Patents

Literature

82results about How to "Strong cross-linking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant and high-salinity-resistant water-plugging profile control agent, and preparation method and application thereof

ActiveCN102533233ABreak usabilityBreak the limitationsFluid removalDrilling compositionBenzaldehydeCyclodextrin

The invention relates to a high-temperature-resistant and high-salinity-resistant water-plugging profile control agent, and a preparation method and application thereof. The water-plugging profile control agent comprises polyacrylamide, a composite crosslinking agent, cyclodextrin, metaphenylene diamine and deoxidant, wherein the composite crosslinking agent consists of aldehyde, phenol and aluminum citrate; the aldehyde is one or the combination of benzaldehyde and paraformaldehyde; and the phenol is one or more of phenol, resorcinol and hydroquinone. The water-plugging profile control agent can resist the temperature of 120 DEG C, can be directly prepared by using water with mineralization degree of 150,000 mg / L, and has high crosslinking performance and long-term stability. The preparation method for the water-plugging profile control agent is simple, convenient to operate, and easy to control, and water-plugging profile control agent has a good plugging effect, and construction can be performed after the water-plugging profile control agent is directly prepared on site.

Owner:PETROCHINA CO LTD

Fabrics having a topically applied silver-based finish with a cross-linked binder system for improved high-temperature wash durability

InactiveUS20040214490A1Highly beneficial durabilityImprove featuresBiochemical fibre treatmentSynthetic resin layered productsCross-linkTopical surface

Improvements in the high-temperature wash durability and discoloration levels for fabrics having topically applied silver-ion treatments (such as ion-exchange compounds, like zirconium phosphates, glasses and / or zeolites) are provided. Such solid compounds are generally susceptible to discoloration and, due to the solid nature thereof, are typically easy to remove from topical surface applications, particularly when laundered at elevated temperatures. The inventive treatment requires the presence of a specific cross-linked binder, either as a silver-ion overcoat or as a padded-on component of a cross-linked binder admixed with the silver-ion antimicrobial compound. In addition, specific metal halide additives (preferably substantially free from sodium ions) may be utilized to combat the discolorations typical of such silver-ion formulations. As a result, high-temperature wash durability, discoloration levels, or both, can be improved to the extent that after a substantial number of standard launderings and dryings, the inventive treatment does not wear away in any appreciable amount and the color of the treatment remains substantially the same as when first applied. The particular treatment method, as well as the treated fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

Fabrics having a topically applied silver-based finish with a cross-linked binder system for improved high-temperature wash durability

InactiveUS20070004300A1Highly beneficial durabilityHigh densityBiochemical fibre treatmentSynthetic resin layered productsTopical surfaceCross-link

Improvements in the high-temperature wash durability and discoloration levels for fabrics having topically applied silver-ion treatments are provided. Such solid compounds are generally susceptible to discoloration and, due to the solid nature thereof, are typically easy to remove from topical surface applications, particularly when laundered at elevated temperatures. The inventive treatment requires the presence of a specific cross-linked binder, either as a silver-ion overcoat or as a padded-on component of a cross-linked binder admixed with the silver-ion antimicrobial compound. In addition, specific metal halide additives may be utilized to combat the discolorations typical of such silver-ion formulations. As a result, high-temperature wash durability, discoloration levels, or both, can be improved to the extent that after a substantial number of standard launderings and dryings, the inventive treatment does not wear away in any appreciable amount and the color of the treatment remains substantially the same as when first applied.

Owner:MILLIKEN & CO

High-efficiency composite grinding sheet and manufacturing method thereof

ActiveCN103612217AHigh bonding strengthImprove acid resistanceAbrasion apparatusGrinding devicesFiberPost curing

The invention discloses a high-efficiency composite grinding sheet and a manufacturing method thereof. The high-efficiency composite grinding sheet comprises a base material, base gel, an abrasive material and composite gel. The abrasive material is attached to the base material through the base gel and the composite gel, the back of selected steel vulcanized fiber paper is coated with the base gel through at least one of the methods of roller painting, blade coating and flat coating; the selected abrasive material is ground into abrasive material particles which are evenly mixed with the composite gel, and then the back of the selected steel vulcanized fiber paper with the base gel is coated with the mixture; a semi-finished product coated with the base gel and the composite gel is detached and sequentially undergoes a post curing process, a flexure and water entrainment process, a laser cutting process, a steel vulcanized fiber paper anti-deformation processing process and a storing process so as to support a grinding sheet finished product. The grinding sheet is sharp, long in service life, resistant to high temperature after being ground, and good in moisture resistance. The manufacturing method can effectively prevent deformation, and the product is large in tensile strength, good in adhesion and strong in grinding performance.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Fabrics having a topically applied silver-based finish with a cross-linked binder system for improved high-temperature wash durability

InactiveUS7132378B2Highly beneficial durabilityHigh densityBiochemical fibre treatmentSynthetic resin layered productsTopical surfaceCross-link

Improvements in the high-temperature wash durability and discoloration levels for fabrics having topically applied silver-ion treatments (such as ion-exchange compounds, like zirconium phosphates, glasses and / or zeolites) are provided. Such solid compounds are generally susceptible to discoloration and, due to the solid nature thereof, are typically easy to remove from topical surface applications, particularly when laundered at elevated temperatures. The inventive treatment requires the presence of a specific cross-linked binder, either as a silver-ion overcoat or as a padded-on component of a cross-linked binder admixed with the silver-ion antimicrobial compound. In addition, specific metal halide additives (preferably substantially free from sodium ions) may be utilized to combat the discolorations typical of such silver-ion formulations. As a result, high-temperature wash durability, discoloration levels, or both, can be improved to the extent that after a substantial number of standard launderings and dryings, the inventive treatment does not wear away in any appreciable amount and the color of the treatment remains substantially the same as when first applied. The particular treatment method, as well as the treated fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

Organic aluminum-zirconium crosslinking agent and preparation method thereof, and low-molecular polymer fracturing fluid

InactiveCN104371699AImprove high temperature resistanceFacilitate cross-linkingDrilling compositionSolubilityFracturing fluid

The invention discloses an organic aluminum-zirconium crosslinking agent and a preparation method thereof, and a low-molecular polymer fracturing fluid. The crosslinking agent is prepared by reacting the following raw materials in parts by weight: 15-25 parts of zirconium salt, 15-25 parts of aluminum salt, 150-250 parts of polyalcohol, 75-85 parts of organic acid, 15-25 parts of gluconate and 55-65 parts of water. The organic aluminum-zirconium crosslinking agent has excellent high temperature resistance, and has favorable crosslinking effect under the conditions of high temperature and high salinity. The organic aluminum-zirconium crosslinking agent is stable under the condition of low pH value, can implement acid crosslinking, and ensures the normal proceeding of the acid fracturing. The organic aluminum-zirconium crosslinking agent has favorable compatibility with polymers and high crosslinking capacity; and the fracturing fluid formed by compounding the organic aluminum-zirconium crosslinking agent with polymers has the advantages of stable gel, excellent solid carrying capacity, excellent viscosity breaking performance and excellent shearing resistance under high-temperature conditions. The organic aluminum-zirconium crosslinking agent has the characteristics of high solubility, no pollution and low damage degree to the reservoir, and has wide application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Engine filter paper dipping agent

InactiveCN1388289AAvoid pollution, hidden dangers of accidents, etc.Improve performanceReinforcing agents additionEmulsionPolyvinyl alcohol

The engine filter paper dipping agent consists of ternary copolymer emulsion in 1-99 wt% and crosslinking agent in 1-20 wt%. The said ternary copolymer emulsion is prepared through the process of: adding emulsifier to the water solution of PVA at 60-70 deg.c and heating to 70-75 deg.c; adding vinyl acetate, acrylate, acrylic acid and initator and heating to 78-90 deg.c; regulate pH value to 5-6 after 0.5-3 hr and cooling to 30-60 deg.c before discharge. The present invention is one environment protecting engine filter paper dipping agent with good use effect and superior to available engine filter paper dipping agent.

Owner:SOUTH CHINA UNIV OF TECH

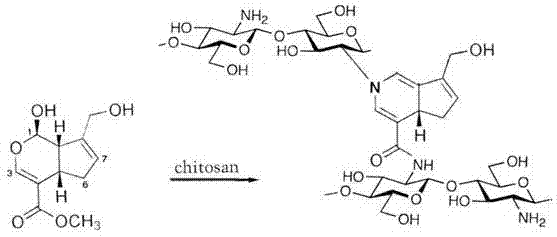

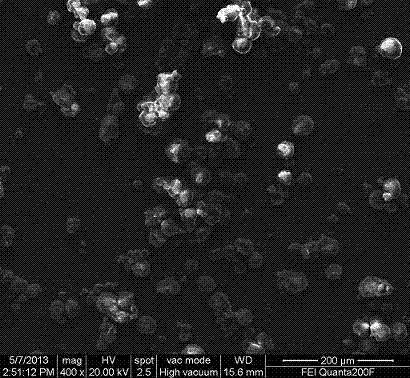

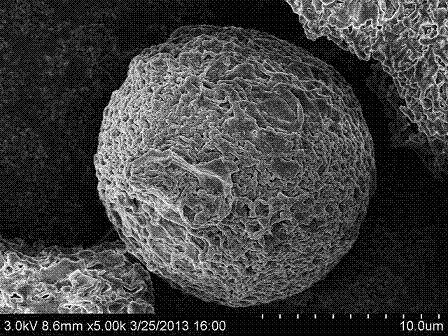

Preparation method of genipin crosslinked chitosan drug-loaded microspheres

InactiveCN103494775AGentle preparationSimple processOrganic active ingredientsPharmaceutical non-active ingredientsWater in oilCrosslinked chitosan

The invention relates to a preparation method of genipin crosslinked chitosan drug-loaded microspheres. The preparation method comprises the steps: after fully agitating water-insoluble oil-based substances with a surfactant evenly as an oil phase mixture by adopting an emulsion chemical-crosslinking method, adding a mixed solution with chitosan and loaded water-soluble drugs into the oil phase mixture as a water phase, fully agitating to an obtain a water-in-oil (W / O) type mixture, fully agitating and dropwise adding a crosslinking agent for crosslinking and curing through an injector, standing to remove the solution at the upper layer, centrifugally washing and drying the settling system at the lower layer respectively through an organic solvent to obtain the corresponding drug-loaded chitosan microspheres. The chitosan microspheres prepared by adopting the preparation method overcomes the defects and shortcomings existing in the traditional preparation method, are simple and easy in technique, low in toxic and side effects and high in mechanical strength, can be widely applied in the fields of food, biology, medical engineering and the like as a drug-use controlled-release carrier.

