Patents

Literature

31results about How to "Good anti-corrosion and waterproof performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

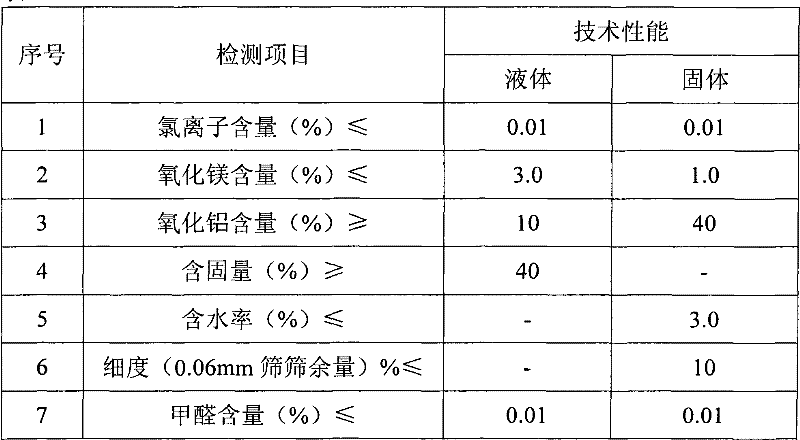

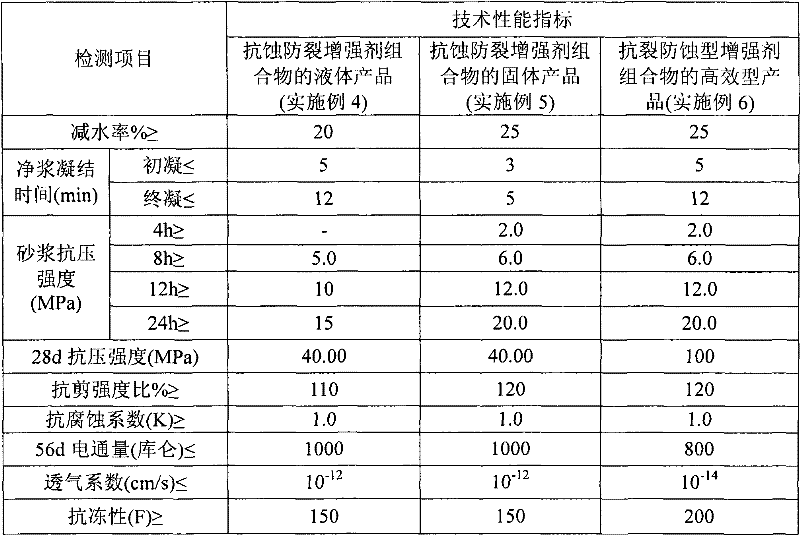

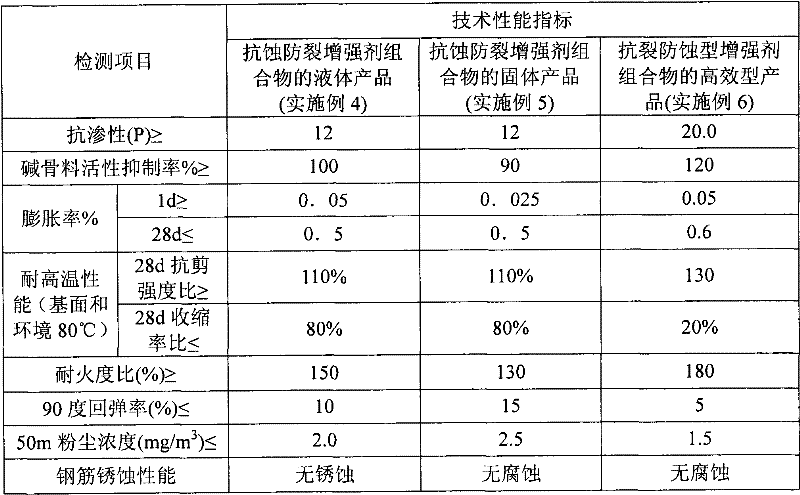

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

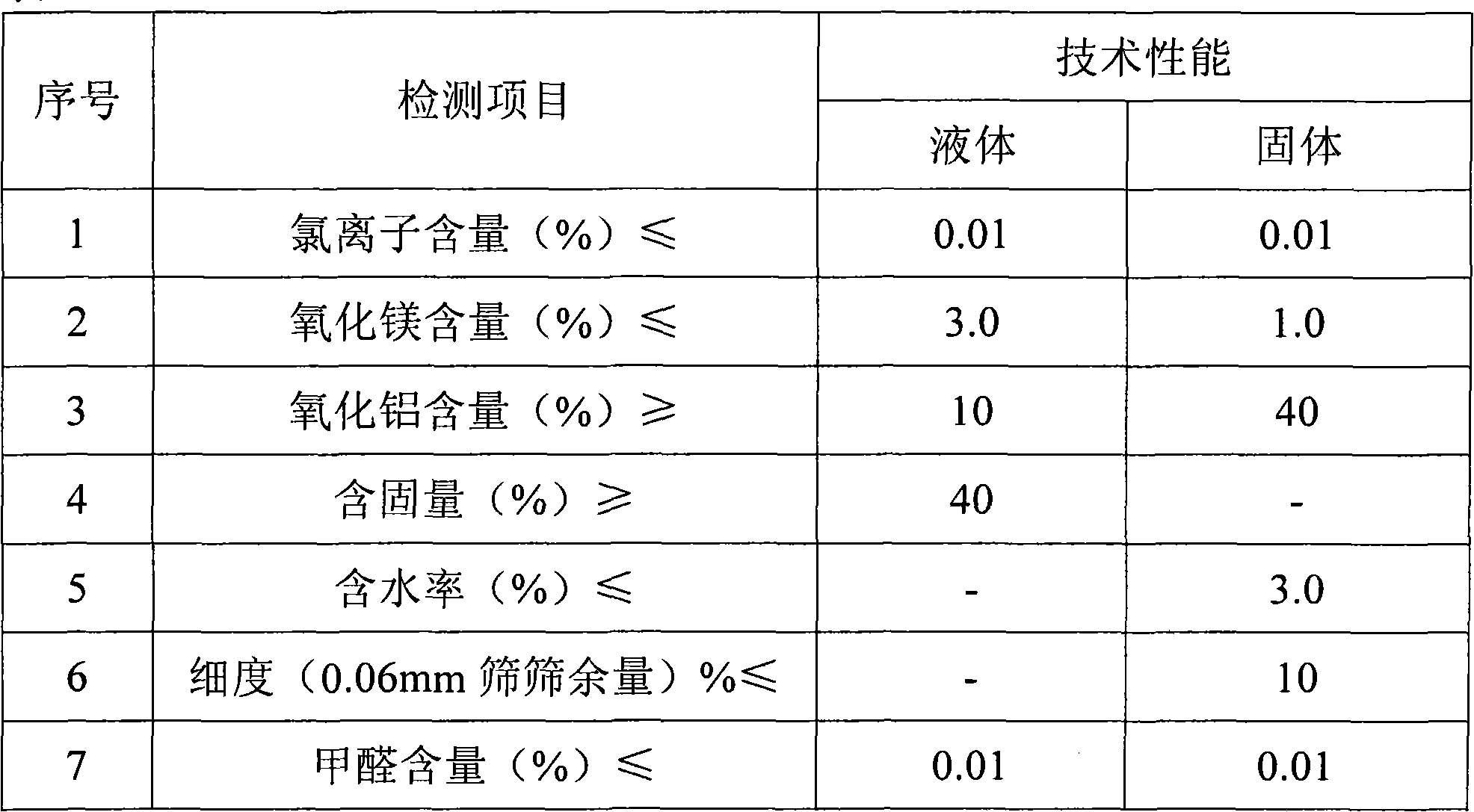

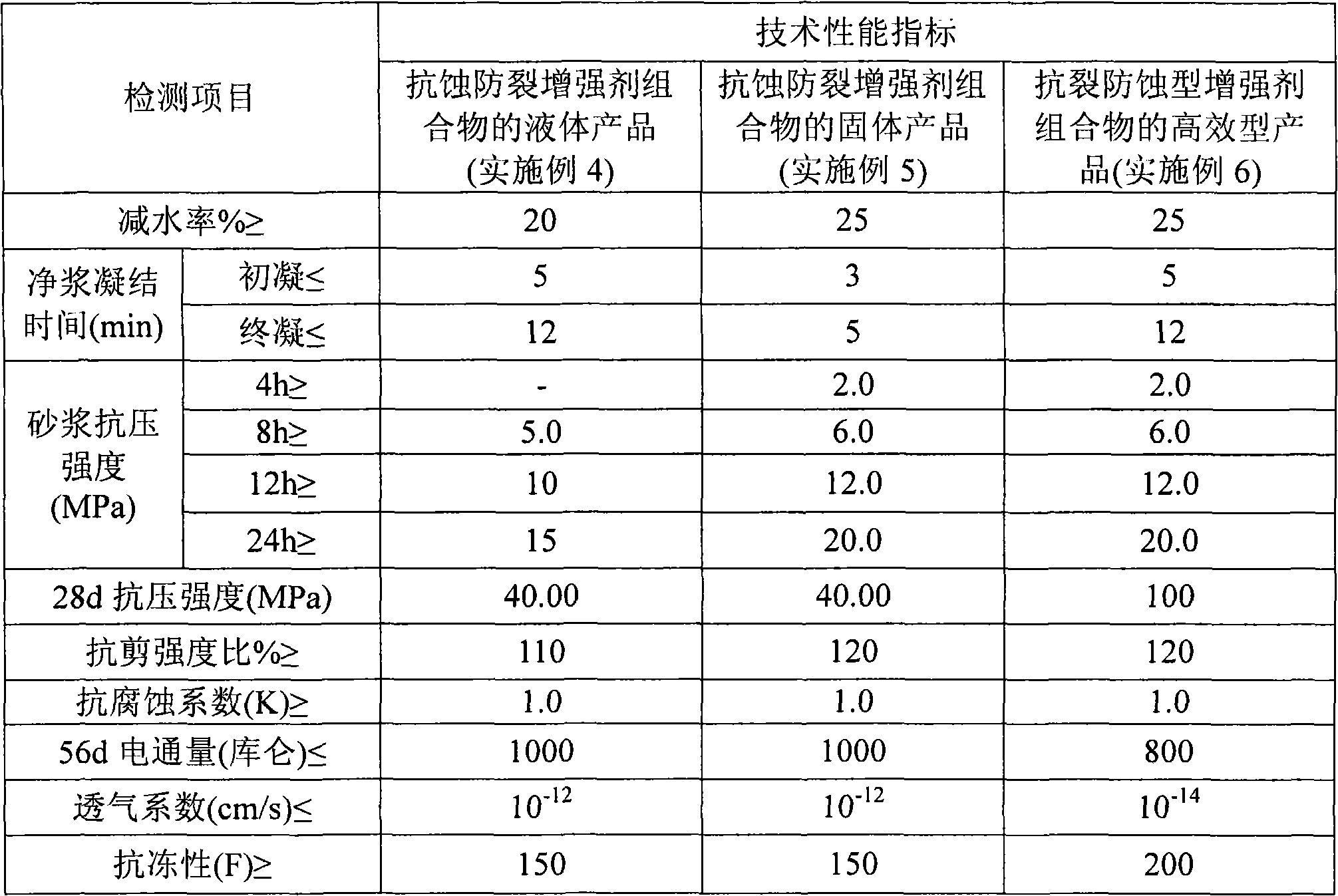

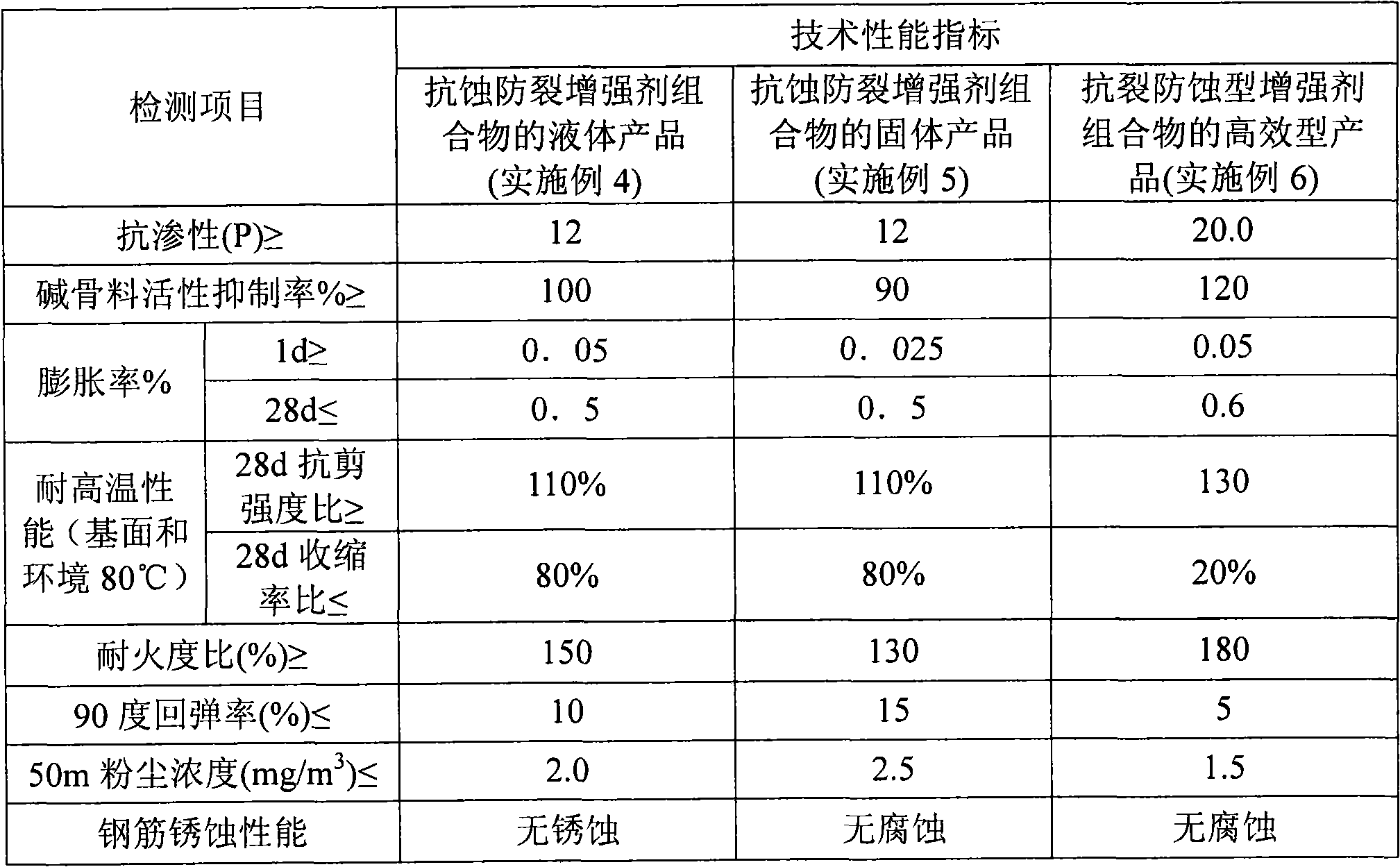

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

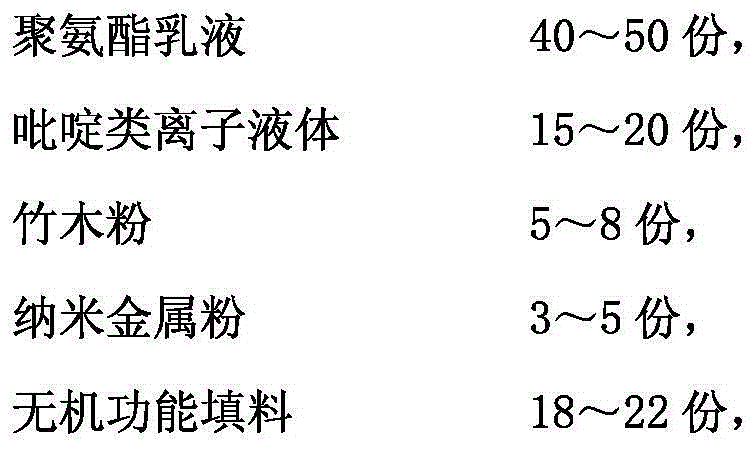

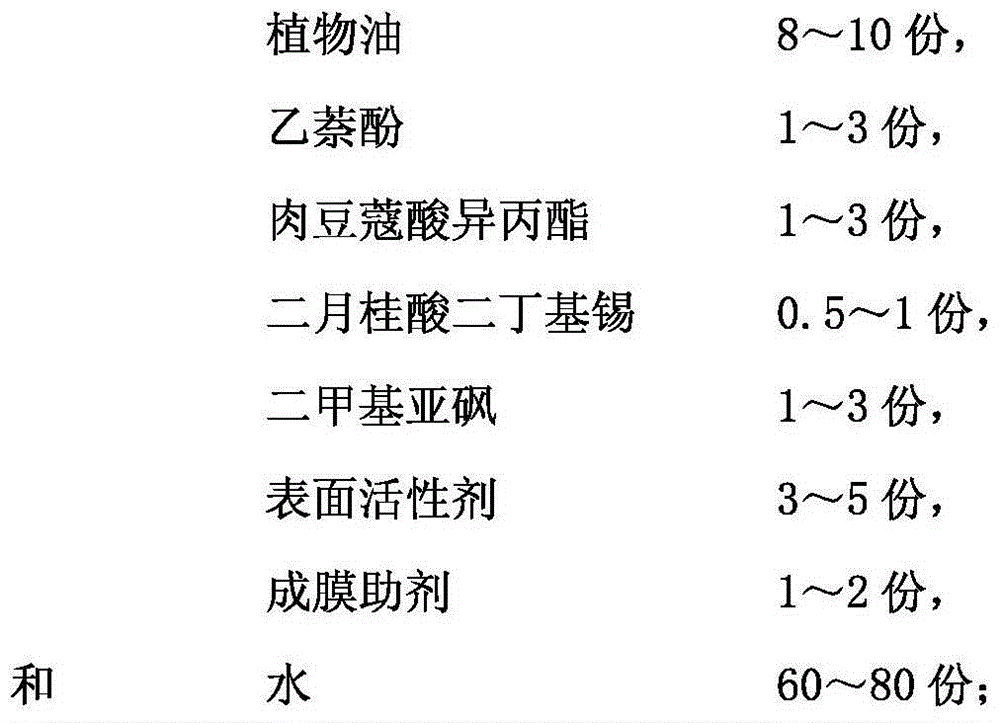

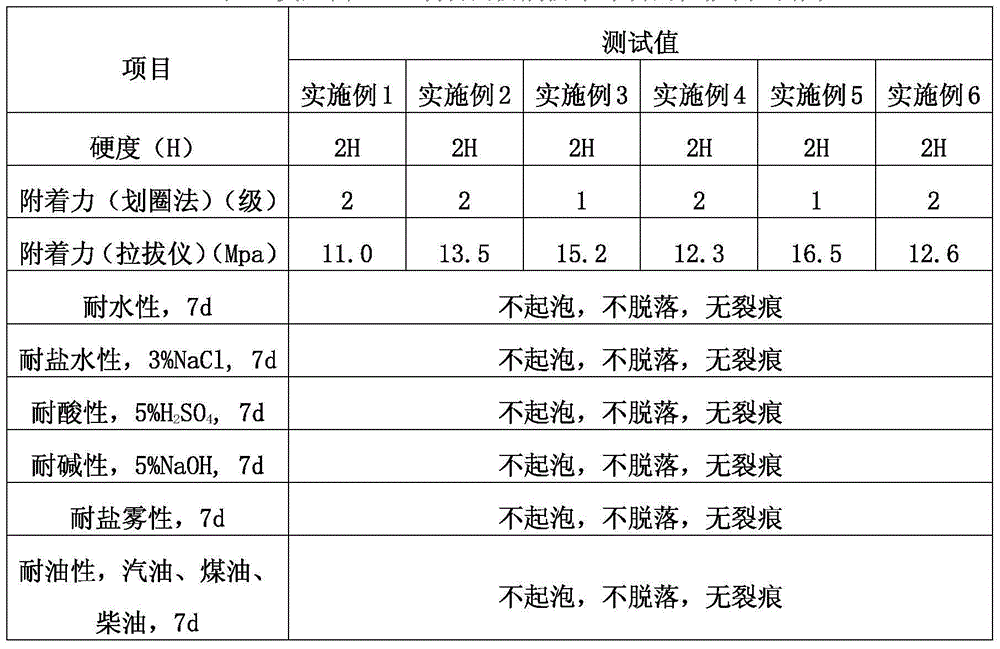

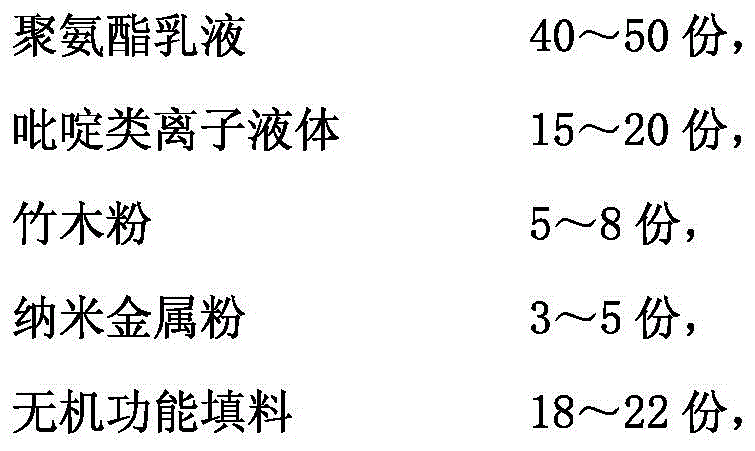

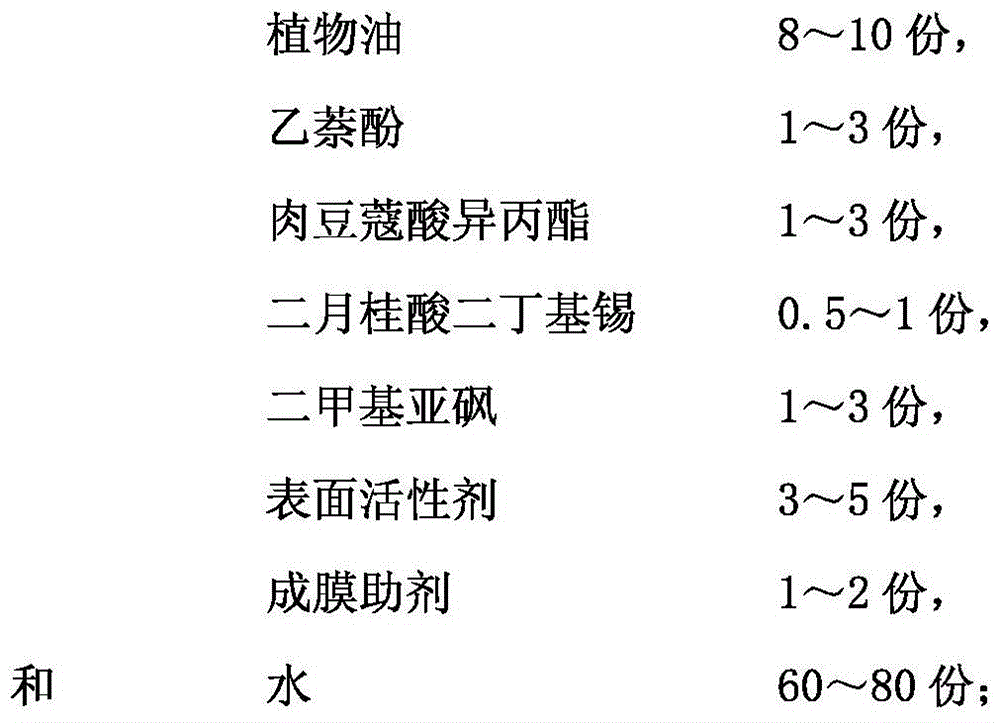

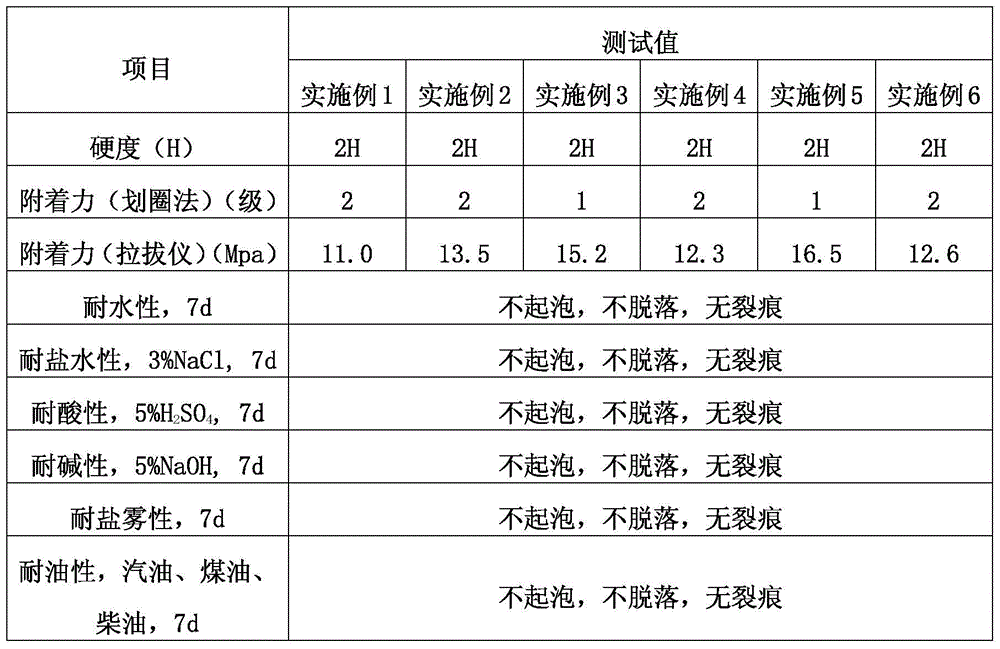

Aqueous polyurethane antiseptic and waterproof coating with high cohesiveness and preparation method of coating

InactiveCN104629600AGood anti-corrosion and waterproof performanceImprove mechanical propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsVegetable oilCrack resistance

The invention discloses an aqueous polyurethane antiseptic and waterproof coating with high cohesiveness. The coating comprises the following raw materials in parts by weight: 40-50 parts of polyurethane emulsion, 15-20 parts of pyridine ionic liquid, 5-8 parts of bamboo powder, 3-5 parts of nanometal, 18-22 parts of inorganic functional filling, 8-10 parts of vegetable oil, 1-3 parts of 2-naphthol, 1-3 parts of isopropyl myristate, 0.5-1 part of dibutyltin dilaurate, 1-3 parts of dimethyl sulfoxide, 3-5 parts of surfactant, 1-2 parts of coalescing agent and 60-80 parts of water. In the invention, pollution-free and environment-friendly ionic liquid is used as a cosolvent, the cohesiveness of the polyurethane emulsion can be greatly improved, and furthermore, nano-particles are uniformly dispersed in the coating, so that the difficult problem of aggregation of the nano-particles is solved. The coating provided in the invention has the advantages of strong cohesiveness, crack resistance, good waterproof performance, good corrosion resistance in severe environments such as acid, alkali, salt and oil, and obviously prolonged service life.

Owner:扬州豪扬新型建筑材料有限公司

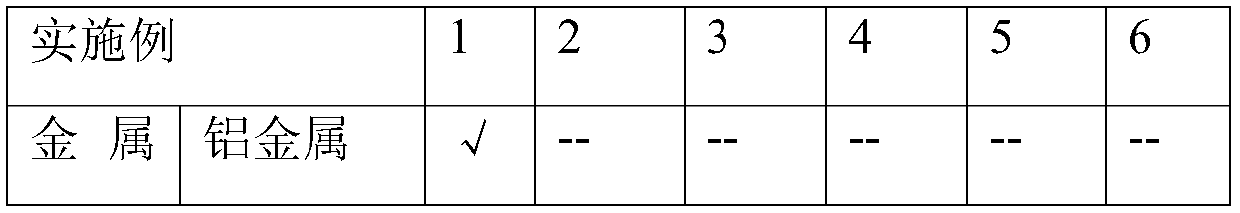

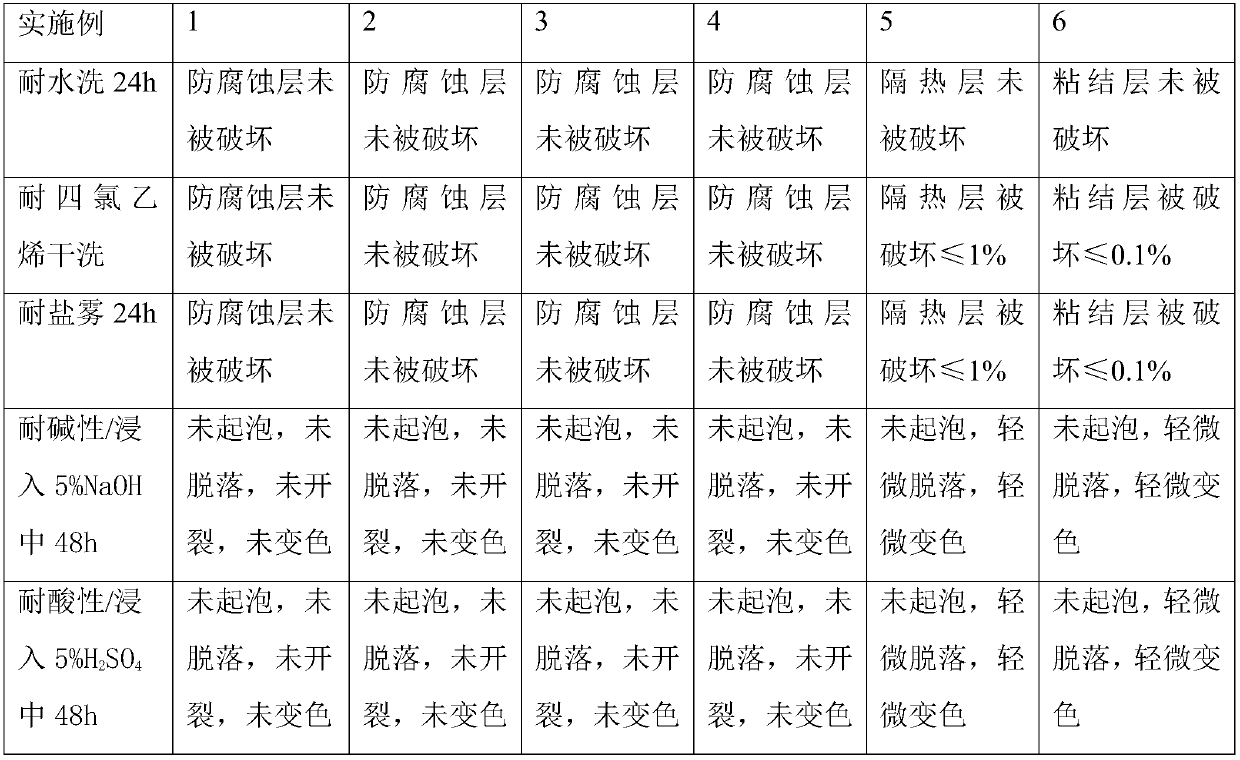

Heat-insulated protective coating of metal material and preparation method thereof

InactiveCN108149238AWith heat insulationWaterproofLiquid surface applicatorsPressure inorganic powder coatingSpray coatingPre treatment

