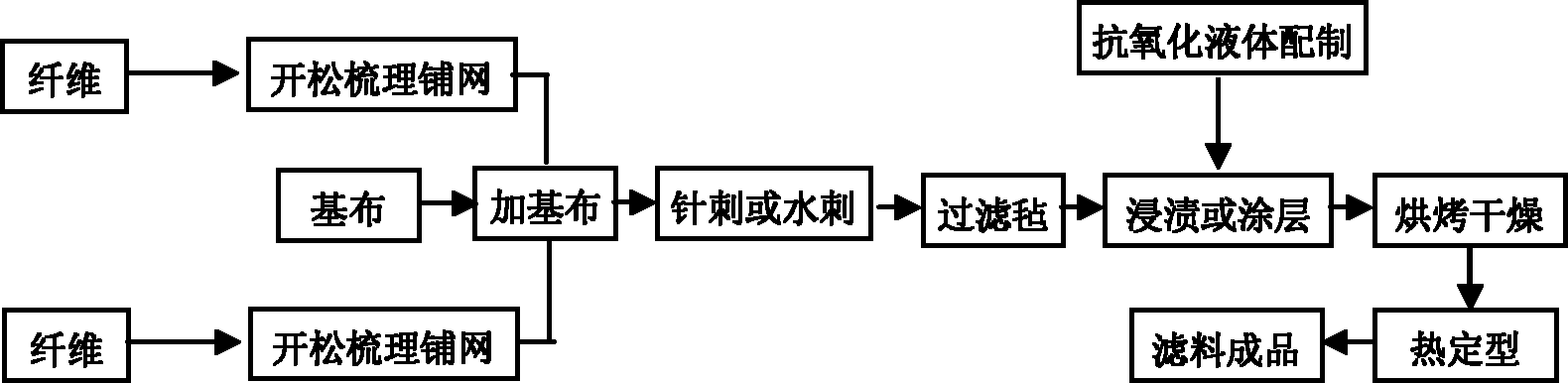

High temperature-resistant anti-oxidation filter material and manufacturing method thereof

ActiveCN102151436ADoes not affect resistanceEfficiency is not affectedLayered productsFiltration separationNeedle punctureOxidation resistant

The invention relates to a high temperature-resistant anti-oxidation filter material and a manufacturing method thereof, belonging to the technical field of high-temperature filter materials. 1%-10% of 2,5-di-tert-butylhydroquinone or rosemary antioxidant liquid is utilized for performing impregnation or coating treatment on a 300-1000g / square meter filter felt produced by the needle puncture method or the spunlacing method for coating an anti-oxidation coating layer with 0.5-50 microns on the surface of the filter felt, and then high-temperature baking treatment and thermosetting with steam or hot oil are performed for 1-60 minutes at the temperature of 100-235 DEG C for forming the high temperature-resistant anti-oxidation filter material for filtering high-temperature smoke dust. In order to solve the defects of the filter material for a bag dust collector in the anti-oxidation aspect, the invention provides the high temperature-resistant anti-oxidation filter material and the manufacturing method thereof, by using the high-temperature antioxidant to perform the impregnation or the coating on the filter material and further performing the baking and the thermosetting treatment,the filter material has the anti-oxidation property, and the too early aging failure of the filter material under a high-temperature oxidation environment can be avoided.

Owner:NORTHEASTERN UNIV

Biomass fuel and preparation method therefor

The present invention provides biomass fuel and a preparation method therefor. The biomass fuel comprises the following ingredients in parts by weight: lignin, agricultural wastes, sea mud, sepiolite flocking, aluminum oxide, silane coupling agents, ammonium chloride, dimethyl silicone oil, yeast extract powder, capsaicin, di-tert-butyl hydroquinone, oxygenates, a shock-resistant and antiknock agent, a combustion improver, and a bulking agent. The biomass fuel has low moisture content and high lignin content. With the use of a large amount of agricultural wastes, air pollution caused by burning agricultural wastes and other activities is greatly reduced, and recycling utilization value is improved, so that the biomass fuel is more environmentally friendly. Compared with conventional biomass fuel particles, the biomass fuel provided by the present invention has a high fuel value, a long burning time, no discharge of harmful gas after combustion, and no corrosion on a combustion device.

Owner:太仓东浔生物科技有限公司

Resin composition for insulation film, and insulation film and circuit board containing same

ActiveCN103319853AImprove heat resistanceLow dielectric constantPrinted circuit detailsPolymer sciencePtru catalyst

The invention provides a resin composition for an insulation film, and the insulation film and a circuit board containing the same. The resin composition comprises: (A) 100 parts by weight of epoxy resins; (B) 20 to 100 parts by weight of a polybutadiene styrene divinylbenzene graft terpolymer resin; (C) 2 to 20 parts by weight of di-tert-butylhydroquinone; (D) 5 to 50 parts by weight of a polyphenylene ether modified cyanate ester resin; and optionally containing at least one of the following components: (E) an inorganic filler, (F) a refined extending sealing agent and (G) a catalyst. By containing the specific components and proportions, the resin composition can achieve high heat resistance, low dielectric constant and low dissipation factor, and is halogen-free, and thus the resin composition can be applied in a protection film of a printed circuit board, an insulating protection film of an electronic building brick or a resin insulation film of a lead frame.

Owner:ELITE MATERIAL

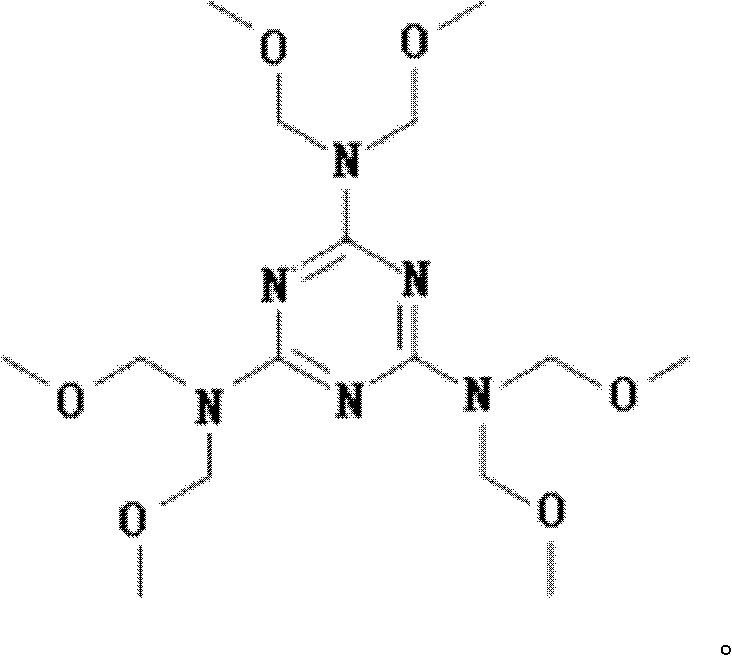

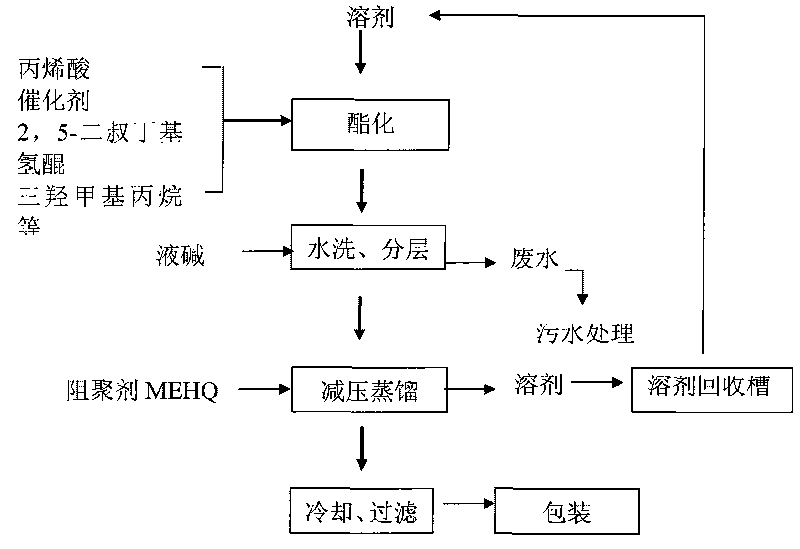

Trimethylolpropane triacrylate and preparation method thereof

ActiveCN101704745AShort reaction timeEasy to washOrganic compound preparationCarboxylic acid esters preparationReaction temperatureWaste treatment

The invention relates to trimethylolpropane triacrylate and a preparation method thereof. The formula of the trimethylolpropane triacrylate comprises the following raw materials in part by weight: solvent 20-50, trimethylolpropane 18-25, catalyst 4-8, 2,5-di-tert-butylhydroquinone 0.06 to 0.1 and acrylic acid 15-20. The preparation method comprises: placing the raw materials into a reaction kettle according to requirements of the formula and stirring the raw materials to perform reaction for 2 to 9 hours; starting a vacuum pump and raising the temperature in the reaction kettle till refluxingis generated and keeping refluxing for 1 to 3 hours; stopping raising the temperature when detecting the mass percentage of hydroxyl in reaction solution is 2 to 4 percent; adding caustic soda liquidinto the reaction kettle, controlling the pH value of the solution to be 7 to 8; standing the solution for delamination; leading waste water in the lower layer to a waste water treatment system; preferably adding polymerization inhibitor into the solution from which the waste water is removed; and distilling the solution at reduced pressure to remove methylbenzene and obtaining the product. Compared with the prior art, the method has the advantages of short reaction time, few by products, low reaction temperature and low production cost.

