Patents

Literature

84results about How to "Content adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

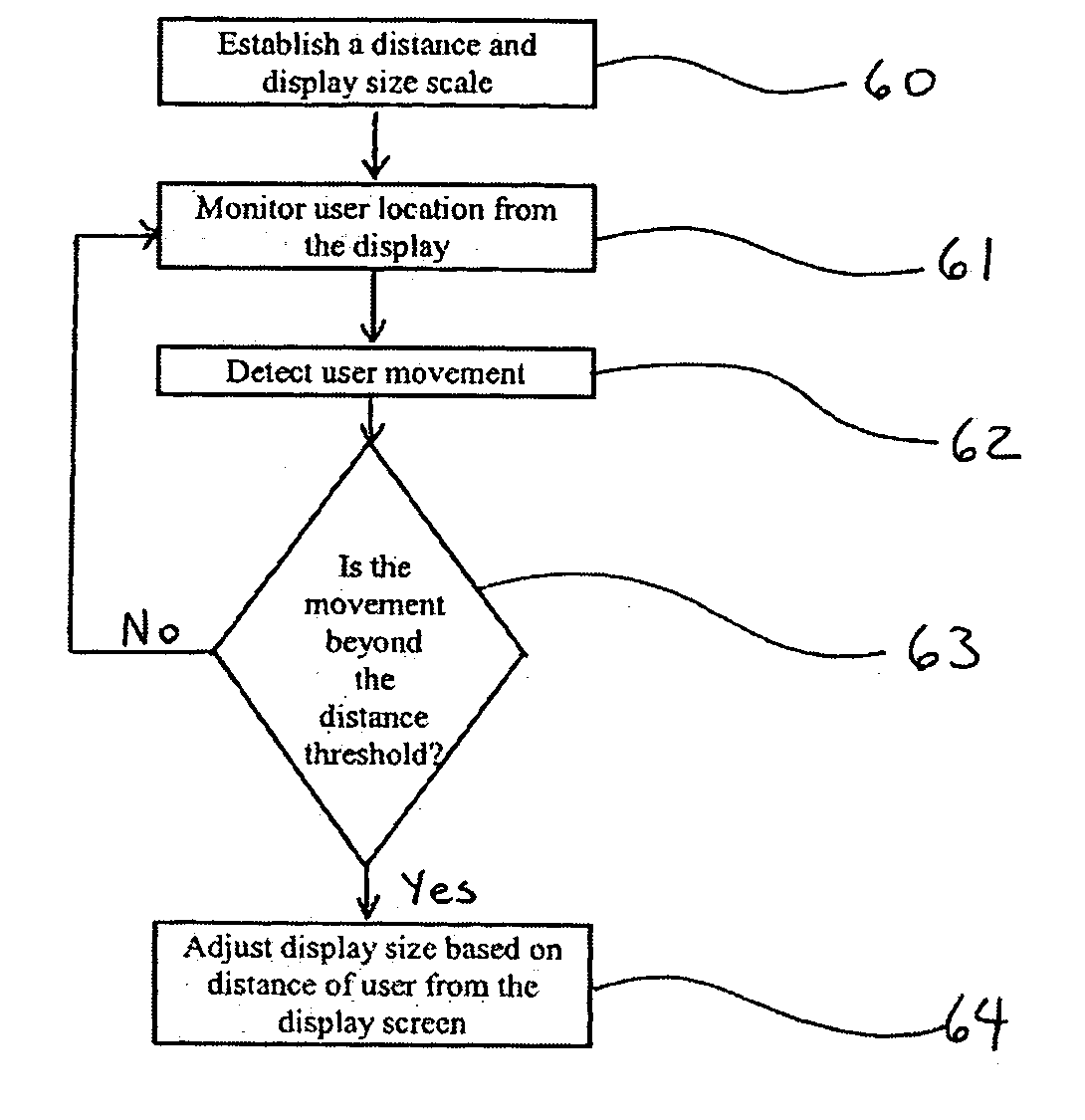

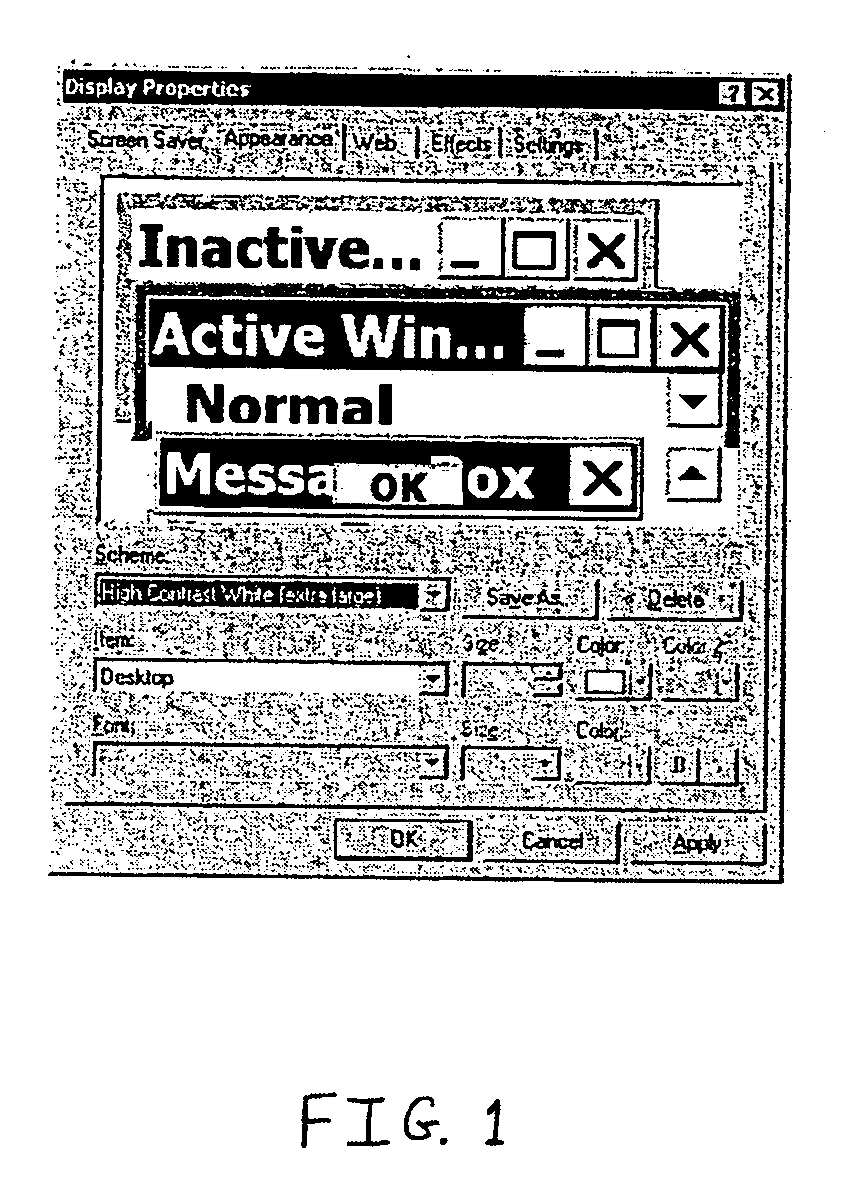

Method and system for adjusting a display based on user distance from display device

InactiveUS20050229200A1Content adjustableConsiderable value to a computing environmentInput/output for user-computer interactionTelevision system detailsFar distanceDisplay device

The present invention is a method and system that adjusts the contents on a display screen based on the distance of the user from the screen. This invention comprises a display screen with a distance approximator mechanism either attached the display screen or positioned in close proximity to the screen. This distance approximator detects user movement and calculates the distance that the user is from the screen. As the distance of the user from the screen increases or decreases, the method of the invention adjusts the contents of the screen. The screen adjustments can comprise enlarging the size of the information on the screen as the user moves further from the screen. The contents can also be reduced as the user returns to a local distance to the display screen. The display content adjustment techniques of the present invention enable a user to view screen contents from abnormally far distances from the screen without the need for the user to continually travel back and forth to and from the display screen.