The invention relates to a heat-insulated protective coating of a metal material and a preparation method of the heat-insulated protective coating of the metal material. The protective coating is formed on the surface of the metal material in a spray coating manner. The heat-insulated protective coating is composed of an adhesive layer, a heat-insulated layer I, a heat-insulated layer II and a corrosion-resistant layer, wherein the surface of the metal material is coated with the adhesive layer, the surface of the adhesive layer is coated with the heat-insulated layer I, the surface of the heat-insulated layer is coated with the heat-insulated layer II, the surface of metal material is coated with the corrosion-resistant layer. The preparation method comprises the following steps of S1, conducting pretreatment on the surface of the metal material; S2, preparing the adhesive layer; S3 preparing the heat-insulated layer I, S4 preparing the heat-insulated layer II and S5 preparing the corrosion-resistant layer. The heat-insulated protective coating of the metal material has the advantages of being resistant to high temperature, stable in structure, good in machining performance and high in combination degree.

Owner:宁波远欣石化有限公司

Method for preparing rubber master batch

ActiveCN102634299AImprove cold resistanceImprove performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceWater vapor

The invention relates to a method for preparing rubber master batch, which is applied to the technical field of anti-corrosive pipes. The rubber master batch is prepared from the following components in parts by weight: 12.5-13.5 parts of styrene butadiene rubber, 1.5-1.6 parts of nature rubber, 9.5-10.5 parts of kaolin, 11.5-12.5 parts of light calcium carbonate with average grain diameter of 1-5 microns; 3.0-3.5 parts of No. 40 engine oil, 1.5-2.0 parts of ethyl acetate and 2.0-2.5 parts of dioctyl phthalate. The method comprises the following step of: putting mixed raw materials into a rubber grinding machine to be ground to form the rubber master batch with the thickness of 1.5-2mm. The method for preparing the rubber master batch has the advantages of improving cold resistance of pressure-sensitive adhesive produced by adopting the rubber master batch to 8-12 DEG C, modifying the performance of the pressure-sensitive adhesive carried on anti-corrosive rubber, enabling the water vapor transmittance to be lower than 0.45mg / cm<2>, improving the anti-corrosive waterproof effect and enabling the water absorption to be lower than 0.30%.