Owner:CAC NANTONG CHEM

Method for inhibiting generation of grease in MTO alkali wash system

ActiveCN103964993AOvercome the shortcomings that affect the effect of MTO alkaline cleaningHigh suppression efficiencyHydrocarbon purification/separationHydrocarbonsAntioxidantTower

The invention relates to a method for inhibiting generation of grease in an MTO alkali wash system, and mainly solves the problem about much grease in the prior art. According to the adopted method for inhibiting generation of grease in the MTO alkali wash system, a grease inhibitor is added into an MTO alkali wash tower, and the inhibitor comprises 5-15 percent of an antioxidant, 10-20 percent of a polymerization inhibitor, 5-15 percent of a dispersing agent and 50-80 percent of a solvent in mass fraction; the antioxidant is 2,5-di-tert-butylhydroquinone diphosphonate, the polymerization inhibitor is triacetonamine, and the dispersing agent is sodium thiosulfate. Due to adoption of the technical scheme, the problem can be better solved, and the method can be used for inhibition of generation of the grease in the MTO alkali wash system.

Owner:CHINA PETROLEUM & CHEM CORP +1

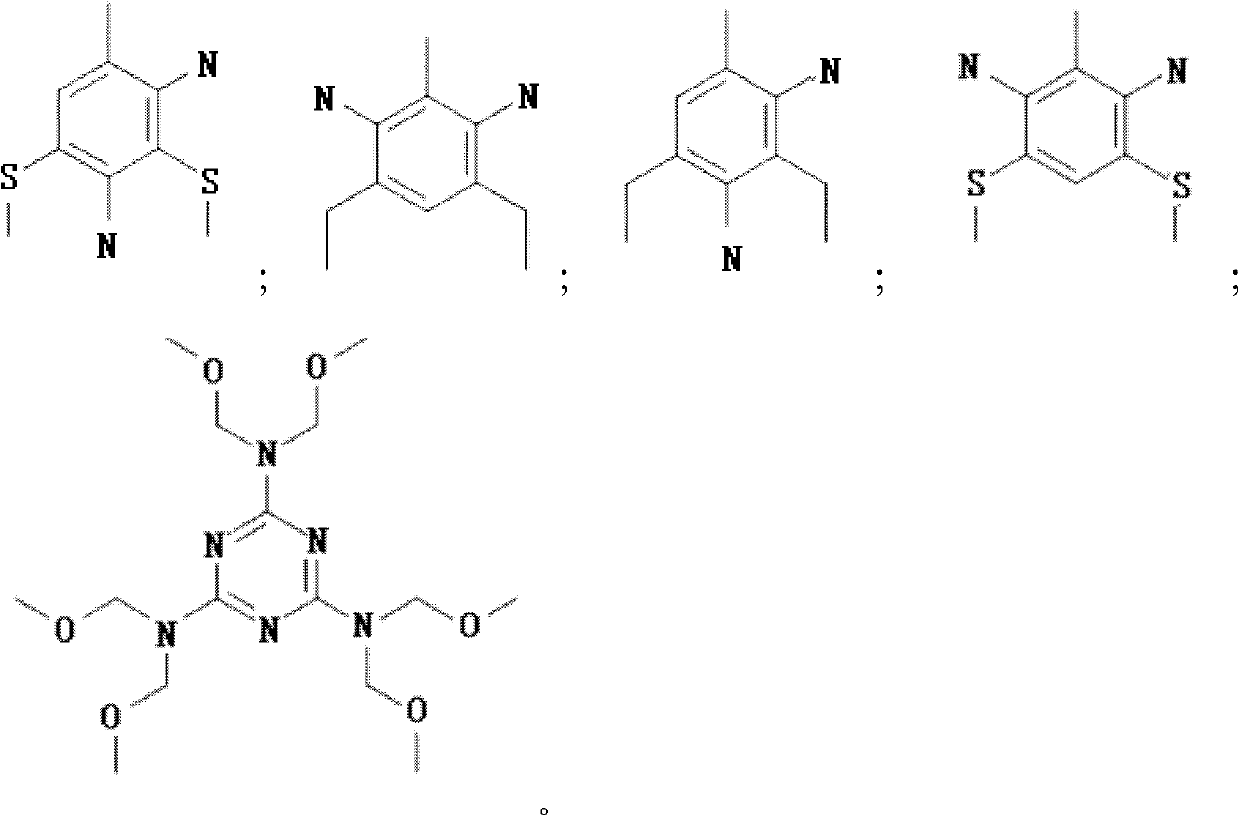

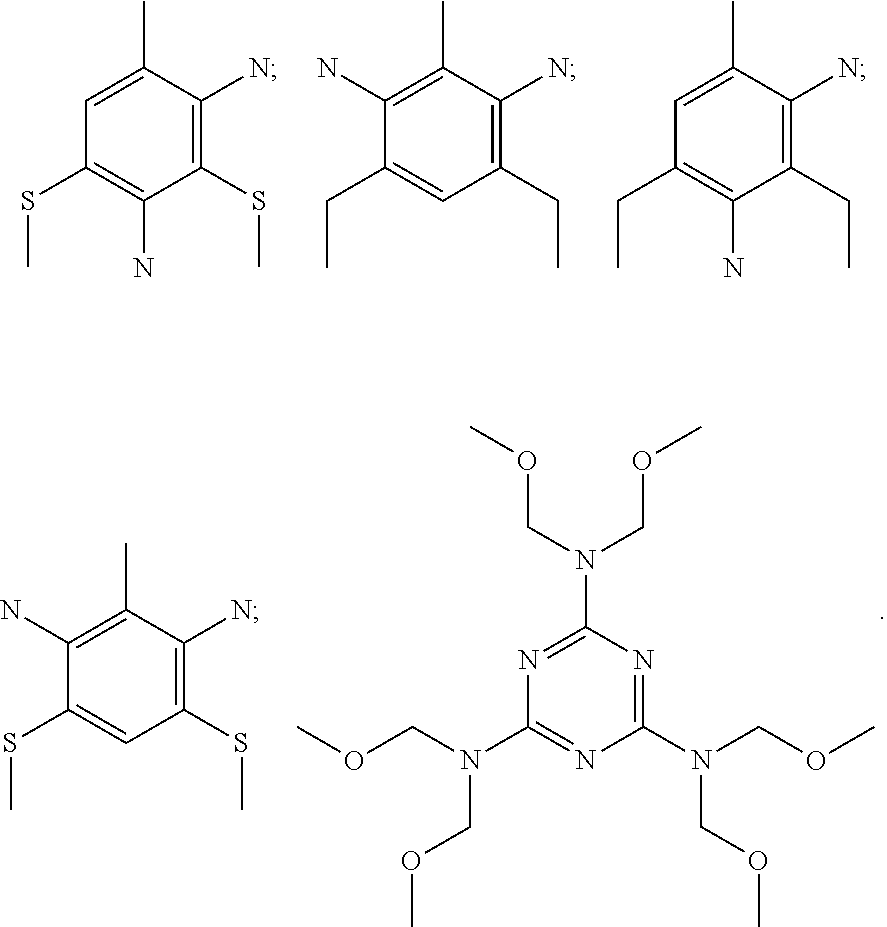

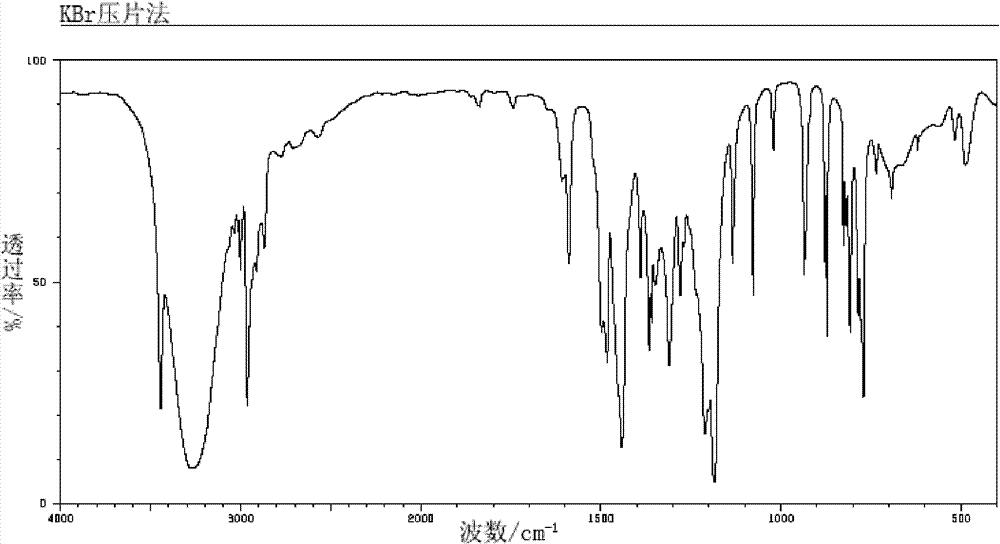

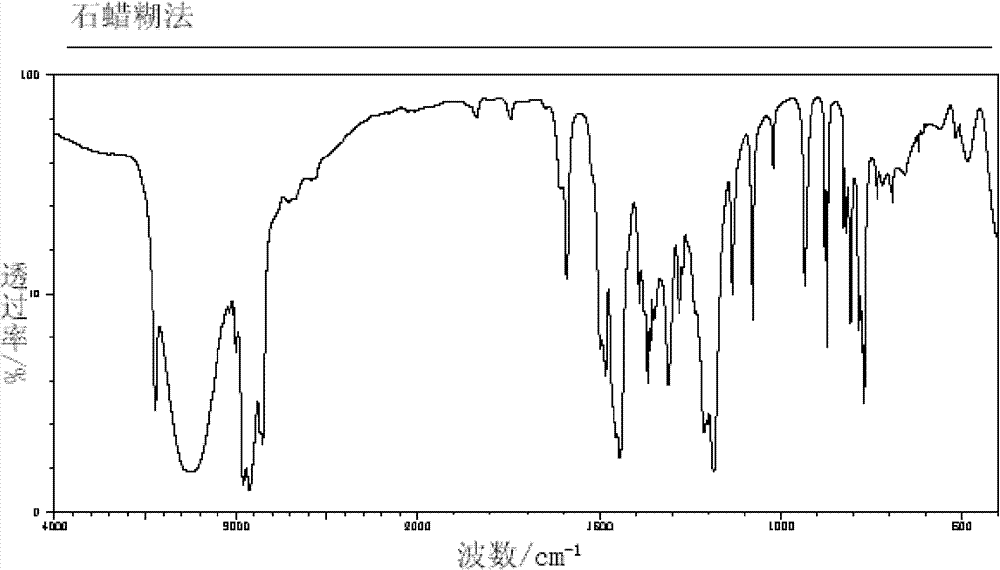

Directional synthetic method of 2, 5-di tertiary butyl hydroquinone

ActiveCN104003847AHigh selectivityAtom economy is highOrganic chemistryOrganic compound preparationChemical synthesisOrganic solvent