Owner:IBM CORP

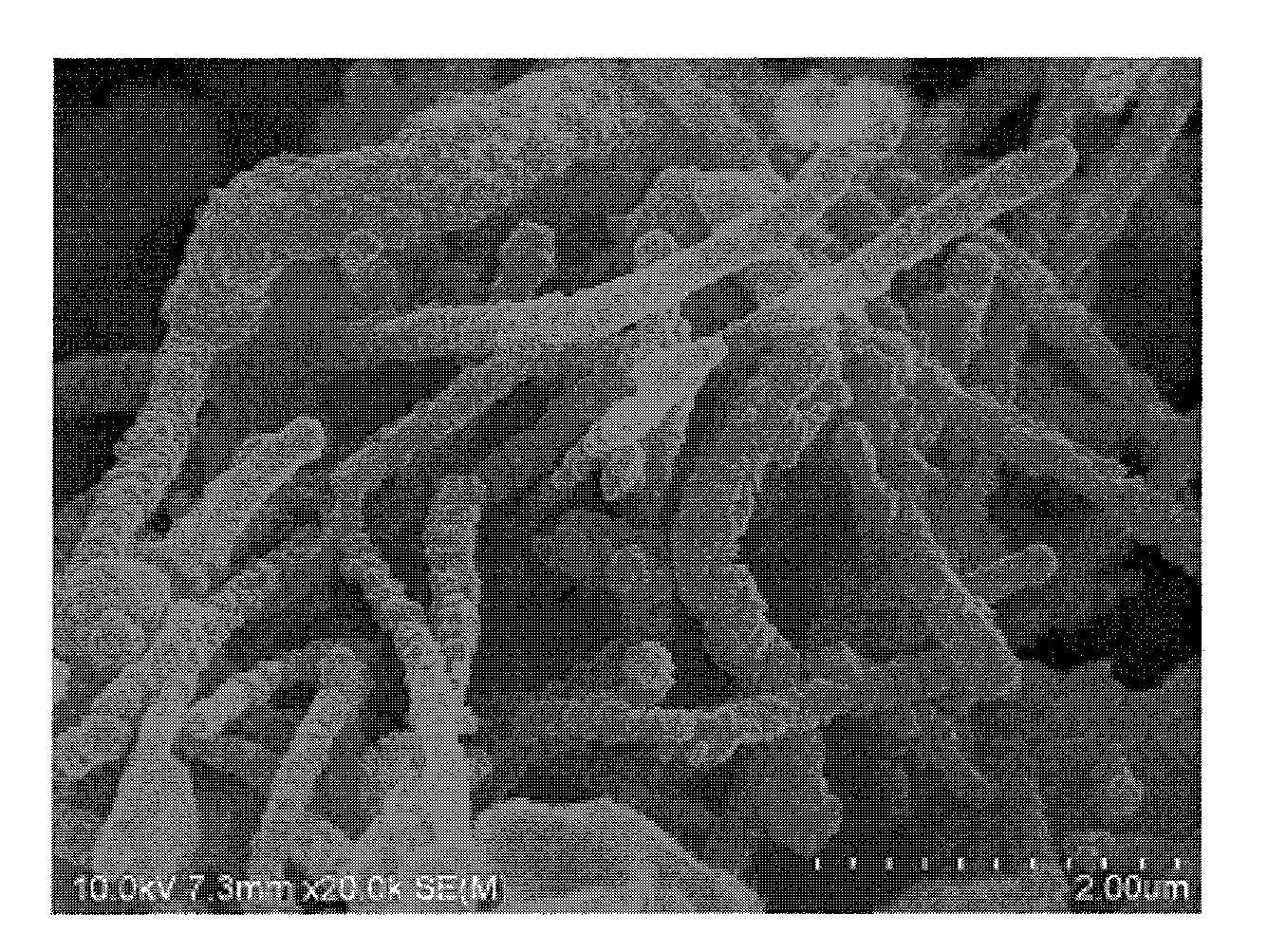

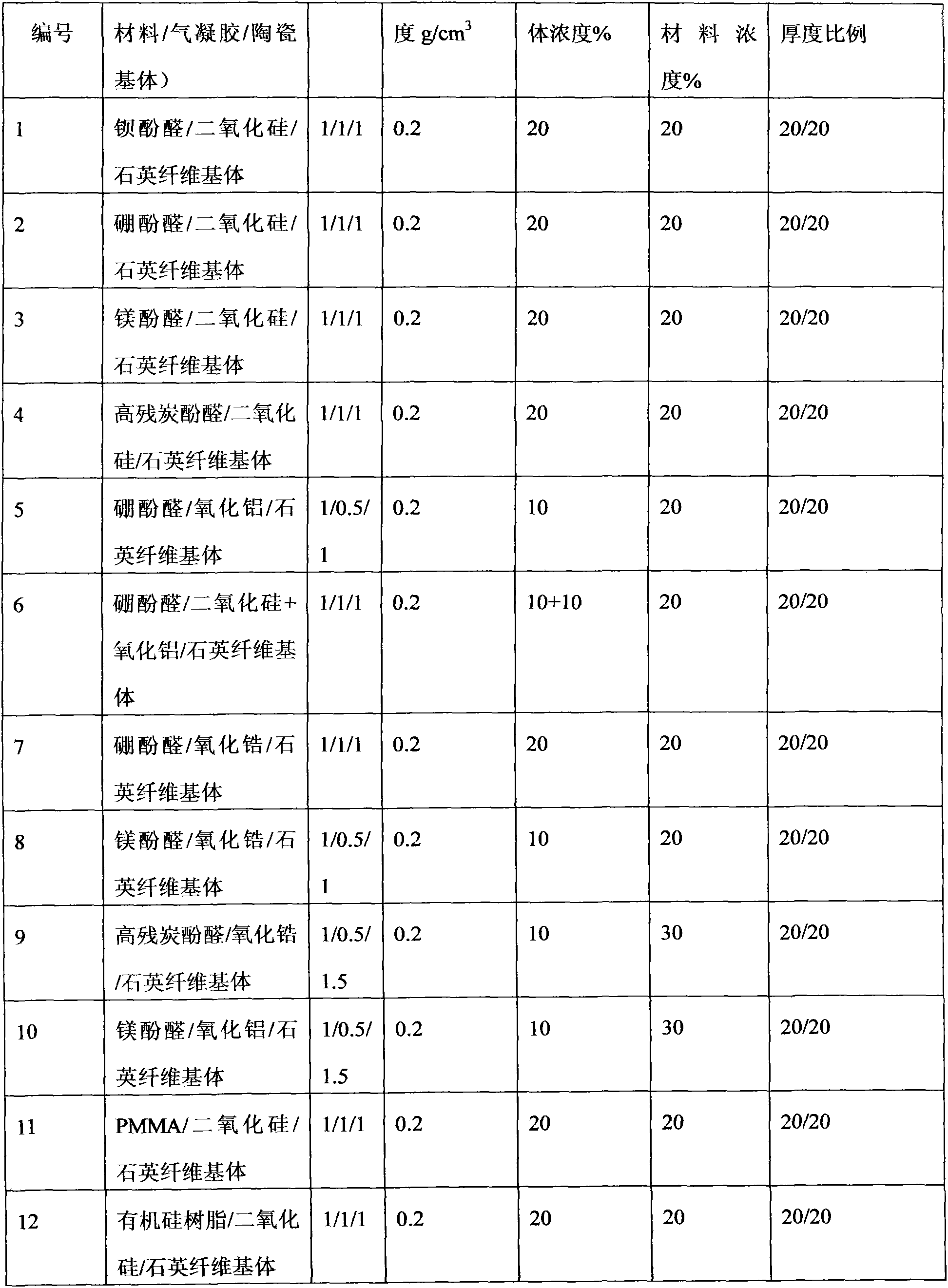

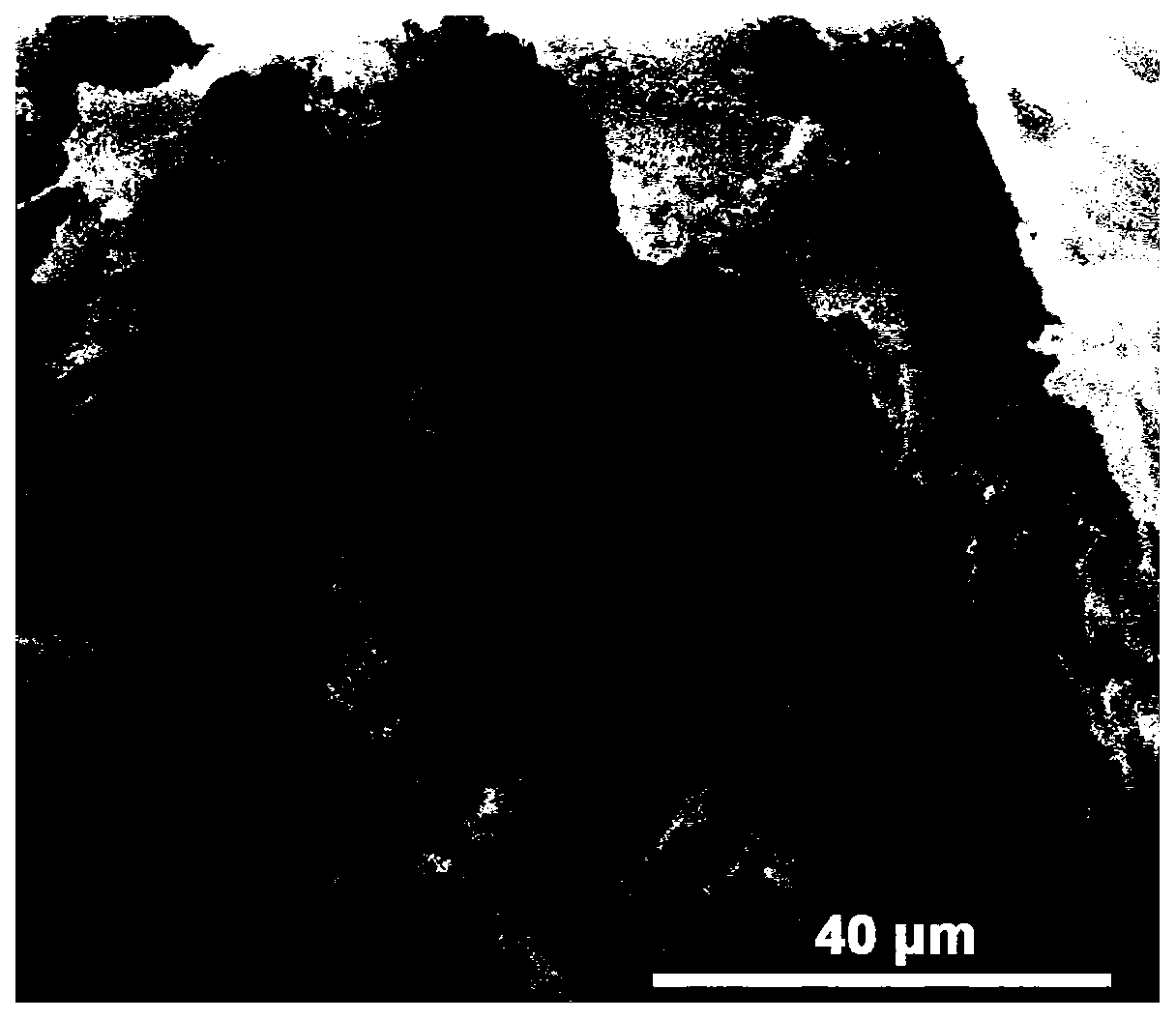

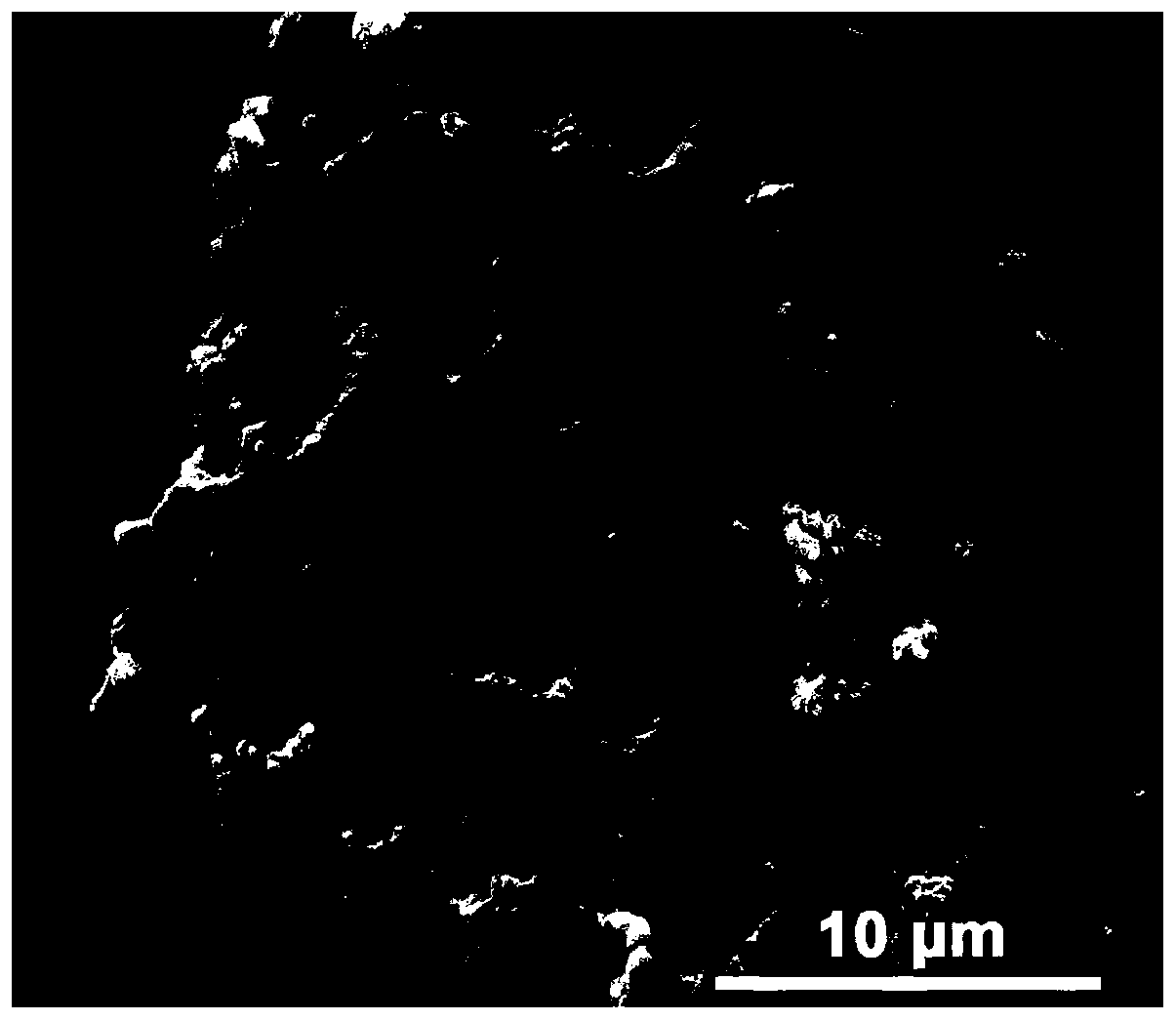

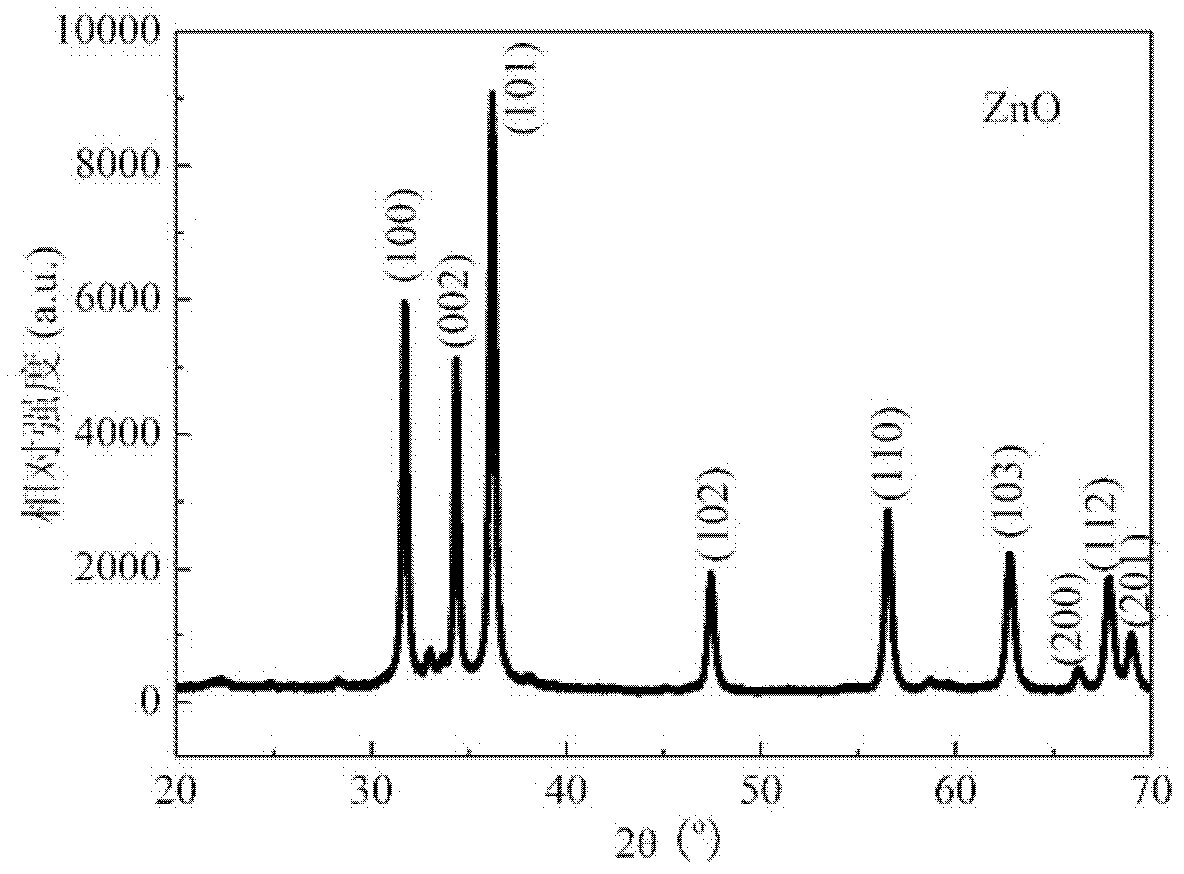

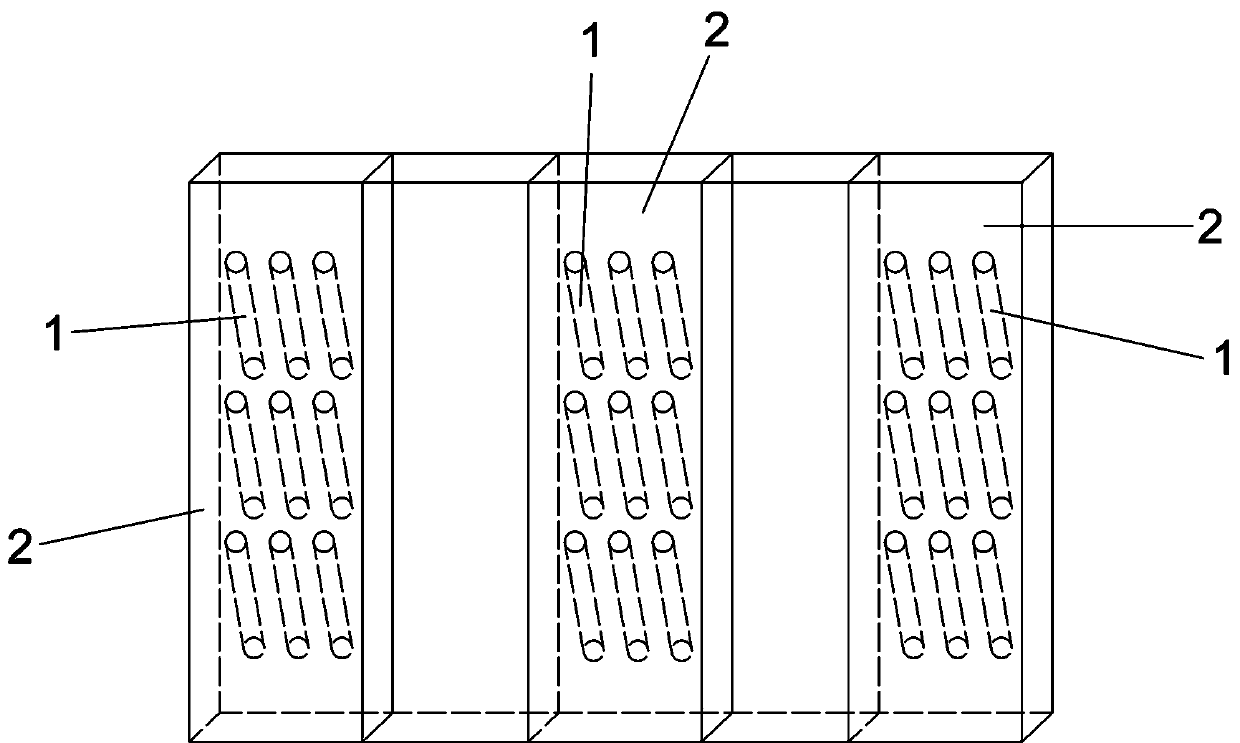

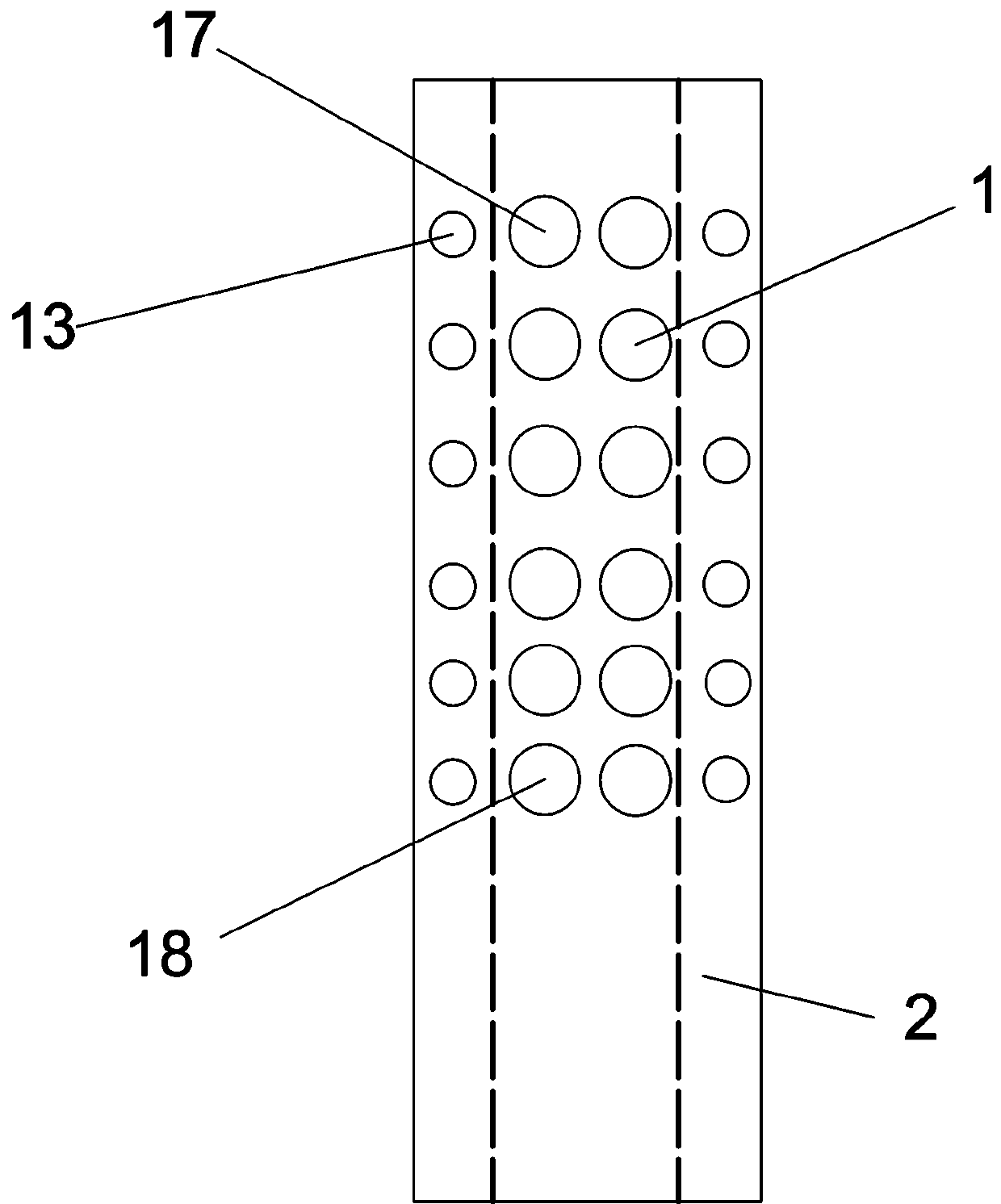