Owner:PETROCHINA CO LTD

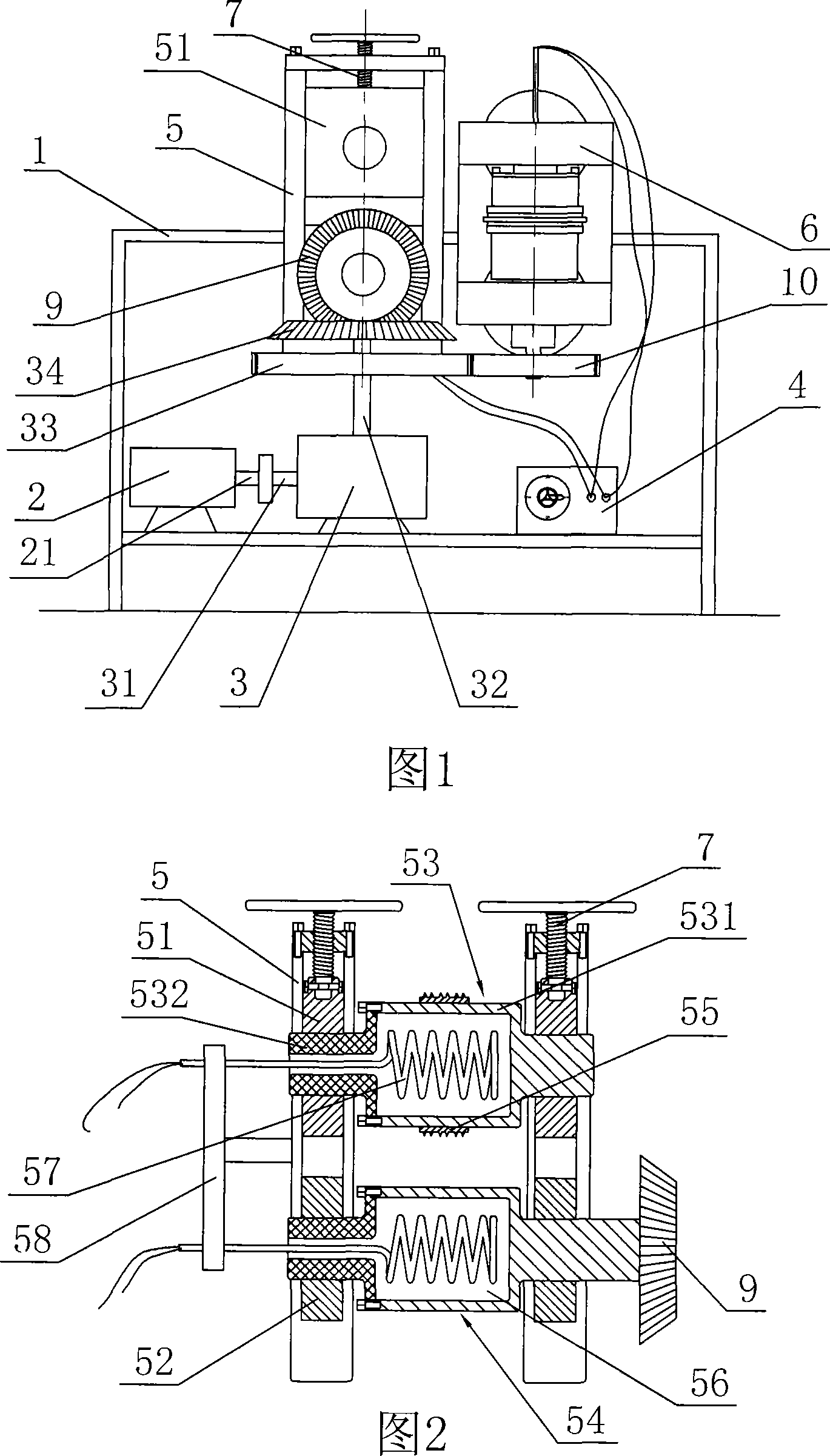

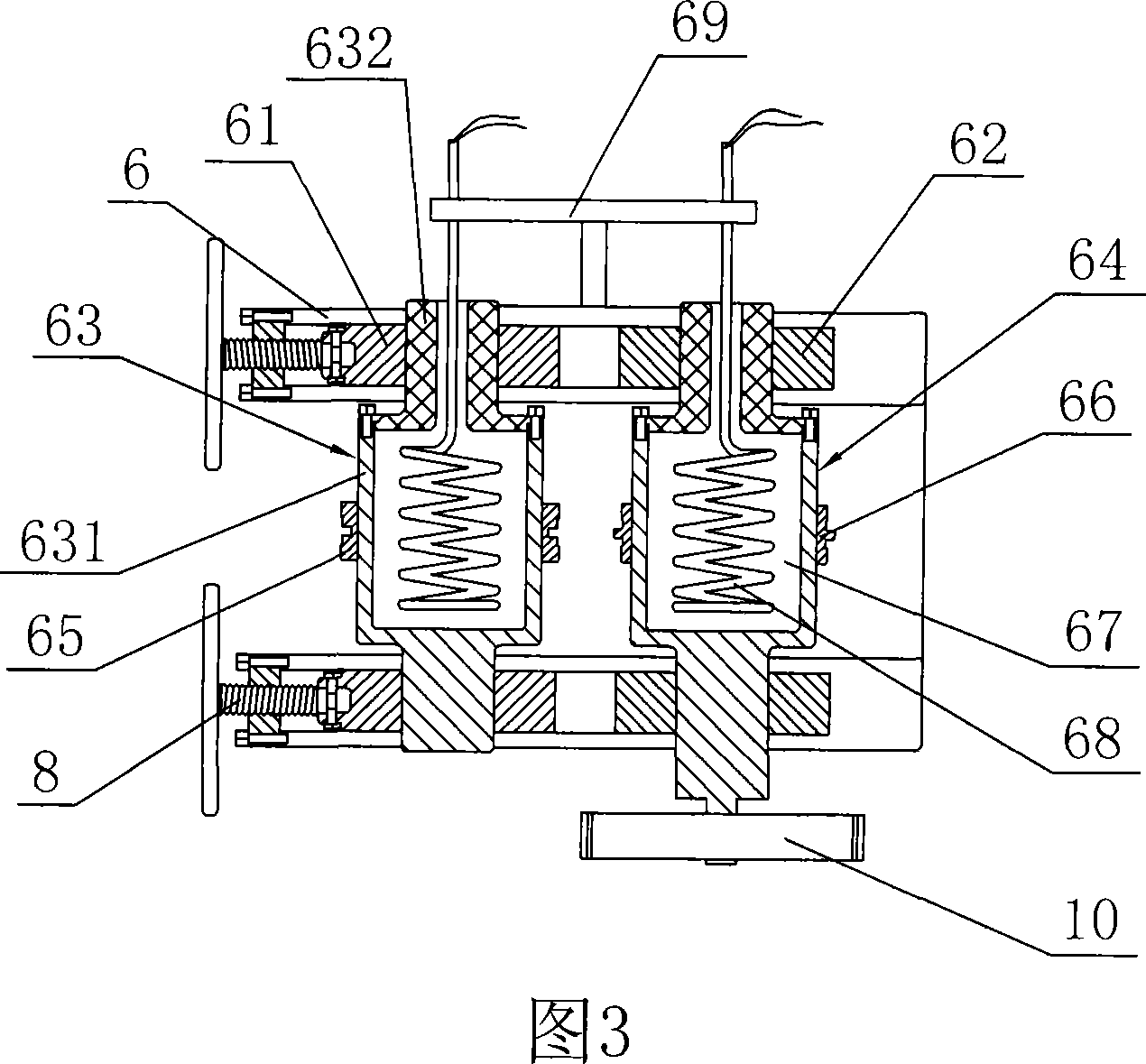

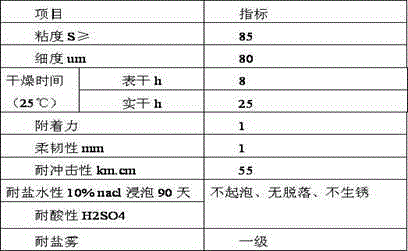

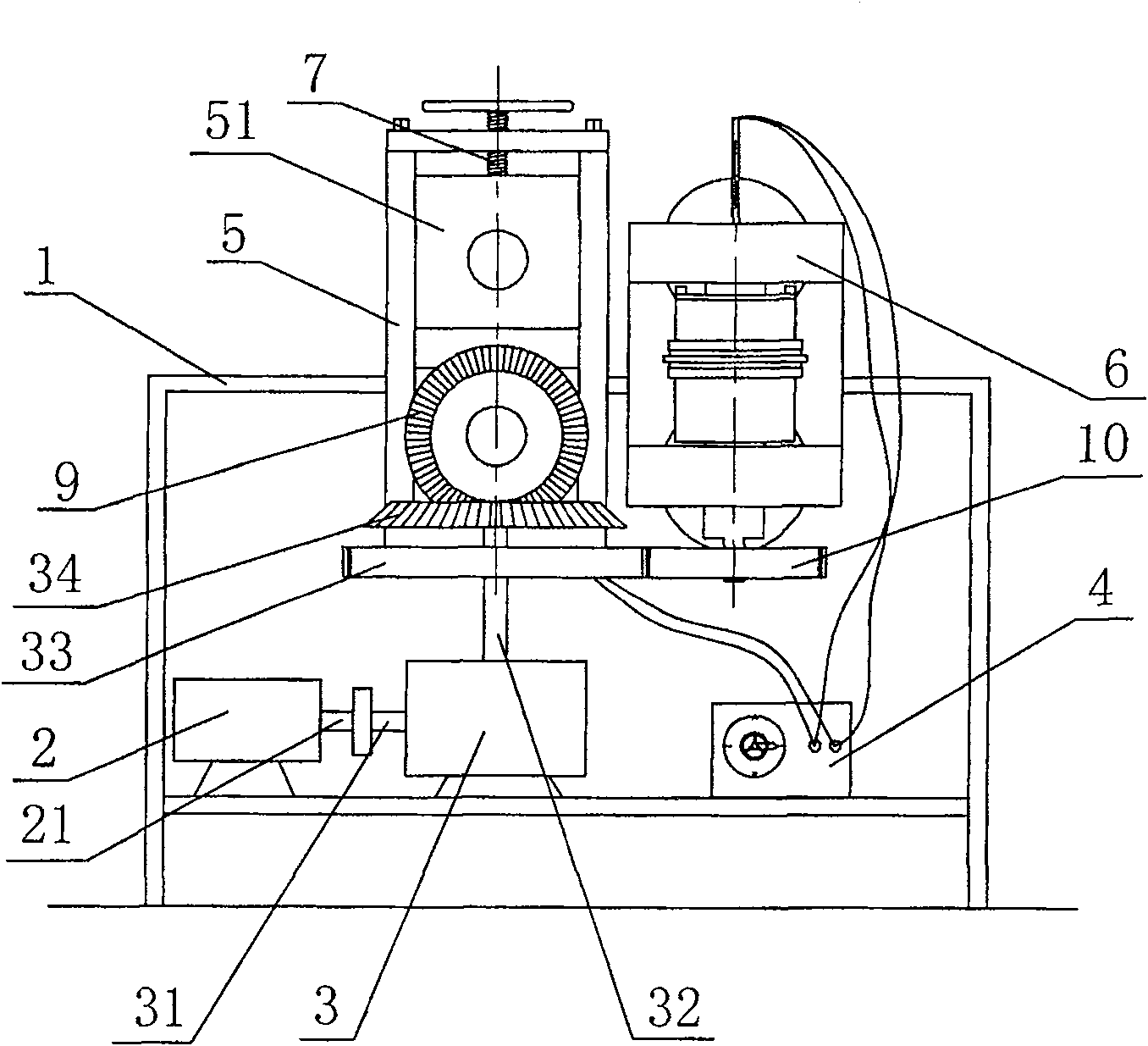

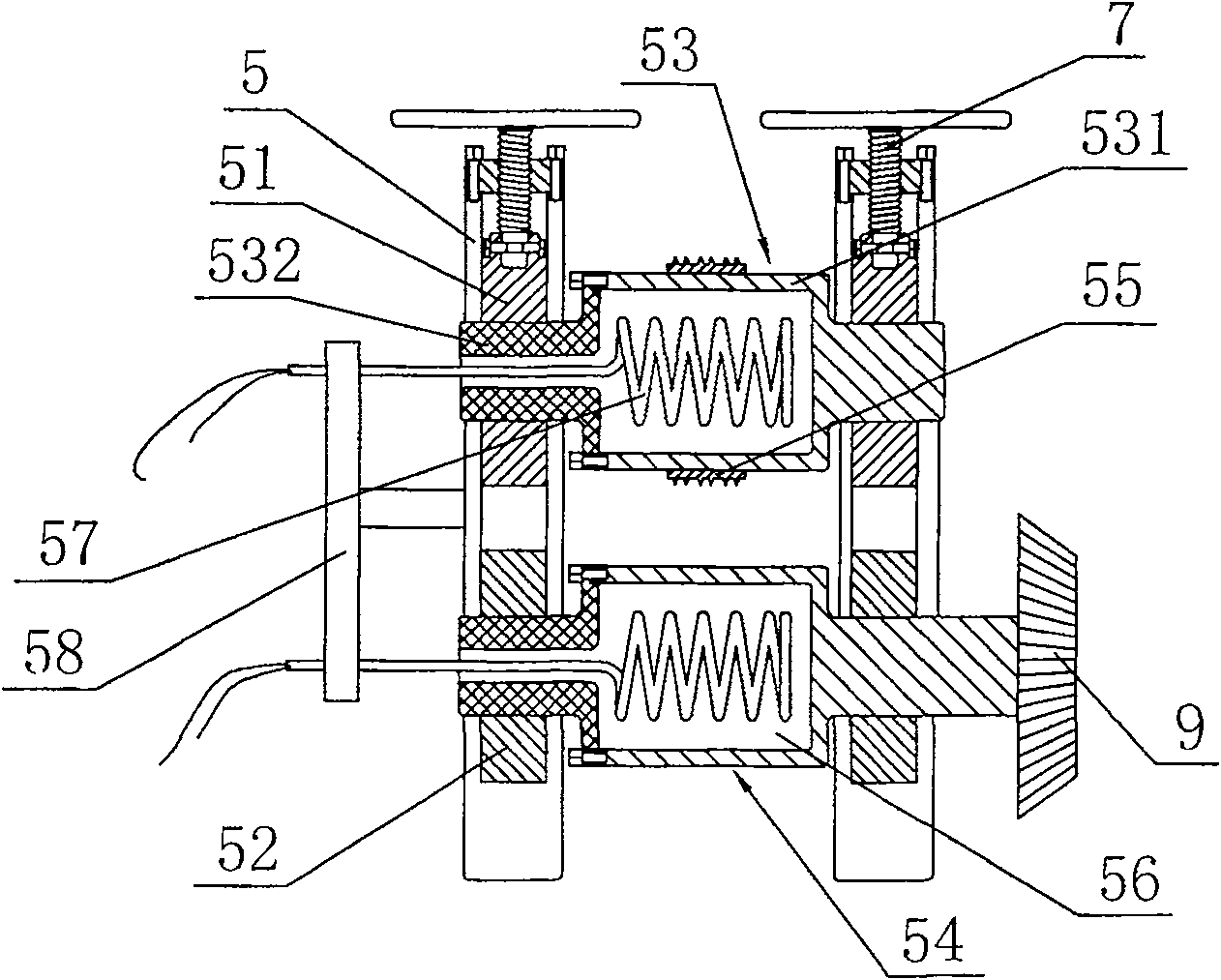

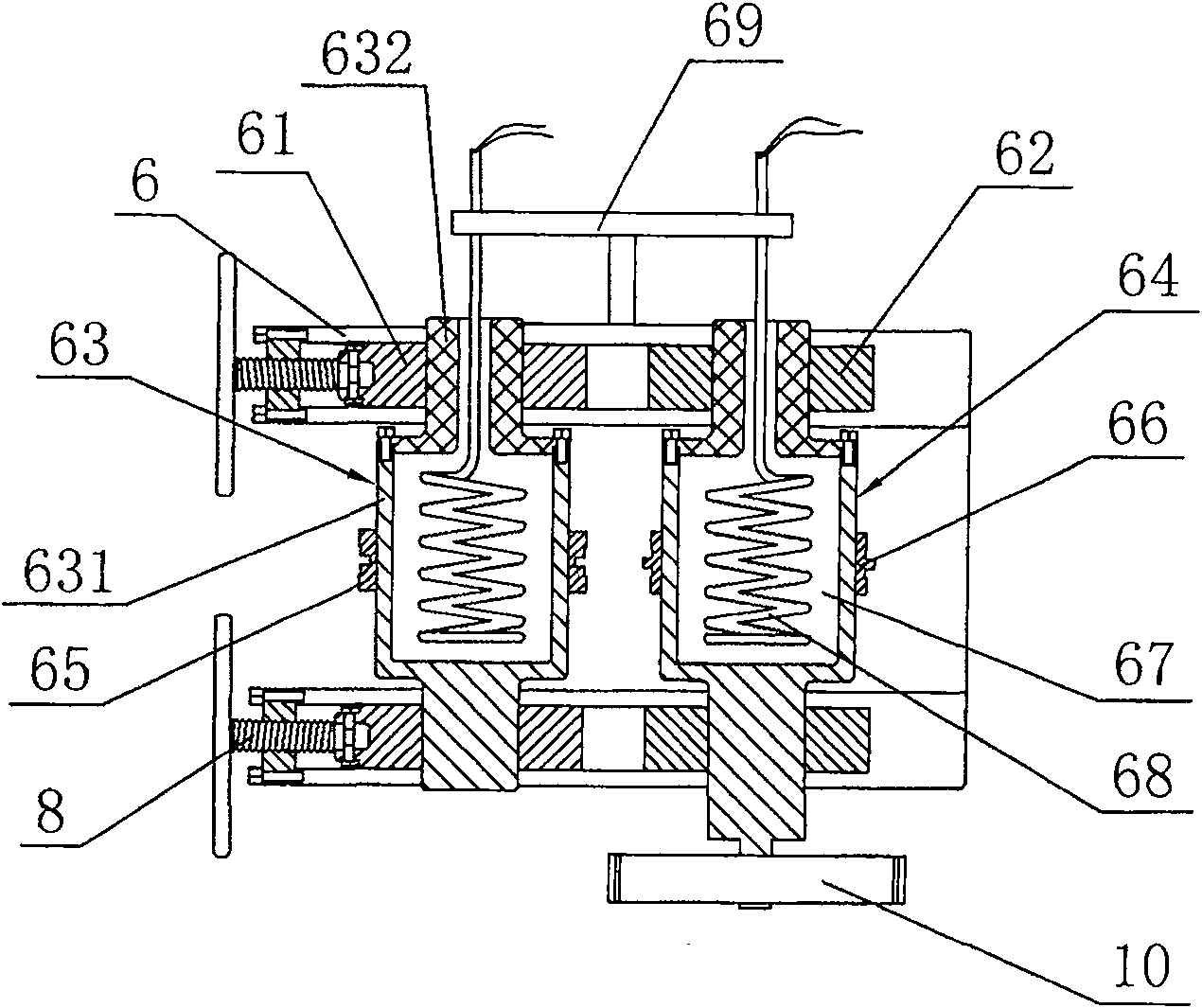

Water-proof processing equipment for wood substance plank stuff and processing method using the same

InactiveCN101234501AEasy to assemble and disassembleLow costWood compressionWood charring/burningElectricityTwo temperature

The invention discloses a waterproof treatment device for wooden board, which is characterized in that a worktable, a longitudinal support and a traverse support are fixedly arranged on the workable in tandem, wherein, the longitudinal support is provided with an adjustable traverse pressure plate device; the adjustable traverse pressure plate device is provided with a traverse heating device; the traverse support is provided with an adjustable longitudinal pressure plate device; the adjustable longitudinal pressure plate device is provided with a longitudinal heating device; the worktable is provided with two temperature control devices that are respectively connected with the traverse heating device and the longitudinal heating device, and is further provided with a driving mechanism simultaneously driving the work of the adjustable traverse pressure plate device and the adjustable longitudinal pressure plate device; the waterproof treatment device for wooden board has the advantages that as the worktable is provided with the adjustable traverse pressure plate device and the adjustable longitudinal pressure plate device, the wooden board can be processed to form at one time; an adjusting screw can be used for adjusting the gap between two pressure shafts so as to lead the pressure shafts to produce pressure to the wooden board, thereby compacting pipe orifices on the surface of the wooden board and playing a part in waterproofing and deformation.

Owner:陈兆红

Preparation method for high-build epoxy coating and prepared coating

InactiveCN105273625ASolution to short lifeHigh tensile strengthChloropene polymer coatingsAnti-corrosive paintsEpoxyResin modified

The invention discloses a preparation method for a high-build epoxy coating. The preparation method comprises the following steps: (1) weighing, by mass, 15 to 25% of asphalt, 5 to 8% of chloroprene rubber and 12 to 14% of epoxy resin modified latex into distilled water, carrying out uniform mixing under stirring, then adding 10 to 20% of titanium dioxide and 10 to 20% of a functional filling material, adding a proper amount of an antifoaming agent, a film forming aid and a thickening agent and carrying out uniform mixing under stirring and dispersion for 30 to 40 min so as to obtain high-build epoxy paste; and (2) weighing, by mass, 10 to 18% of coal tar pitch, 2 to 4% of coal tar and 2 to 6% of an accessory material, adding the weighed materials into the high-build epoxy paste, carrying out stirring for 30 to 55 min and adjusting viscosity and a pH value so as to prepare the high-build epoxy coating. The invention also discloses the high-build epoxy coating. The high-build epoxy coating has better weatherability, deformation resistance, high tensile strength, great ductility, strong adaptability to contraction and cracking deformation of a base layer, and superior acid resistance, alkali resistance, corrosion resistance and water resistance and can be easily constructed on any complex part.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Processing technique of tung oil floor

InactiveCN100563959CGood anti-corrosion and waterproof performanceGood anti-corrosion, insect-proof and moisture-proof performanceWood working apparatusSolid woodRoom temperature

The invention discloses a floor, in particular to a processing technology of tung oil floor, which is mainly used for processing solid wood floor. The processing steps of this processing technology are as follows: after sanding the front surface of the board with a moisture content of 7-12% and four sides without grooves, bake and preheat to 50±5°C, wipe a layer of cooked tung oil on the front surface of the floor with a cotton cloth ; After the floor is dried for 6-10 minutes, bake and preheat to 50±5℃, and then wipe a layer of cooked tung oil on the front of the floor with a cotton cloth; Then at room temperature 25±10°C, wipe a layer of cooked tung oil with a cotton cloth on the four sides and back of the grooved floor; wait for the floor to dry for 8 to 12 minutes, then wipe a layer of cooked tung oil with a cotton cloth on the six sides of the floor. Tung oil, after drying for 24±4 hours, pack it for inspection and put it into storage. The invention has the advantages of environmental protection, anti-deformation, moisture-proof and moth-proof, and retains the original natural properties of wood.