Owner:NANCHANG UNIV

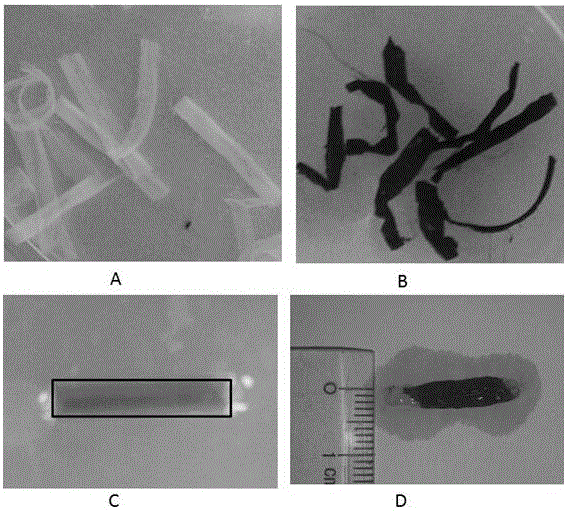

Artificial nerve graft constructed based on chip-type acellularized scaffold and preparation method of artificial nerve graft

ActiveCN106730034AAvoid the disadvantages that if the strength is too small, it will easily remain, and if the strength is too high, it will be crushedImproved cell loading capacityTissue regenerationProsthesisAdhesiveSpinal cord

The invention relates to an artificial nerve graft constructed based on a chip-type acellularized scaffold and a preparation method of the artificial nerve graft, belonging to the field of tissue engineering. According to the artificial nerve graft and the preparation method, heterogeneous animal medulla spinalis, skeletal muscle or tendon acellularized tissue slices are adopted as a bracket, genipin is adopted for crosslinking cytokines, autologous ecto mesenchymal stem cells are planted on the bracket, and fibrous protein is taken as an adhesive for constructing the artificial nerve graft, so that the repairing of the nervous tissue is promoted. The artificial nerve graft and the preparation method have the advantages that the preparation cost is low, the period is short, the preparation raw materials are easily available, and the preparation is simple and is easy to operate. The constructed artificial nerve graft has low immunogenicity, contains a large number of autologous stem cells and cell factors, and is beneficial for adjusting the nerve injury microenvironment, and promoting the nerve regeneration and myelinogenesis. The artificial nerve graft can be used for preparing peripheral nerve and medulla spinalis defect, and has the broad application prospect.

Owner:JIANGSU UNIV

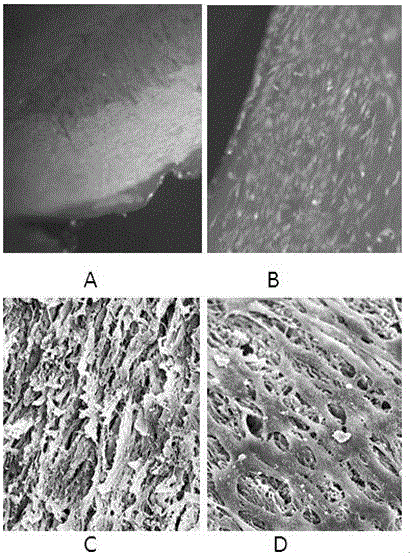

Macroscopic fibers based on directional arrangement of bacterial cellulose nanofibers and preparation method of macroscopic fibers

InactiveCN105926050AFavor high orientationImprove the disadvantages of plastic swellingWet spinning methodsSpinning solutions preparationPolymer scienceYoung's modulus

The invention relates to macroscopic fibers based on directional arrangement of bacterial cellulose nanofibers and a preparation method of the macroscopic fibers. Carboxymethyl-modified bacterial cellulose nanofibers are processed with a wet spinning forming and crosslinking technology, and continuous preparation of the macroscopic-assembling fibers based on the bacterial cellulose nanofibers is realized. On the basis of influence of the force field environment on nanofiber orientation and regulation of technological parameters, regulation of design and performance of a macroscopic fiber structure is realized, and the macroscopic fibers with high mechanical properties are prepared; further, by means of cross-linking of oxygen-containing groups of the nanofibers, the acting force among the nanofibers is increased, Young modulus and tensile strength are improved, the defect of plasticizing swelling of the macroscopic fibers under a high-humidity condition is remarkably overcome, so that the excellent mechanical properties and flexibility of the bacterial cellulose nanofibers are more effectively represented in the aspect of macroscopic size from the perspective of nanoscale, and the bacterial cellulose nanofiber based macroscopic fibers with high crystallinity (in a cellulose crystal form I) and high performance can be obtained.

Owner:DONGHUA UNIV

Phosphorus-containing flame-retardant polyester ionomer/nanocomposite material and preparation method thereof

The invention discloses a phosphorus-containing flame-retardant polyester ionomer / nanocomposite material and a preparation method thereof. The phosphorus-containing flame-retardant polyester ionomer / nanocomposite material is prepared by in-situ polymerization of terephthalic acid or dimethyl terephthalate, ethylene glycol, phosphorus-containing ion monomers (i) or phosphorus-containing ion monomers (ii), inorganic nanoparticles or / and organic modified inorganic nanoparticles. The numbers of phosphorus-containing ion group structure units in the composite material account for 2% to 5% of the numbers of structure units of the terephthalic acid or the dimethyl terephthalate in the composite material. The content of the inorganic nanoparticles or / and organic modified inorganic nanoparticles accounts for 0.5 to 10% of the total mass of the composite material. Meanwhile, the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material is excellent in flame retardance, melt drip resistance and crystallization resistance. The intrinsic viscosity of the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material can reach 0.6dL / g to 1.0dL / g. Thus, the phosphorus-containing flame-retardant polyester ionomer / nanocomposite material can be directly taken as a raw material used for preparing fibers, engineering plastics, thin films and the like.

Owner:SICHUAN UNIV

Anti-corrosion process for steel structure

InactiveCN109622332ASimple anti-corrosion processSimple processAnti-corrosive paintsSpecial surfacesEpoxyHydrogen

The invention discloses an anti-corrosion process for a steel structure. The anti-corrosion process comprises the following steps of S1, surface pretreatment of the steel structure, S2, surface descaling of the steel surface, S3, preparation of waterborne rust anticorrosive coating for the steel structure, S4, preparation of a primer, S5, steel structure coating, and S6, paint coating quality inspection and acceptance. The anti-corrosion process combines the characteristics of an epoxy emulsion and an acrylic emulsion to improve the comprehensive performance of the coating, a polyaniline emulsion is directly added into the coating to solve the compatibility problem between polyaniline and other polymer emulsions and the stability problem of the prepared anticorrosive coating, the anti-corrosion performance of the coating is improved, acid and active hydrogen in conversion liquid and polyaniline can promote the curing of the epoxy resin to be used as a curing agent for an epoxy emulsion, the process is simple, and the cost is low. The anti-corrosion process of the steel structure is simple, has good anti-corrosion performance and simple construction, can greatly reduce the labor intensity of coating, has high weather resistance, and can realize long-term protection for the steel structure.

Owner:淮北市菲美得环保科技有限公司

Diffusion and dialysis membrane for alkali recovery as well as preparation method and application of same

ActiveCN102908915AImprove stabilityWon't fall offSemi-permeable membranesDialysis membranesOrganic solvent

The invention discloses an organic-inorganic hybrid cation exchange membrane for alkali recovery in manners of diffusion and dialysis as well as a preparation method and an application of the membrane. The diffusion and dialysis membrane consists of an organic phase and an inorganic phase, wherein the organic phase is polyvinyl alcohol (PVA); the inorganic phase is a mixture of silanol and alkoxy silane; and the cation exchange membrane has a moisture content of 38-105 percent, an ion exchange capacity of 0.30-2.10 mmol / g, an alkali dialysis coefficient of 0.010-0.025 m / h and a separation factor of 11.3-33.5. The organic-inorganic hybrid cation exchange membrane as well as the preparation method and the application of the membrane has the beneficial effects that the silanol containing an ion exchange group is directly introduced, the ion exchange capacity is obtained, therefore, the reaction process is simple and controllable; as the whole reaction process is carried out in a water phase, and no organic solvent is required, the reaction process is green and environmentally-friendly; and the obtained hybrid cation exchange membrane has high mechanical strength and high thermal stability and can be applied to the field of alkali recovery.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of graphene modified polyester composite material based on liquid phase stripping

InactiveCN111592640AReinforcement stiffnessReinforced cross-linking degreeGrapheneOrganic solventGraphene