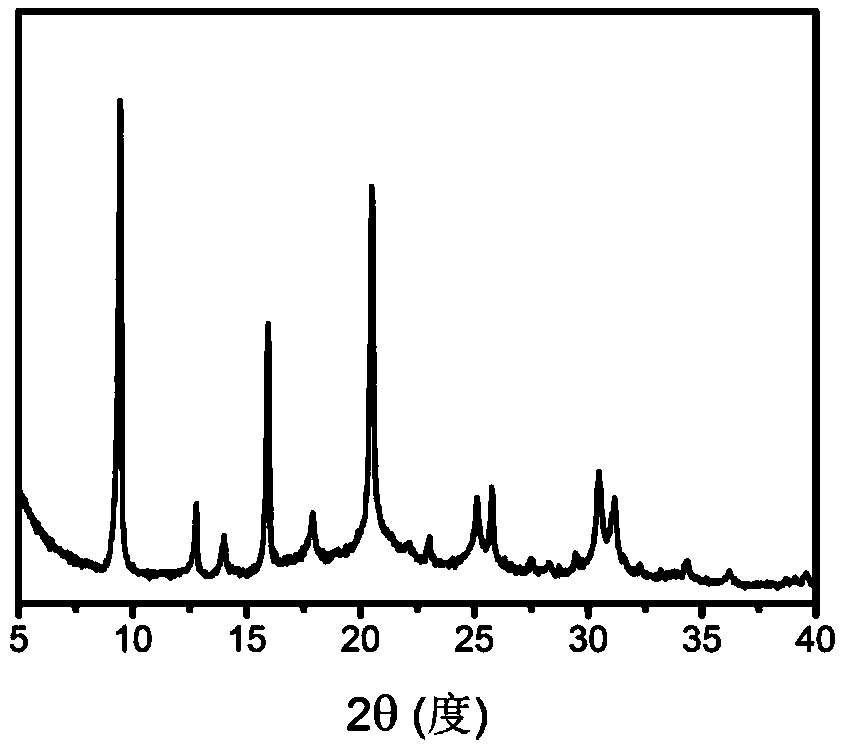

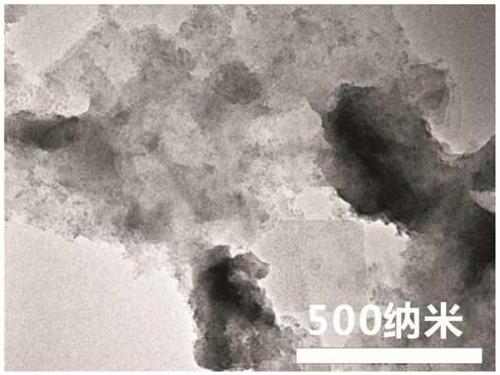

NANO silicon-carbon composite material and preparation method thereof

ActiveUS20140302396A1Improve cycle stabilityShort production processMaterial nanotechnologyElectrolysis componentsCarbon compositesSilicon dioxide