Owner:湖州旺宝装饰材料有限公司

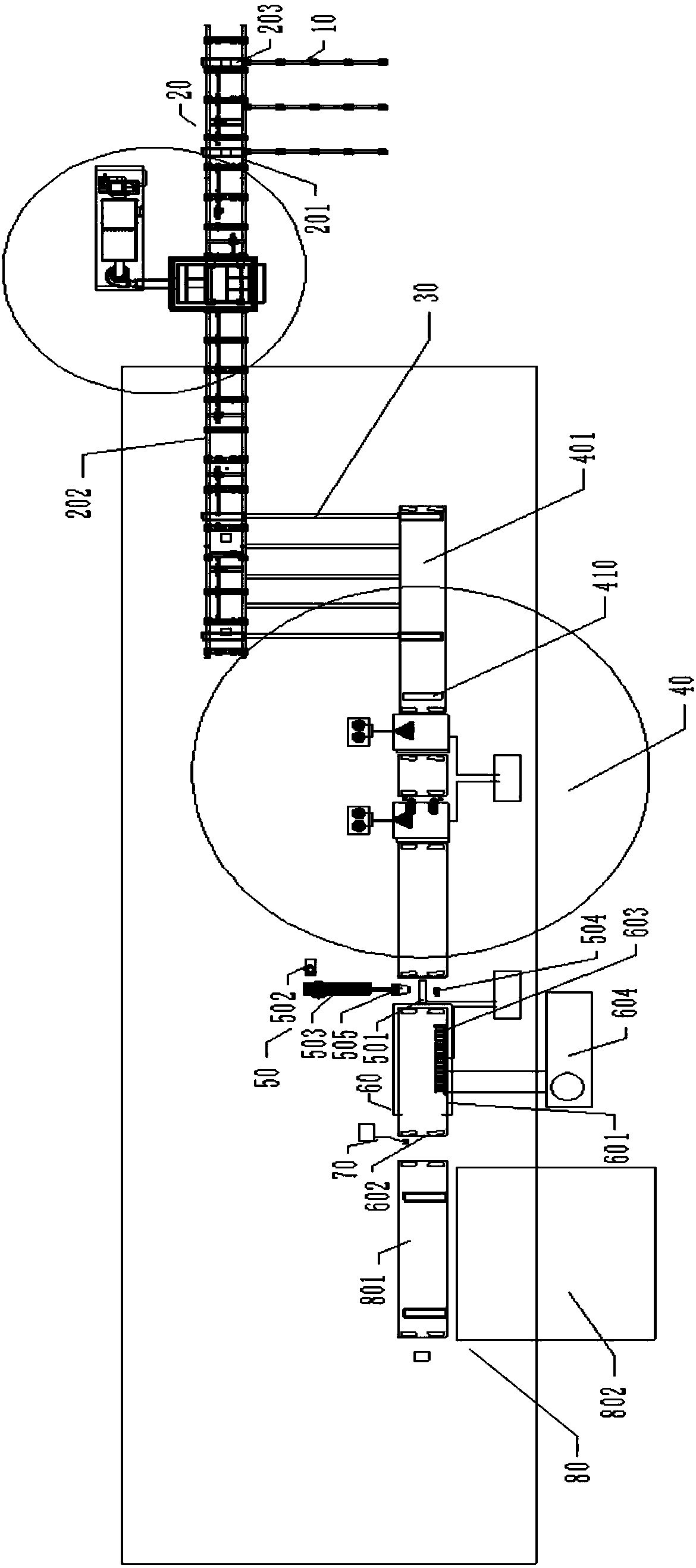

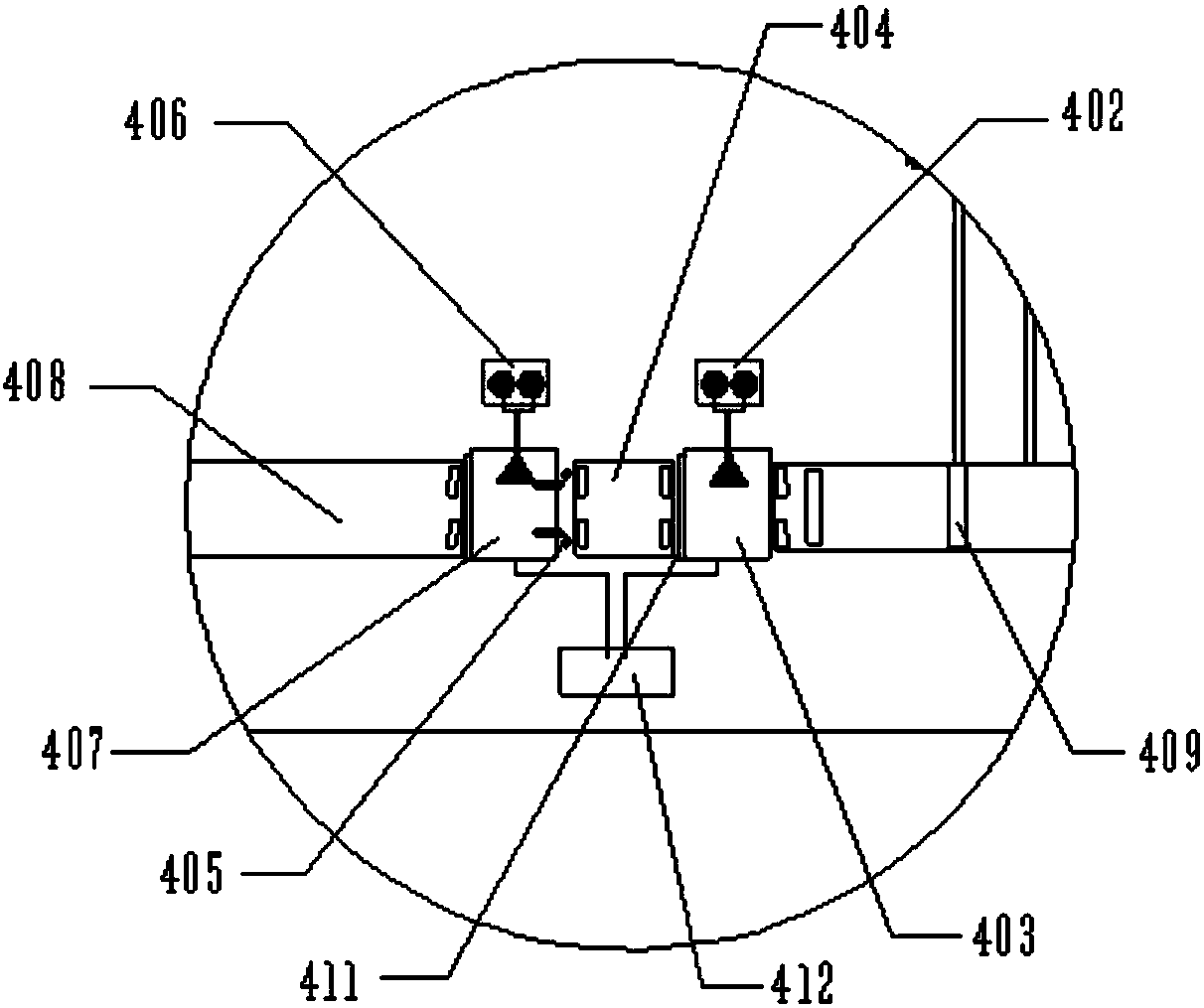

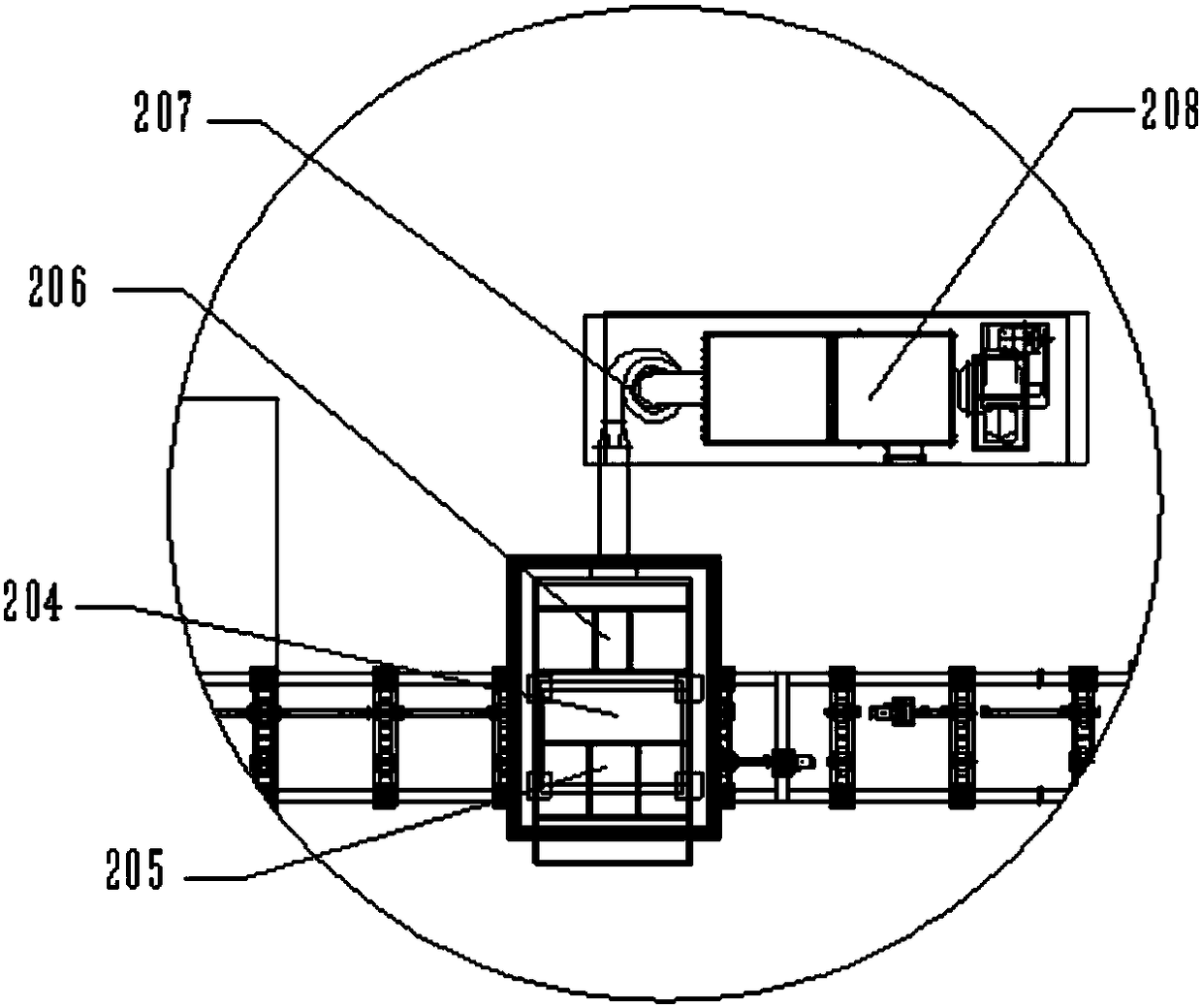

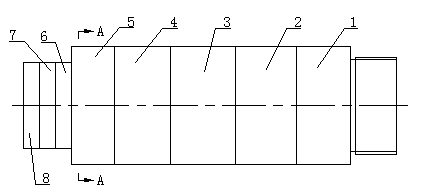

Continuous collinear spray-coating winding prefabricated directly-buried thermal insulation pipe production line and applications thereof

PendingCN109383051AAvoid energy consumptionShort processTubular articlesThermal insulationSpray coating

The invention provides a continuous collinear spray-coating winding prefabricated directly-buried thermal insulation pipe production line and applications thereof. The continuous collinear spray-coating winding prefabricated directly-buried thermal insulation pipe production line comprises a pipe feeding platform 1, a rust removing shot blasting part, a pipe feeding platform 2, a polyurethane spraying part, a polyethylene winding part, a spray cooling part, a cutting part and a finished product storage part, wherein the output end of the pipe feeding platform 1 is connected to the input end ofthe rust removing shot blasting part, the output end of the rust removing shot blasting part is connected to the input end of the pipe feeding platform 2, the output end of the pipe feeding platform2 is connected to the input end of the polyurethane spraying part, the polyurethane spraying part, the polyethylene winding part and the spray cooling part are sequentially adjacent and are collinearly arranged, and the cutting part is arranged between the output end of the spray cooling part and the input end of the finished product storage part. According to the present invention, by using the production line, the production process can be effectively simplified, the energy consumption can be reduced, the production efficiency can be increased by twice, and the labor intensity can be saved;and the continuous collinear spray-coating winding prefabricated directly-buried thermal insulation pipe production line can be used for the production processing of various types of directly-buried thermal insulation pipes so as to meet the requirements of different users.

Owner:德士达(天津)管道设备有限公司

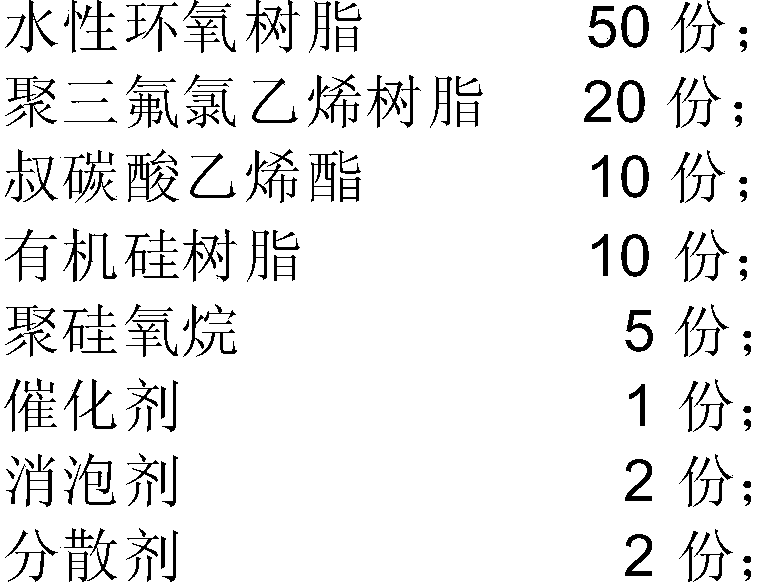

Anticorrosive and waterproof polymer coating for concrete structure

InactiveCN109679391AImprove smoothnessGood adhesionAnti-corrosive paintsSilicone resinPolychlorotrifluoroethylene

The invention relates to anticorrosive and waterproof materials for buildings, in particular to an anticorrosive and waterproof polymer coating for a concrete structure. The anticorrosive and waterproof polymer coating comprises a liquid material and a powder material, wherein the group A liquid material is prepared from waterborne epoxy resin, polytrifluorochloroethylene resin, vinyl tertcarbonate, silicone resin, polysiloxane, a catalyst, a defoamer and a dispersant; the group B powder material is prepared from graphite flakes, glass flakes, mica flakes, quartz sand, ceramic raw materials, high calcium powder and inorganic pigment by mixing. The anticorrosive and waterproof polymer coating has the cost lower than that of fiber reinforced plastics, polyurethane and epoxy resin, high product adhesion and durability, the surface smoothness of the coating on the outer surface of concrete after construction can be improved substantially, the ageing resistance of the product is good, the coating can be used for longer time, and the anticorrosive and waterproof properties are better.

