Cabinet body board material of high and low voltage power distribution cabinet and preparation method of cabinet body board material

A technology for power distribution cabinets and cabinet body panels, applied in the field of high and low voltage power distribution cabinet cabinet body panels and its preparation, can solve the problems of short effective service life, poor comprehensive protection performance, unfavorable application and promotion, etc., and achieve strong structural stability , good anti-corrosion and water resistance, and high comprehensive application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

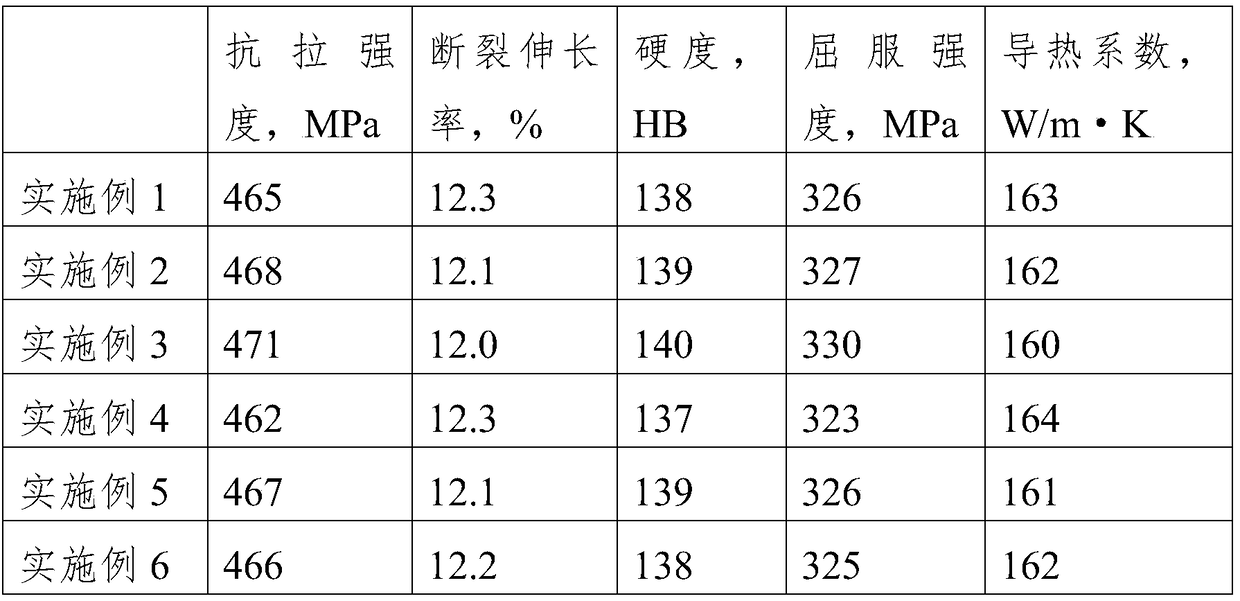

Examples

Embodiment 1

[0024] A high and low voltage power distribution cabinet cabinet body plate, including a hot-pressed inner alloy layer, a wood-plastic layer, and an outer alloy layer. Aluminum alloy plate, the wood-plastic layer adopts ABS-based foamed wood-plastic board, and the thickness ratio of the inner alloy layer, outer alloy layer, and wood-plastic layer is 1:1:3.

[0025] The mass percentages of glass fiber, nitride and aluminum-based alloy in the composite aluminum alloy plate are 5 wt% of glass fiber, 0.4 wt% of nitride and the balance of aluminum-based alloy. The glass fibers are alkali-free glass fibers with an aspect ratio of 7-8; the nitrides include boron nitride, magnesium nitride, and silicon nitride, and the particle size of the nitrides is 1-5 μm. Among them, boron nitride, magnesium nitride, and silicon nitride The mass ratio of magnesium and silicon nitride is 1:0.2:1; the aluminum-based alloy includes the following components in mass percentage: Cu 1.8%, Mn 0.48%, Si0.5...

Embodiment 2

[0036] A high and low voltage power distribution cabinet cabinet body plate, including a hot-pressed inner alloy layer, a wood-plastic layer, and an outer alloy layer. Aluminum alloy plate, the wood-plastic layer adopts ABS-based foamed wood-plastic board, and the thickness ratio of the inner alloy layer, outer alloy layer, and wood-plastic layer is 1:1:3.

[0037] The mass percent content of glass fiber, nitride and aluminum-based alloy in the composite aluminum alloy plate is 4 wt% of glass fiber, 0.3 wt% of nitride and the balance of aluminum-based alloy. The glass fibers are alkali-free glass fibers with an aspect ratio of 7-8; the nitrides include boron nitride, magnesium nitride, and silicon nitride, and the particle size of the nitrides is 1-5 μm. Among them, boron nitride, magnesium nitride, and silicon nitride The mass ratio of magnesium and silicon nitride is 1:0.4:1.5; the aluminum-based alloy includes the following components in mass percentage: Cu 2.1%, Mn 0.52%, ...

Embodiment 3

[0043] A high and low voltage power distribution cabinet cabinet body plate, including a hot-pressed inner alloy layer, a wood-plastic layer, and an outer alloy layer. Aluminum alloy plate, the wood-plastic layer adopts ABS-based foamed wood-plastic board, and the thickness ratio of the inner alloy layer, outer alloy layer, and wood-plastic layer is 1:1:3.

[0044] The mass percent content of glass fiber, nitride and aluminum-based alloy in the composite aluminum alloy plate is 2.5wt% of glass fiber, 0.5wt% of nitride and the balance of aluminum-based alloy. The glass fibers are alkali-free glass fibers with an aspect ratio of 7-8; the nitrides include boron nitride, magnesium nitride, and silicon nitride, and the particle size of the nitrides is 1-5 μm. Among them, boron nitride, magnesium nitride, and silicon nitride The mass ratio of magnesium and silicon nitride is 1:0.1:1; the aluminum-based alloy includes the following components in mass percentage: Cu 2.0%, Mn 0.45%, Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com