The invention relates to the technical field of graphene composite material preparation, aims at the problems in the prior art that graphene in a graphene modified polyester composite material is poorin integrity and prone to agglomeration, and discloses a preparation method of a graphene modified polyester composite material based on liquid phase stripping. The preparation method comprises the following steps: taking a graphite derivative as a raw material, dispersing the graphite derivative in an organic solvent, adding a dispersing agent, and preparing a graphene dispersion liquid under the ultrasonic-assisted action; mixing the graphene dispersion liquid with a polyester monomer and a catalyst, and performing esterification reaction and condensation polymerization to obtain the graphene polyester nano composite material. According to the method, a liquid-phase stripped graphene modified polyester composite material is adopted, the agglomeration phenomenon of the graphene after liquid phase stripping is reduced, the stability and integrity of the graphene are improved, the physical and chemical properties of the graphene are relatively strong, the uniform dispersity of the graphene in the modified polyester composite material is further improved, and the finally obtained product graphene polyester fiber is durable in performance and high in washing resistance.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Multi-purpose gelatin fiber preparing method based on closed type waterborne polyurethane in-situ cross linking

InactiveCN105821519AGood compatibilityImprove performanceConjugated cellulose/protein artificial filamentsWet spinning methodsFiberCross-link

The invention relates to a multi-purpose gelatin fiber preparing method based on closed type waterborne polyurethane in-situ cross linking .The preparing method comprises the steps that firstly, a gelatin aqueous solution and closed type waterborne polyurethane emulsion are mixed evenly, and a spinning solution is obtained; secondly, the spinning solution is spun into gelatin / closed type waterborne polyurethane composite fibers with a dry or wet spinning technology; finally, in the subsequent drying process, closed type waterborne polyurethane is subjected to closed-form solution, isocyanate groups obtained through closed-form solution further react with active groups in gelatin, and thus the effects of in-situ cross linking and great improvement of the mechanical property of the composition fibers are achieved .Due to the fact that waterborne polyurethane and gelatin are in good compatibility, the adding quantity of the gelatin component in the composite fibers is large, and the excellent performance of gelatin is fully embodied; besides, waterborne polyurethane is nontoxic, and the biological compatibility of the composite fibers cannot be influenced after cross-linking modification is performed on gelatin; a covalence reaction exists between waterborne polyurethane and gelatin, the mechanical property of the composition fibers can be greatly improved in a lasting mode, and the composite fibers have application prospects in biomedical, tissue engineering and textile and garment fields and the like .

Owner:SICHUAN UNIV

Female shoe with anti-aging sole and preparation process thereof

PendingCN112266508AIncrease connection densityImprove aging resistanceSolesDomestic footwearPolymer scienceVulcanization

