High-strength high-toughness ceramic composite material and preparation method thereof

A ceramic composite material, high-strength and tough technology, applied in the field of ceramic materials, can solve the problems of limited toughening effect of ceramic composite materials, difficulty in being dispersed, and difficult sintering and compacting of ceramic materials, so as to solve the problem of safety in use and improve strength and toughness , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

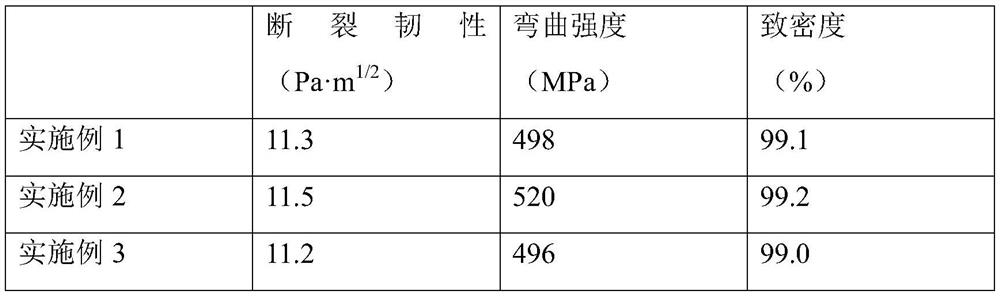

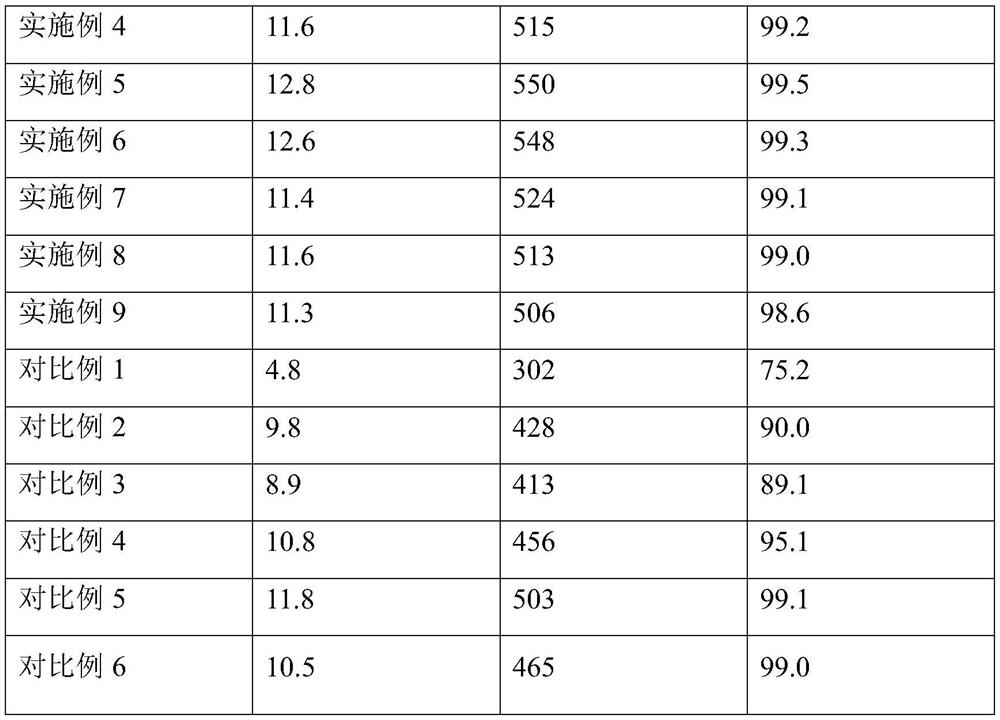

Examples

Embodiment 1

[0042] Embodiment 1 A method for preparing a high-strength and tough ceramic composite material, comprising the following steps:

[0043] 1) Mixing: Weigh the following raw materials by weight, weigh 500 grams of SiC powder with a median particle size of 2 μm, 500 grams of Si powder with a median particle size of 1 μm, 5 grams of dextrin, and 5 grams of tetramethylammonium hydroxide. gram, 2020 grams of deionized water, put the above various raw materials into a ball mill for ball milling, the ball-to-material ratio is 5:1, and the rotating speed is 30r / min, and ball milling for 5h obtains a mixed slurry.

[0044] 2) Molding: The resulting slurry is spray-dried and granulated. After drying, the average particle size of the pellets is 150 μm. The green body is obtained by dry molding, and the pressing height is limited by a stopper to control the volume of the green body, so that the green body The overall porosity is controlled at 25%.

[0045] 3) In-situ nitriding: put the b...

Embodiment 2

[0051] A method for preparing a high-strength and tough ceramic composite material, comprising the following steps:

[0052] 1) Mixing: Take the following raw materials by weight, B with a median particle size of 50 μm 4 C powder 500g, Si with a median particle size of 50μm 3 N 4 400g powder, 100g Si powder with a median particle size of 30μm, 20g polyvinyl alcohol, 10g dextrin, 10g polyvinyl butyral, 1500g deionized water, put the above raw materials into the mixer , with a rotating speed of 60r / min, stirring for 5h to obtain a mixed slurry.

[0053] 2) Molding: The resulting slurry is spray-dried and granulated. The average particle size of the pellets is 300 μm. The green body is obtained by dry molding. The rate is controlled at 30%.

[0054] 3) In-situ nitriding: put the biscuit into the nitriding furnace, firstly evacuate to 20Pa, then fill with 0.4MPa nitrogen, the nitriding temperature is 1500°C, and the nitriding time is 50 hours. Porous β-Si is obtained after co...

Embodiment 3

[0060] A method for preparing a high-strength and tough ceramic composite material, comprising the following steps:

[0061] 1) Mixing: Weigh the following raw materials by weight, 750 grams of SiC powder with a median particle size of 150 μm, 250 grams of Si powder with a median particle size of 100 μm, 50 grams of methyl cellulose, and 1 gram of n-octanol. 525 grams of ionized water, the above various raw materials are put into a sand mill, the abrasive ratio is 6:1, the rotating speed is 20r / min, sand milling for 5h to obtain a mixed slurry.

[0062] 2) Molding: The obtained slurry is spray-dried and granulated, and the average particle size of the granules is 300 μm, and the green compact is obtained by dry molding, and the pressing height is limited by a stopper, so as to control the volume of the green compact, so that the overall compact The porosity is controlled at about 35%.

[0063] 3) In-situ nitriding: put the biscuit into the nitriding furnace, firstly evacuate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com