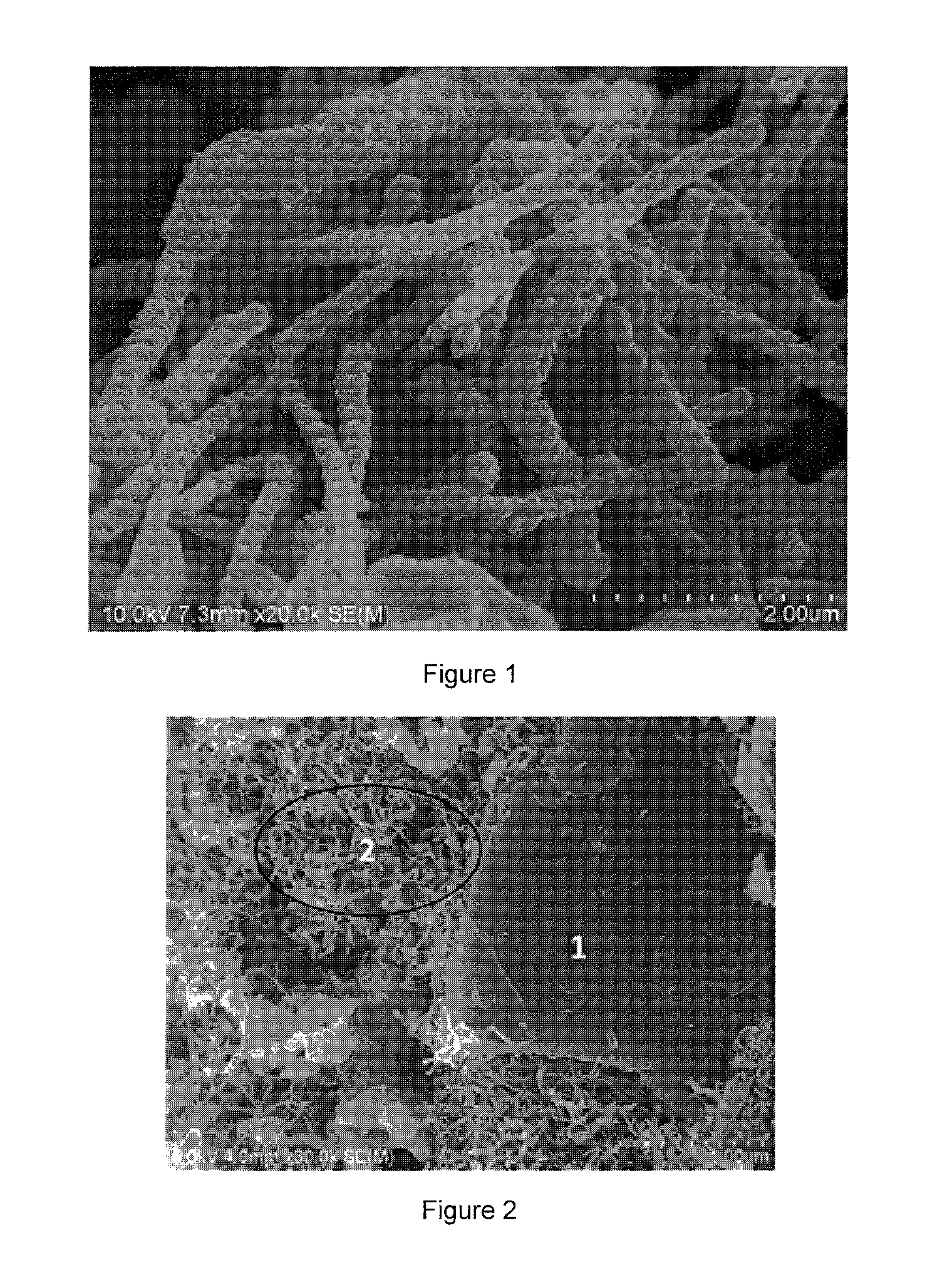

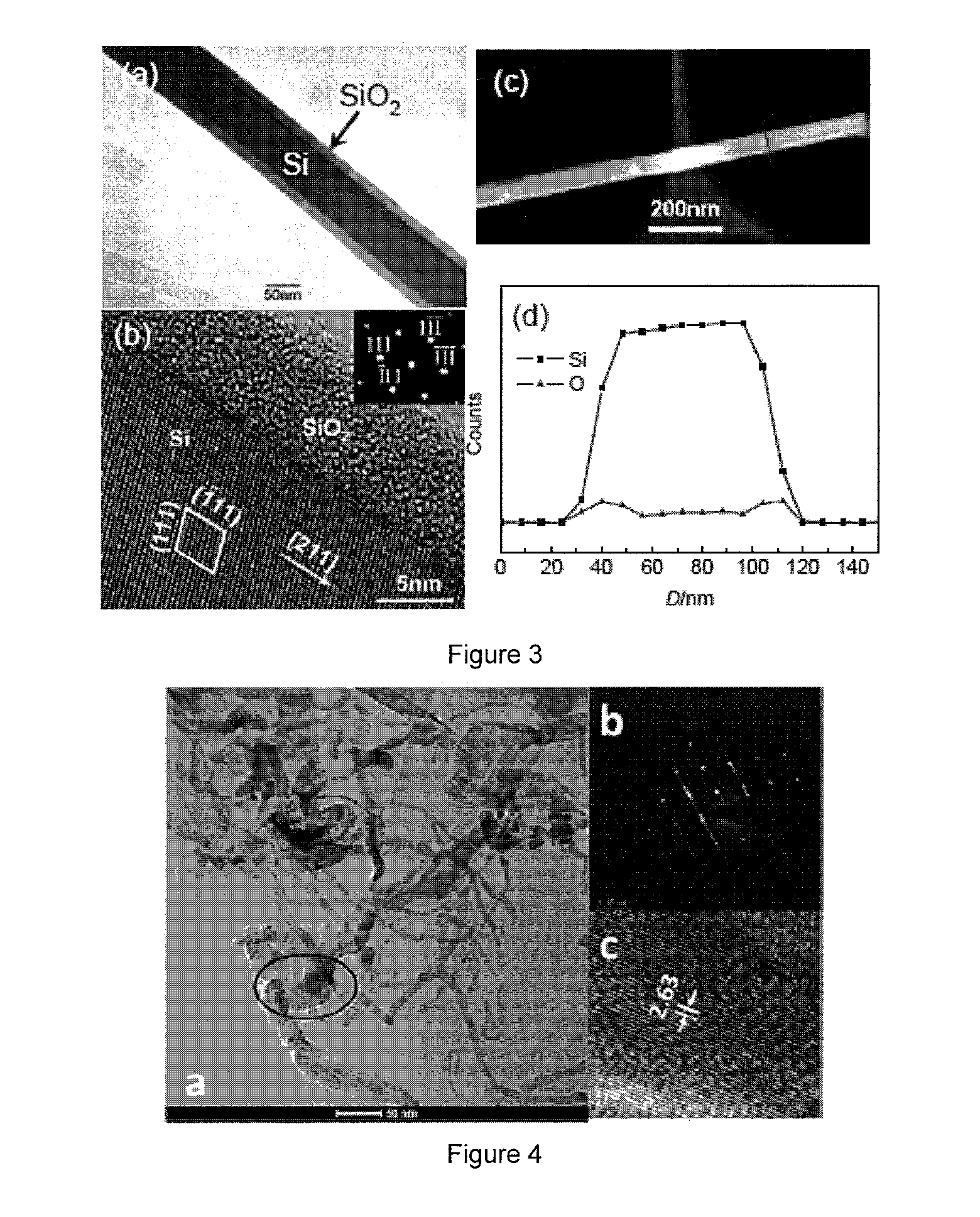

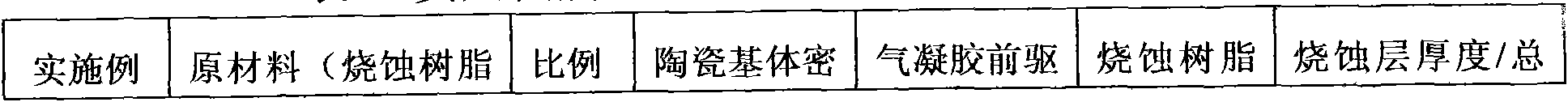

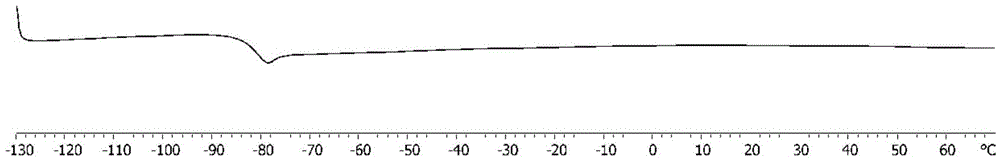

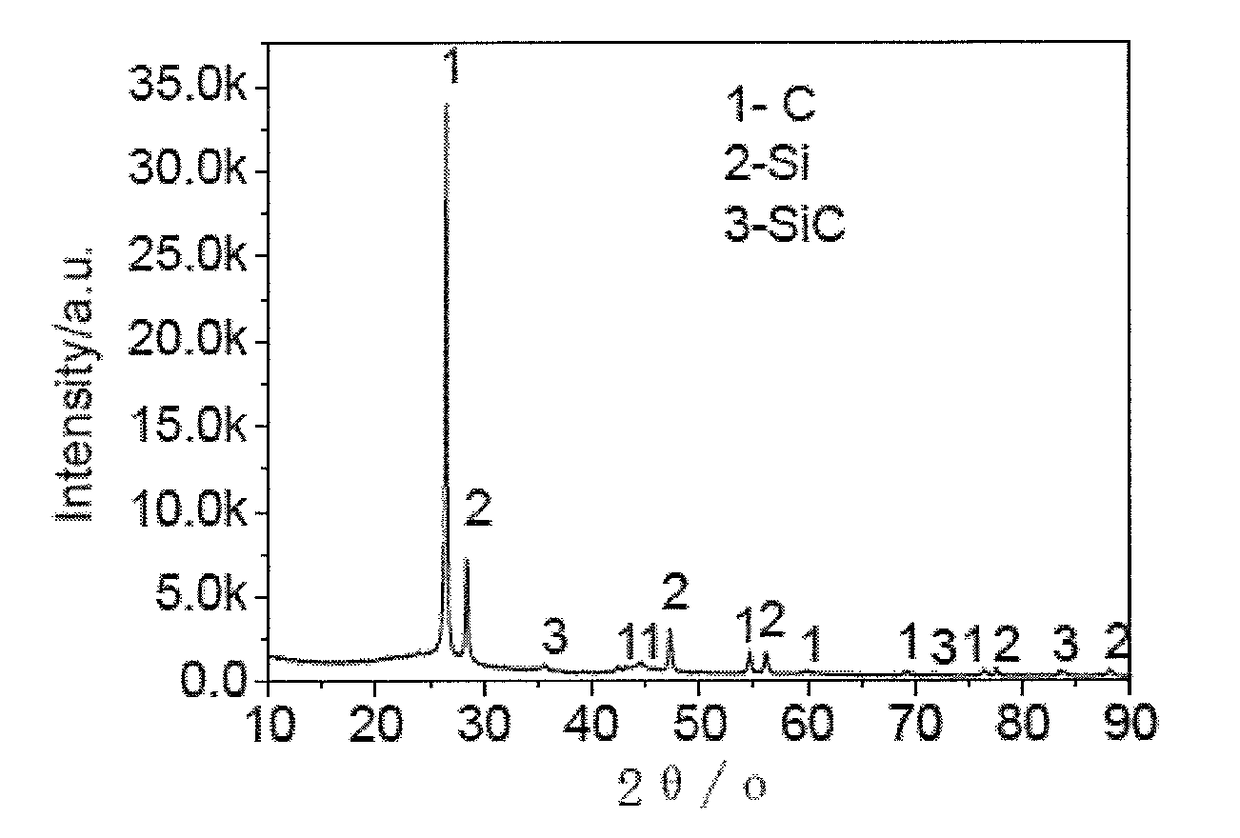

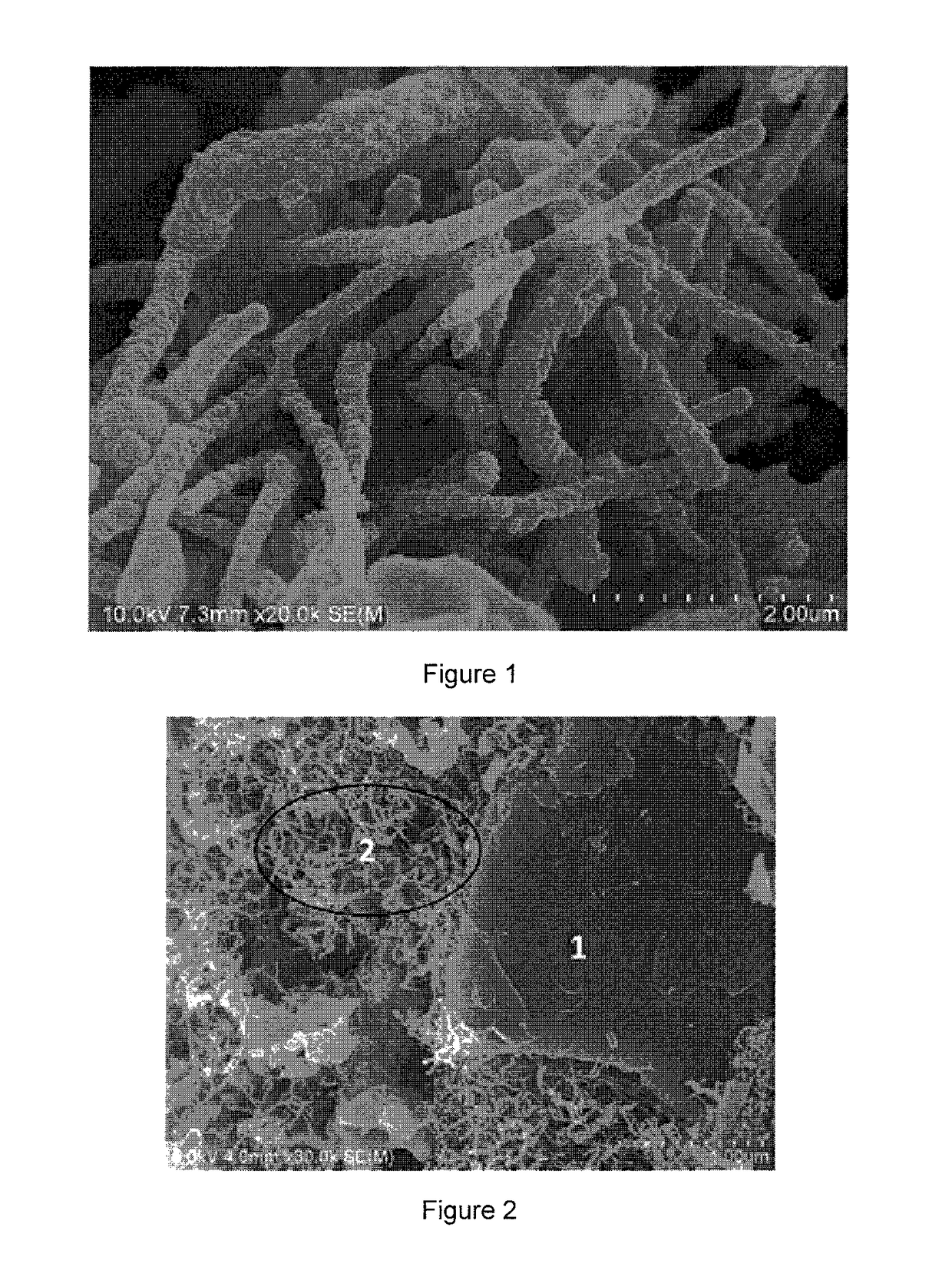

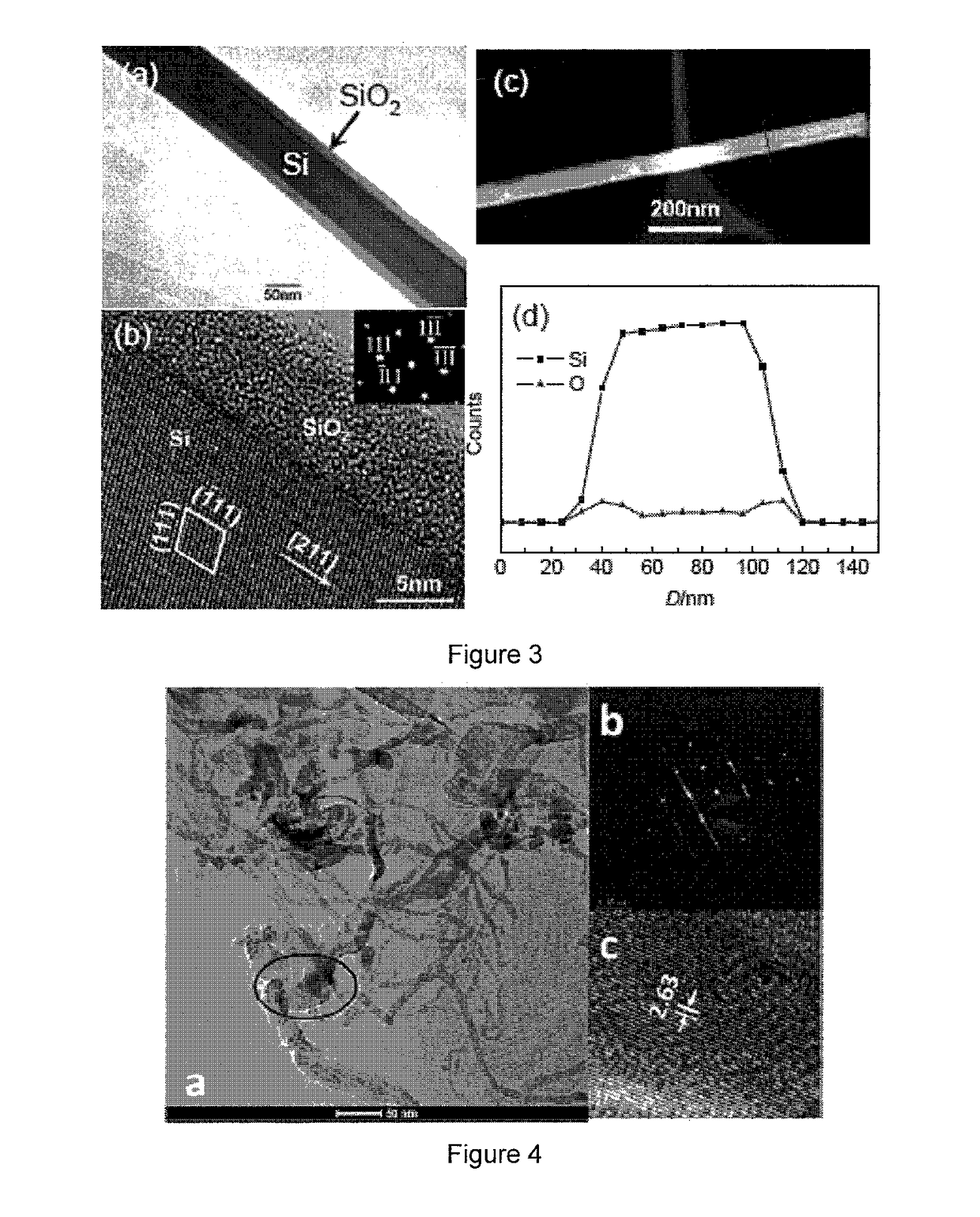

The invention relates to a nano silicon-carbon composite negative material for lithium ion batteries and a preparation method thereof. A porous electrode composed of silica and carbon is taken as a raw material, and a nano silicon-carbon composite material of carbon-loaded nano silicon is formed by a molten salt electrolysis method in a manner of silica in-situ electrochemical reduction. Silicon and carbon of the material are connected by nano silicon carbide, and are metallurgical-grade combination, so that the electrochemical cycle stability of the nano silicon-carbon composite material is improved. The preparation method of the nano silicon-carbon composite material provided by the invention comprises the following steps: compounding a porous block composed of carbon and silica powder with a conductive cathode collector as a cathode; using graphite or an inert anode as an anode, and putting the cathode and anode into CaCl2 electrolyte or mixed salt melt electrolyte containing CaCl2 to form an electrolytic cell; applying voltage between the cathode and the anode; controlling the electrolytic voltage, the electrolytic current density and the electrolytic quantity, so that silica in the porous block is deoxidized into nano silicon by electrolytic reduction, and the nano silicon-carbon composite material for lithium ion batteries is prepared at the cathode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

