Stain-resistant exterior wall latex paint and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

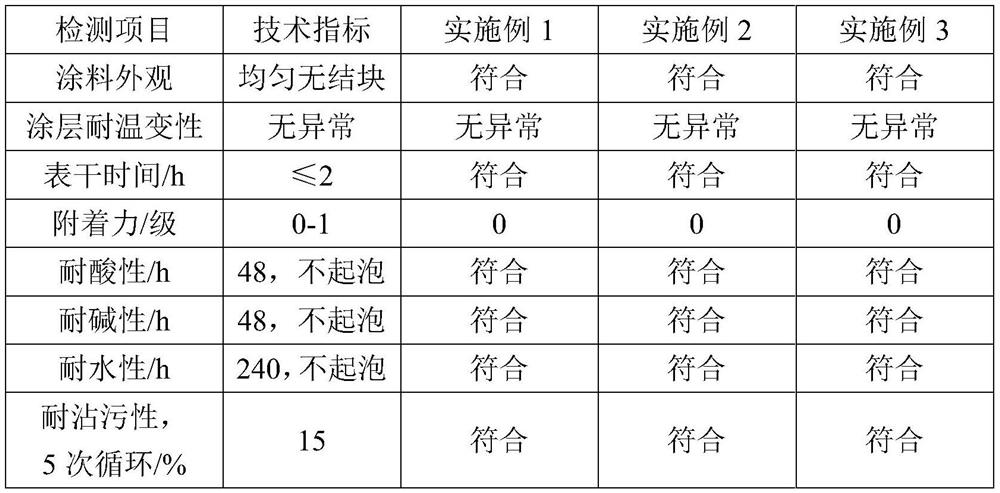

specific Embodiment 1

[0026] In the present embodiment, by weight, the specific formula is:

[0027] Acrylic Monomer Copolymer 15 copies Emulsifier 1 copy Ammonium persulfate 0.5 parts filler 40 copies Modified Dispersant 2 copies Coalescent 1 copy thickener 0.5 parts Defoamer 0.8 parts Modified siloxane 0.5 parts water 30 copies

[0028] Among them, the modified dispersant is polycarboxylate ammonium salt; the emulsifier is reactive emulsifier COPS-1; the film-forming aid is TEXANOL; the thickener is an associative thickener; Non-toxic defoamer; filler is bentonite.

[0029] Among them, the acrylic monomer copolymer is composed of glycidyl methacrylate, acrylic acid, styrene and butyl acrylate, and the weight ratio of glycidyl methacrylate, acrylic acid, styrene and butyl acrylate is 1:3:70 :240.

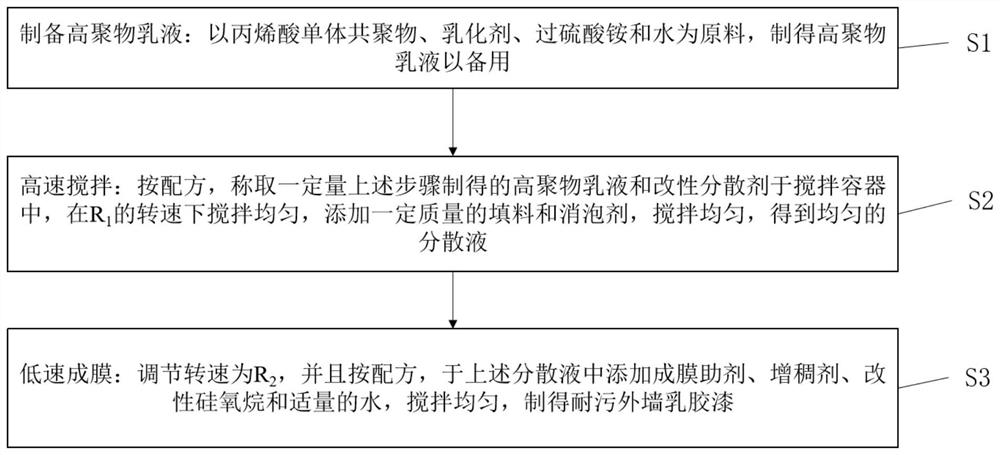

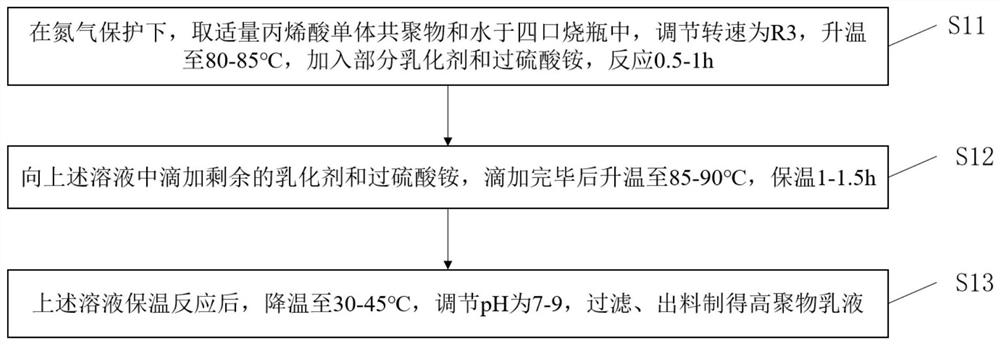

[0030] figure 1 Be the flow chart of the preparation method of a kind of stain-resistant exterior wall latex paint of th...

specific Embodiment 2

[0035] In the present embodiment, by weight, the specific formula is:

[0036] Acrylic Monomer Copolymer 25 copies Emulsifier 3 copies Ammonium persulfate 1 copy filler 50 copies Modified Dispersant 8 servings Coalescent 2 copies thickener 1.5 servings Defoamer 1.5 servings Modified siloxane 2 copies water 50 copies

[0037] Among them, the modified dispersant is polycarboxylate ammonium salt; the emulsifier is phosphate emulsifier PP40; the film-forming aid is TEXANOL; the thickener is alkali-swellable thickener; the defoamer is mineral oil modified Defoamer; filler is heavy calcium carbonate.

[0038] Among them, the acrylic monomer copolymer is composed of glycidyl methacrylate, acrylic acid, styrene and butyl acrylate, and the weight ratio of glycidyl methacrylate, acrylic acid, styrene and butyl acrylate is 1:5:80 : 250.

[0039] figure 1 Be the flow chart of the preparation method of a kind...

specific Embodiment 3

[0044] In the present embodiment, by weight, the specific formula is:

[0045] Acrylic Monomer Copolymer 20 copies Emulsifier 2 copies Ammonium persulfate 0.8 parts filler 45 copies Modified Dispersant 6 servings Coalescent 1 copy thickener 1.2 parts Defoamer 1.2 parts Modified siloxane 1 copy water 40 copies

[0046] Among them, the modified dispersant is ammonium polycarboxylate; the emulsifier is reactive emulsifier COPS-1; the film-forming aid is TEXANOL; the thickener is alkali-swellable thickener; Non-toxic defoamer; filler is talcum powder.

[0047] Among them, the acrylic monomer copolymer is composed of glycidyl methacrylate, acrylic acid, styrene and butyl acrylate, and the weight ratio of glycidyl methacrylate, acrylic acid, styrene and butyl acrylate is 1:4:75 :245.

[0048] figure 1 Be the flow chart of the preparation method of a kind of stain-resistant exterior wall latex paint of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com