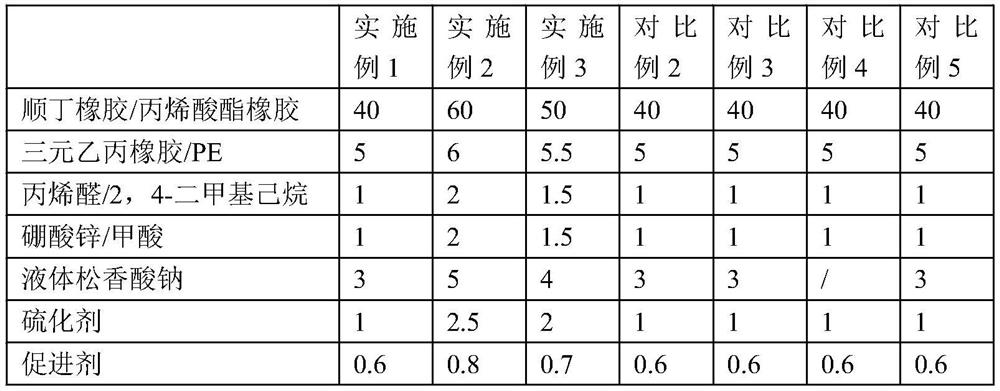

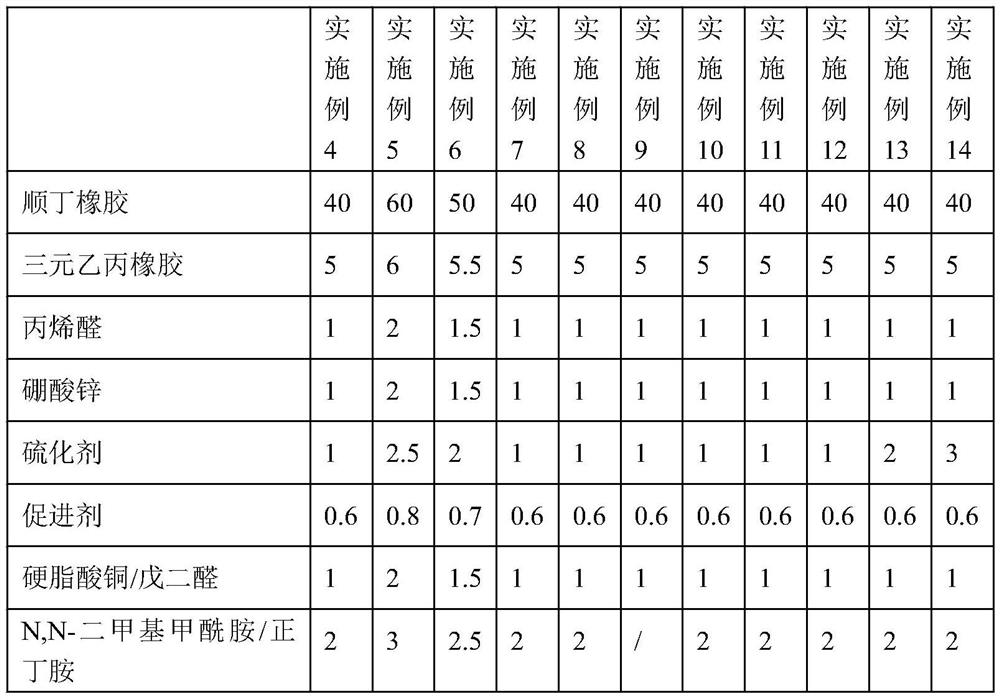

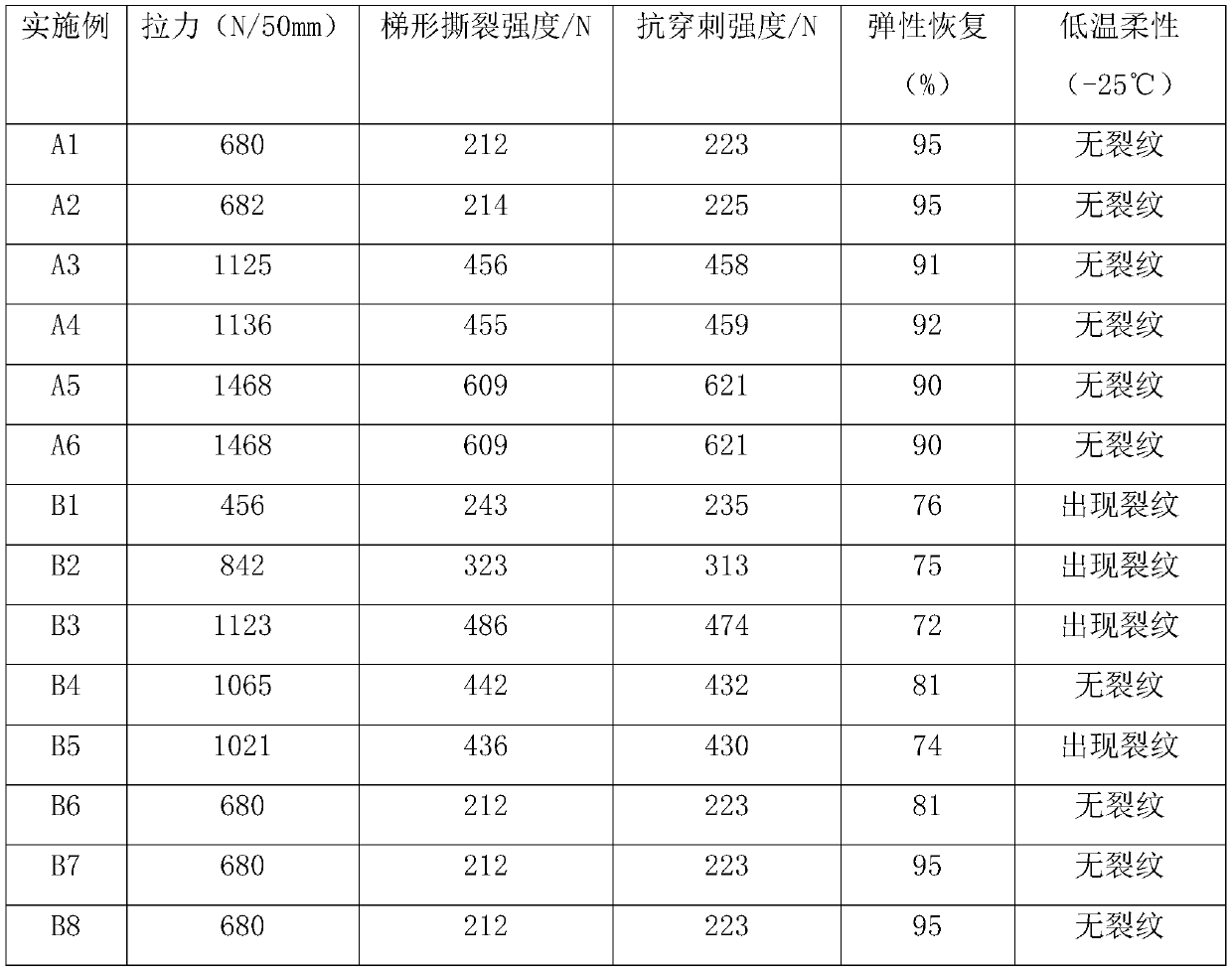

The invention relates to the field of shoes, and discloses a female shoe with an anti-aging sole and a preparation process thereof. Thefemale shoe with an anti-aging sole comprises a vamp and a sole,wherein the sole comprises the following raw materials in parts by weight: 40-60 parts of butadiene rubber, 5-6 parts of ethylene propylene diene monomer, 1-2 parts of acrolein, 1-2 parts of zinc borate, 3-5 parts of liquid sodium abietate, 1-2.5 parts of a vulcanizing agent, and 0.6-0.8 part of an accelerant. The preparation process comprises the following steps of mixing raw materials, conducting vulcanization, and forming a female shoe. The process has the following advantages and effects that the blended ethylene propylene diene monomer and butadiene rubber have good weather resistance, heat resistance and acid and alkali resistance; butadiene rubber containing double bonds is easily subjected to chain propagation reaction with acrolein, ethylene propylene diene monomer and the like, so that the bonding density among the components is improved, and the anti-aging performance is improved; after zinc borate and liquid sodium abietate are mixed, the problems that the content of doublebonds is increased due to addition of butadiene rubber and acrolein, the shoe sole is easily eroded by oxygen in air, and the mechanical property is reduced can be solved, and the aging resistance ofthe shoe sole is improved.

Owner:WENZHOU BAILIDUO SHOES CO LTD

Sunflower seeds with tomato flavor and processing method of sunflower seeds

The invention discloses sunflower seeds with a tomato flavor and a processing method of the sunflower seeds, and belongs to the technical field of food processing. The method involves the sunflower seeds with the tomato flavor, and processing raw materials comprise tomato sauce. The processing method of the sunflower seeds with the tomato flavor comprises the processing steps of weighing the raw materials including the tomato sauce, brine preparation, stewing, draining, drying and cooling. The sunflower seeds with the tomato flavor and the processing method of the sunflower seeds have the advantages that the tomato sauce is taken as the raw material to prepare the sunflower seeds, the processed sunflower seeds are delicious with slight sweetness and sour, can promote salivary secretion, reduce sweet greasy and greasy feelings and can prevent thirst, excessive internal heat and other problems caused by excessive intake of the sunflower seeds when the sunflower seeds are eaten. The sunflower seeds with the tomato flavor have an oral cavity drying coefficient less than 5.0, and are obviously superior to commercially available sunflower seeds.

Owner:CHACHA FOOD CO LTD

Corrosion resistance technology of steel structure

InactiveCN109848012ASimple anti-corrosion processSimple processPretreated surfacesAnti-corrosive paintsEpoxyWeather resistance

The invention discloses a corrosion resistance technology of a steel structure. The corrosion resistance technology of the steel structure comprises the following steps of S1, carrying out surface pretreatment on the steel structure; S2, derusting the surface of a steel material; S3, preparing a waterborne over-rust corrosion protective coating of the steel structure; S4, coating the steel structure; and S5, inspecting and accepting the oil paint coating quality. According to the corrosion resistance technology of the steel structure provided by the invention, the characteristics of an epoxy emulsion and an acrylic emulsion are combined, so that the combination property of a coating is improved; a polyaniline emulsion is directly added into the coating, so that the compatible problem of polyaniline and other macromolecule emulsions and the stability problem of the prepared corrosion-resistance coating are solved, and the corrosion resistance of the coating is improved; and acid and reactive hydrogen in the polyaniline can promote the curing of the epoxy resin, and the polyaniline is used as a curing agent of the epoxy emulsion, so that the process is simple and low in cost. The corrosion resistance technology of the steel structure is simple, not only has favorable corrosion resistance, but also is simple and convenient to construct, is capable of greatly relieving the labor intensity of coating, has high weather resistance at the same time, and can realize long-time protection on the steel structure.