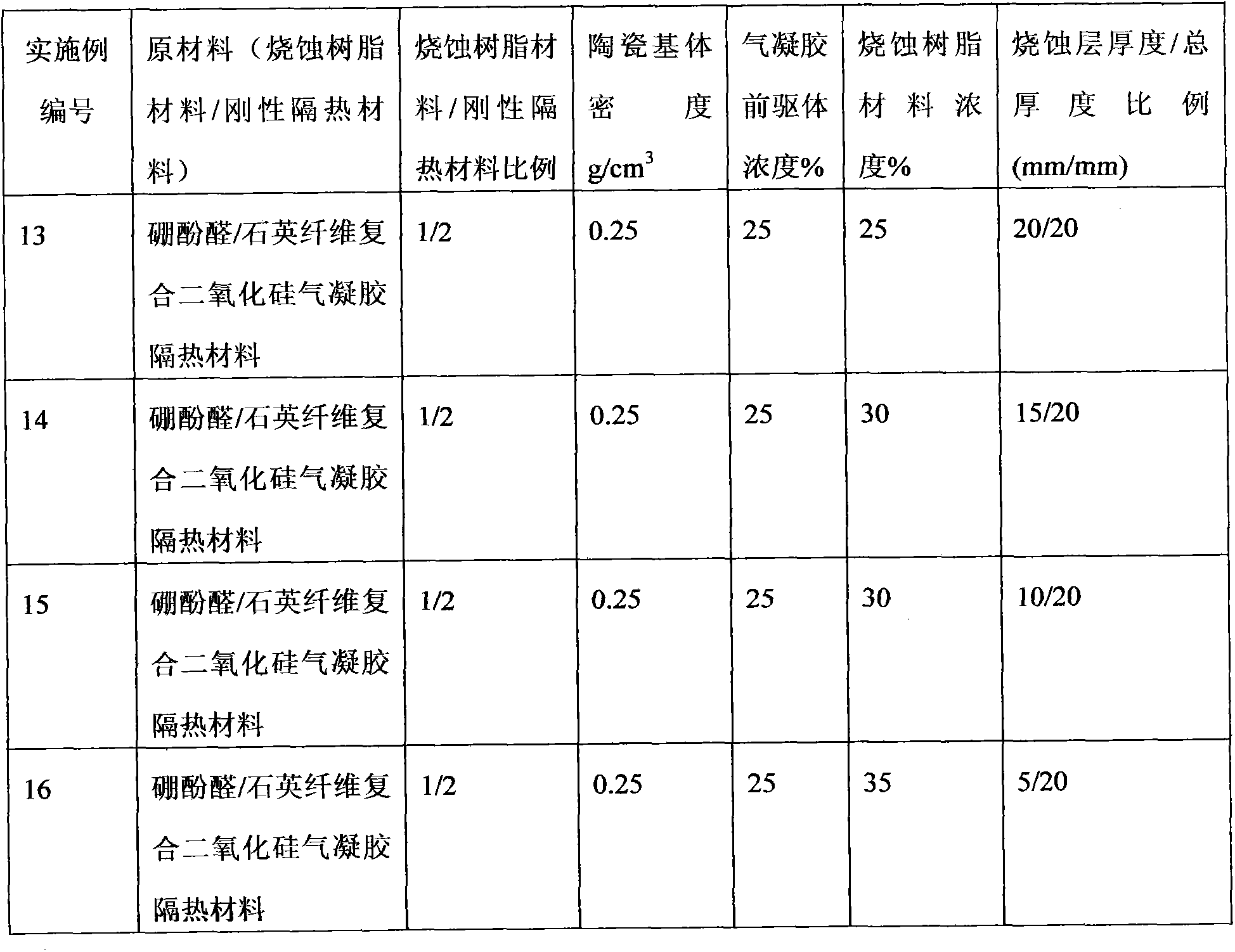

Micro-ablation insulating material and preparation method thereof

InactiveCN103449825AGood ablative thermal insulation capabilityDimensional abilityThermal insulationPolyresin

The invention discloses a micro-ablation insulating material. The micro-ablation insulating material comprises an ablation resin material and a rigid thermal-insulation material, wherein the rigid thermal-insulation material comprises a ceramic base body and an aerogel material. The invention also provides a preparation method of the micro-ablation insulating material. The method comprises the steps of compounding the aerogel material and the ceramic base body to manufacture the rigid thermal-insulation material, compounding the rigid thermal-insulation material and the ablation resin material, and gelling, drying and curing the ablation resin material. The proportions of the rigid thermal-insulation material and the ablation resin material, and the composition and the structure of the composition of the rigid thermal-insulation material and the ablation resin material in the thickness direction can be adjusted according to different using requirements. The micro-ablation insulating material has high designability, excellent superhigh-temperature heat-insulating property, strong variable-dimension ability and good processing performance, can be manufactured into various profiles and sizes, and has good application prospect in the fields of external protection of reentry type aircrafts and thermal protection of superhigh-temperature engines.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