The invention belongs to the fields of fine chemicals and chemical synthesis, and discloses a directional one-step synthetic method of 2, 5-di tertiary butyl hydroquinone. According to the method, tertiary butyl alcohol and hydroquinone are used as raw materials for directional synthesis of the 2, 5-di tertiary butyl hydroquinone in the presence of a catalyst and water as a solvent. The directional one-step synthetic method of the 2, 5-di tertiary butyl hydroquinone is simple and convenient in operation and low in requirement on equipment; the yield of the 2, 5-di tertiary butyl hydroquinone can reach 90%, the purity reaches more than 99%, almost all the raw materials are converted into the target product, the selectivity and high atom economy are high; the directional one-step synthetic method is less in catalyst attrition, and avoids the use of aromatic hydrocarbons and ketones and other organic solvents, and the reaction mother liquor can be used repeatedly, the pollution of the environment can be minimized.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of high-performance fluoride rubber/silicone rubber cable sheath material

InactiveCN105802090AGood weather resistanceAccelerated corrosionRubber insulatorsInsulated cablesElastomerCalcium silicate

The invention discloses a preparation method of a high-performance fluoride rubber / silicone rubber cable sheath material. The preparation method comprises the following steps of performing primary mixing on fluoride rubber, silicone rubber, epoxy acrylate elastomer, hydrogenated butadiene-acrylonitrile rubber, maleic anhydride grafted polyethylene and methyl vinyl silicone rubber grafted methacrylic acid-2,2,2-trifluoroethyl to obtain a primary rubber compound; adding carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofibers, sepiolite fibers and calcium hydroxide, and mixing for 1 to 5 minutes; adding 2,6-di-tert-butyl paraaminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane, 5,5'- dimethyl-5,10-dihydracridine, and mixing for 3 to 8 minutes; adding stearic acid, inositol hexaphosphate, epoxidized linseed oil, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, N,N'-meta phenylene bismaleimide, phenolic resin and an accelerator, mixing for 5 to 10 minutes and then vulcanizing for two times.

Owner:ANHUI HUAYU CABLE GRP

Purification method for tertiary butyl hydroquinone

InactiveCN102838454AHigh purityReduce processing costsOrganic chemistryOrganic compound preparationPurification methodsHydroquinone Compound

The invention discloses a purification method for tertiary butyl hydroquinonel, relates to the tertiary butyl hydroquinone, and provides the purification method for the tertiary butyl hydroquinonel, which has the advantages of high efficiency, simple method and capability of meeting national food safety standard. The purification method comprises the following steps of: (1) uniformly mixing hydroquinone, tertiary butyl hydroquinonel and 2,5-ditertbutylhydroquinone, adding water, stirring and then filtering mixture; (2) adding filter cakes obtained by the step (1) into formic acid, recrystallizing, separating out the 2,5-ditertbutylhydroquinone and filtering off the 2,5-ditertbutylhydroquinone; and (3) desolventizing filtrate obtained by the step (2), removing the formic acid to obtain the tertiary butyl hydroquinonel and recycling the formic acid. The content of the obtained tertiary butyl hydroquinonel can reach up to 99 percent.

Owner:XIAMEN UNIV +1

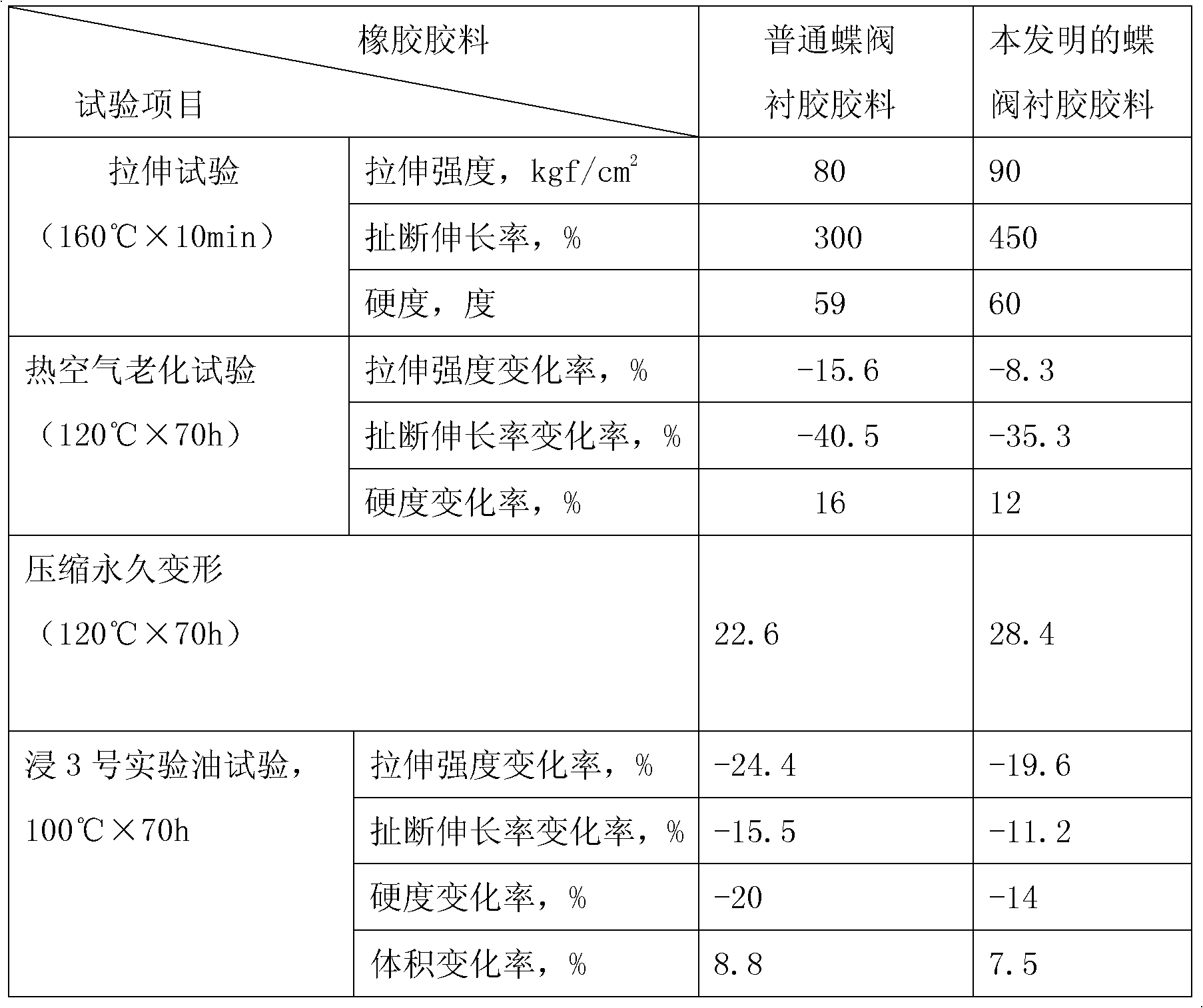

Rubber lining rubber material for corrosion resisting butterfly valve lined with rubber, and preparation method for rubber lining rubber material

The invention discloses a rubber lining rubber material for a corrosion resisting butterfly valve lined with rubber. The rubber lining rubber material is formed by mixing a rubber material A and a rubber material B, wherein the rubber material A comprises the following raw materials in part by weight: 85 to 95 parts of nitrile rubber 3305, 0.3 to 0.5 part of sulphur, 4 to 6 parts of magnesium oxide, 3 to 4 parts of stearic acid, 1 to 2 parts of antioxygen 2,5-di-tert-butylhydroquinone (DTBHQ), 1 to 2 parts of antiager RD, 1 to 2 parts of antiager 4010NA, 3 to 4 parts of paraffin, 22 to 25 parts of fast extrusion carbon black, 62 to 65 parts of high wear resistant carbon black 330, 18 to 22 parts of dioctyl ester, 25 to 35 parts of calcium carbonate, 3 to 4 parts of accelerator, 1 to 2 parts of accelerator tetramethylthiuram disulphide (TMTD), and 1 to 2 parts of accelerator tetraethyl-thinram disulfide (TETD); and the rubber material B comprises the following raw materials in part by weight: 82 to 87 parts of homopolymerization epichloro-hydrin rubber, 12 to 18 parts of copolymerization epichloro-hydrin rubber, 1 to 2 parts of zinc stearate, 1 to 3 parts of antiager RD, 0.4 to 0.6part of rubber change element, 1 to 2 parts of rhine wax, 45 to 55 parts of fast extrusion carbon black, 10 to 14 parts of kieselguhr, 5 to 8 parts of dioctyl ester,4 to 6 parts of lead dioxide, 0.8 part of vulcanizer trithiocyanuric acid (TCY), and 1 to 2 parts of accelerator Na-22. The rubber lining rubber material has good comprehensive performance, and the butterfly valve which is obtained through vulcanization has the characteristics of high air tightness, weather fastness, chilling resistance, and oil resistance and the like; meanwhile, the material cost is low.