Owner:淮北市菲美得环保科技有限公司

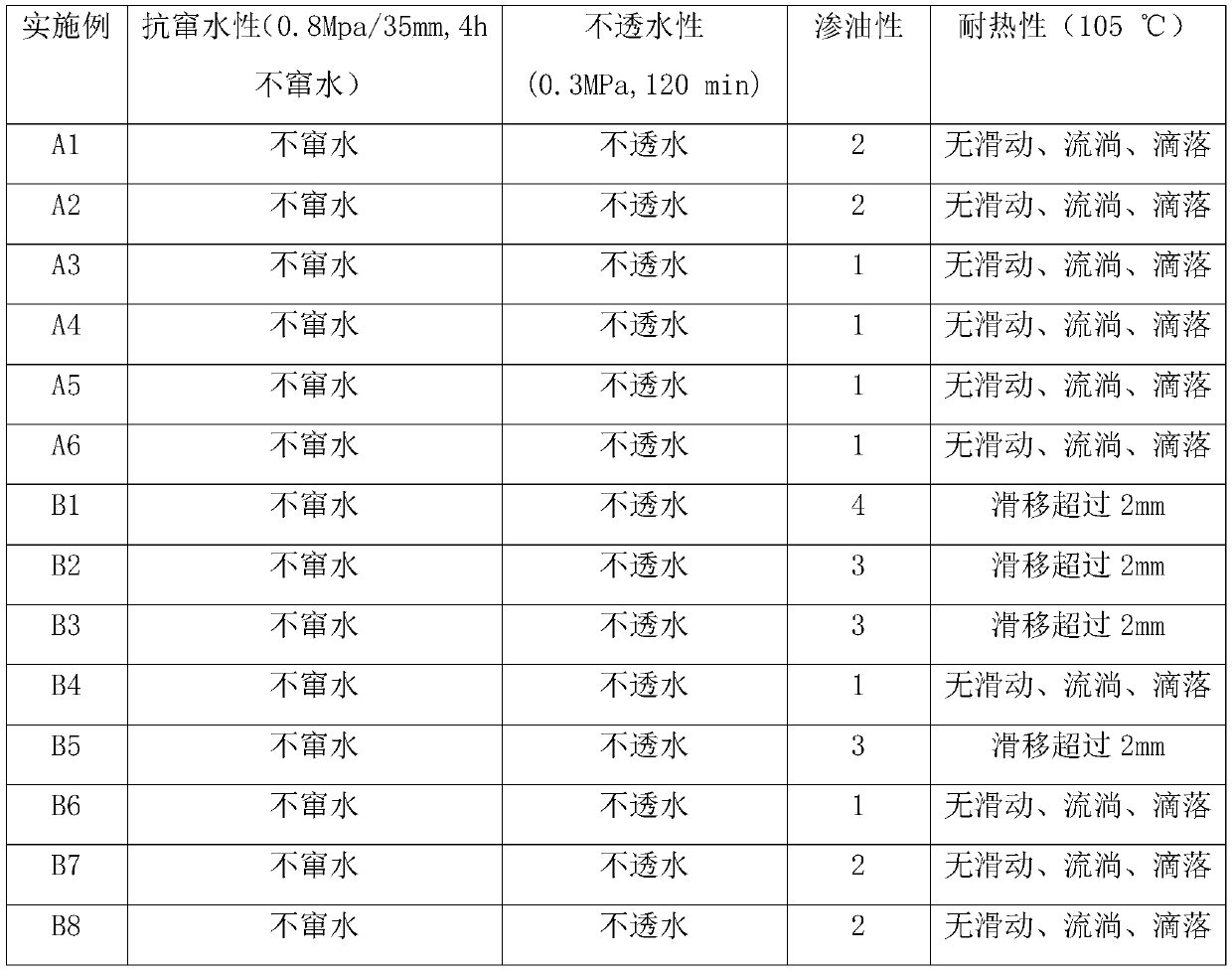

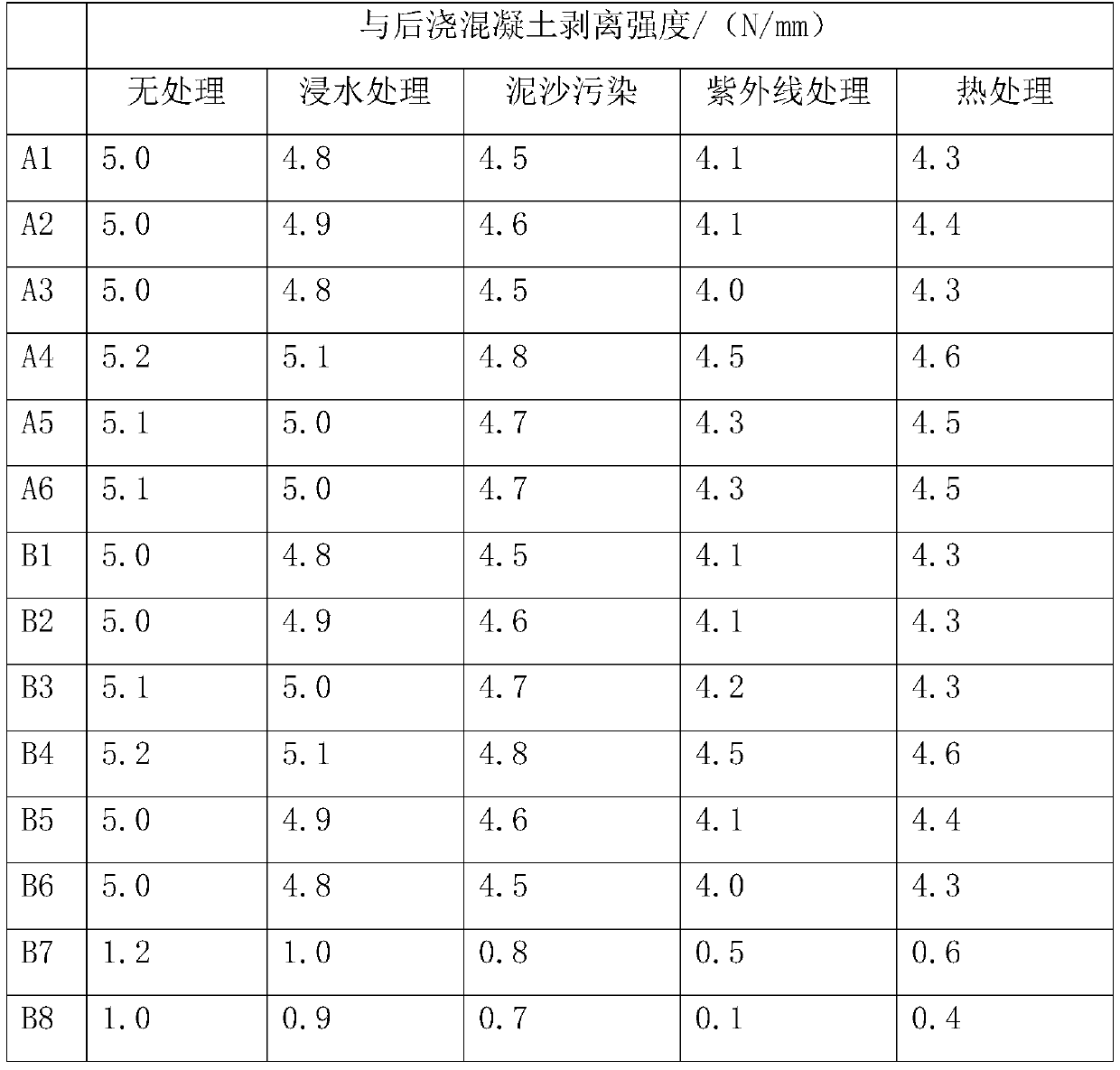

Asphalt-based pre-coating waterproof system

ActiveCN111546717ALow viscosityImprove permeabilitySynthetic resin layered productsLaminationCross linkerPolymer emulsion

The invention discloses an asphalt-based pre-coating waterproof system. A building surface to be pre-coated is used as a base surface and comprises a first modified asphalt layer, a base layer, a second modified asphalt layer, a protective layer and a functional layer in sequence from bottom to top; the protective layer is used for protecting an asphalt coating; the functional layer and post-castconcrete realize mutual adhesion of a body; the first modified asphalt layer and the second modified asphalt layer comprise the following components in parts by weight: 35 to 65 parts of asphalt, 5 to30 parts of a modifier, 15 to 30 parts of mineral powder, 0.01 to 0.1 part of a cross-linking agent, 0.01 to 0.1 part of a heat stabilizer and 0.01 to 0.1 part of a viscosity regulator; the modifiercomprises SBS, SBR, IIR and SIS. The protective layer and the functional layer take a polymer emulsion and a cement component as base materials, compounding of the same material is ensured, the integrity is good, a cement-based sand-containing coating layer is used as the functional layer, the weight ratio of the polymer emulsion to the cement component to graded sand is optimized, bonding with apost-cast concrete body is achieved, the bonding effect is remarkably improved, and the waterproof effect is more reliable.

Owner:SHENZHEN ZHUOBAO TECH

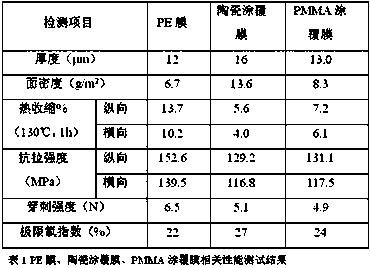

Modified PMMA, preparation method thereof and preparation method of high-specific capacity flame-retardant lithium battery membrane by using modified PMMA

PendingCN110591134AGood physical and chemical propertiesGood flexibilityCell component detailsCoatingsChemistryOrganic inorganic

The invention belongs to the technical field of battery membranes, and particularly relates to modified PMMA, a preparation method thereof and a preparation method of a high-specific capacity flame-retardant lithium battery membrane by using the modified PMMA. Bonding crosslinking is performed on active groups in a guanidine salt and polar groups in a PMMA copolymer precursor through an initiatorAIBN so as to obtain the modified PMMA, and a coating on the high-specific capacity flame-retardant lithium battery membrane is formed through compound mixing of the modified PMMA and polysiloxane. The membrane has an organic-inorganic hybrid-structured coating, and therefore the membrane has high heat resistance, mechanical properties and flame retardancy.

Owner:XINXIANG ZHONGKE SCI&TECH

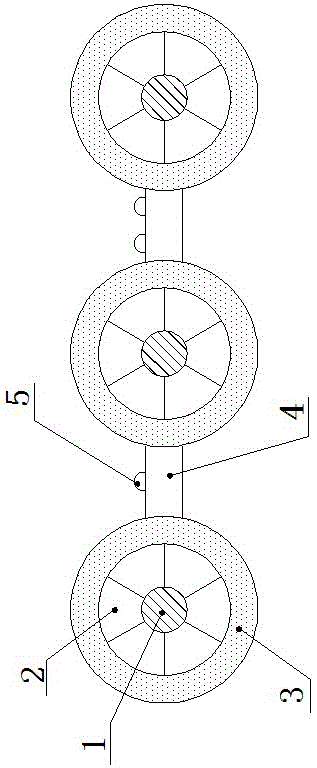

Parallel bundle-assembled overhead insulation cable and production process thereof

ActiveCN106298014AHigh breaking forceIncrease the installation distanceFlexible cablesFlexible conductorsYarnFiber

The invention relates to a parallel bundle-assembled overhead insulation cable and a production process thereof. The parallel bundle-assembled overhead insulation cable comprises compression conductors, the compression conductors are formed by twisting of circular carbon fiber yarns and irregular hard aluminum wires arranged at outer walls of the circular carbon fiber yarns, outer walls of the compression conductors are provided with insulating layers, the insulating layers are connected with connecting ribs, and the upper surfaces of the connecting ribs are provided with marking lines. The production process of the parallel bundle-assembled overhead insulation cable comprises wire drawing, wire twisting, extrusion molding, and crosslinking. The cable and the production process thereof are advantageous in that the production efficiency is high, the service lifetime is long, the overall cost is low, and the promotion is facilitated.