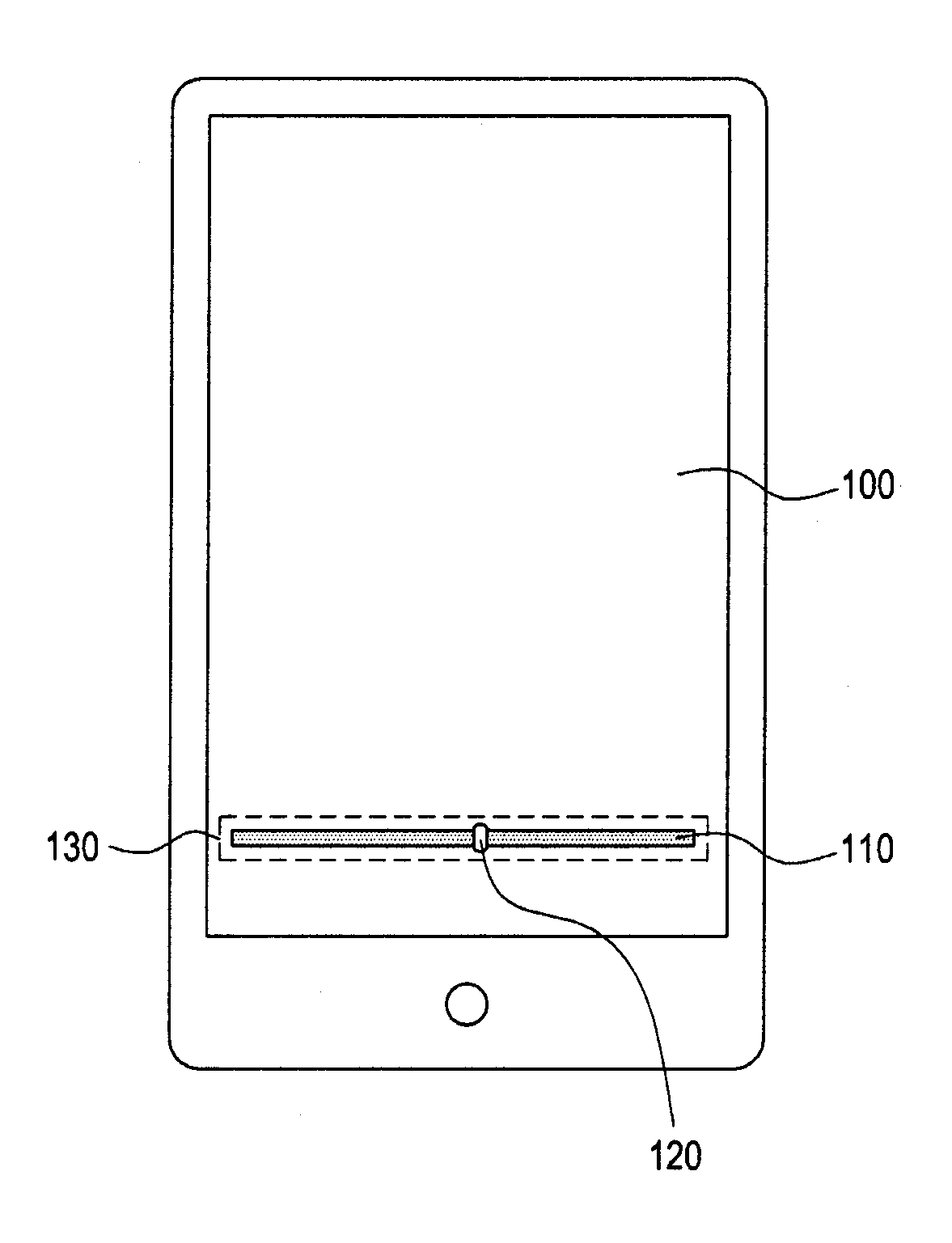

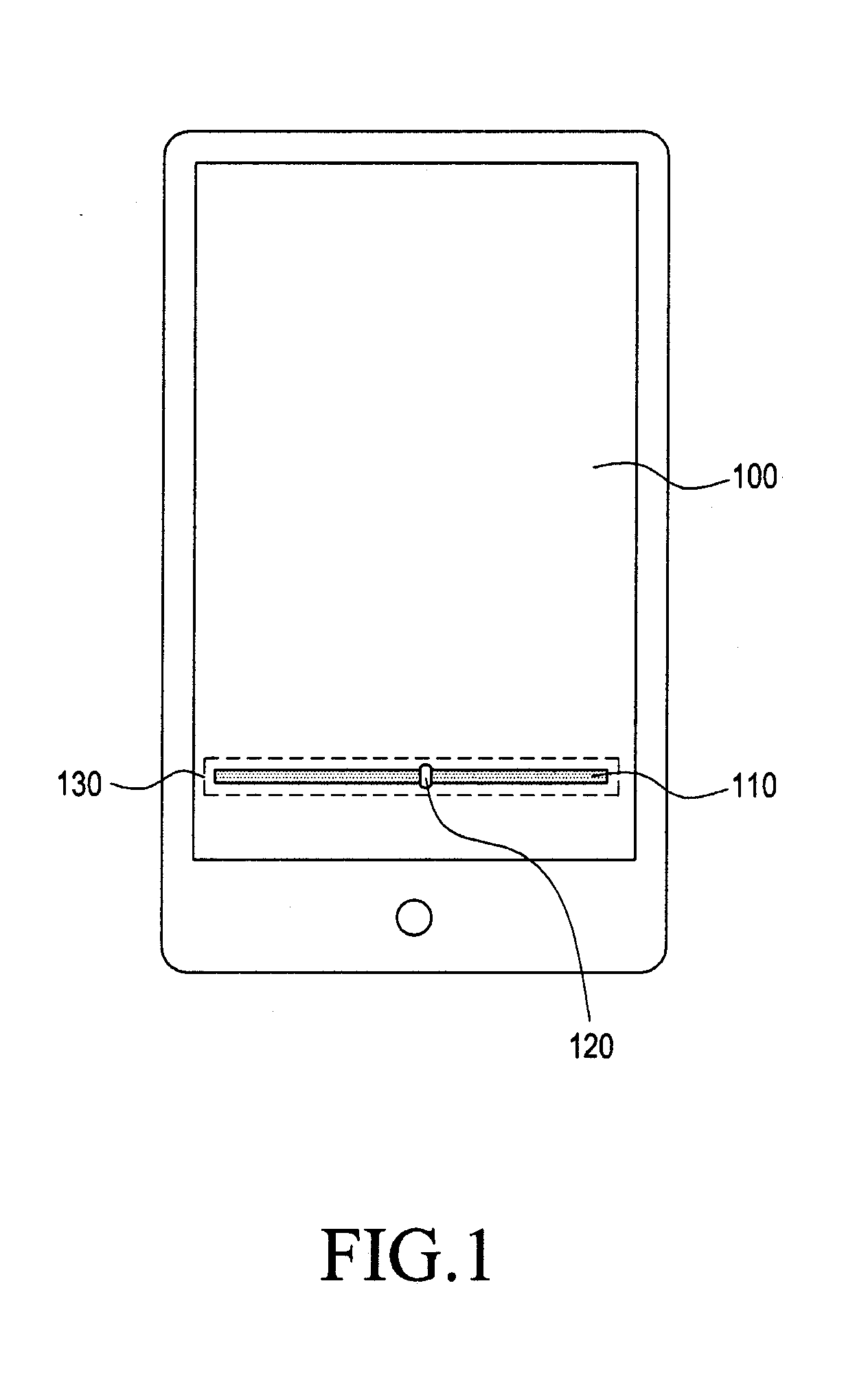

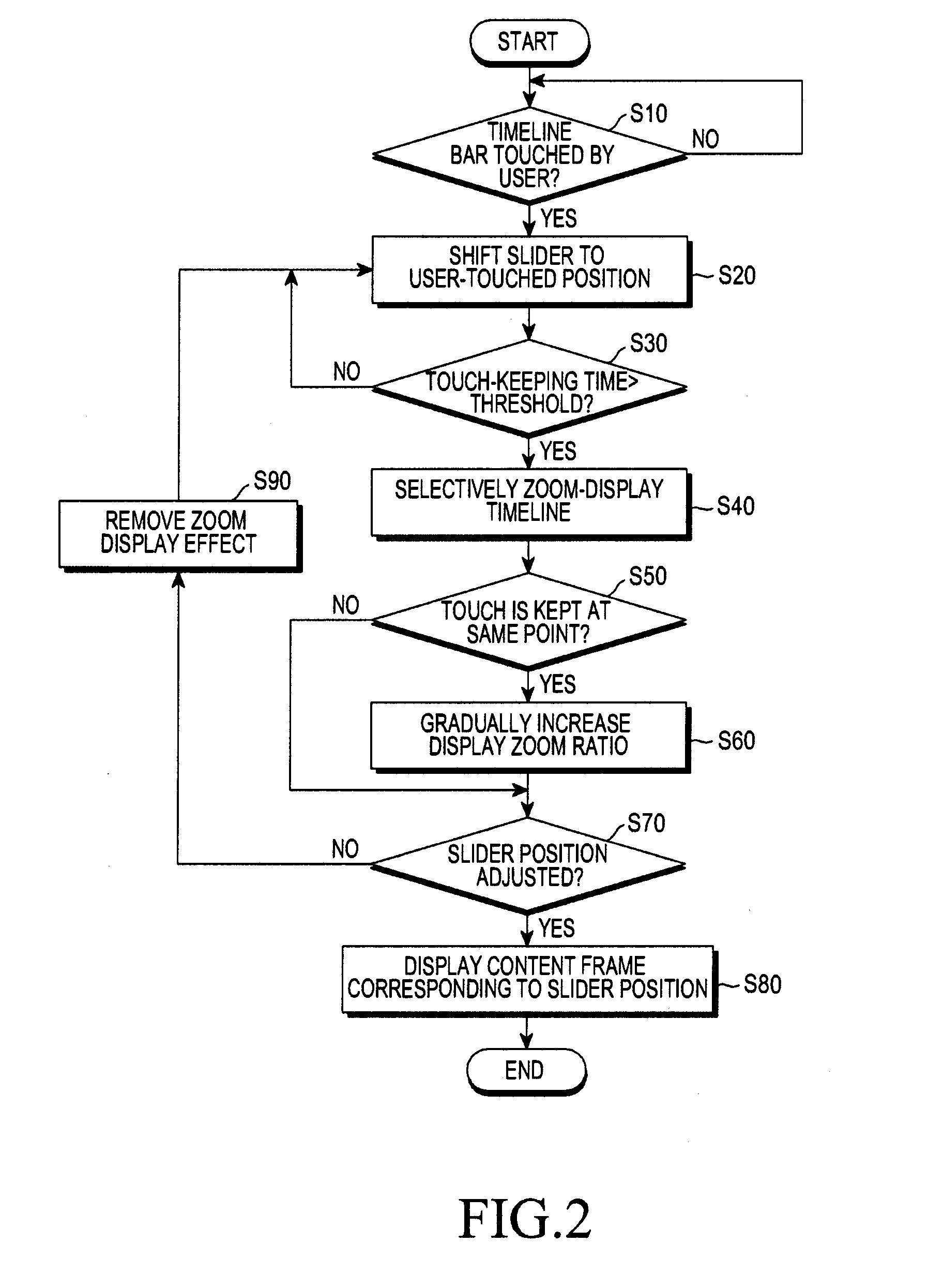

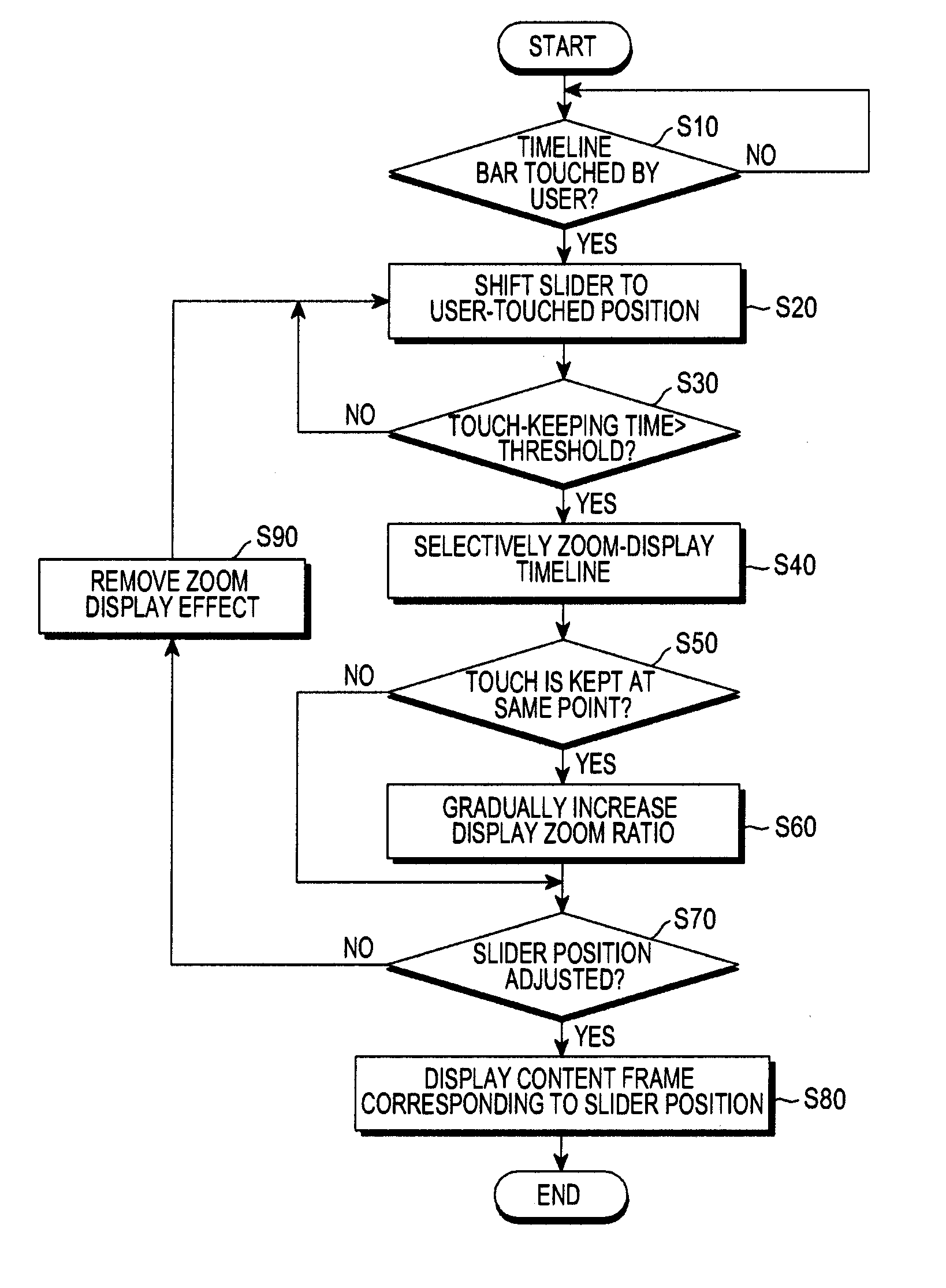

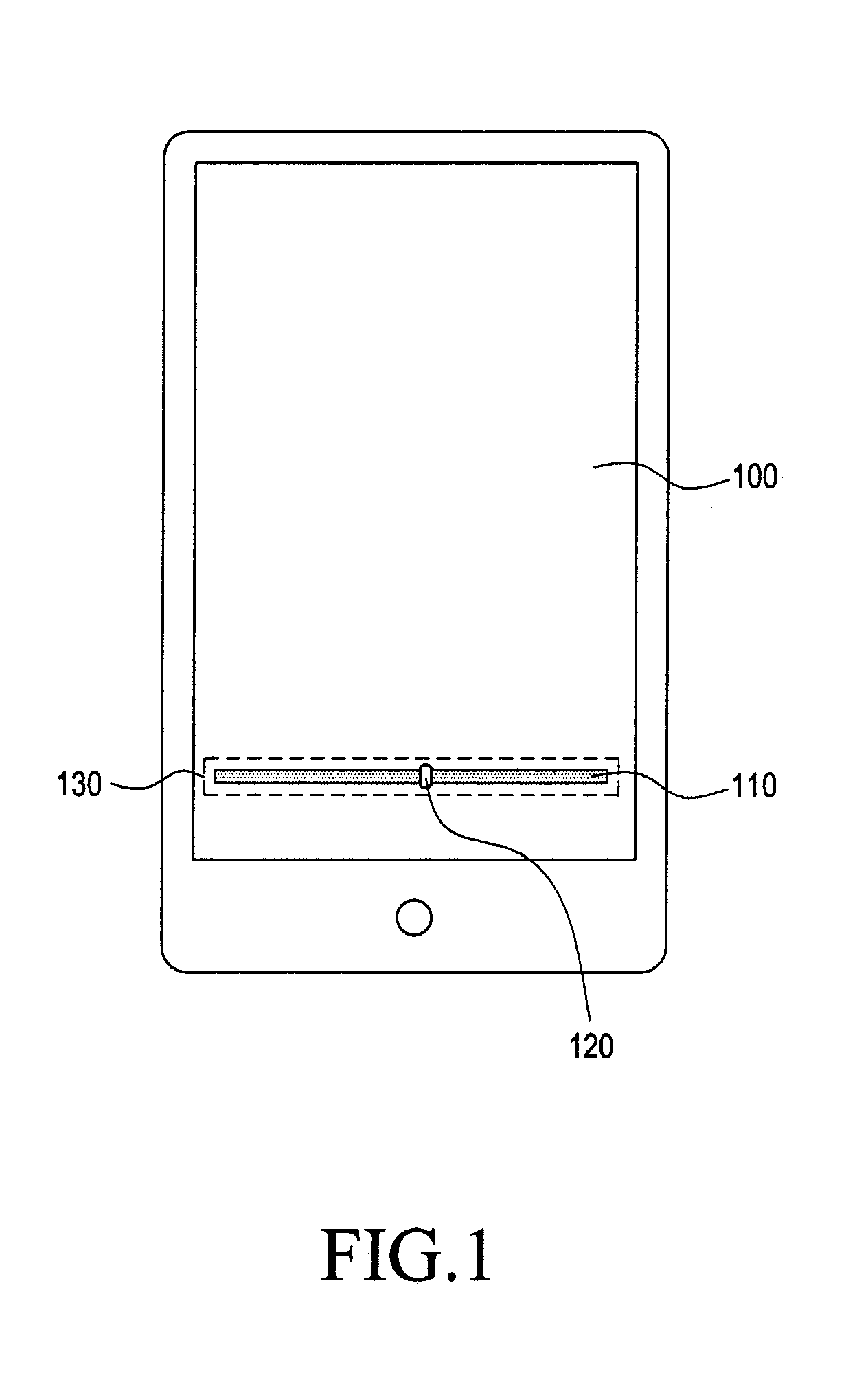

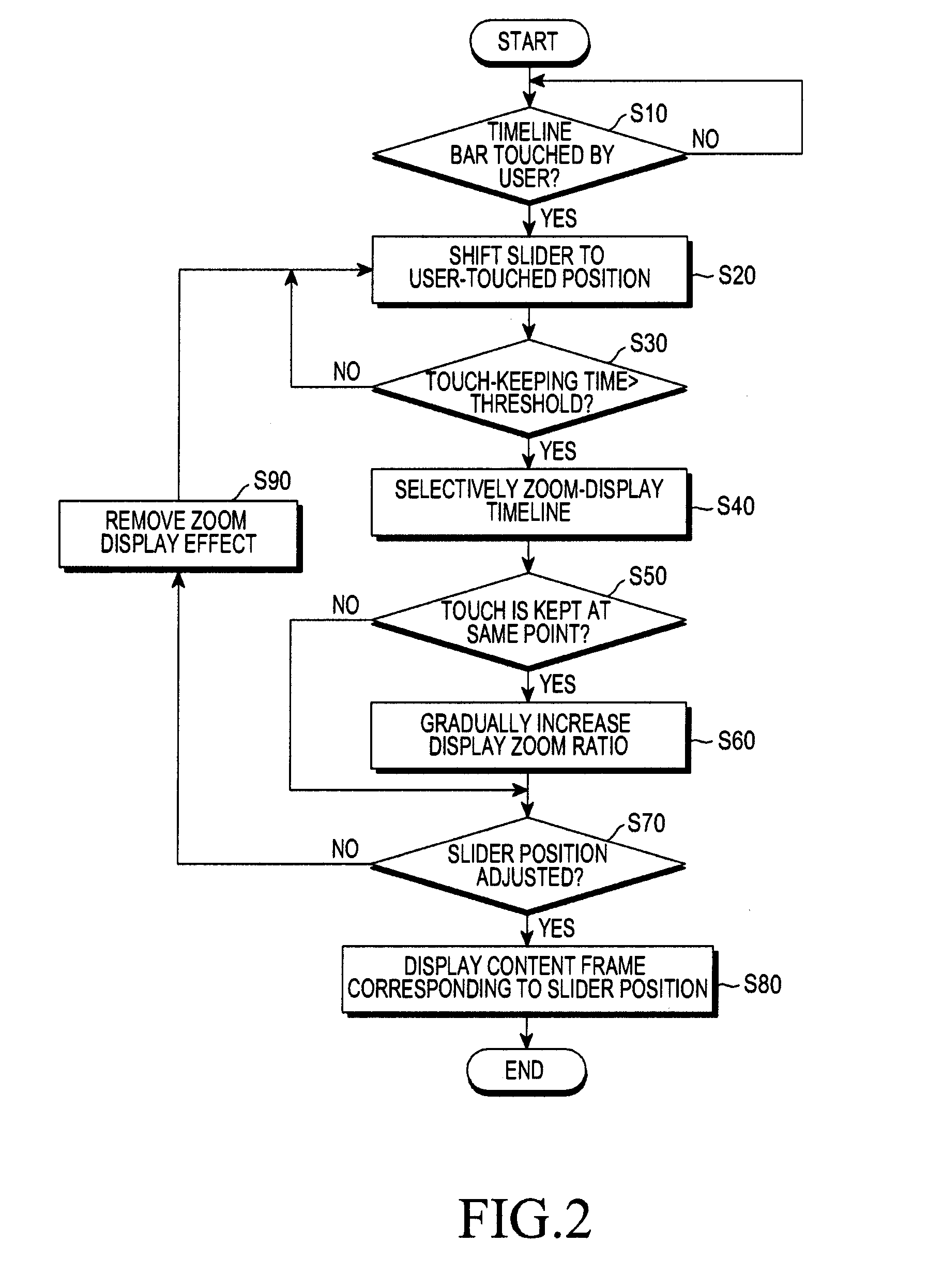

Method and apparatus for controlling a display of multimedia content using a timeline-based interface

ActiveUS20120308204A1Content adjustableEasy to controlColor television signals processingRecord information storageEvent triggeredTouchscreen

A touch screen control method for controlling a playback of multimedia content using a timeline-based interface includes detecting a selection at a specific location on the timeline; and selectively zoom-displaying an area around the location where the selection is detected the position on the timeline where the event trigger has occurred.

Owner:SAMSUNG ELECTRONICS CO LTD

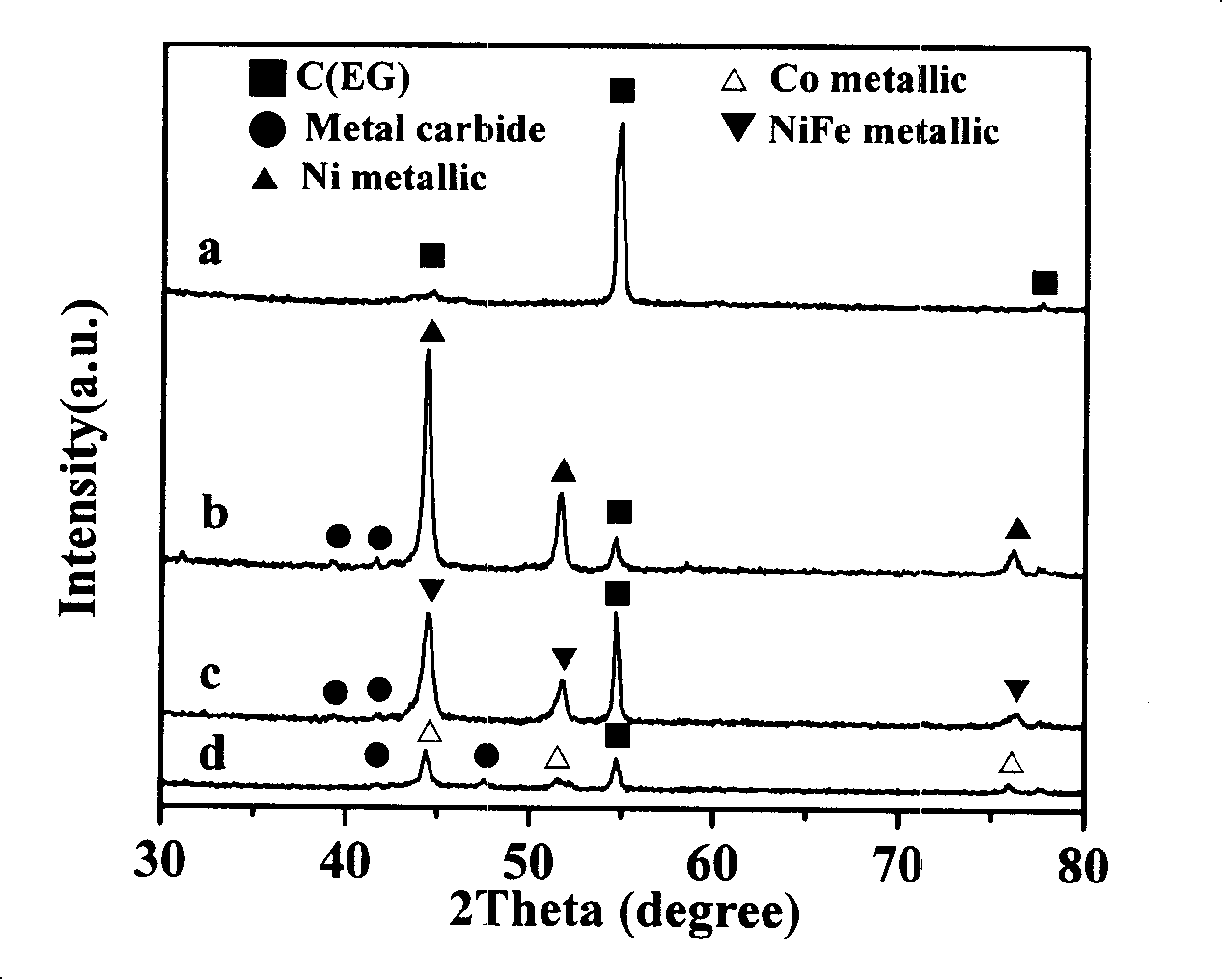

Method for preparing electromagnetic shielding light graphite based nanometer magnetic metal composite material

InactiveCN101179921AStir and disperse evenlyEnable mass manufacturingMagnetic/electric field screeningScreening apparatusLow frequency bandElectromagnetic shielding