Owner:山东蓝盟防腐科技股份有限公司

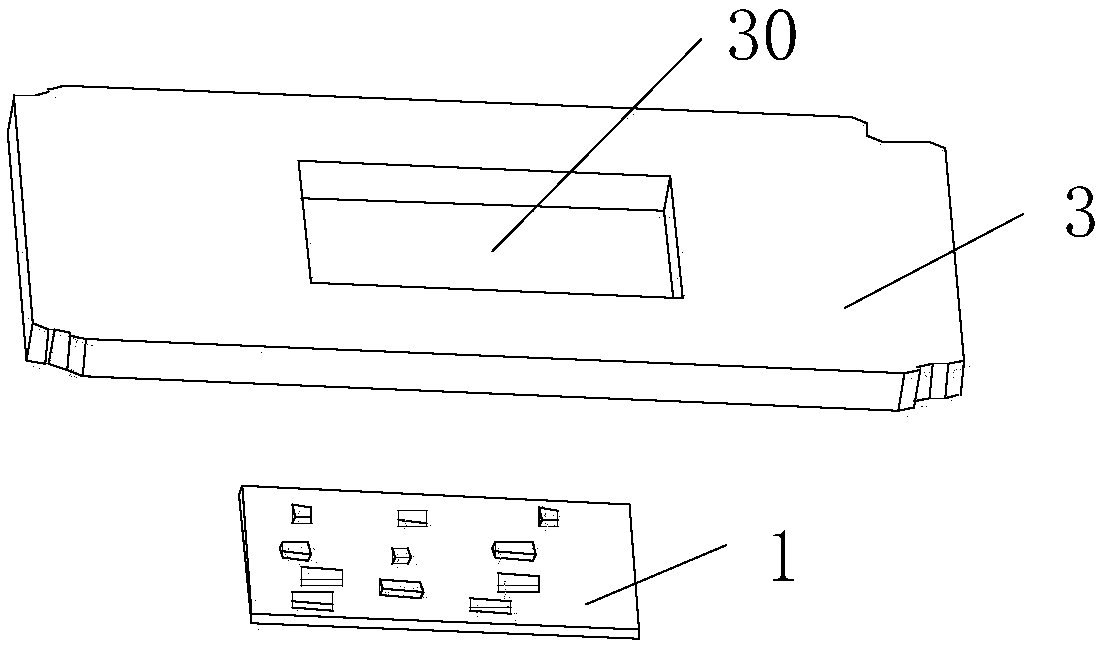

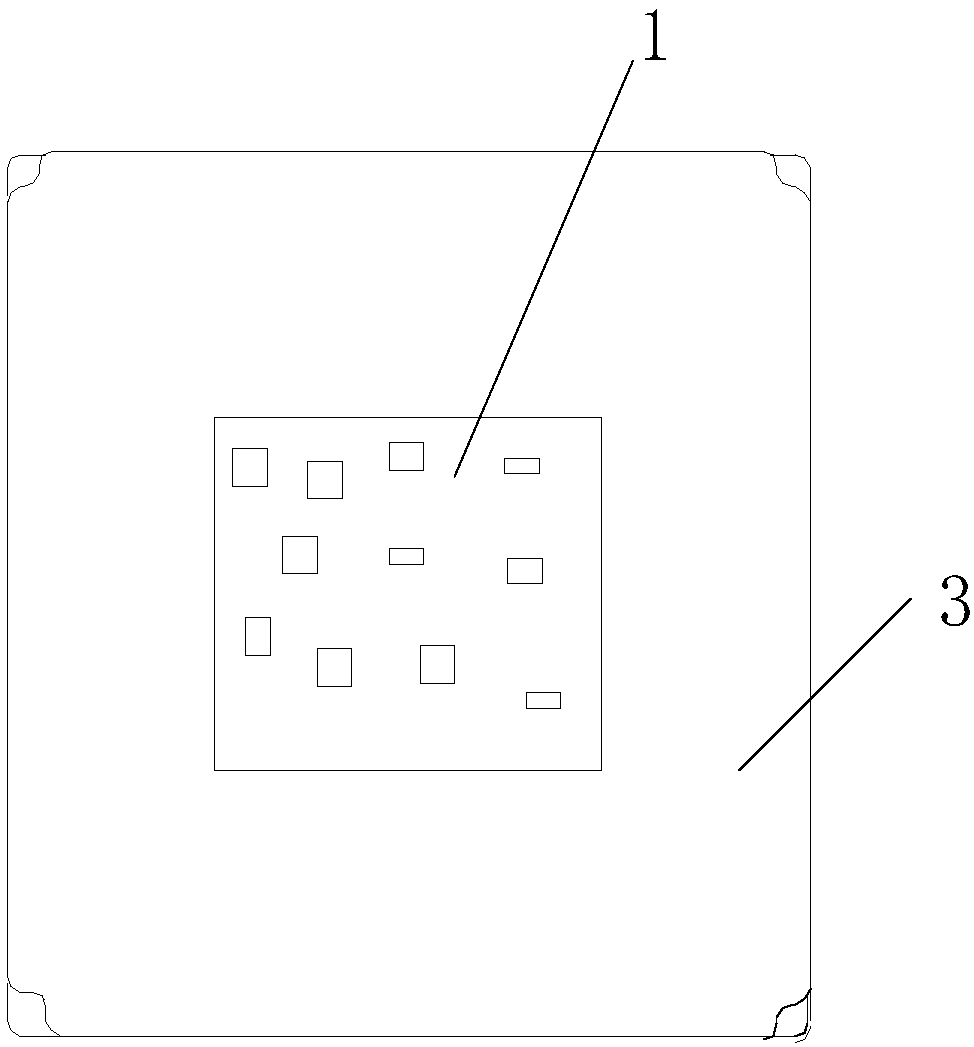

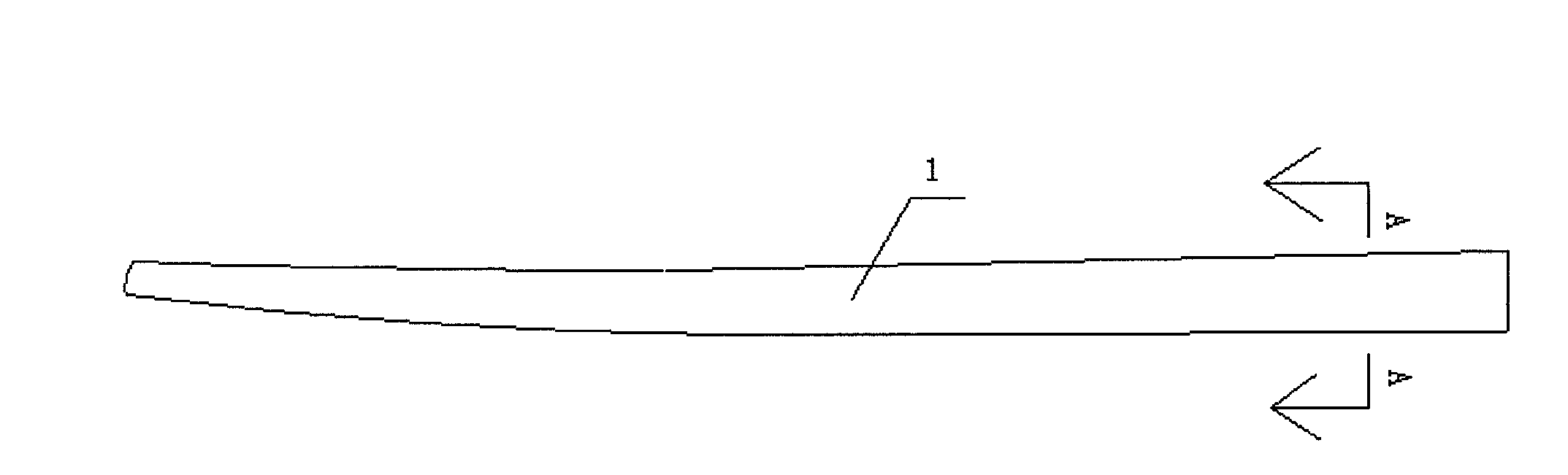

Battery protection plate, adhesive pouring die and battery

InactiveCN107681213AExtended service lifeImprove the safety of useCells structural combinationBatteriesPower flowElectrical battery

The invention discloses a battery protection plate, an adhesive pouring die and a battery. The battery protection plate comprises a battery protection plate body and an adhesive pouring layer; the battery protection plate body comprises electronic components and a substrate; the electronic components are attached to the substrate; the adhesive pouring layer covers the electronic components; and the adhesive pouring layer is heat dissipation adhesive for conducting heat generated by the electronic components to the outer side. The heat dissipation adhesive, which is solidified and formed easily, is poured in the battery protection plate body for covering and patching the electronic components, so as to dissipate the heat generated by the electronic components on the whole battery protectionplate, thereby prolonging the service life of the battery protection plate at a relatively high working current, prolonging the service life and improving use safety of the battery.

Owner:SUNWODA ELECTRONICS

Anticorrosive enhanced glass fibre and magnesium board for architectural decoration and preparation method thereof

The invention discloses an anticorrosive enhanced glass fibre and magnesium board for architectural decoration. The anticorrosive enhanced glass fibre and magnesium board for architectural decoration is characterized by being prepared from the following raw materials, by weight, 5-7 parts of tourmalinite powder, 42-45 parts of light calcined magnesia, 40-42 parts of magnesium chloride hexahydrate, 0.2-0.25 part of a silane coupling agent kh550, 1.5-2 parts of waterborne polyurethane, 6-8 parts of 5% polyvinyl alcohol solution, 5-7 parts of talcum powder, 7-9 parts of basalt fibre, 4.5-5 parts of metakaolin, 2.5-3 parts of aluminium dihydrogen phosphate, 0.6-0.8 part of a water reducer UNF-2, 15-18 parts of thermoplastic phenolic resin, 5-6 parts of 25% urotropine aqueous solution, 1.5-2.5 parts of aluminium silicate fibre and a proper amount of pure water. By combination of adding a modifier and coating a resin layer, corrosion resistance and waterproofness of the glass fibre and magnesium board are greatly enhanced. Meanwhile, the glass fibre and magnesium board contains tourmalinite powder and can release negative ions which are beneficial to human body. Thus, the anticorrosive enhanced glass fibre and magnesium board is very suitable to be used as a building decoration material.

Owner:ANHUI XINRUN NEW MATERIALS

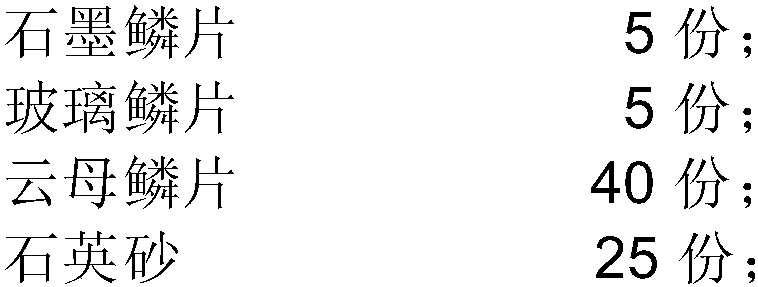

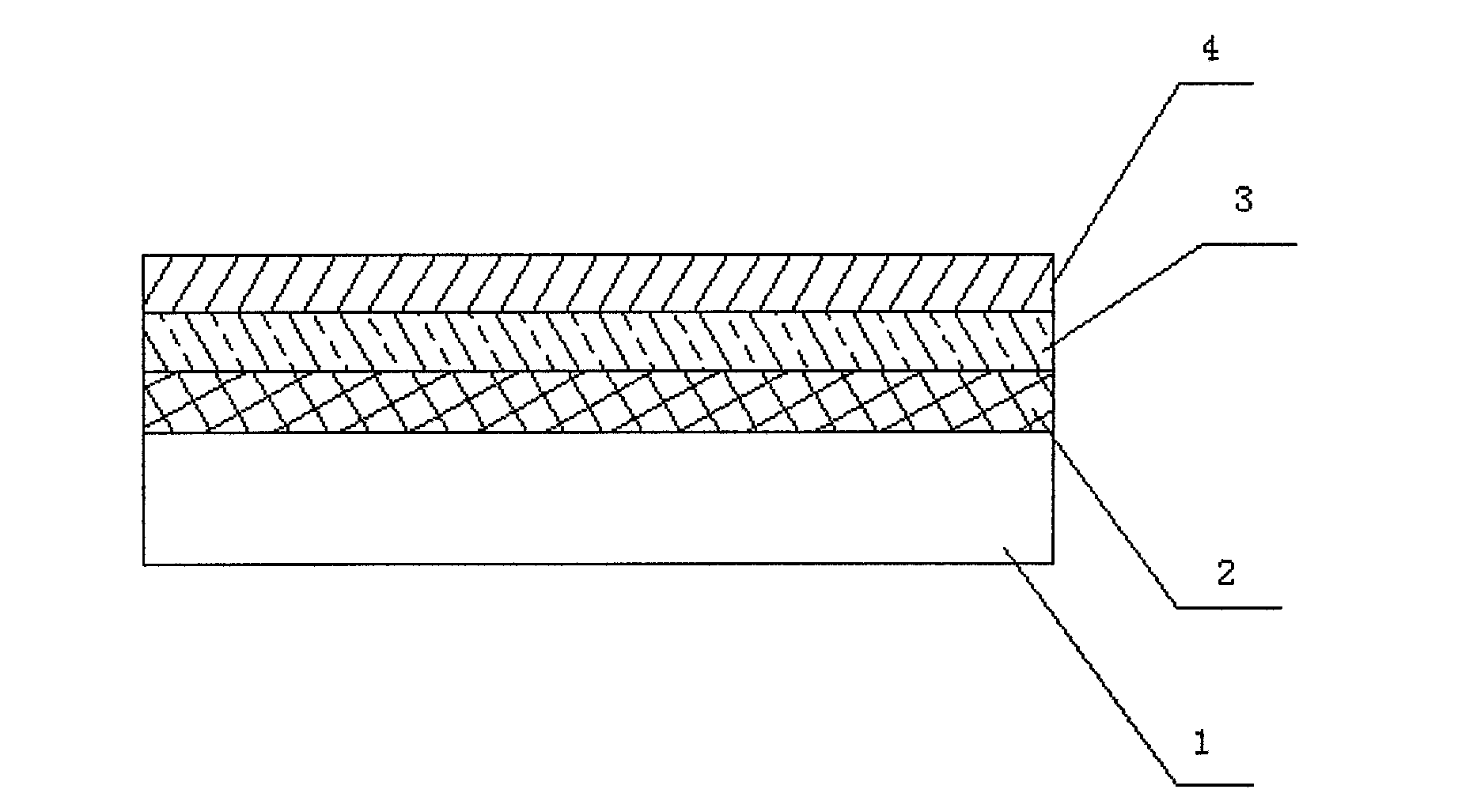

Rubbing strip with paint-sprayed surface

InactiveCN103042991AImproved weather and impact resistanceGood anti-corrosion and waterproof performanceVehicle componentsWeather resistanceVarnish

The invention relates to a rubbing strip, in particular to a rubbing strip with the paint-sprayed surface, and belongs to the technical field of automobile plastic parts. The rubbing strip is characterized in that the rubbing strip is made of modified polyvinylchloride, and the modified polyvinylchloride contains acrylate copolymers. Paint is sprayed on the upper portion of the rubbing strip (1), the rubbing strip (1) is provided with a primer layer (2), the primer layer (2) is provided with a finish paint layer (3), and the finish paint layer (3) is provided with a varnish layer (4). The rubbing strip with the paint-sprayed surface is made of the modified polyvinylchloride and is strong in plasticity, the acrylate copolymers are contained in the modified polyvinylchloride to serve as a toughening modification agent of the polyvinylchloride, and accordingly weather resistance and impact resistance of the rubbing strip are improved. Besides, primer, finish paint and varnish are coated on the surface of the rubbing strip, so that the rubbing strip has good anti-corrosive and waterproof performances and is good in brightness retention and color retention, attractive and appropriate.

Owner:曹克波

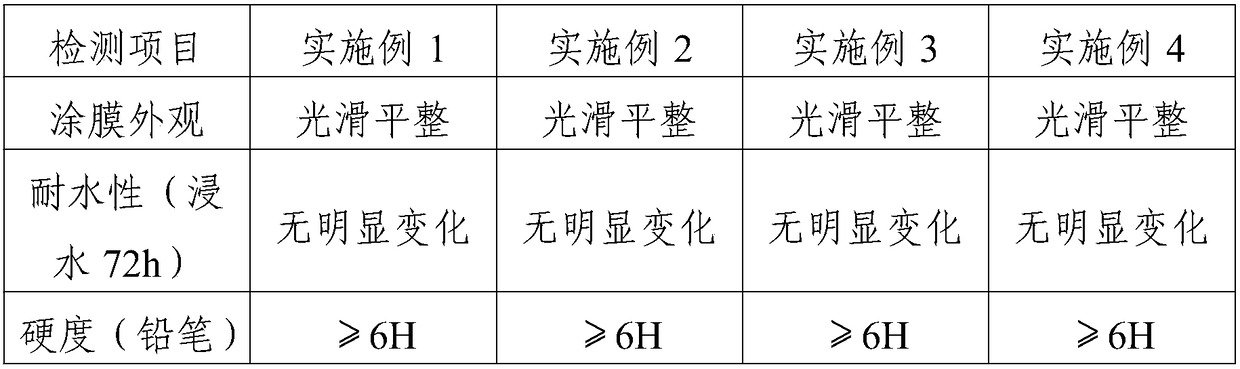

Special high-performance coating for junction boxes and preparation method of coating

InactiveCN109096906AImprove waterproof performanceImprove the bactericidal effectAntifouling/underwater paintsPaints with biocidesFiberAntioxidant

The invention provides a special high-performance coating for junction boxes and a preparation method of the coating and relates to the technical field of coatings. The special high-performance coating for the junction boxes is prepared from raw materials as follows: a waterborne polyurethane emulsion, a polyacrylate emulsion, a styrene-acrylic emulsion, reinforcing fiber, hollow beads, texanol, pigment, hexenyl distearamide, higher aliphatic alcohol, inorganic filler, triethanolamine, industrial salt, ethylene glycol, hexahydroxy methyl-etherified melamine, emulsified silicone oil, a hinderedphenol antioxidant, a nonionic fluorinated surfactant, an organosilicon waterproofing agent, an anti-corrosion bactericide and a brominated flame retardant. Under the cooperation and synergistic action of all raw materials, the waterproof property, anti-corrosion bactericidal activity and anti-crack performance of the coating are greatly improved. The coating has the advantages of good anti-corrosion and waterproof effects, has very excellent weather fastness and good leveling property, cannot peel off easily, has long life cycle, can be sprayed and brushed and has very excellent covering property for tiny cracks.

Owner:ANHUI HONGQIAO METAL MFG

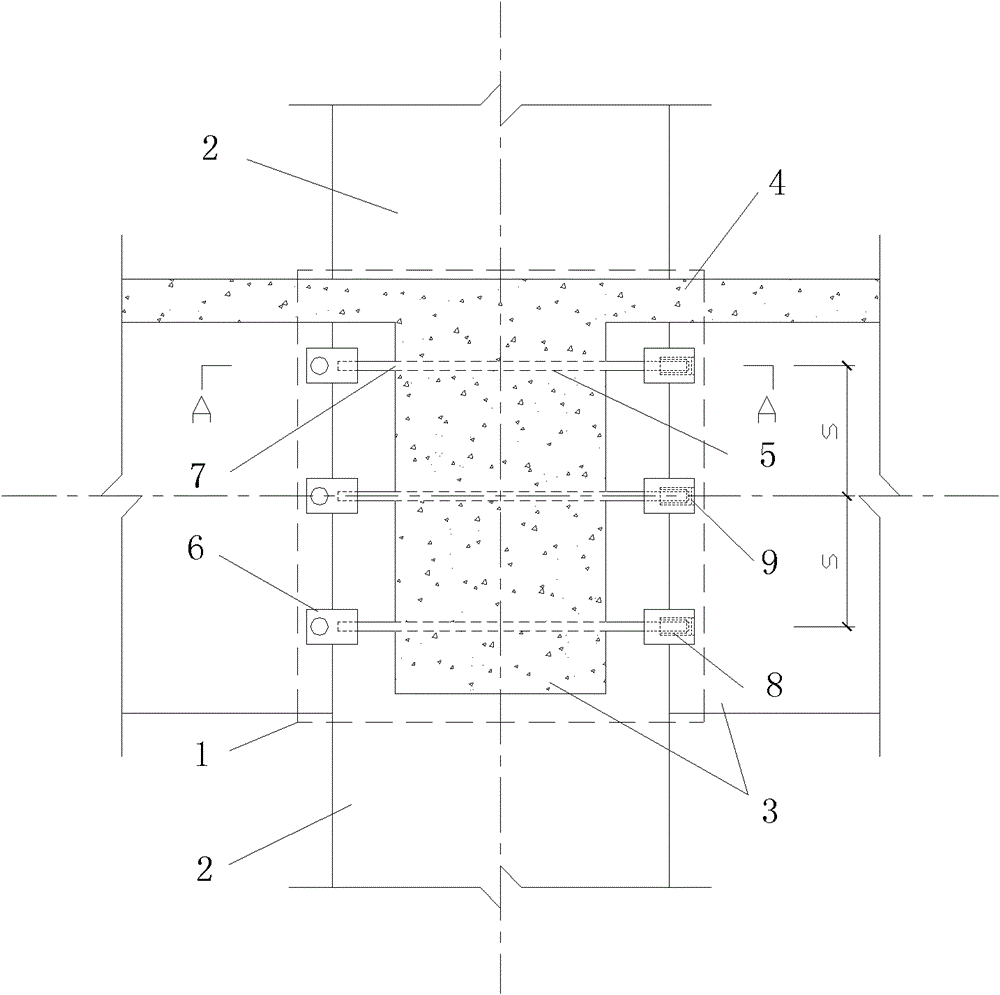

Efficient heat-preservation oil delivering pipeline

InactiveCN107606394AGood insulation performanceAvoid oil cloggingThermal insulationPipe heating/coolingPetroleumEngineering

The invention discloses an efficient heat-preservation oil delivering pipeline comprising an inner pipeline body and an outer pipe pipeline body. A heat-preservation layer, an anti-corrosion layer anda waterproof layer are arranged between the inner pipeline body and the outer pipe pipeline body. A plurality of heat-preservation pipes are arranged in the heat-preservation layer; the exteriors ofthe heat-preservation pipes in the heat-preservation layer are filled with glass cotton; a partition plate is arranged in each heat-preservation pipe and divides the heat-preservation pipe into two cavities; the cavities close to the inner pipeline body are filled with foam; and the cavities away from the inner pipeline body are filled with desiccants. Heating wires are wound on the outer walls ofthe heat-preservation pipes. Sawteeth of the waterproof layer and the anti-corrosion layer are mutually embedded. Delivering hanging blocks are arranged on the two sides of the outer pipe pipeline body, and clamping grooves are formed in the bottom faces of the delivering hanging blocks. According to the efficient heat-preservation oil delivering pipeline, through the special structure, the pipeline has good heat-preservation performance, oil blockage can be avoided, the convenience of oil delivering is improved, the stability of the oil pipeline structure is enhanced, and the anti-corrosionlayer and the waterproof layer are arranged, so that the anti-corrosion and waterproof performance of the pipeline is greatly improved, and carrying and mounting are facilitated.

