Surface preservative for civil air defense facility and preparation method of surface preservative

A preservative and facility technology, applied in the field of surface preservatives of civil air defense facilities and its preparation, can solve problems such as failure to reach expected life, reduced corrosion resistance, erosion, etc., achieve good anti-corrosion and waterproof performance, prolong service life, and use materials simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

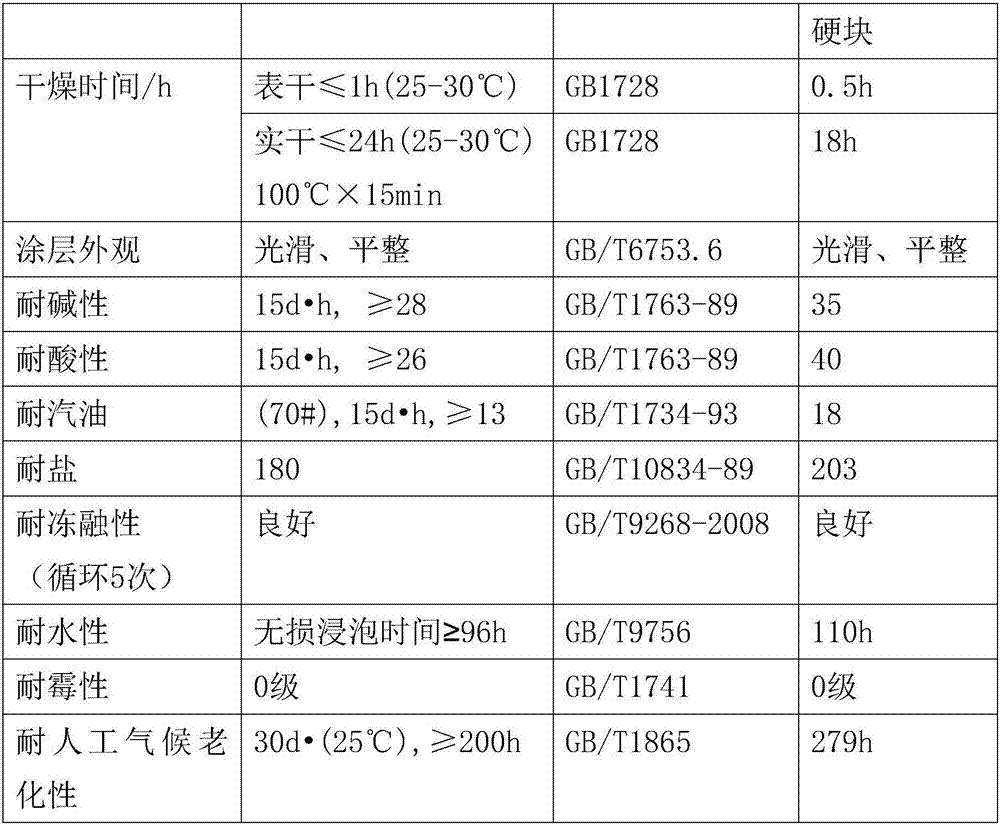

Examples

Embodiment 1

[0023] A surface preservative for civil air defense facilities, comprising the following components in parts by mass:

[0024] 20 parts of rosin glyceride, 15 parts of polyurethane, 8 parts of modified nano-diatomaceous earth powder, 5 parts of mica iron oxide, 5 parts of sodium lauryl sulfate, 5 parts of titanium carbide, 5 parts of Hao Dioxide, 0.1 part of coupling agent , 0.2 parts of adhesion promoter, 3 parts of pigment, 30 parts of water.

[0025] The adhesion promoter is one or more of polymethacrylate, ethylene-propylene copolymer, and styrene-diene copolymer.

[0026] The pigment is titanium white, lithopone, iron red or chrome yellow.

[0027] The preparation method of described modified nano diatomite powder is:

[0028] 1) Grind diatomite, pass through a 500-600 mesh sieve, add water twice its mass, then add butyl acetate, stir and react at room temperature for 15-20 hours, dry, and grind to obtain modified diatomite powder;

[0029] 2) drying the modified diato...

Embodiment 2

[0039] A surface preservative for civil air defense facilities, comprising the following components in parts by mass:

[0040] 25 parts of rosin glyceride, 22 parts of polyurethane, 14 parts of modified nano diatomite powder, 12 parts of mica iron oxide, 7 parts of sodium lauryl sulfate, 7 parts of titanium carbide, 7 parts of Hao Dioxide, 0.3 parts of coupling agent , 0.3 parts of adhesion promoter, 6 parts of pigment, 40 parts of water.

[0041] The adhesion promoter is one or more of polymethacrylate, ethylene-propylene copolymer, and styrene-diene copolymer.

[0042] The pigment is titanium white, lithopone, iron red or chrome yellow.

[0043] The preparation method of described modified nano diatomite powder is:

[0044] 1) Grind diatomite, pass through a 500-600 mesh sieve, add water twice its mass, then add butyl acetate, stir and react at room temperature for 15-20 hours, dry, and grind to obtain modified diatomite powder;

[0045] 2) drying the modified diatomite p...

Embodiment 3

[0055] A surface preservative for civil air defense facilities, comprising the following components in parts by mass:

[0056] 22 parts of rosin glyceride, 18 parts of polyurethane, 10 parts of modified nano-diatomaceous earth powder, 7 parts of mica iron oxide, 6 parts of sodium lauryl sulfate, 6 parts of titanium carbide, 6 parts of Hao Dioxide, 0.2 parts of coupling agent , 0.2 parts of adhesion promoter, 5 parts of pigment, 35 parts of water.

[0057] The adhesion promoter is one or more of polymethacrylate, ethylene-propylene copolymer, and styrene-diene copolymer.

[0058]The pigment is titanium white, lithopone, iron red or chrome yellow.

[0059] The preparation method of described modified nano diatomite powder is:

[0060] 1) Grind diatomite, pass through a 500-600 mesh sieve, add water twice its mass, then add butyl acetate, stir and react at room temperature for 15-20 hours, dry, and grind to obtain modified diatomite powder;

[0061] 2) drying the modified diat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com