Owner:安徽金源流体控制技术有限公司

Method for controlling polymerization in rectification process of 1,4-cyclohexanedimethanol

ActiveCN102795966AReduce generationOrganic compound preparationHydroxy compound preparationCyclohexanedimethanolBoiling point

The invention relates to a method for controlling polymerization in a rectification process of 1,4-cyclohexanedimethanol. A rectification method is mainly adopted. The method is characterized in that a rectification tower with the height of 12 meters and the diameter of 0.8 meter is used, and 2,5-ditertbutyl hydroquinone polymerization inhibitor is rectified in vacuum of 0.100MPa below zero. The invention has the advantages that the colorless and transparent 1,4-cyclohexanedimethanol of which the content is more than 99.9 percent can be obtained by adopting the method. The method is adopted by the following reasons that when a crude product is rectified, because the boiling point of the 1,4-cyclohexanedimethanol is 286 DEG C, the 1,4-cyclohexanedimethanol is dehydrated and polymerized very seriously at a high temperature, and the yield (the rectification yield is about 90 percent) of the 1,4-cyclohexanedimethanol is greatly affected; and by using the rectification tower with the height of 12 meters and the diameter of 0.8 meter and adding the 2,5-ditertbutyl hydroquinone polymerization inhibitor in the vacuum of 0.100MPa below zero, high-temperature dehydration and polymerization of the 1,4-cyclohexanedimethanol are greatly reduced, and the rectification yield is over 97 percent.

Owner:江苏恒祥化学股份有限公司

Improved aging-resistant waterproof coating material

The invention discloses an improved aging-resistant waterproof coating material. The improved aging-resistant waterproof coating material is prepared from the following raw materials in parts by weight: 5-10 parts of fluoro-olefin resin, 2.5-3.8 parts of 4-methyl guaiacol, 3.5-8 parts of glycol, 2.5-7 parts of white latex, 1.2-3.5 parts of propylene glycol methylether acetate, 1.2-2.8 parts of trimethylol propane triacrylate, 1.5-3.6 parts of 5-di-tert-butyl-hydroquinone and 2.3-3.8 parts of aluminum-carbon firebrick powder. According to the waterproof coating material disclosed by the invention, the aluminum-carbon firebrick powder is added, and density differences exist between the aluminum-carbon firebrick powder and other ingredients, so that when the waterproof coating material disclosed by the invention is coated on a waterproof surface, the aluminum-carbon firebrick powder in the waterproof coating material can be of layered distribution due to different densities and can exert a waterproof effect like that of two-felt three-oil; a finished product of the waterproof coating material has the advantages of convenience in construction, strong bonding power and tensile resistance and good ageing resistance.