Owner:CHENGDU KESHENG PETROLEUM TECH

Preparation method of bamboo waterproof and mildew-proof coating

PendingCN111518424AImprove permeabilityImproves loss resistanceAntifouling/underwater paintsAlkali metal silicate coatingsSilicone GelsCellulose

The invention relates to a bamboo waterproof anticorrosive coating and a preparation method thereof, and belongs to the technical field of bamboo protection. According to the invention, a self-made swelling agent is used for swelling in an amorphous region of cellulose; permeation of the waterproof anticorrosive coating is facilitated; after coating infiltration, metal silver ions can be firmly fixed in bamboo wood by silica gel; the loss resistance of a mildew preventive is improved; the protection performance of the bamboo material on mould is improved through the metal silver ions; nano halloysite particles are used as a carrier; the loss resistance is further achieved; in addition, sodium silicate reacts with hydrochloric acid and is heated and decomposed to generate nano silicon dioxide particles; nanometer silicon dioxide particles are embedded into the microstructure of bamboo fibers, so that bamboo density is increased, water penetration is prevented. Meanwhile, a large numberof nano silicon dioxide particles are bonded to bamboo fibers, micro rough protrusions are formed on the surfaces and the interiors of the bamboo fibers, the contact angle between the bamboo and wateris increased, a hydrophobic interface is formed, and the anti-corrosion and waterproof performance of bamboo is improved.

Owner:泉州市康佑佳莲涂料科技有限公司

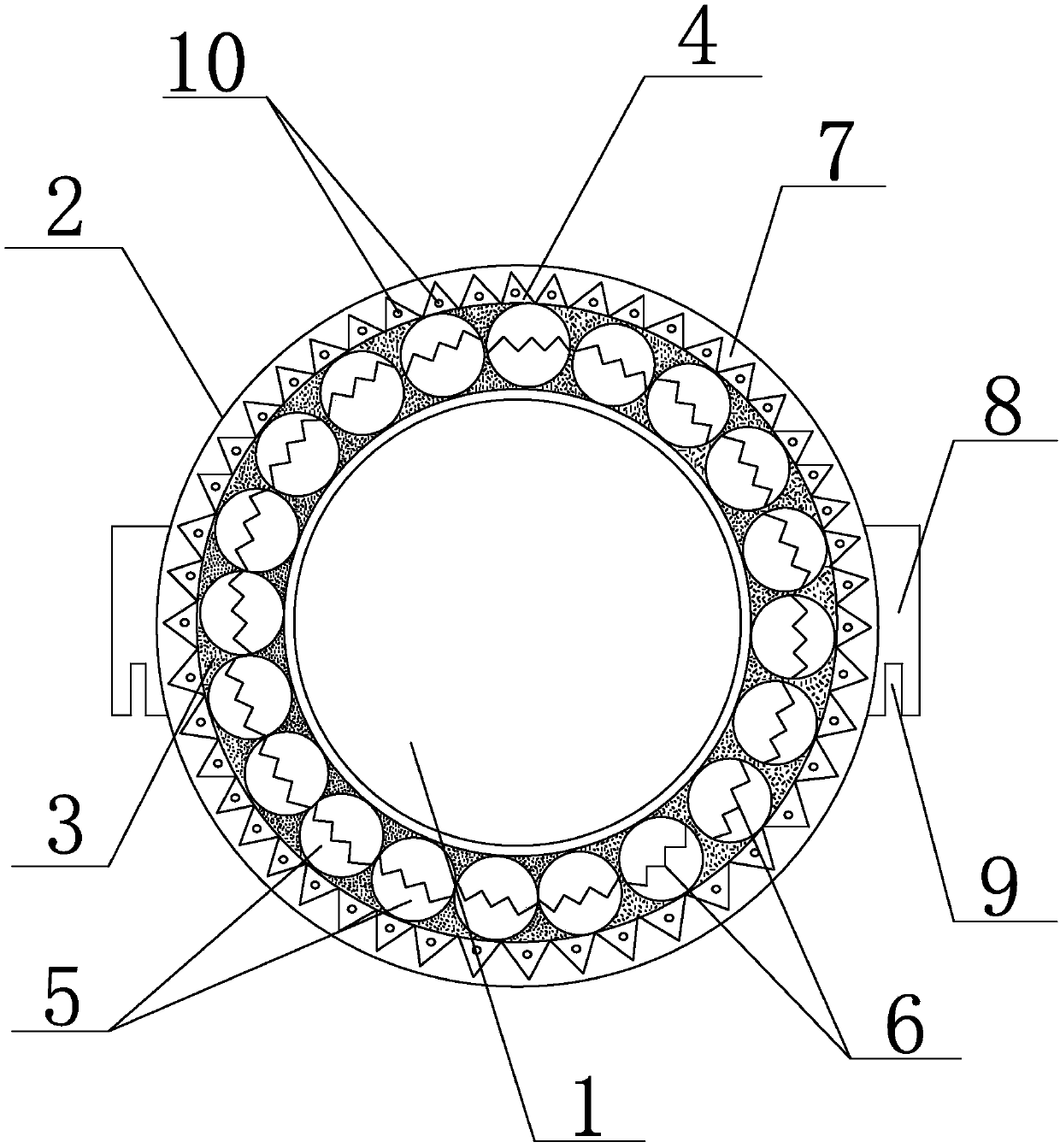

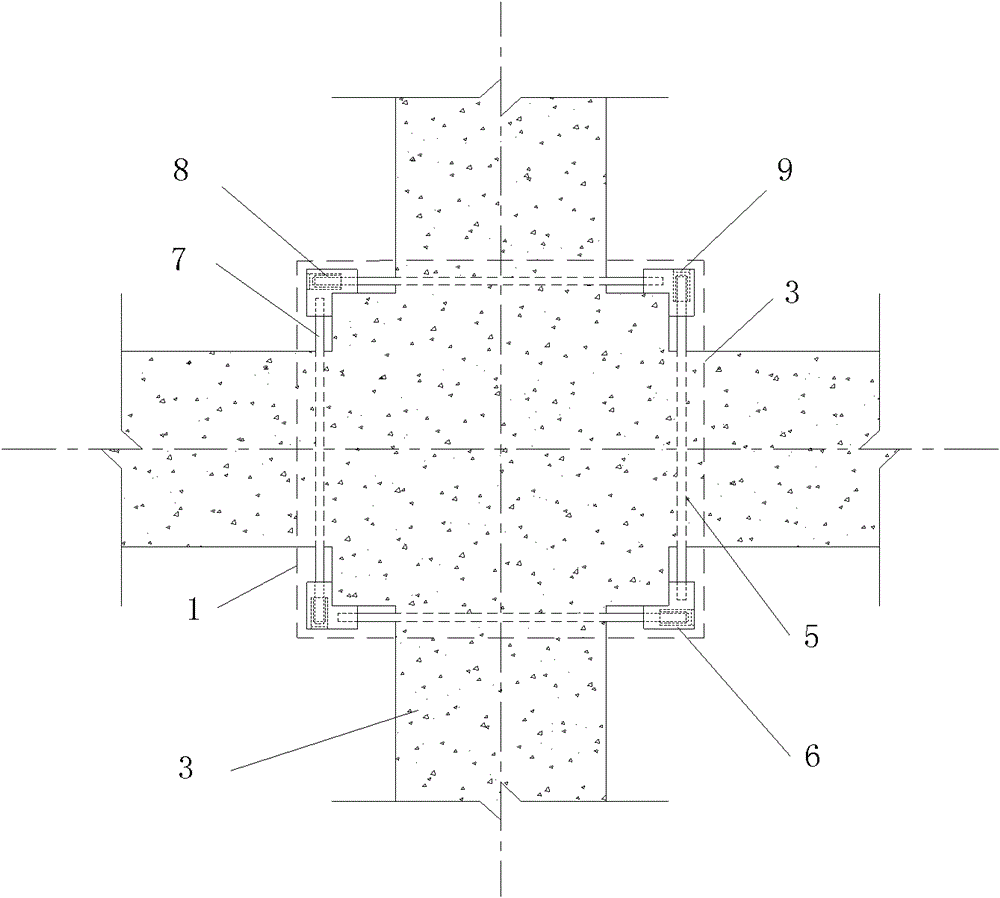

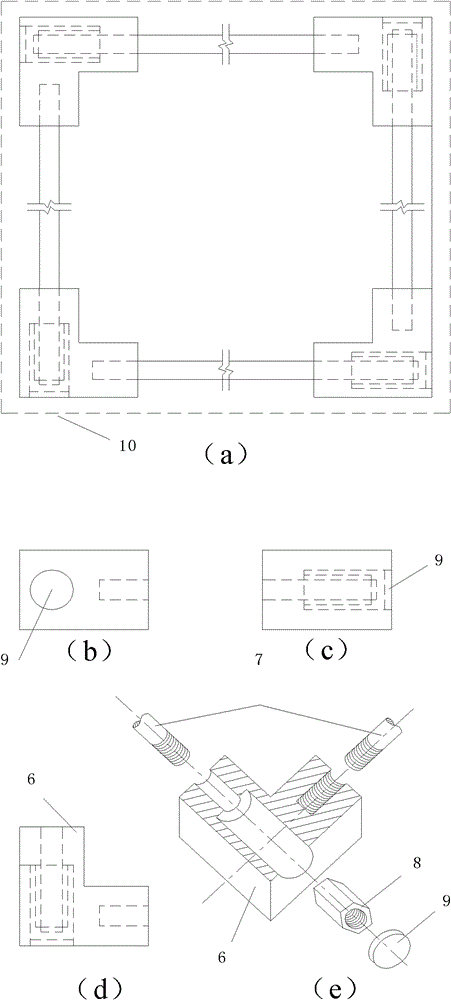

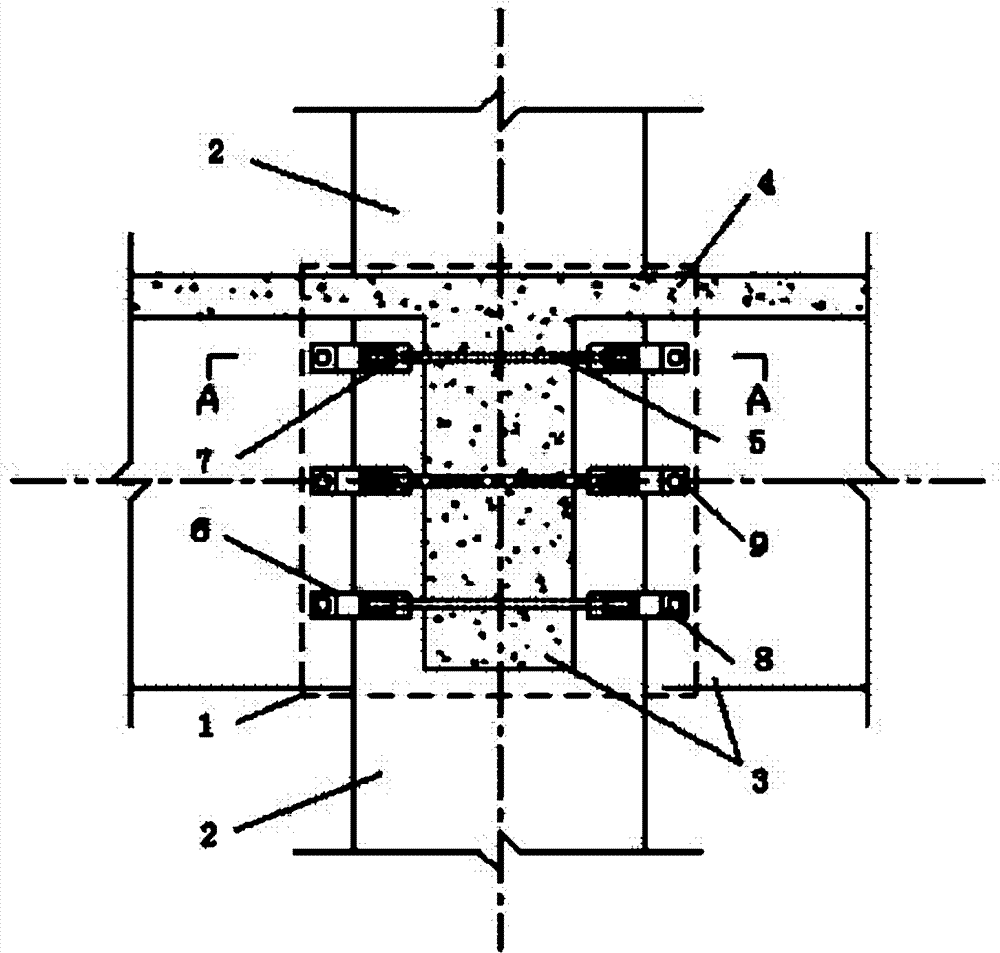

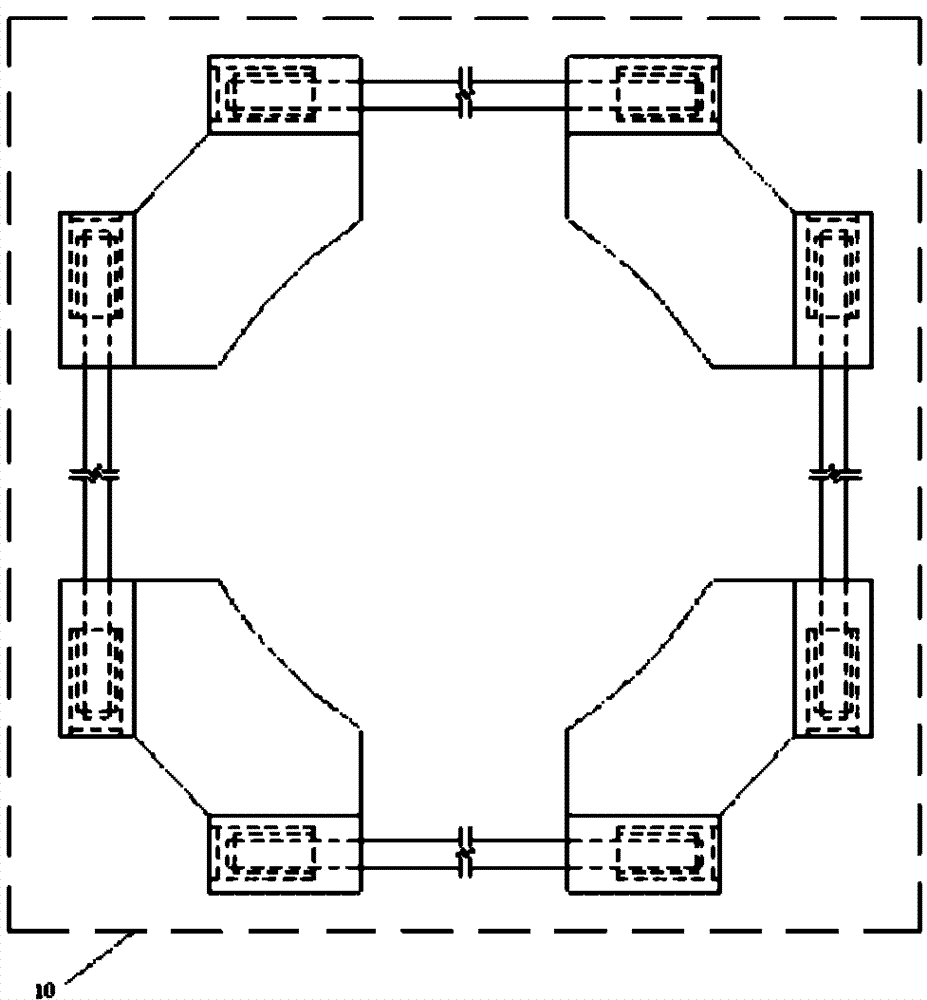

PC steel rod reinforcement device in the core area of multi-high-rise frame space nodes

InactiveCN102518315BIncreased shear capacityIncrease stiffnessBuilding repairsShock proofingFloor slabStress conditions

A device for strengthening a prestressed concrete (PC) steel bars of a panel point core area in a multi-high-rise frame space belongs to the field of civil engineering strengthening construction and comprises the panel point core area, L-shaped anchoring fasteners, the PC steel bars, nuts and sealing caps. A through hole is arranged at one end of each L-shaped anchoring fastener, and a bind hole is arranged at the other end of each L-shaped anchoring fastener and provided with inner threads. The panel point core area is a rectangular area formed by intersecting columns, beams and floor slabs, and polishing treatment is performed to four corners of the panel point core. Two ends of each PC steel bar are provided with outer threads. One end of each L-shaped anchoring fastener is connected with one end of each PC steel bar through the reserved blind hole inner threads, the other end of each L-shaped anchoring fastener penetrates through the other end of each PC steel bar with a reserved through hole to be connected with the nuts. The sealing caps are installed outside the nuts. Four L-shaped anchoring fasteners and four PC steel bars form a circle of PC steel bar hoops for restraining the panel point core area through the nuts. The device can directly bear shearing force, provide three-dimensional restraining effect, relieve stress lagging and improve common working conditions of a novel structure and an existing structure and stress conditions of the core area.