Owner:HENAN LESHAN CABLE

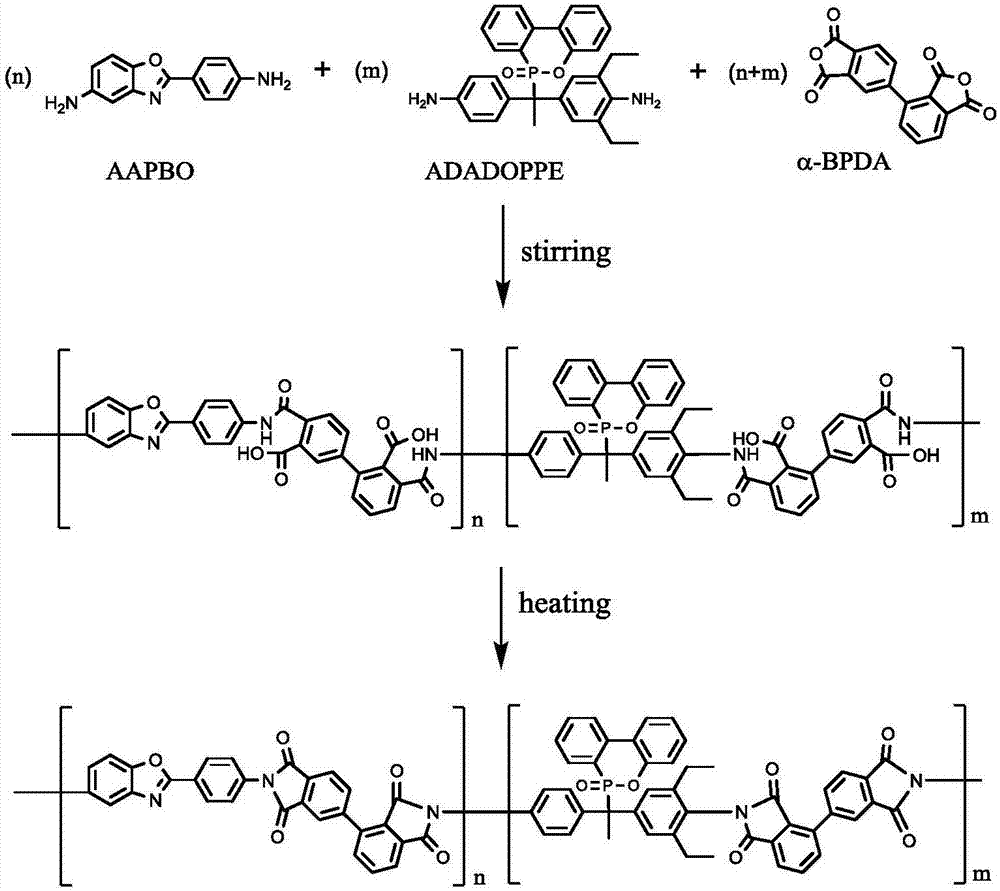

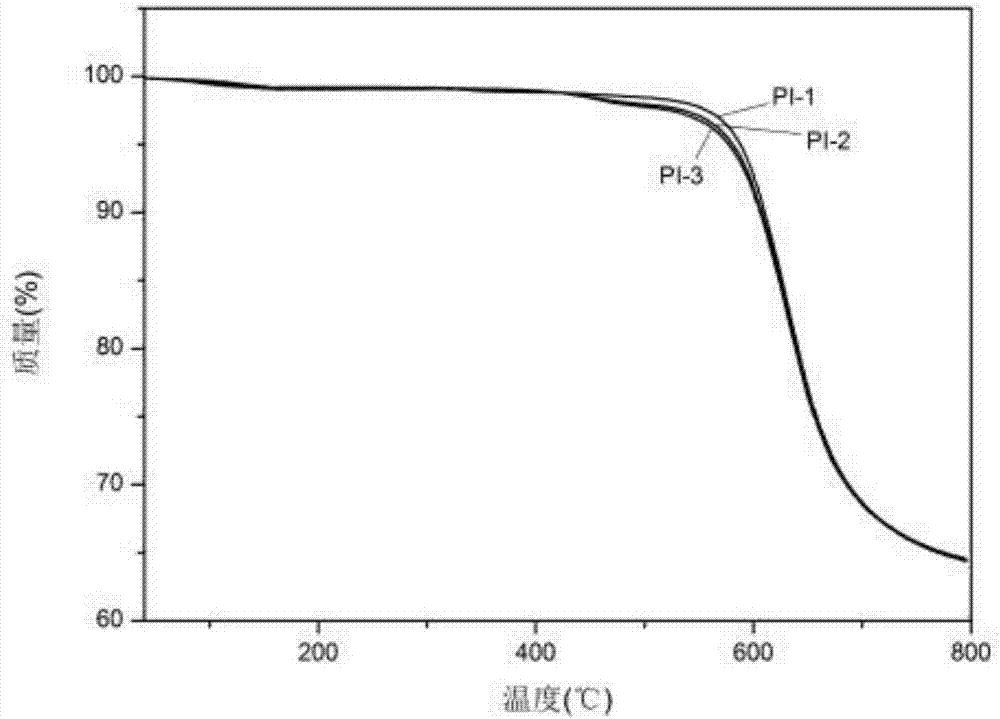

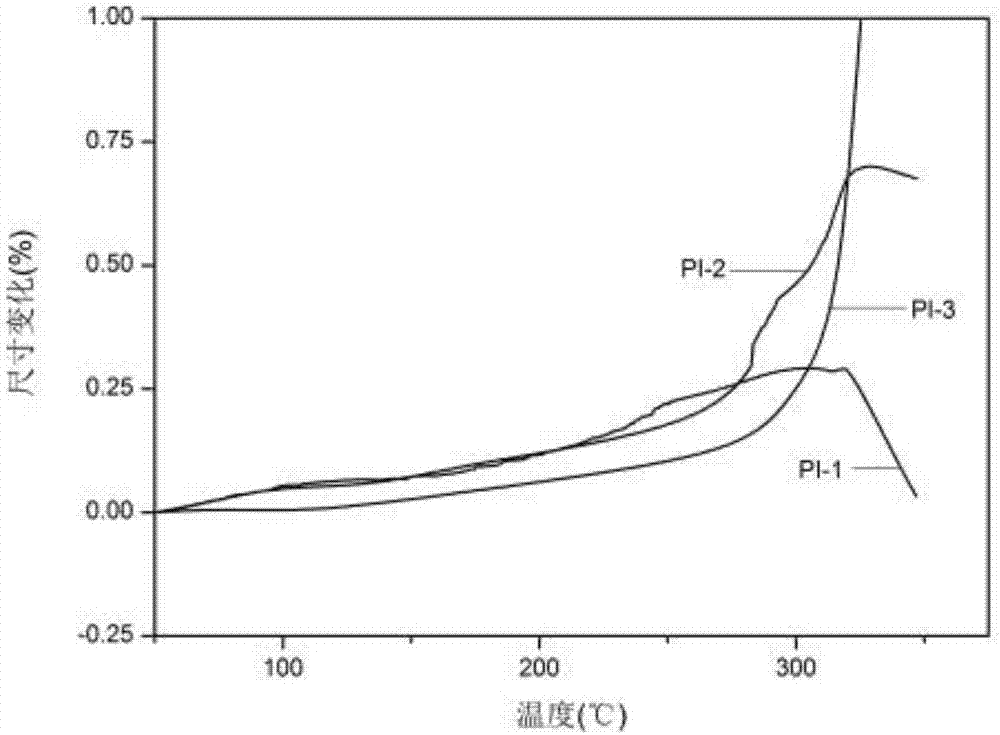

High-flame-retardancy high-strength high-transparence polyimide film and preparation method thereof

ActiveCN107141475AImprove flame retardant performanceHigh transparencyGroup 5/15 element organic compoundsBond energyBenzoxazole

The invention discloses a high-flame-retardancy high-strength high-transparence polyimide film and a preparation method thereof. The preparation method comprises the following steps: 1) dissolving 4-amino phenyl-3,5-diethyl-4-amino phenyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-phosphoryl ethane and 2-(4-amino phenyl)-5-amino benzoxazole into a polar solvent, and stirring till the components are completely dissolved so as to obtain a mixed solution; 2) adding 2,3'3,4-biphenyltetracarboxylic dianhydride into the mixed solution, and keeping the temperature of a reaction system so as to obtain a polyamide acid adhesive after the reaction is completed; 3) uniformly coating a plate mold with the polyamide acid adhesive, performing programmed heating thermal imidization, after the heating program is completed, cooling to the room temperature, and demolding, so as to obtain the high-flame-retardancy high-strength high-transparence polyimide film. Due to introduction of a phosphorus element, the flame retardancy and the transparence of the high-flame-retardancy high-strength high-transparence polyimide film disclosed by the invention are improved; due to introduction of a benzoxazole heteroaromatic structure in a main chain, the bond energy of a primary bond is improved, and furthermore the mechanical properties and the thermal resistance can be improved.

Owner:HUBEI DINGLONG CO LTD

Manufacturing method of edible sodium alginate/gelatin 3D gel scaffold adopting tea polyphenol coating for cultured meat

InactiveCN113892643AImprove adhesionStrong cross-linkingSkeletal/connective tissue cellsCell culture supports/coatingCultured meatCell adhesion

The invention relates to a manufacturing method of an edible sodium alginate / gelatin 3D gel scaffold adopting a tea polyphenol coating for cultured meat, the 3D gel scaffold manufactured by the method can be used for proliferation, differentiation and culture of skeletal muscle stem cells, which provides organized support for the cultured meat, and belongs to the field of future food science and technology. The method comprises the following steps: uniformly mixing sodium alginate and gelatin with a certain concentration according to a certain ratio, fully reacting at room temperature for more than 2 hours, refrigerating overnight, and soaking in a calcium chloride / tea polyphenol solution to obtain the sodium alginate / gelatin 3D gel scaffold coated by the tea polyphenol. The manufacturing method is simple and efficient, and no toxic cross-linking agent is used. The obtained sodium alginate / gelatin 3D gel scaffold with the tea polyphenol coating has good cell adhesion and compatibility, and can be used for proliferation, differentiation and culture of skeletal muscle stem cells. The invention provides a manufacturing method of a novel and edible 3D scaffold for the research of cultured meat.

Owner:NORTHWEST A & F UNIV

Profile control agent and preparation method thereof

InactiveCN106634910AGood selective water shutoff performanceOil flow resistance is smallDrilling compositionSodium carbonateTemperature resistance

The invention relates to a profile control agent and a preparation method thereof. The profile control agent is prepared from 0.5% to 1.0% of polyacrylamide, 0.1% to 0.3% of a compound cross-linking agent, 0.1% to 0.3% of a stabilizer, 2% to 4% of an inorganic particle inductive agent, 0.04% to 0.1% of a deoxidant and the balance of water with the degree of mineralization of smaller than or equal to 15000 mg / L, wherein the used compound cross-linking agent is prepared from 0.8% of resorcinol, 7% of isopropanol, 0.4% of sulfamic acid, 0.7% of hexamine and the balance of water; the stabilizer is hydroquinone; the inorganic particle inductive agent is sodium carbonate; and the deoxidant is thiourea. The profile control agent disclosed by the invention has the characteristics of high cross-linking capacity, long-term stability, high temperature resistance, high salinity, low cost, environmental protection and the like, so that the profile control agent has great application potential.

Owner:陕西庆华石油建设有限公司

Glass fiber air filtration filter material treating agent and preparation method

ActiveCN106432578AStrong transparencyImprove oxidation resistanceFibre typesAir filtrationGlass fiber

The invention provides a glass fiber air filtration filter material treating agent and a preparation method. The glass fiber air filtration filter material treating agent is characterized by being prepared from, by weight, 298-307 parts of acrylic acid, 13-18 parts of hydroxyethyl methylacrylate, 56-60 parts of sodium methallyl sulfonate, 200-235 parts of water, 20-30 parts of isopropyl alcohol, 7-13 parts of sodium persulfate and 32-36 parts of acrylonitrile through a solution polymerization method. A glass fiber filter material is treated, the strength and anti-abrasion and anti-bending performance of the glass fiber air filtration filter material can be effectively improved, and the treated glass fiber filter material is good in oxidation resistance, good in film forming transparency and not prone to resurgence.