Owner:南京施美特防水材料有限公司

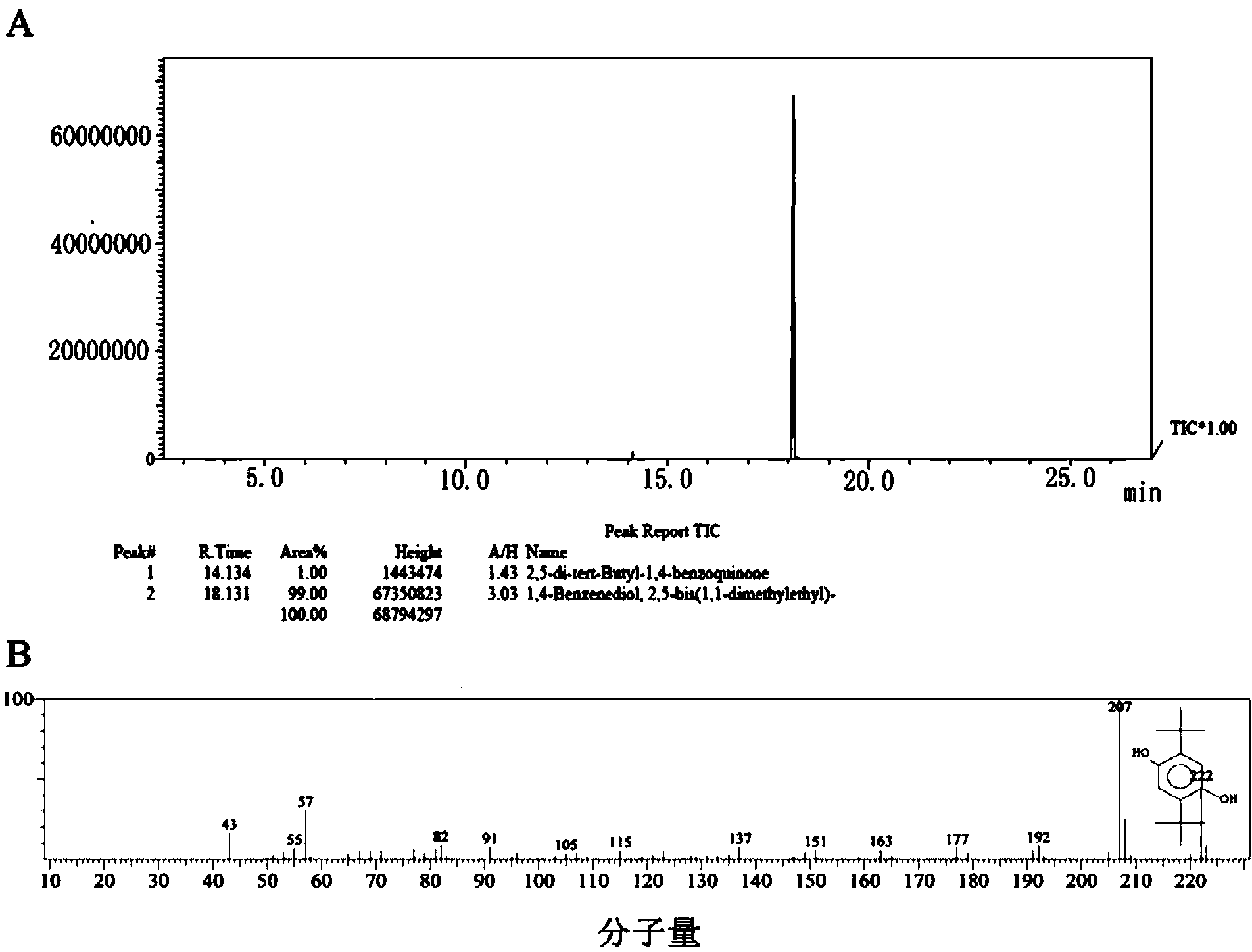

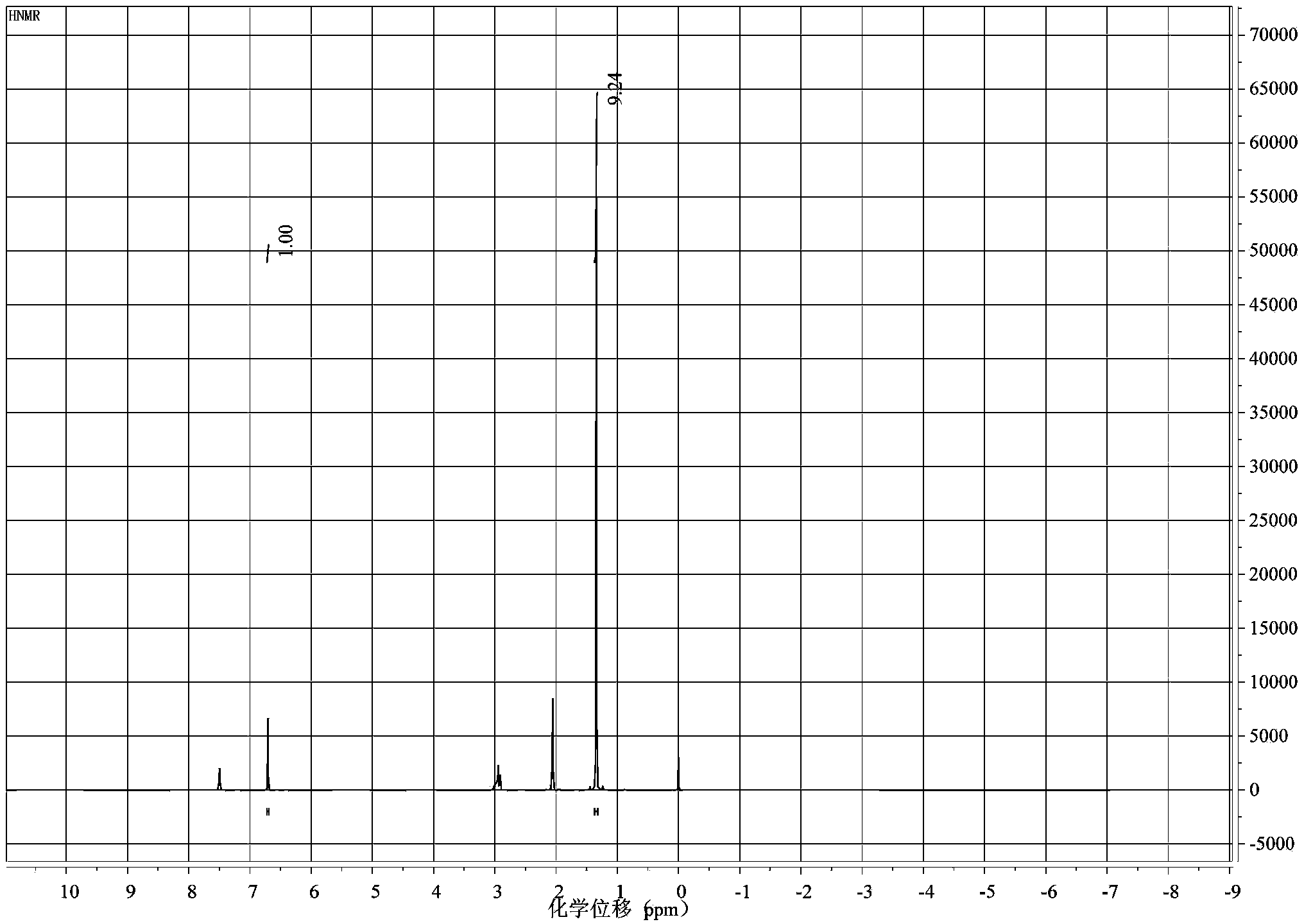

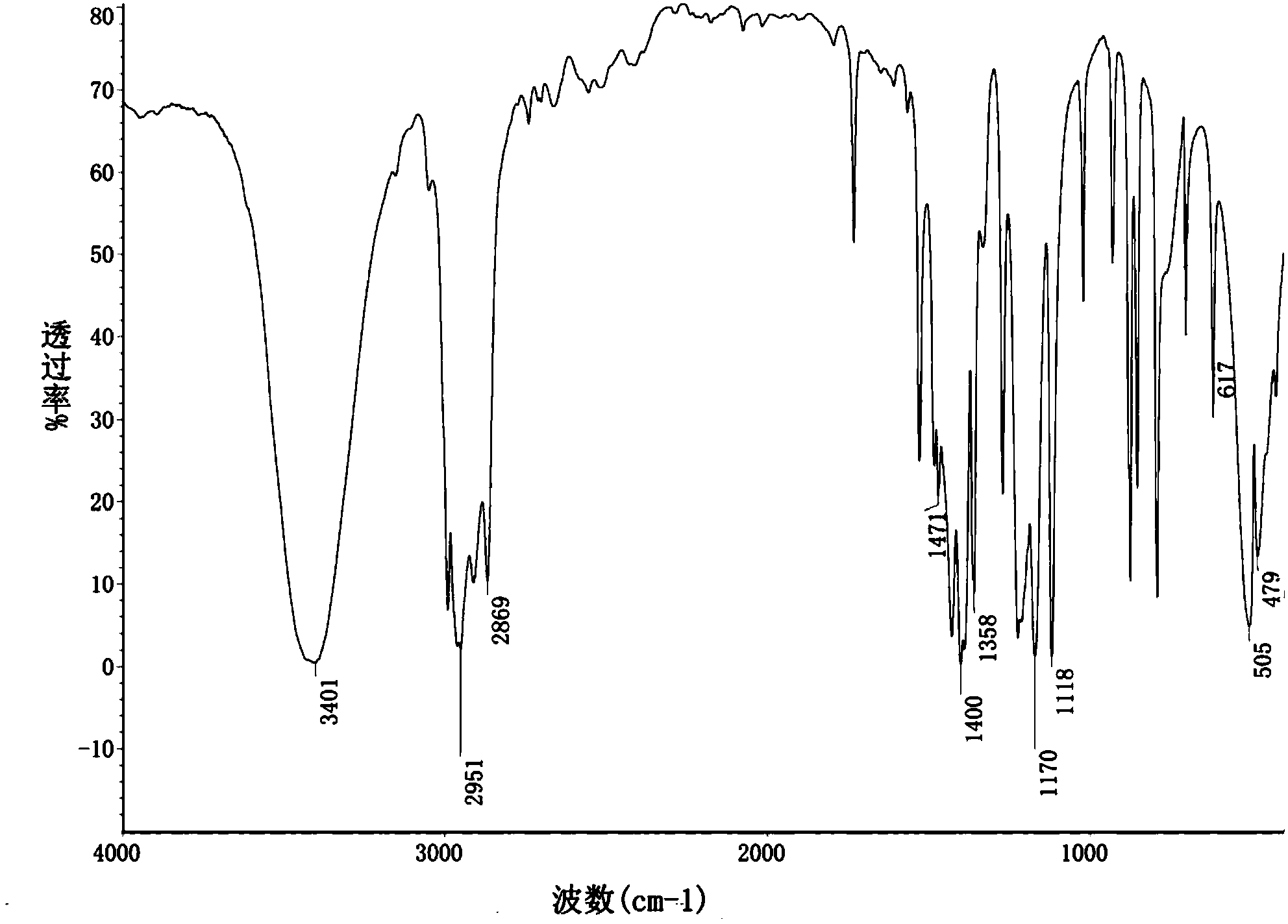

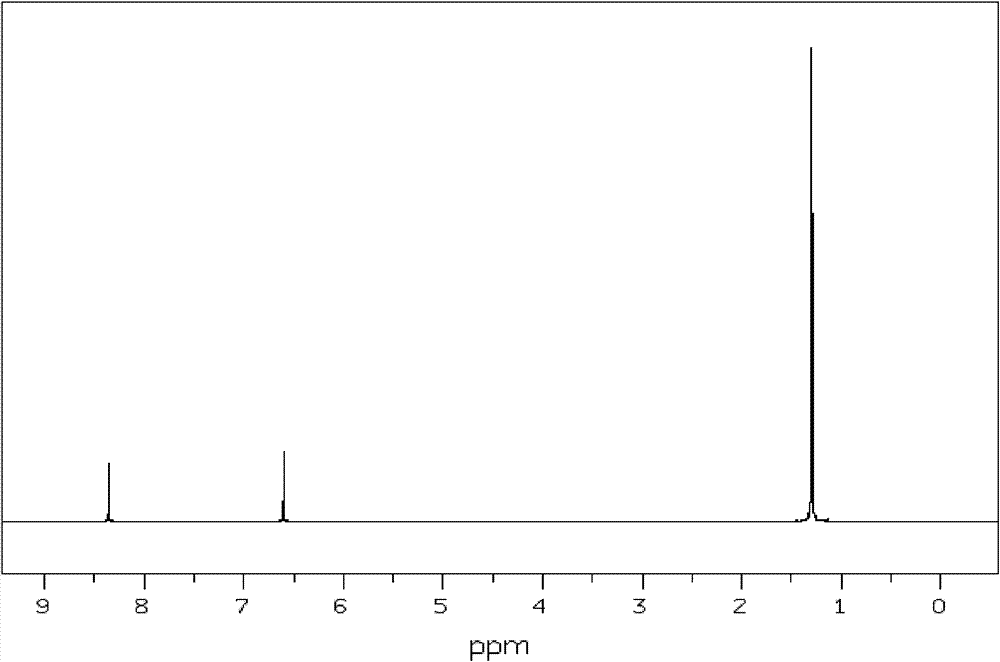

Production method of DTBHQ (2-5-di-tert-butylhydroquinone)

InactiveCN102190564AQuality improvementTBHQ content decreasedOrganic chemistryOrganic compound preparationEconomic benefitsTert-Butylhydroquinone

The invention discloses a production method of DTBHQ (2-5-di-tert-butylhydroquinone), which comprises the following steps: predrying, soaking in hot water, carrying out primary centrifugalizing, soaking in a solvent, carrying out post centrifugalizing, drying, pulverizing and screening. In the invention, before the crude product is soaked, the crude product is soaked in hot water to remove part of TBHQ (tert-butylhydroquinone), so that the content of the TBHQ in the crude product is relatively decreased, and the content of the DTBHQ is relatively increased, thereby enhancing the quality of the final product; meanwhile, the mass ratio of tert-butyl alcohol to water is adjusted, and the utilization ratio of raw materials is increased; and in addition, the invention controls the overall production process more precisely, thereby being beneficial to obtaining the product with higher quality and saving the production cost, and obvious economic benefit can be obtained after large-scale production is implemented.

Owner:GUANGZHOU TAIBANG FOOD TECH

Biodiesel antioxidant and application method thereof

InactiveCN105733713AImprove Oxidation StabilityImprove qualityBiofuelsLiquid carbonaceous fuelsBiodieselAntioxidant

The present invention is a biodiesel antioxidant and an application method thereof. The biodiesel antioxidant is prepared from a primary antioxidant and a secondary antioxidant by compounding, the primary antioxidant is 2,6-di-tert-butylhydroquinone, the secondary antioxidant is beta, beta,-thiodipropionic acid dilauryl ester, and the weight percentage of the primary antioxidant is 40-60%. The biodiesel antioxidant can significantly increase the oxidation stability of biodiesels, greatly improves the quality and grade of the biodiesels, is low in price and low in dosage, can effectively extend the service life of oil products. At the same time, the added antioxidant has no obvious effect on other physical and chemical properties of the biodiesels.

Owner:上海天之冠可再生能源有限公司

Energy-saving engineering machinery hydraulic oil and preparation method thereof

InactiveCN105820860AImprove wear resistanceReduce consumptionLubricant compositionIndustrial equipmentLubrication

The invention discloses energy-saving engineering machinery hydraulic oil. The energy-saving engineering machinery hydraulic oil is prepared from, by weight, 0.2-0.9 part of tricresyl phosphate, 0.8-1.2 parts of antiwear agent, 4-6 parts of benzotriazole octadecylamine salt, 2-4 parts of ethylene glycol oleate, 75-85 parts of hydrogenated styrene isoprene copolymer, 1.5-2.5 parts of monoene succinimide, 1.5-2.5 parts of 2,5-di-tert-butylhydroquinone, 2.5-3.5 parts of 4,4'-dioctyl diphenylamine, 4-8 parts of polymethacrylate, 0.02-0.04 part of dimethicone and 850-950 parts of base oil. The energy-saving engineering machinery hydraulic oil has good wear resistance and can provide a lubrication guarantee in time at different working stages; equipment runs stably, pressure is evenly transferred, friction and abrasion are reduced, temperature rise is low, heat dissipation is rapid, power losses are reduced, energy consumption is reduced, and the oil replacement period is prolonged. The energy-saving engineering machinery hydraulic oil is suitable for hydraulic systems of various kinds of industrial equipment, engineering machinery, metallurgical machinery and the like.