Owner:BEIJING UNIV OF TECH

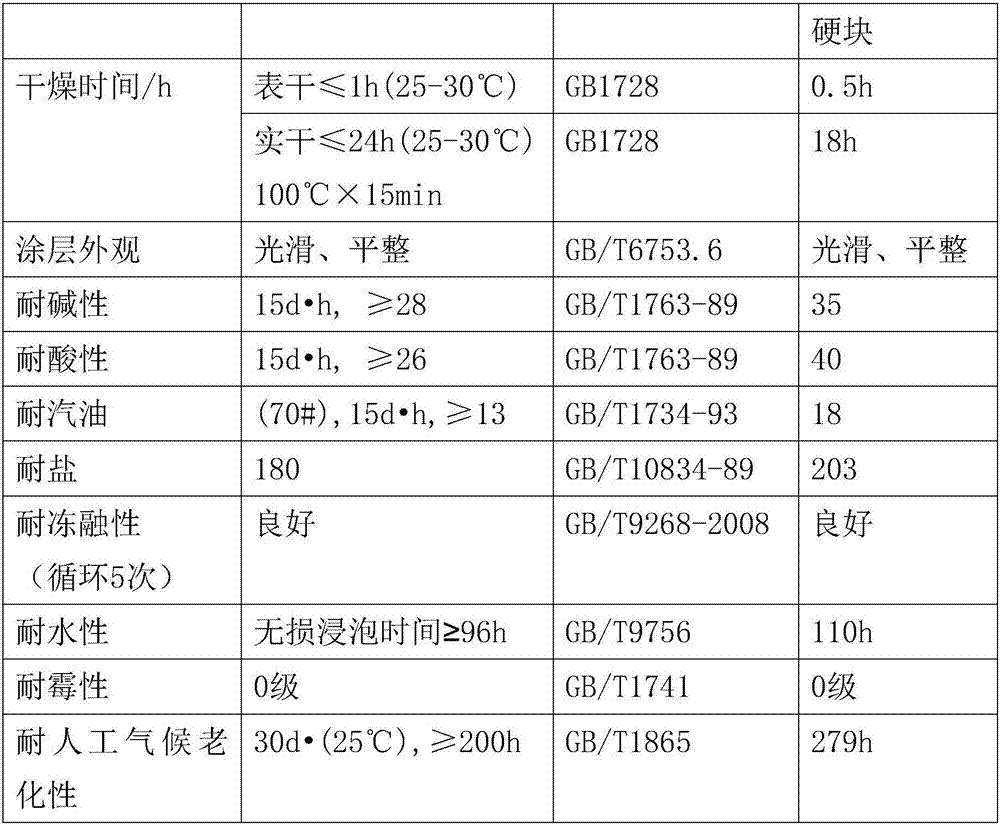

Surface preservative for civil air defense facility and preparation method of surface preservative

InactiveCN107353827AGood anti-corrosion and waterproof performanceExtended service lifeRosin coatingsAnti-corrosive paintsTitanium carbideMoisture

The invention provides a surface preservative for a civil air defense facility and a preparation method of the surface preservative. The surface preservative for the civil air defense facility is prepared from, by mass, 20-25 parts of rosin glyceride, 15-22 parts of polyurethane, 8-14 parts of modified nano diatomite in powder, 5-12 parts of micaceous iron oxide, 5-7 parts of sodium lauryl sulfate, 5-7 parts of titanium carbide, 5-7 parts of zirconium dioxide, 0.1-0.3 part of coupling agent, 0.2-0.3 part of adhesion promoters, 3-6 parts of pigments and 30-40 parts of water. The surface preservative for the civil air defense facility has the advantages of being good in acid, alkali, salt and gasoline corrosion resistance, resistant to freezing and melting, moisture, mildew, artificial climatic aging and the like, and capable of maintaining good weather resistance under various physicochemical erosion and effectively protecting the surface of the civil air defense facility.

Owner:阜南县民安人防工程设备有限公司

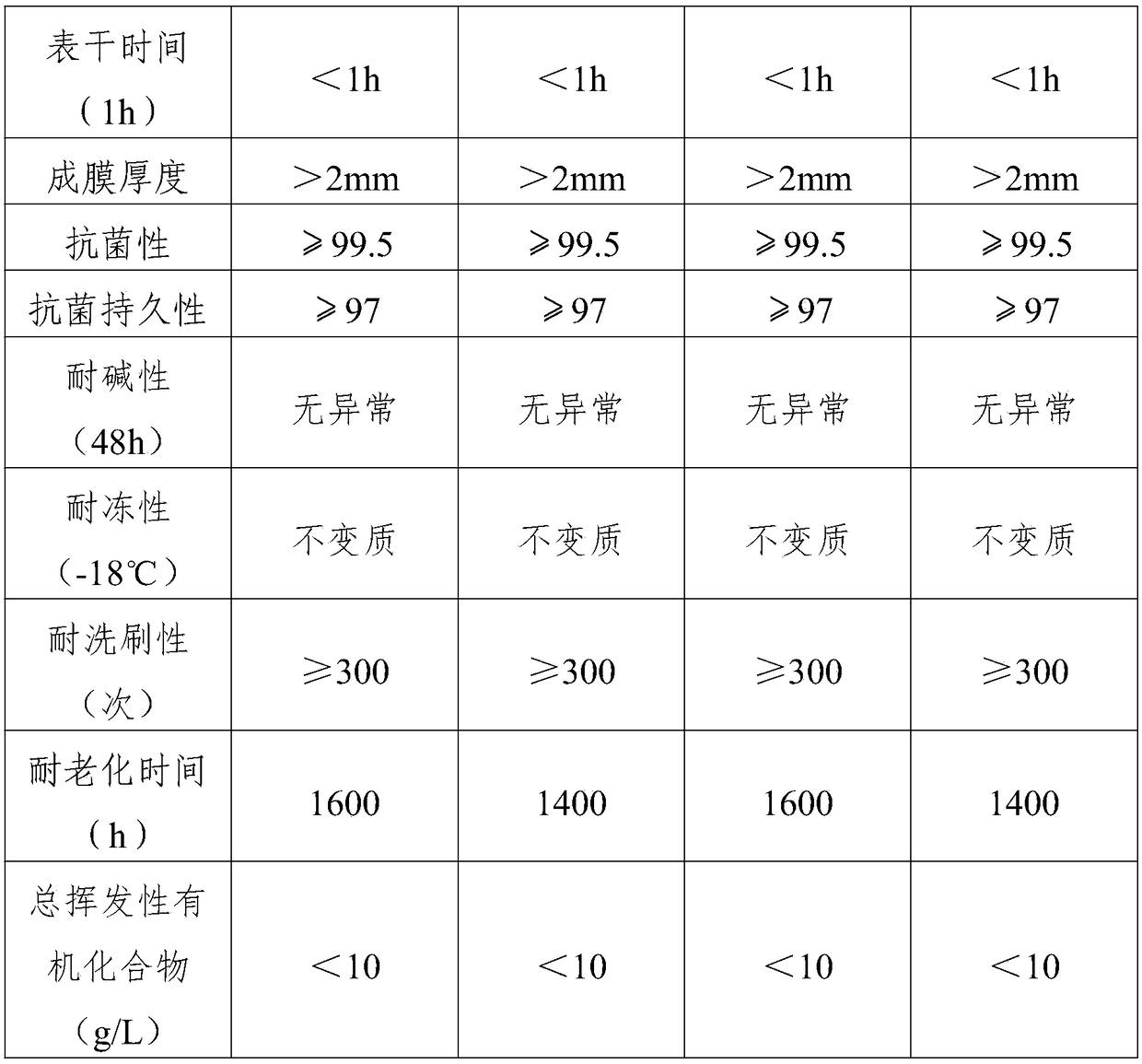

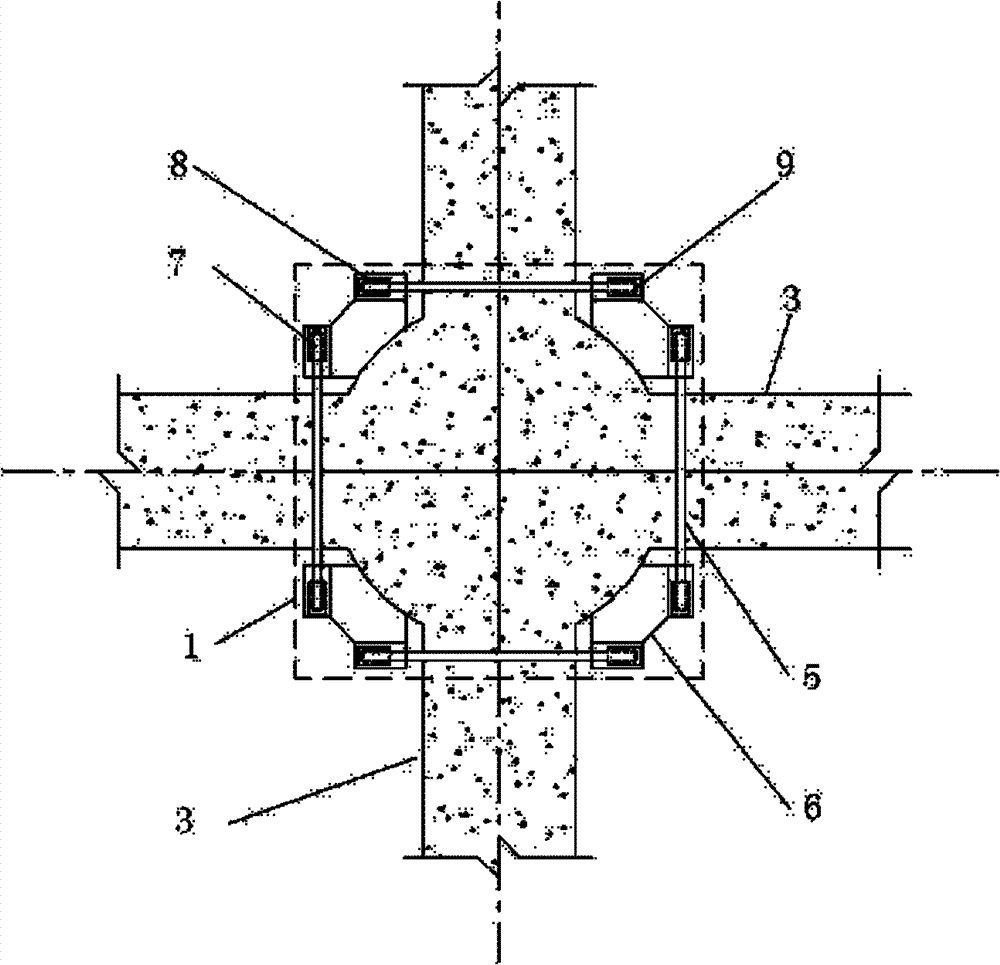

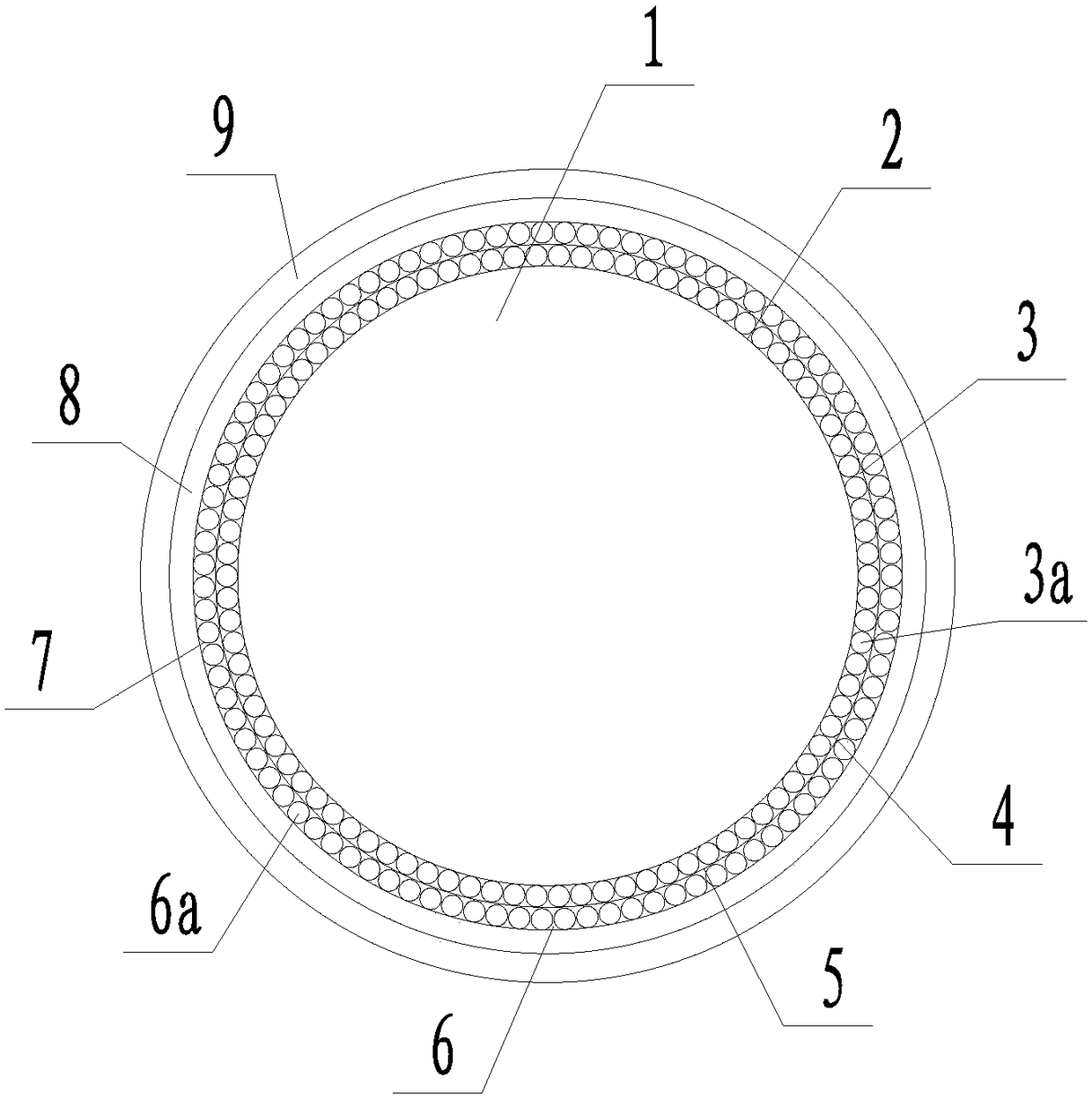

Device for strengthening PC steel bar in core area of space node of reinforced concrete cylindrical frame

InactiveCN102587686BIncreased shear capacityIncrease stiffnessBuilding repairsShock proofingStress conditionsReinforced concrete

The invention relates to a device for strengthening a PC steel bar in a core area of a space node of a reinforced concrete cylindrical frame, belonging to the strengthening construction field of civil engineering. The device comprises a node core area, an arc anchoring buckle, PC steel bars, nuts and a sealing cap, wherein through holes are formed on two legs of the arc anchoring buckle; the node core area is a cylindrical area composed of a column, a beam and a floor, which are intersected; four arc corners of the node core area are polished; external screw threads are arranged on two ends of the PC steel bar; one leg of the arc anchoring buckle is connected with the nut by one end of the PC steel bar penetrating through the preformed through hole; the sealing cap is arranged outside the nut; four arc anchoring buckles and four PC steel bars form a round PC steel bar hoop for limiting the node core area by the nuts. The device can directly bear shearing force, provide three-way constraint action, relieve stress lagging and improve co-working condition of new and old structures and stress condition of the core area.

Owner:BEIJING UNIV OF TECH

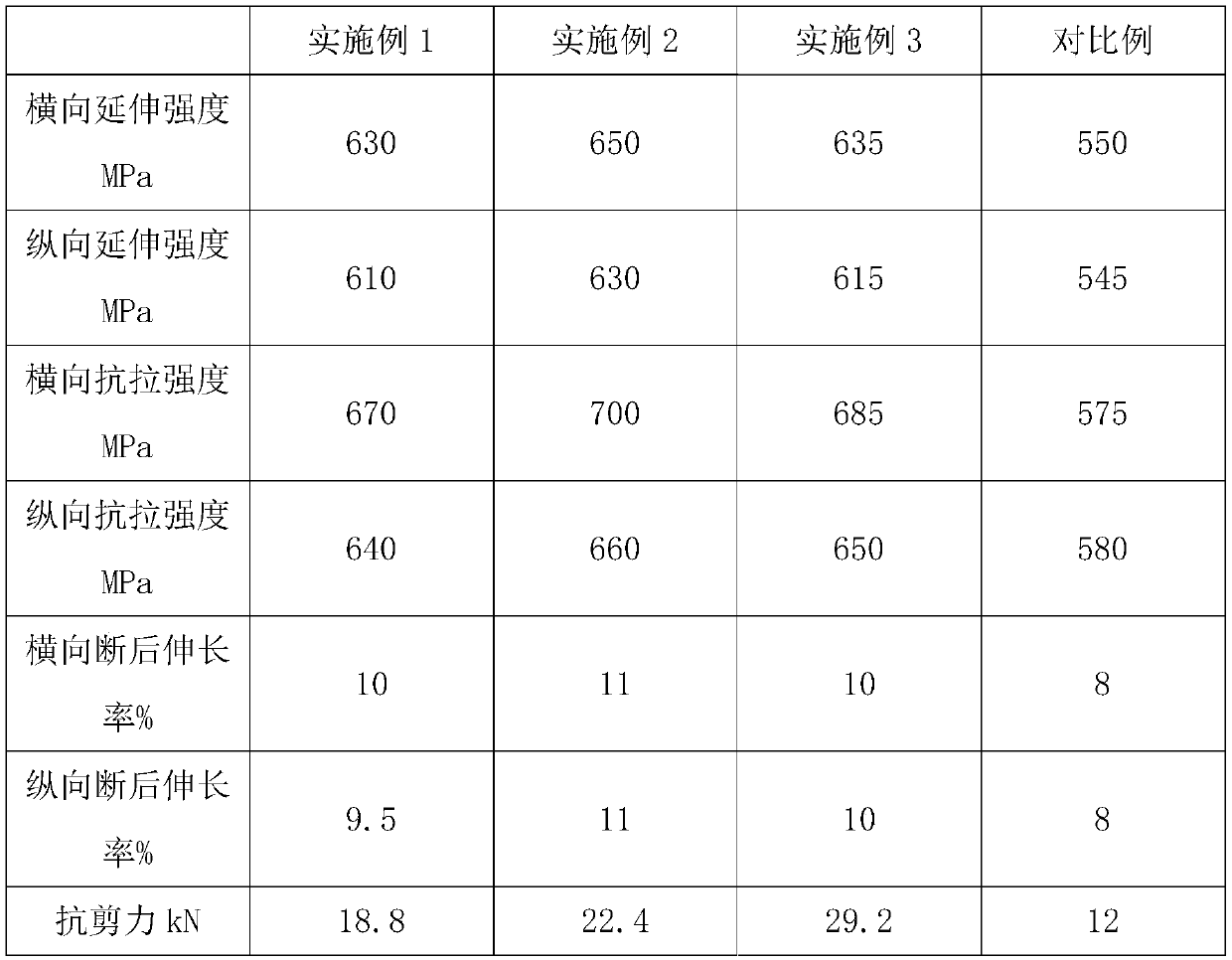

A method for manufacturing high-strength railway steel mesh

The invention discloses a method for manufacturing a high-strength railway reinforcing mesh. The method comprises the following steps that step 1, a steel bar straightening machine is utilized to straighten a steel bar, and then the steel bar is cut into segments according to the size; step 2, the segmented steel bars are added to a diluted hydrochloric acid solution to be oscillated for 2-4h andtaken out to be dried; step 3, the surfaces of the steel bars are coated with an ethyl cellulose alcohol solution and dried to obtain coated steel bars; step 4, the coated steel bars are straightenedand cut into reinforcing rods, the reinforcing rods are arranged to form a mesh structure, and connecting points of the reinforcing rods are marked; step 5, ethyl cellulose on the surfaces of the reinforcing rods at the connecting points is removed by using ethanol, and then the connecting points are subjected to abrasion cutting to form grooves; step 6, the interiors of the grooves are coated with a neoprene adhesive, assembly is performed to form a mesh structure, and the peripheries of the connecting points are welded and solidified; and step 7, a layer of high-density polyethylene film issprayed on the surface of a prefabricated steel mesh, and then illumination is performed for 1-2h to obtain the high-strength railway reinforcing mesh. The method solves the problem of corrosion of the reinforcing mesh in the concrete setting process.