Owner:LIAONING FIXED STAR FINE CHEM

Multifunctional wear-resistant material

InactiveCN102173651BImprove wear resistanceImprove corrosion resistanceWear resistantShock resistance

Owner:王立珍

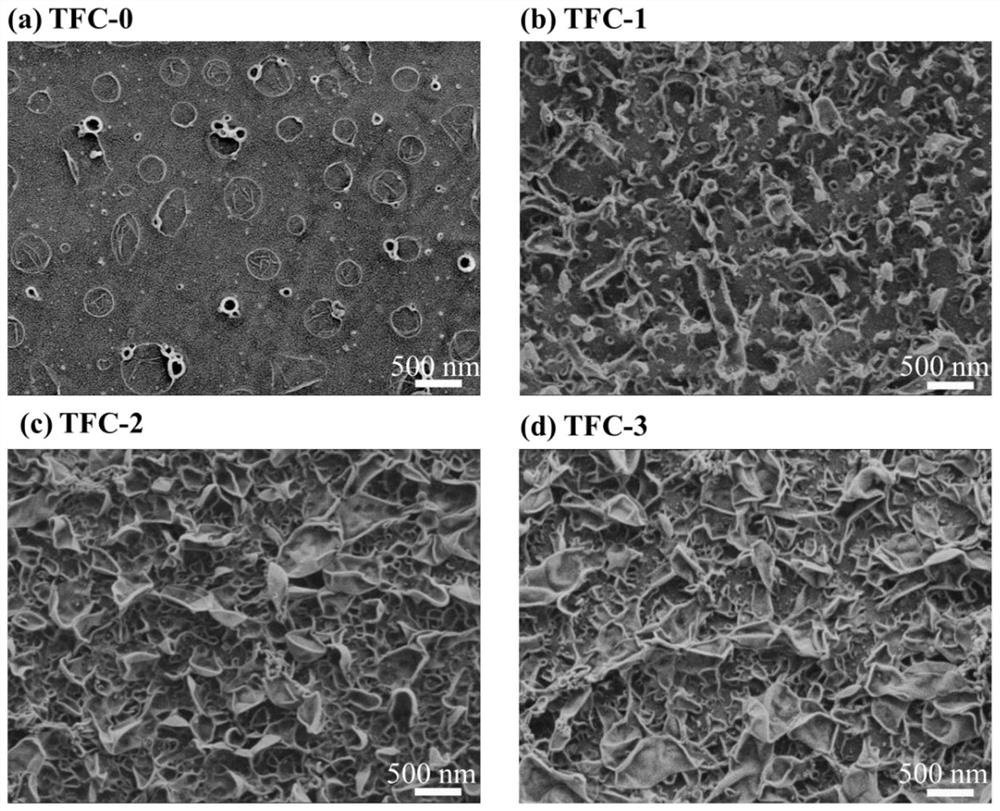

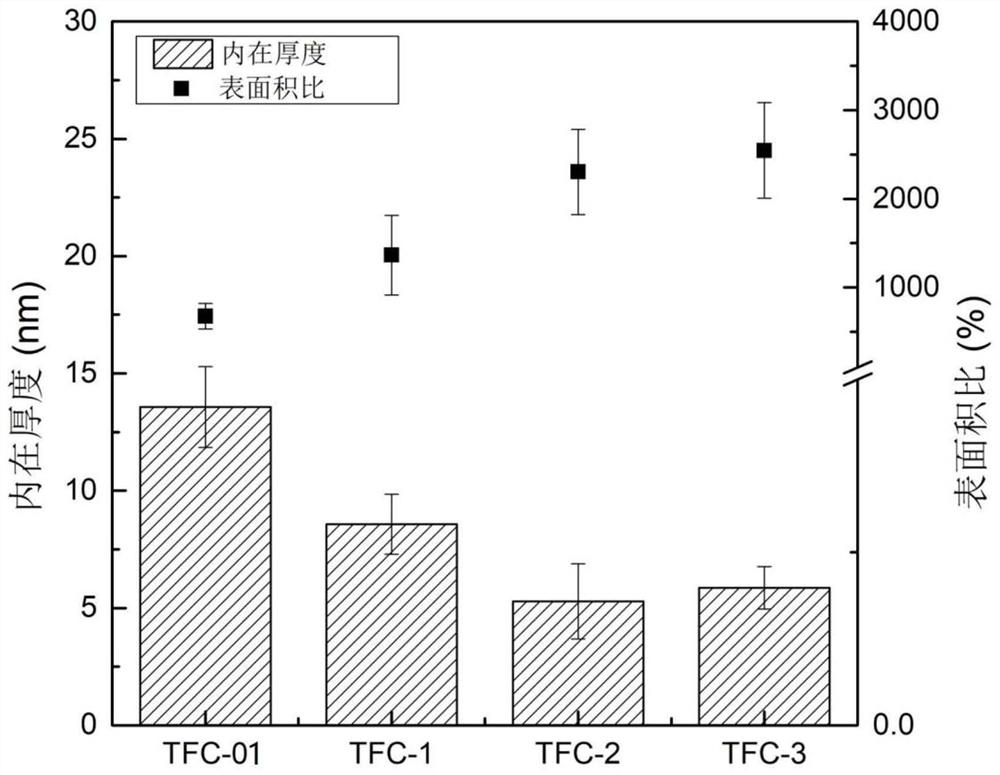

A kind of polyamide film layer composite reverse osmosis film and its preparation method and application

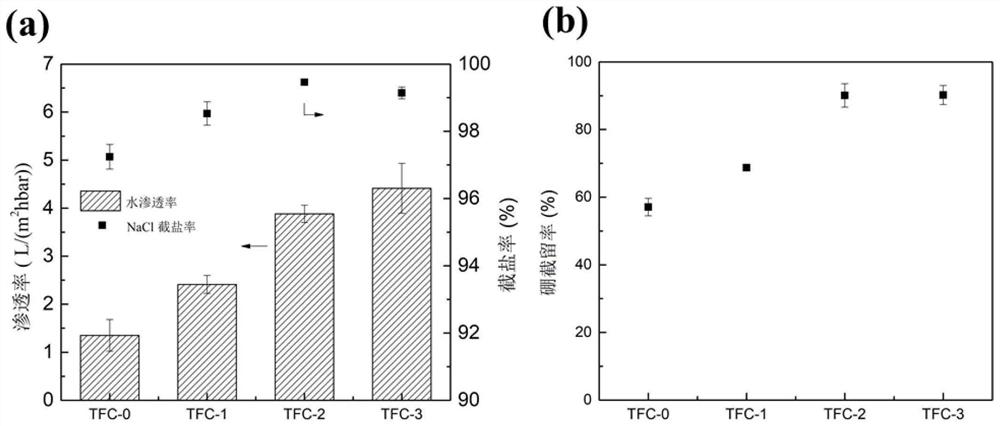

ActiveCN112657352BIncrease the degree of cross-linkingReduce intrinsic thicknessSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceReverse osmosis

The invention provides a polyamide film layer composite reverse osmosis membrane and its preparation method and application. First, an ultra-thin metal-organic framework CuBDC nanosheet with amphiphilic properties is prepared and placed on the water / oil two-phase interface. Among them, the water phase is an aqueous solution of m-phenylenediamine, and the oil phase is n-hexane. After the n-hexane is completely volatilized, the n-hexane solution containing trimesoyl chloride is slowly added to the interface to react to form a modified polyamide film layer. The thin film is carefully placed on the base of the ultrafiltration membrane to prepare a polyamide thin-layer composite reverse osmosis membrane. The intrinsic thickness of the polyamide film formed on the CuBDC-assisted free interface is about 5nm. The ultra-thin metal-organic framework nanosheets provide directionality for the thermal diffusion of the interfacial polymerization reaction, strengthen the intensity of the interfacial polymerization reaction, and improve the oil transfer of m-phenylenediamine. The rate of diffusion in the phase direction increases the surface area and cross-linking degree while forming an ultra-thin polyamide film, and greatly improves the flux and salt interception rate of the film.

Owner:TONGJI UNIV

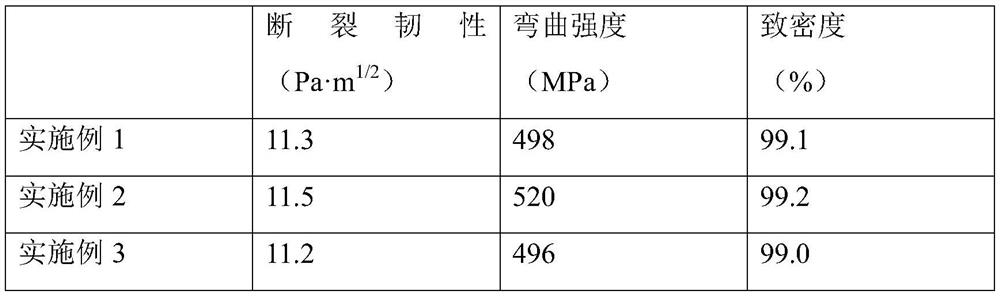

High-strength high-toughness ceramic composite material and preparation method thereof

The invention relates to the field of ceramic materials, and particularly discloses a high-strength and high-toughness ceramic composite material and a preparation method thereof. The preparation method of the ceramic composite material comprises the steps of weighing ceramic-based powder, elemental Si powder, an adhesive, a dispersing agent and deionized water in proportion, mixing, pulping, molding and preparing into a biscuit, and after the biscuit is subjected to high-temperature nitriding treatment, generating a three-dimensional cross-linked beta-Si3N4 whisker network in situ by the elemental Si powder to obtain a porous beta-Si3N4 / ceramic composite green body; soaking the composite green body into a coupling agent solution for modification treatment, drying, and filling a liquid organic carbon source into pores in the modified composite green body by adopting a soaking process; performing high-temperature vacuum carbonization on the composite green body; and carrying out high-temperature vacuum infiltration on the carbonized green body to obtain Si, reacting the melt Si with residual carbon to generate SiC, and filling residual pores with Si. According to the preparation method of the ceramic composite material provided by the invention, the compact high-strength and high-toughness ceramic composite material can be prepared.