Owner:广州国机润滑科技有限公司

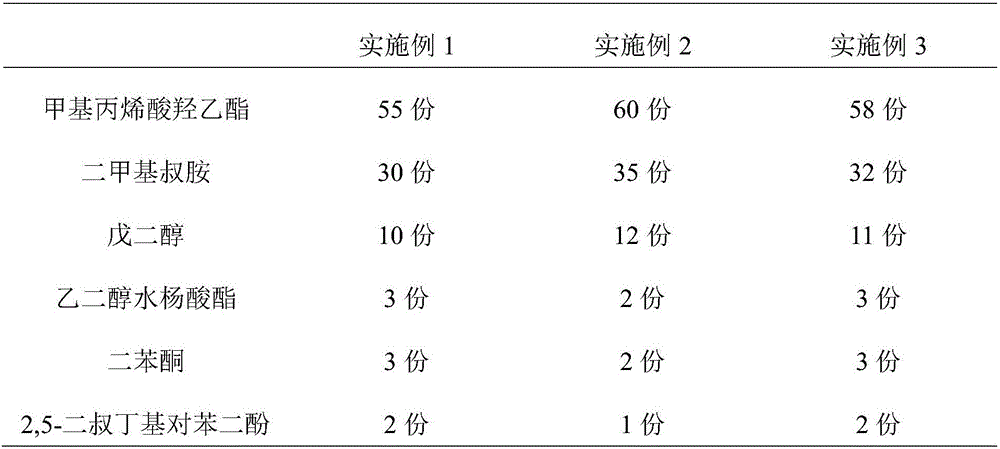

Aluminum alloy section wooden transfer method

InactiveCN106379098ANatural patternsDecorative surface effects(Hydroxyethyl)methacrylatePerformance index

The invention discloses an aluminum alloy section wooden transfer method. Firstly, an aluminum alloy section is subject to surface treatment; the surface of the aluminum alloy section is subject to transfer primer electrostatic spraying, and curing is achieved; and finally wooden transfer is carried out on the surface of transfer primer. The transfer primer is composed of hydroxyethyl methylacrylate, dimethylamine, pentanediol, hydroxyethyl salicylate, benzophenone and 2,5-ditert-butyl hydroquinol. The aluminum alloy section wooden transfer method has the remarkable effect that the primer film hardness, the abrasive resistance, the shock resistance, the hydrochloric acid resistance, the mortar resistance, the solvent resistance, the washing fastness resistance, aberration and other performance indexes are higher than the standards.

Owner:广安市鼎鑫金属科技有限公司

Synthetic method for dicyclopentadiene ethoxy methacrylate

InactiveCN106045849AReduce manufacturing costSimple stepsOrganic compound preparationCarboxylic acid esters preparationHydroxybenzoate Ethers(Hydroxyethyl)methacrylate

The invention relates to a simple synthetic method for dicyclopentadiene ethoxy methacrylate. The synthetic method is characterized in that in the presence of an appropriate catalyst and polymerization inhibitor, addition reaction of hydroxyethyl methacrylate and dicyclopentadiene is used for synthesizing dicyclopentadiene ethoxy methacrylate. The catalyst is strong acid or super acid and includes boron trifluoride diethyl etherate, chlorosulfonic acid, fluorosulfuric acid, trifluoro sulfoacid, polyphosphoric acid, phosphotungstic acid and silicotungstic acid. The polymerization inhibitor is one of or a combination of phenothiazine, hydroquinone, p-benzoquinone, p-hydroxyanisole, 2-tert-butyl-hydroquinone, 2,5-di-tert-butylhydroquinone, dibutyl dithiocarbamic acid and 2,2,6,6-tetramethyl-4-hydroxy-piperidine nitroxide free radical, wherein the combination is formed by two components mentioned above.

Owner:山东瑞博龙化工科技股份有限公司

Resin composition for insulation film

ActiveUS8808862B2Improve heat resistanceLow dielectric constantSynthetic resin layered productsDomestic articlesDivinylbenzenePolybutadiene

A resin composition includes (A) 100 parts by weight of epoxy resin; (B) 20 to 100 parts by weight of polybutadiene styrene divinylbenzene graft terpolymer resin; (C) 2 to 20 parts by weight of di-tert-butylhydroquinone (DTBHQ); (D) 5 to 50 parts by weight of polyphenyl ether modified cyanate ester resin; and at least one of (E) inorganic filler, (F) chain extending sealing agent, and (G) catalyst. The resin composition is characterized by specific ingredients and proportions thereof to attain high heat resistance, low dielectric constant Dk, and low dielectric dissipation factor Df, and being halogen-free, and therefore is applicable to protective film of printed circuit boards, insulating protective film of electronic components, and resin insulation film of leadframes.

Owner:ELITE MATERIAL

Fireproof and anti-corrosion wall body heat insulation and thermal isolation paint material

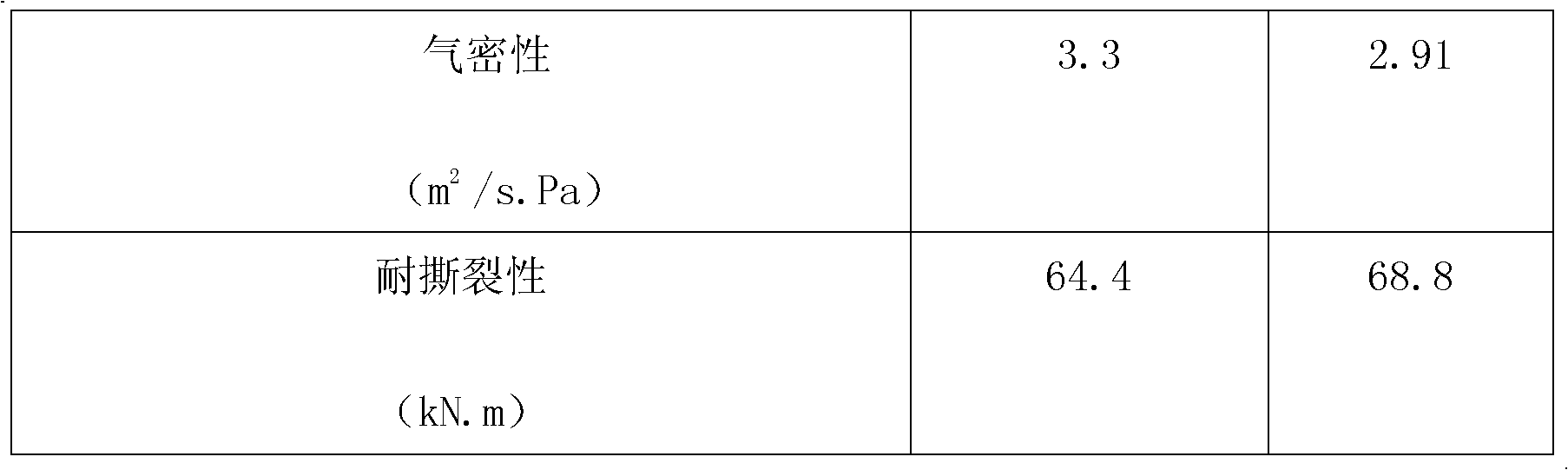

InactiveCN106634110AImprove insulation effectImprove fire performanceFireproof paintsAnti-corrosive paintsThermal isolationPoly(butylene succinate)

The invention discloses a fireproof and anti-corrosion wall body heat insulation and thermal isolation paint material, which is prepared from the following raw materials in parts by weight: 40 to 60 parts of epoxy resin, 10 to 20 parts of molybdenum-modified phenolic resin, 5 to 10 parts of poly(butylene succinate), 10 to 20 parts of EVA emulsion, 3 to 12 parts of hydroxyl silicone oil, 20 to 30 parts of ceramic hollow microspheres, 10 to 20 parts of silicon dioxide hollow spheres, 5 to 10 parts of triallyl isocyanurate, 3 to 8 parts of polyanionic cellulose, 8 to 15 parts of propylene glycol, 5 to 15 parts of hydrotalcite powder, 1 to 3 parts of sodium polyacrylate, 2 to 6 parts of polyvinyl pyrrolidone, 6 to 12 parts of ethylene glycol diglycidyl ether, 0.5 to 1.5 parts of 2,5-di-tert-butylhydroquinone, 5 to 15 parts of vinyl tris(beta-methoxyethoxy) silane, 2 to 5 parts of tetraphenyl bisphenol A diphosphate and 15 to 30 parts of deionized water. The fireproof and anti-corrosion wall body heat insulation and thermal isolation paint material belongs to a wall body heat insulation and thermal isolation paint material obtained through experiments for multiple times, and has the advantages that the good thermal isolation and heat insulation performance is realized; meanwhile, good flame retardant and fireproof performance, weather resistant performance and anti-corrosion performance are realized.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

Modified aluminum nitride powder toughened epoxy resin composite material and manufacture method thereof

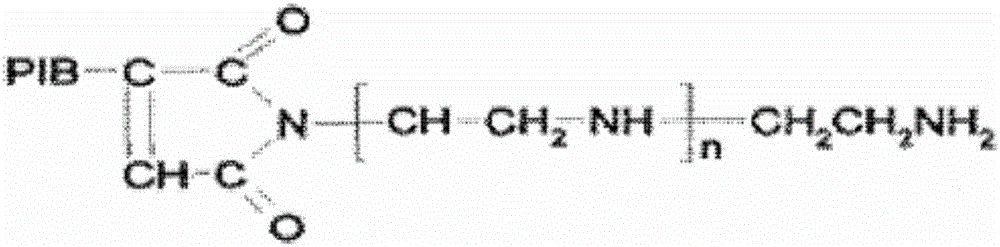

InactiveCN104403272AHigh hardnessGood anti-corrosion and waterproof performanceEpoxyTemperature resistance

The invention discloses modified aluminum nitride powder toughened epoxy resin composite material. The modified aluminum nitride powder toughened epoxy resin composite material is characterized by being prepared from the following raw materials in parts by weight: 49 to 59 parts of epoxy resin, 2 to 3 parts of aluminum nitride powder, 5 to 8 parts of linseed oil, 1.2 to 3.2 parts of dicumyl peroxide, 0.8 to 1.4 parts of a titanate coupling agent TMC-TTS, 7 to 9 parts of dioctyl sebacate, 8 to 10 parts of diethylene glycol dimethacrylate, 4 to 7 parts of polyvinylpyrrolidone, 6 to 9 parts of 2,5- di-tert-butylhydroquinone, 10 to 13 parts of dipropylene glycol methyl ether, 3 to 5 parts of polyisobutene, 4 to 7 parts of imethylaminopropylamine, and 3 to 6 parts of an assistant. The modified aluminum nitride powder toughened epoxy resin composite material has the advantages that the aluminum nitride powder is taken as a filler and is subjected to surface treatment, meanwhile other effective constituents are mixed and added to the raw materials, epoxy resin prepared is high in hardness, temperature resistance, waterproofness and tenacity, and the performance of a coating prepared from the composite material is greatly improved.