Owner:江阴市邦泰金属制品有限公司

Transformer preservative paint and preparation method thereof

InactiveCN107254227AImprove anti-corrosion performanceImprove water resistanceFireproof paintsAnti-corrosive paintsTransformerAcrylic resin

The invention discloses transformer preservative paint which comprises the following raw materials in parts by weight: 30-50 parts of high-hardness aqueous acrylic resin, 20-28 parts of polyurethane, 15-25 parts of red lead, 1-3 parts of phenyl silicon oil, 5-8 parts of diethylenetriamine, 3-5 parts of ethyl acetate, 4-8 parts of triphenyl phosphate, 2-3 parts of zinc borate, 5-10 parts of packing, 1-2 parts of a defoaming agent, 2-3 parts of a dispersing agent, 2-4 parts of a preservative, 4-8 parts of houttuynia cordata, 1-3 parts of a thickening agent and 10-20 parts of deionized water. The transformer preservative paint disclosed by the invention is relatively small in raw material quantity, relatively low in cost, relatively simple in preparation process and very good in temperature resistance and corrosion resistance.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

Water-proof processing equipment for wood substance plank stuff and processing method using the same

InactiveCN100563958CEasy to assemble and disassembleLow costWood compressionWood charring/burningElectricityTemperature control

The invention discloses a waterproof treatment equipment for wooden boards, which is characterized in that it includes a workbench and a longitudinal support and a transverse support fixedly arranged on the workbench front and back, the longitudinal support is provided with an adjustable transverse platen device, and the adjustable transverse platen device There is a horizontal heating device on the top, an adjustable longitudinal platen device on the horizontal support, a longitudinal heating device on the adjustable longitudinal platen device, and a temperature control device electrically connected to the horizontal heating device and the longitudinal heating device on the workbench. , the workbench is provided with a driving mechanism that simultaneously drives the adjustable horizontal platen device and the adjustable longitudinal platen device; It is processed and shaped, and the gap between the two final shafts can be adjusted by adjusting the screw, so that the final shaft can exert pressure on the wooden board, thereby compacting the tube holes on the surface of the wooden board, which has the effect of waterproofing and preventing deformation.

Owner:陈兆红

Anti-corrosive water tank

InactiveCN107572082AGood anti-corrosion and waterproof performanceLow costBoxesWaste managementWater tanks

The invention discloses an anti-corrosive water tank. The anti-corrosive water tank comprises a water tank main body with an integrated structure, wherein tank side reinforcing columns communicating with two opposite inner side surfaces are arranged in the water tank main body; tank body reinforcing rib convex columns bulged inwards into the water tank main body are arranged in the water tank mainbody; water inlet ports are formed in the top of the water tank main body; and a small water outlet port and a large water outlet port are formed in the bottom of the water tank main body. Accordingto the anti-corrosive water tank, installation connecting pieces and other parts are omitted, so that installation is not needed; due to the integrally-formed structure, deformation is avoided, and the waterproof and anti-corrosive effects are improved; and the water tank main body is high in anti-corrosive and waterproof performance, low in cost, and capable of increasing the strength of the anti-corrosive water tank, buffering the impact force of water inlet in a use process, and prolonging the service life of the anti-corrosive water tank.

Owner:广东巨隆防腐设备有限公司

Waterborne waterproof anticorrosive paint and preparation method thereof

InactiveCN108531031AGood anti-corrosion and waterproof performanceEasy to prepareAntifouling/underwater paintsPaints with biocidesMetakaolinEmulsion

The invention discloses waterborne waterproof anticorrosive paint and a preparation method thereof. The waterborne waterproof anticorrosive paint comprises, by weight, 40-60 parts of waterborne acrylic emulsion, 20-30 parts of dimethyl siloxane, 15-25 parts of butyl acetate, 10-20 parts of benzoyl chloride, 6-15 parts of dibutyl phthalate, 5-15 parts of organic montmorillonite, 2-8 parts of nano titanium dioxide, 3-8 parts of ground calcium carbonate, 4-8 parts of calcined metakaolin powder, 5-10 parts of polyvinyl alcohol, 3-10 parts of polypropionamide fiber, 1-6 parts of preservative, 1-5 parts of film forming aid, 0.5-3 parts of thickener, 0.2-0.8 part of wetting dispersant and 20-40 parts of deionized water. The waterborne waterproof anticorrosive paint has the advantage of good anticorrosive and waterproof performance, and the preparation method is simple, low in cost and suitable for large-scale popularization and use.

Owner:合肥金云新材料有限公司

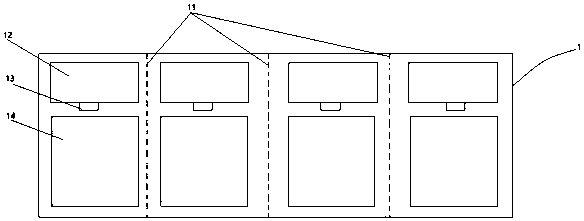

Anti-corrosion waterproof garbage can for garbage classification

InactiveCN110803411AEasy to sort garbageExtended service lifeRefuse receptaclesProcess engineeringStructural engineering

The invention provides an anti-corrosion waterproof garbage can for garbage classification. The anti-corrosion waterproof garbage can comprises a box body and a plurality of garbage bags, wherein a plurality of baffles are connected in the box body; the inner space of the box body is divided into a plurality of compartments which are arranged in parallel by the baffles; garbage throwing openings are formed in the positions, corresponding to the compartments, of a front panel of the box body; one garbage bag is arranged in each compartment; hook protrusions are arranged on the positions, closeto the garbage throwing openings, of the front panel of the box body in a protruding mode; garbage classification marks are attached to the positions, positioned below the garbage throwing openings, of the front panel of the box body; two-dimensional codes are sprayed on the front panel of the box body; and the outer surface of the box body is coated with anti-corrosion waterproof paint. The garbage can be used for storing four kinds of garbage in a classified mode, the structural design is reasonable, the good anti-corrosion waterproof performance is achieved, the service life is long, the manufacturing cost is low, and the economic benefit is good.

Owner:SUZHOU HAOLI CULTURE MEDIA TECH CO LTD

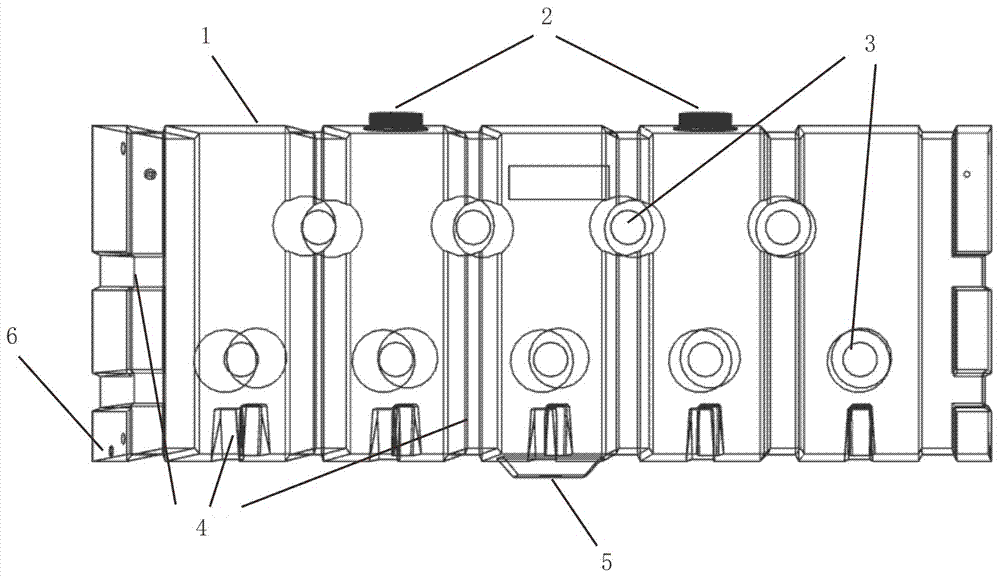

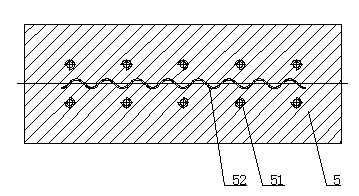

Wood plastic tile extrusion mold

InactiveCN103568251AHigh strengthGood anti-corrosion and waterproof performanceDomestic articlesWaveform shapingEngineering

The invention discloses a wood plastic tile extrusion mold. The mold comprises a mold body (1), a second transition plate (2), a first transition plate (3), a cylinder manifold (4), a die (5), a third water jacket (6), a second water jacket (7) and a first water jacket (8), the die (5) is provided with a plurality of screwed holes (51), a bore (52) is arranged in the middle of the die (5), and the cross section of the bore (52) has a waveform-shaped groove shape. The mold has a production efficiency, and wood plastic tiles having the advantages of high strength, good anticorrosive and waterproof performances, environmental protection, beauty and long service life can be produced through the mold.

Owner:湖北高新明辉模具有限公司

Method for preparing rubber master batch

ActiveCN102634299BImprove cold resistanceImprove performanceNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesive beltEthyl acetate

The invention relates to a method for preparing rubber master batch, which is applied to the technical field of anti-corrosive pipes. The rubber master batch is prepared from the following components in parts by weight: 12.5-13.5 parts of styrene butadiene rubber, 1.5-1.6 parts of nature rubber, 9.5-10.5 parts of kaolin, 11.5-12.5 parts of light calcium carbonate with average grain diameter of 1-5 microns; 3.0-3.5 parts of No. 40 engine oil, 1.5-2.0 parts of ethyl acetate and 2.0-2.5 parts of dioctyl phthalate. The method comprises the following step of: putting mixed raw materials into a rubber grinding machine to be ground to form the rubber master batch with the thickness of 1.5-2mm. The method for preparing the rubber master batch has the advantages of improving cold resistance of pressure-sensitive adhesive produced by adopting the rubber master batch to 8-12 DEG C, modifying the performance of the pressure-sensitive adhesive carried on anti-corrosive rubber, enabling the water vapor transmittance to be lower than 0.45mg / cm<2>, improving the anti-corrosive waterproof effect and enabling the water absorption to be lower than 0.30%.

Owner:PETROCHINA CO LTD

Cabinet body board material of high and low voltage power distribution cabinet and preparation method of cabinet body board material

InactiveCN109466133AImprove wear resistanceImprove corrosion resistanceFlat articlesMetal layered productsPorosityFiber

The invention provides a cabinet body board material of a high and low voltage power distribution cabinet and a preparation method of the cabinet body board material. The cabinet body board material comprises an inner alloy layer, a wood plastic layer and an outer alloy layer which are formed through hot-pressing; the inner alloy layer and the outer alloy layer are composite type aluminum alloy plates doped with glass fiber / nitrides respectively; the wood plastic layer is an ABS based foaming wood plastic plate; and the thickness ratio of the inner alloy layer to the outer alloy layer to the wood plastic layer is 1:1:4. Through the recombination of multi-layer, aluminum alloy is adopted, and the wood plastic layer is arranged internally, the overall specific gravity is reduced, the cabinetbody board material is convenient to use and install, light in weight and high in strength, the wood plastic layer consists of ABS resin and wood chippings as base bodies, a powder filler, a modifierand a foaming agent are filled, the cabinet body board material is of high corrosion prevention and water prevention while the strength is guaranteed, a plastic body with high porosity internally isgenerated, the powder filler is loaded with wood cellulosics and resin chains, and the crosslinking property is good.

Owner:南京福禄源电子科技有限公司

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

A double-layer reverse high-strength aluminum alloy armored submarine cable

ActiveCN106448856BAvoid spreadingExtended service lifeSubmarine cablesCable/conductor manufactureHigh intensityUltimate tensile strength

The invention discloses a double-layer reverse high-strength aluminum alloy armored ocean cable. The double-layer reverse high-strength aluminum alloy armored ocean cable comprises a cable core. A first anticorrosive coating is arranged on the outer side of the cable core, a first armoring layer is arranged on the outer side of the first anticorrosive coating and comprises a plurality of first molded single wires, and a second anticorrosive coating is arranged on the outer surface of each first molded single wire. A third anticorrosive coating is arranged on the outer side of the first armoring layer, a second armoring layer is arranged on the outer side of the third anticorrosive coating and comprises a plurality of second molded singles lines, and a fourth anticorrosive coating is arranged on the outer surface of each second molded single wire. The first molded single wires and the second molded single wires are stranded reversely. The double-layer reverse high-strength aluminum alloy armored ocean cable has the advantages that steel wires are prevented from being loosened effectively, and the service life of the ocean cable is prolonged; the anticorrosion and waterproofing effect is improved effectively; the overall strength of the armoring layers is improved effectively.

Owner:CHONGQING TAISHAN CABLE +3

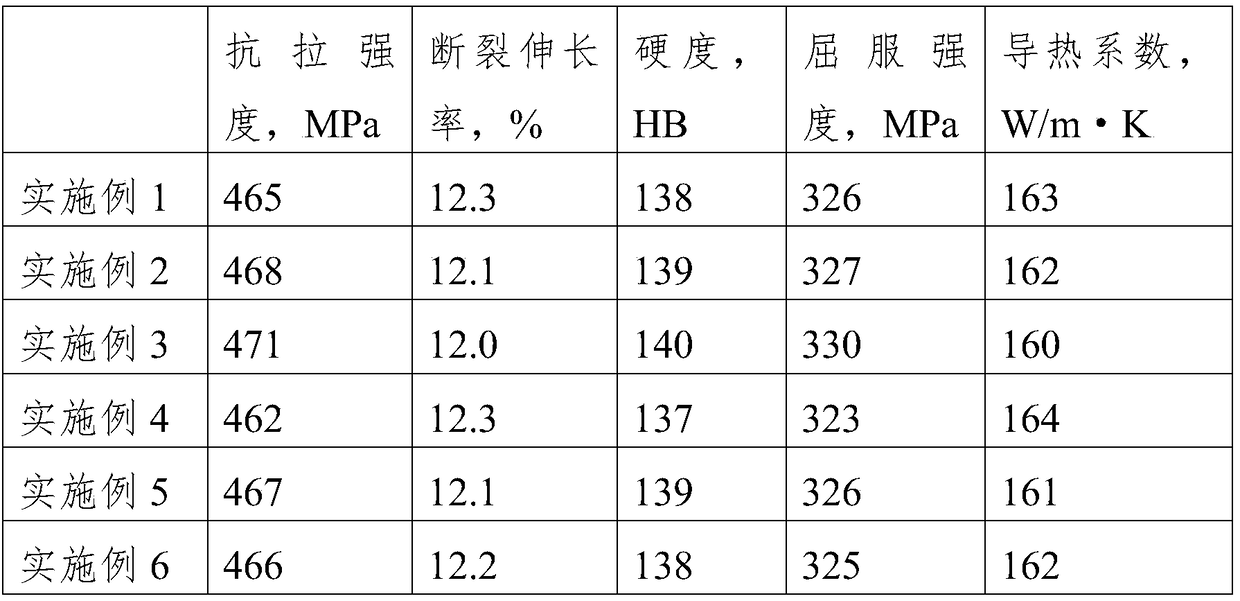

High-adhesive water-based polyurethane anti-corrosion and waterproof coating and preparation method thereof

InactiveCN104629600BGood anti-corrosion and waterproof performanceImprove mechanical propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsCrack resistancePolyurethane adhesive

The invention discloses an aqueous polyurethane antiseptic and waterproof coating with high cohesiveness. The coating comprises the following raw materials in parts by weight: 40-50 parts of polyurethane emulsion, 15-20 parts of pyridine ionic liquid, 5-8 parts of bamboo powder, 3-5 parts of nanometal, 18-22 parts of inorganic functional filling, 8-10 parts of vegetable oil, 1-3 parts of 2-naphthol, 1-3 parts of isopropyl myristate, 0.5-1 part of dibutyltin dilaurate, 1-3 parts of dimethyl sulfoxide, 3-5 parts of surfactant, 1-2 parts of coalescing agent and 60-80 parts of water. In the invention, pollution-free and environment-friendly ionic liquid is used as a cosolvent, the cohesiveness of the polyurethane emulsion can be greatly improved, and furthermore, nano-particles are uniformly dispersed in the coating, so that the difficult problem of aggregation of the nano-particles is solved. The coating provided in the invention has the advantages of strong cohesiveness, crack resistance, good waterproof performance, good corrosion resistance in severe environments such as acid, alkali, salt and oil, and obviously prolonged service life.

Owner:扬州豪扬新型建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com