Owner:NINGBO VULCAN TECH CO LTD

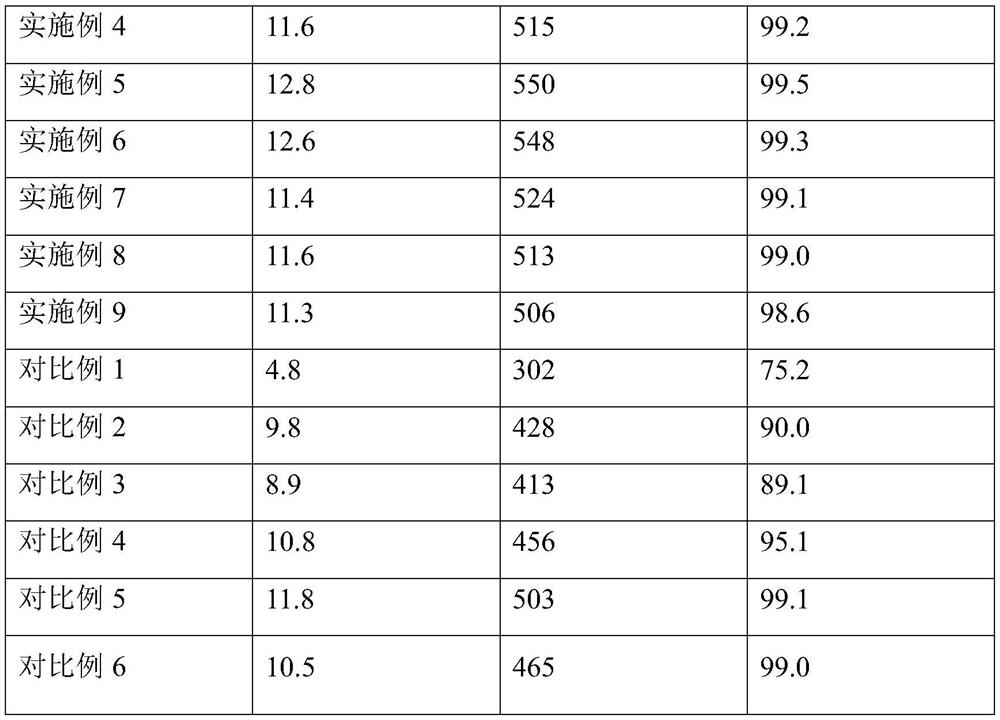

High-thermal-conductivity semi-cured adhesive film of metal substrate and preparation method of high-thermal-conductivity semi-cured adhesive film

ActiveCN113337230AImprove heat dissipationImprove flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePolyvinyl alcohol

The invention discloses a high-thermal-conductivity semi-cured adhesive film of a metal substrate, which is characterized by comprising the following components in parts by weight: 100 parts of epoxy resin, 16-24 parts of heat-conducting filler, 20-50 parts of a curing agent and 3-9 parts of a curing agent accelerator, wherein the heat-conducting filler is modified boron nitride / tantalum disilicide microspheres. The semi-cured adhesive film is obtained by mixing the epoxy resin and the heat-conducting filler and then curing the mixture through a curing agent, wherein the heat-conducting filler uses boron nitride as a base material, modification is carried out on the basis of boron nitride, then the modified boron nitride and tantalum disilicide are combined to form microspheres, functional groups on the surface of the modified boron nitride and tantalum disilicide can generate microspheres under the action of a salt template and polyvinyl alcohol, the formed microspheres have larger specific surface area and certain flexibility, and the mechanical properties and toughness of the epoxy resin can be enhanced while the thermal conductivity of the epoxy resin is improved.

Owner:SHENZHEN CHUANGHUI ALLIANCE TECH

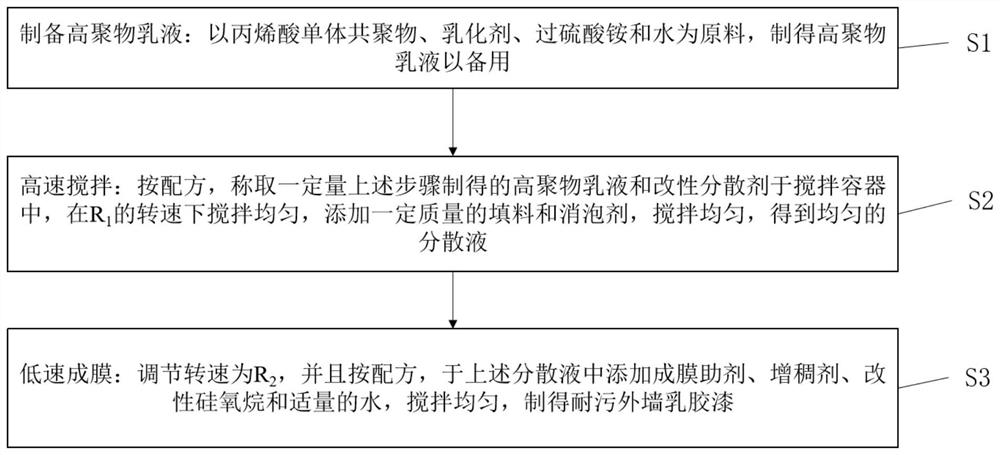

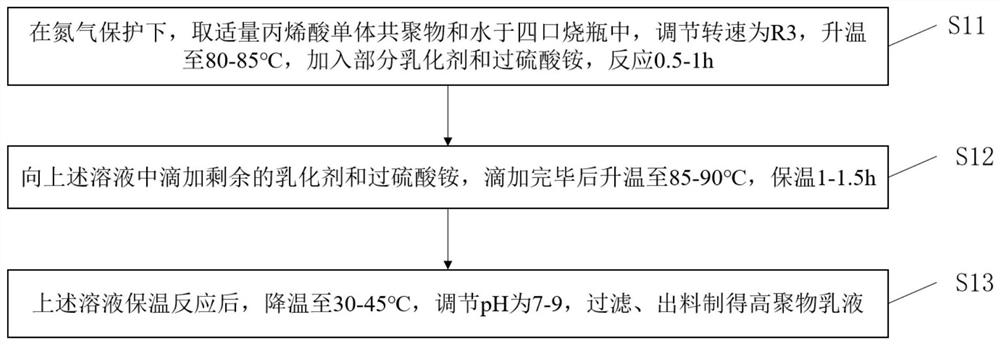

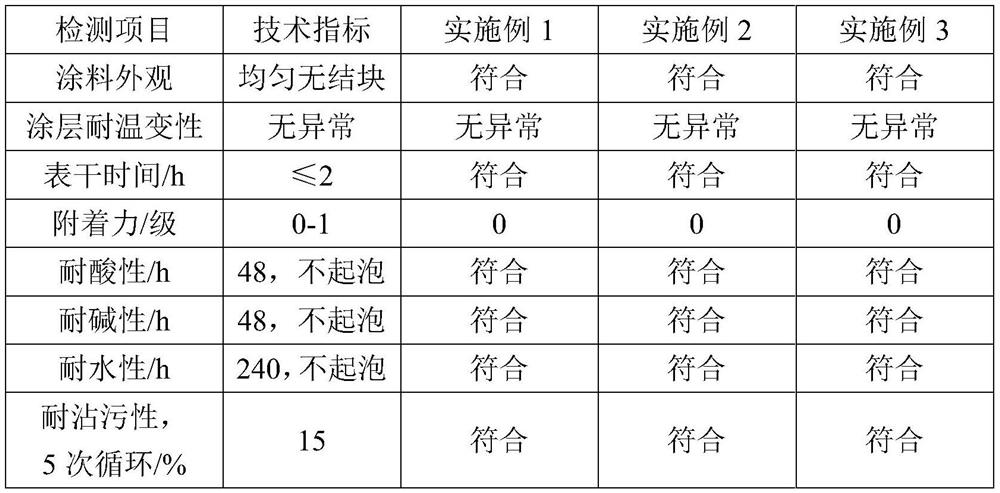

Stain-resistant exterior wall latex paint and preparation method thereof

InactiveCN113683932AImprove stain resistanceIncrease the degree of cross-linkingEmulsion paintsPolymer scienceCarboxylic acid

The invention relates to the technical field of building exterior wall decoration materials, in particular to stain-resistant exterior wall latex paint which comprises, by weight, 15-25 parts of acrylic monomer copolymer, 1-3 parts of emulsifier, 0.5-1 part of ammonium persulfate, 40-50 parts of filler, 2-8 parts of modified dispersing agent, 1-2 parts of coalescing agent, 0.5-1.5 parts of thickener, 0.8-1.5 parts of defoaming agent, 0.5-2 parts of modified siloxane and 30-50 parts of water; wherein the modified dispersing agent is polycarboxylic acid ammonium salt. The invention also provides a preparation method of the stain-resistant exterior wall latex paint. The acrylic monomer copolymer, the emulsifier and the ammonium persulfate are used as raw materials to form a compact net-shaped structure with high crosslinking degree, high rigidity and high tensile property, so that the stain resistance of the latex paint is improved; a medium PVC coating is prepared, so that the stain resistance of the coating is enhanced; and the added modified dispersing agent and hydrophobic modified siloxane aid further enhance the stain resistance of the exterior wall latex paint.

Owner:安徽朗凯奇科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com