Owner:WUHU BAOYI AMUSEMENT EQUIP

A kind of preparation technology of tert-butyl hydroquinone

ActiveCN105294403BReduce usageLow DTBHQ contentOrganic chemistryOrganic compound preparationWarm waterSolvent

The invention relates to the technical field of antioxidant preparation methods, and particularly relates to a preparation process of tert-butylhydroquinone (TBHQ). The preparation process comprises the following steps of (1) simultaneously adding excessive dilute sulphuric acid, equimolar hydroquinone and tertiary butyl acetate to a reaction still, wherein the weight ratio of the dilute sulphuric acid to the tertiary butyl acetate is 1:(3 to 6); (2) stirring and heating to 85 to 95 DEG C, and reacting for 1 to 8 hours; (3) stopping stirring, cooling to 65 to 75 DEG C, and then performing centrifugal filtration, wherein filtrate of sulphuric acid is recycled, and obtained filter residues are washed with 1 to 3 times warm water, so as to obtain a crude product of the TBHQ. Compared with the prior art, the preparation process has the advantages that the hydroquinone and the tertiary butyl acetate are used as raw materials, and the dilute sulphuric acid is used as a catalyst and a reaction solvent, so as to promote a reaction; tertiary butyl is supplied by the tertiary butyl acetate, so that side reactions are reduced; the crude product contains 70% to 75% of TBHQ, the content of DTBHQ (Di-Tert-Butylhydroquinone) as a by-product is low, the yield can reach 65 to 70% after purification, the yield is greatly increased, and great economic benefits are obtained.

Owner:东莞市感恩食品科技有限公司

Terminated poly(ether-ether-ketone), and preparation method thereof

ActiveCN102250299BImprove thermal stabilityGood chemical stabilityPoly ether ether ketoneHydroquinone

The invention relates to 2,5-di-tert-butyl-terminated poly(ether-ether-ketone) (PEEK), and a preparation method thereof. The end-capped poly(ether-ether-ketone) provided by the invention has advantages of easily controllable molecular weight, high heat resistance, good chemical stability, radiation resistance, good toughness, and the like.

Owner:吴疆

Heat-insulation coating

InactiveCN102702813BLow thermal conductivityImprove fire resistanceReflecting/signal paintsEpoxyAntioxidant

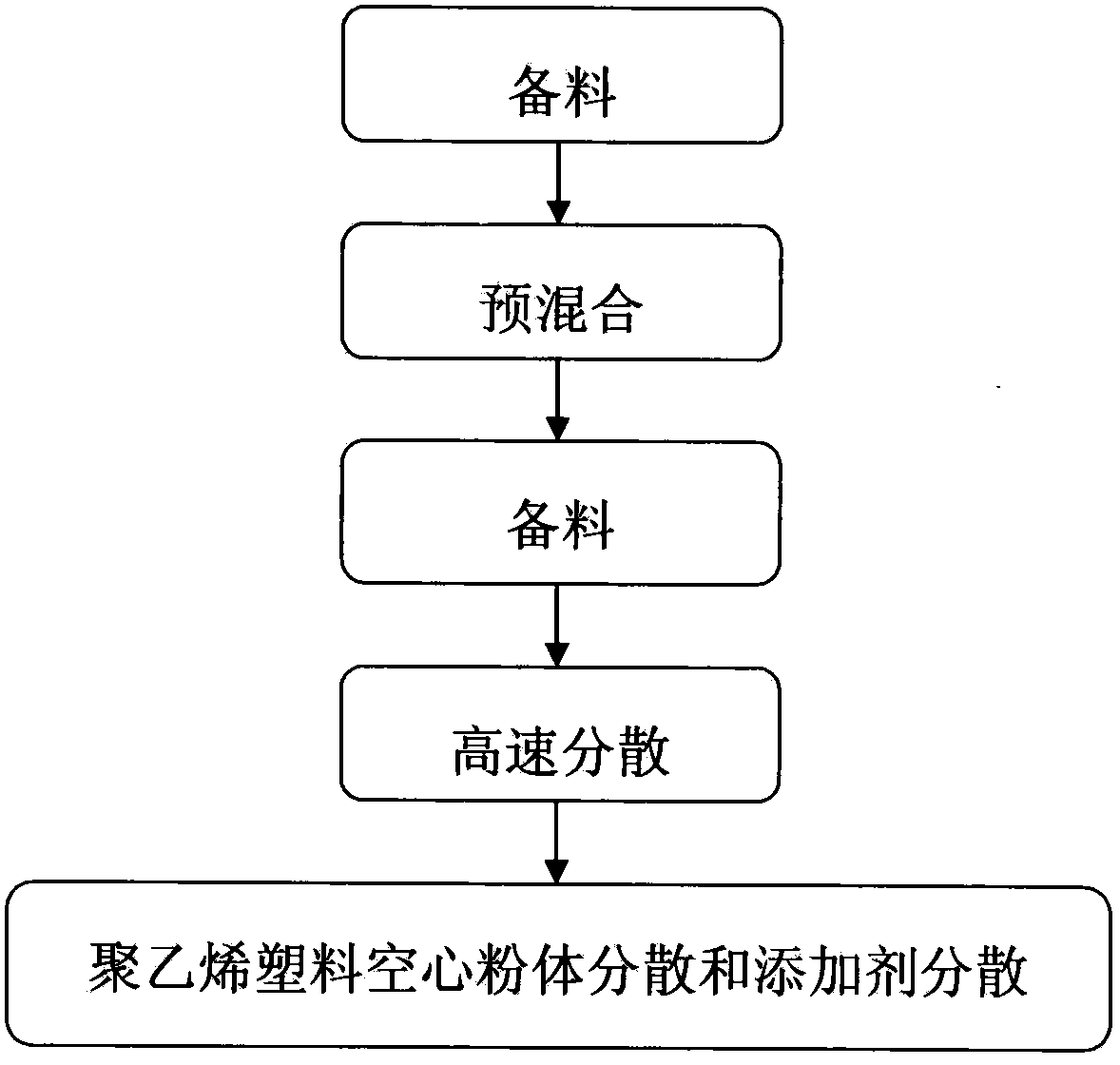

The invention relates to a heat-insulation coating which is prepared by blending the following raw materials in percent by weight: 20-25% of base epoxy resin, 15-20% of polyethylene plastic hollow powder as main body, 25-30% of water, 15-20% of adhesive A agent and 5-20% of additive B agent, wherein the A agent is composed of the following components in percentage by weight: 15% of methyl methacrylate, 35% of ethyl acrylate, 40% of butyl acrylate and 10% of activator; and the B agent is composed of the following components in percentage by weight: 20% of di-tertiary-butyl hydroquinone antioxidant, 25% of acid-resistant additive, 25% of alkaliproof additive, 10% of toughness additive and 20% of defoaming agent. After the coating is coated on the external walls of general cement houses, the room temperature can be decreased by 6-8 DEG C; flowing phenomenon does not exist when the temperature is more than 55-70 DEG C, and cracking and falling phenomena do not appear even if the temperature is lower than minus 40-minus 50 DEG C.

Owner:KARAMAY BEIDE CHEM

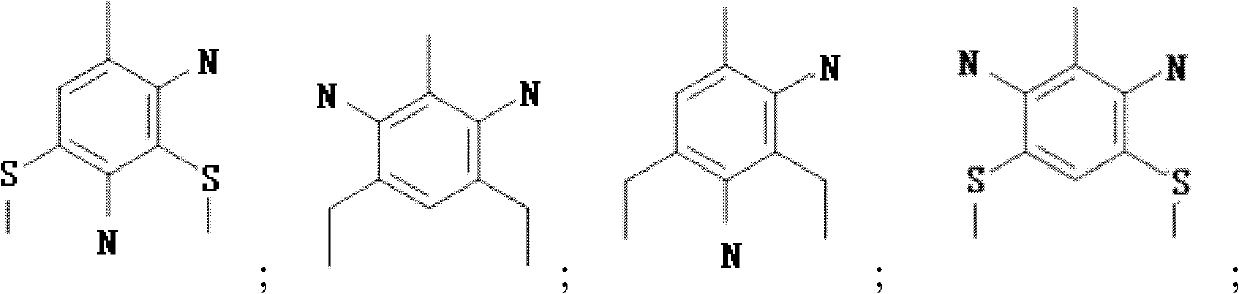

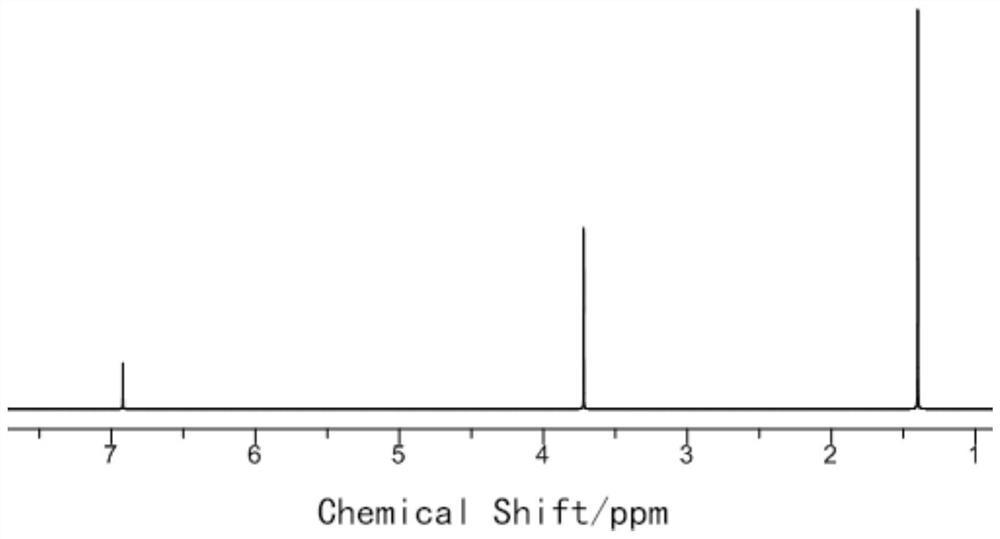

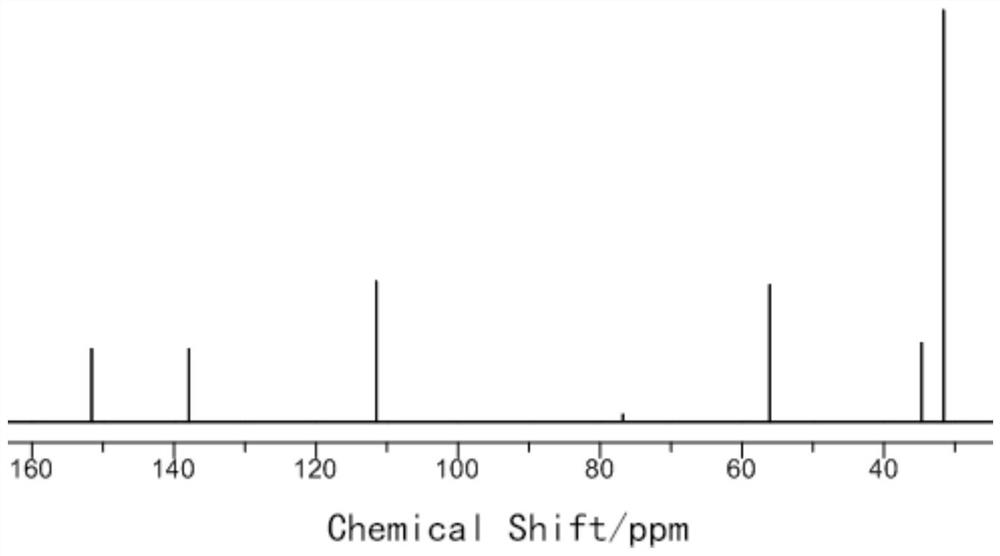

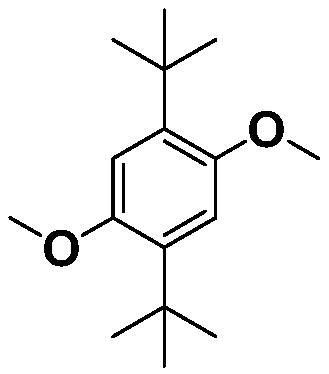

Preparation method of 2, 5-di-tert-butyl-p-dimethoxybenzene

InactiveCN112876342ALower requirementSimple processOrganic compound preparationEther preparation by ester reactionsPtru catalystOrganic solvent

The invention discloses a preparation method of 2, 5-di-tert-butyl-p-dimethoxybenzene, which comprises the following steps: (1) reacting tert-butyl alcohol with hydroquinone in a first solvent under the action of a first catalyst, cooling and crystallizing after the reaction is finished, filtering, washing and drying to obtain 2,5-di-tert-butyl hydroquinone; and (2) reacting the 2, 5-di-tert-butyl hydroquinone obtained in the step (1) with methyl iodide in a second solvent under the action of a second catalyst, cooling to room temperature after the reaction is finished, adding brine and an organic solvent into the reaction liquid for extraction, washing the obtained organic layer, and performing vacuum drying to obtain the 2, 5-di-tert-butyl-p-dimethoxybenzene product. The method has the advantages of simple process, mild reaction conditions, environmental protection, low cost and high yield.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Double-layer asphalt chloroethylene antistatic plastic floor

InactiveCN102373794AEasy to installLow priceSynthetic resin layered productsBuilding insulationsMethacrylateRare earth

The invention belongs to a PVC (Polyvinyl Chloride) floor, and in particular relates to a double-layer asphalt chloroethylene antistatic plastic floor. The double-layer asphalt chloroethylene antistatic plastic floor is characterized by comprising a double-layer structure, wherein a surface layer is made of an auxiliary material; a bottom layer is made of a primary material; in parts by weight, the primary material comprises 100-120 parts of polyvinyl chloride resin, 50-60 parts of asphalt, 20-30 parts of electro-conductive carbon black, 8-10 parts of rare earth stabilizer R108A, 25-30 parts of dipentaerythritol and 5-10 parts of ethoxylated aliphatic alkylamine; and the auxiliary material comprises 100-120 parts of polyvinyl chloride resin, 10-12 parts of MBS (Methacrylate-Butadiene-Styrene) resin, 3-5 parts of zinc stearate, 4-6 parts of dibutyl phthalate, 5-8 parts of tribasic lead sulfate and 2-4 parts of ditertbutyl hydroquinone resin. The double-layer asphalt chloroethylene antistatic plastic floor has the advantages of being convenient to pave and low in price, etc.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for ship cable

InactiveCN105860373AImprove low temperature resistanceEasy to processRubber insulatorsCalcium silicateCarbon nanotube

The invention discloses a special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for a ship cable. The material is prepared from fluoride rubber, fluorine-containing acrylate rubber, epoxy acrylate rubber, HNBR, maleic anhydride grafted polyethylene, stearic acid, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, trimethylolpropane trimethacrylate, phenolic resin, carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofiber, magnesium hydroxide, calcium hydroxide, inositol hexaphosphate, epoxidation triglyceride fatty acid, epoxy linseed oil, 2,6-ditert-butyl-p-aminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane and accelerant. The special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for the ship cable is high in strength, good in anti-ageing performance, excellent in oil resistance and low temperature resistance and capable of meeting use requirements of ship cable sheaths.

Owner:ANHUI HUAYU CABLE GRP

Specific unsaturated polyester resin for manufacturing metal polished particles and preparation method of specific unsaturated polyester resin

InactiveCN105542133ALow heat release temperatureAvoid crackingPolishing compositions with abrasivesCobaltAccelerant

The invention discloses specific unsaturated polyester resin for manufacturing metal polished particles and a preparation method of the unsaturated polyester resin. The preparation method of the unsaturated polyester resin comprises the following steps: adding phthalic anhydride, maleic anhydride and propylene glycol in a reaction kettle according to a mol ratio of (1.8 to 1.9): 1: (2.9 to 3.1), carrying out a melt phase polycondensation reaction at a temperature of 160 to 220 DEG C, and adding hydroquinone after the reaction is completed to obtain polycondensate; adding the polycondensate to styrene, and stirring to uniformly dilute at the temperature of 50 to 85 DEG C; reducing the temperature of the material to below 50 DEG C, sequentially adding benzoquinone, 2, 5-di-tert-butylhydroquinone, a cobalt-series accelerant and an amine-series accelerant, and uniformly stirring to obtain the finished product. The unsaturated polyester resin is low in viscosity, and short in gelation time; the metal polished particles prepared from the unsaturated polyester resin and filler have high Bacho hardness and good impact toughness.

Owner:CHANGZHOU TIANMA GROUP CO LTD

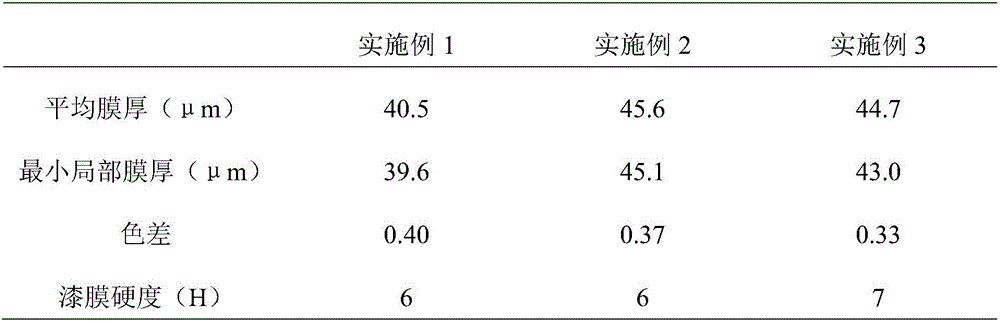

Nitrile rubber composition

InactiveUS20160152790A1Good effectSmall volume changeNon-metal conductorsConductive materialNitrile rubberPolymer science

A nitrile rubber composition comprising 5 to 50 parts by weight of carbon black, 5 to 60 parts by weight of graphite having an average particle diameter of 5 μm or less, 5 to 50 parts by weight of conductive carbon other than these carbon black and graphite, and 0.5 to 3.5 parts by weight of 2,5-di-tert-butylhydroquinone or 2,5-di-tert-amylhydroquinone as an antioxidant, based on 100 parts by weight of nitrile rubber. The nitrile rubber composition can yield a vulcanization molded product, besides maintaining characteristics as a conductive material, satisfying muddy water resistance, sealing properties, and low torque characteristics required for rolling bearing oil seals for vehicles, etc., and having a rubber volume change kept low when the product is washed with water after exposure to an antifreezing agent.

Owner:NOK CORP

A kind of biomass fuel and preparation method thereof

ActiveCN105419899BReduce moisture contentHigh lignin contentBiofuelsSolid fuelsEnvironmental resistanceCapsaicin

The invention provides a biomass fuel and a preparation method thereof. The biomass fuel includes the following ingredients in parts by weight: lignin, agricultural waste, sea mud, sepiolite wool, alumina, silane coupling agent, chlorinated Ammonium, simethicone, yeast powder, capsaicin, di-tert-butyl hydroquinone, oxygen enhancer, anti-shock and explosion-proof agent, combustion enhancer, loosening agent. The biomass fuel has low moisture content and high lignin content, and utilizes a large amount of agricultural waste, which not only greatly reduces the air pollution caused by activities such as burning agricultural waste, but also improves the use value of recycling and is more environmentally friendly. Compared with conventional biomass fuel particles, it has high combustion value, long combustion time, no harmful gas emission after combustion, and will not corrode combustion equipment.

Owner:太仓东浔生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com