The invention relates to a preparation method of a lightweight graphite-based nano-magnetic metal composite material used for electromagnetic shielding, which belongs to the related field of electromagnetic shielding materials; the precursor solution of expanded graphite and magnetic metal is mixed and stirred evenly, and dried after evaporating the solvent. The obtained mixture is treated in a reducing atmosphere at 300°C-1000°C, passivated with ordinary nitrogen and cooled to room temperature to obtain a composite material of expanded graphite and magnetic nanometer metal, and the relative content of the two can be adjusted. The composite material is light in texture, has excellent electromagnetic properties, and can be pressed into various shapes required. The material has excellent electromagnetic shielding performance in the range of 300kHz-1.5GHz, reaching 70-105dB, and the addition of magnetic metal improves the electromagnetic shielding performance of the expanded graphite in the low-frequency band. The method is simple and efficient, suitable for mass preparation, and the obtained product is expected to be applied in aerospace, military, electronic and electrical products.

Owner:NANJING UNIV

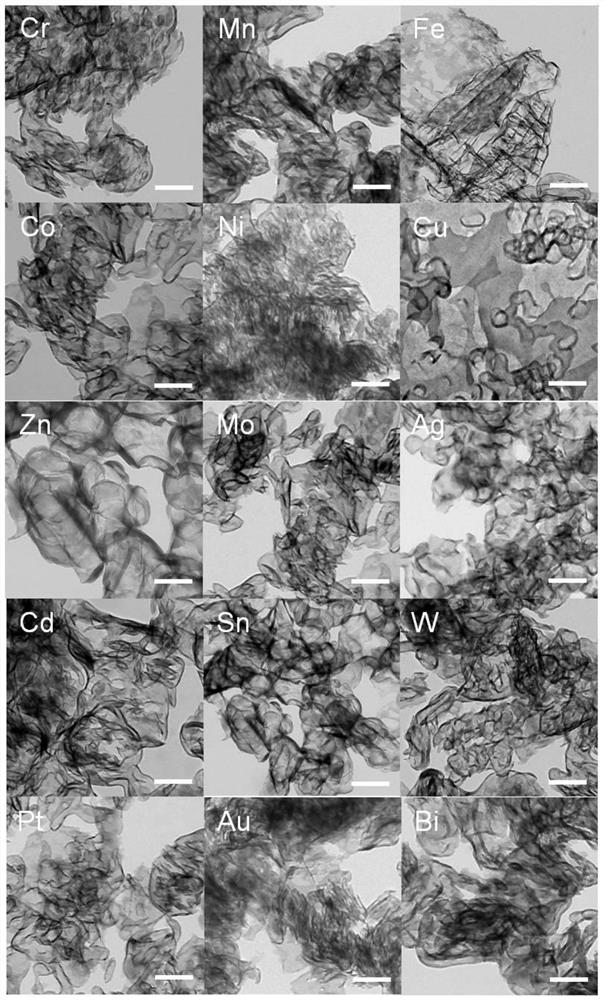

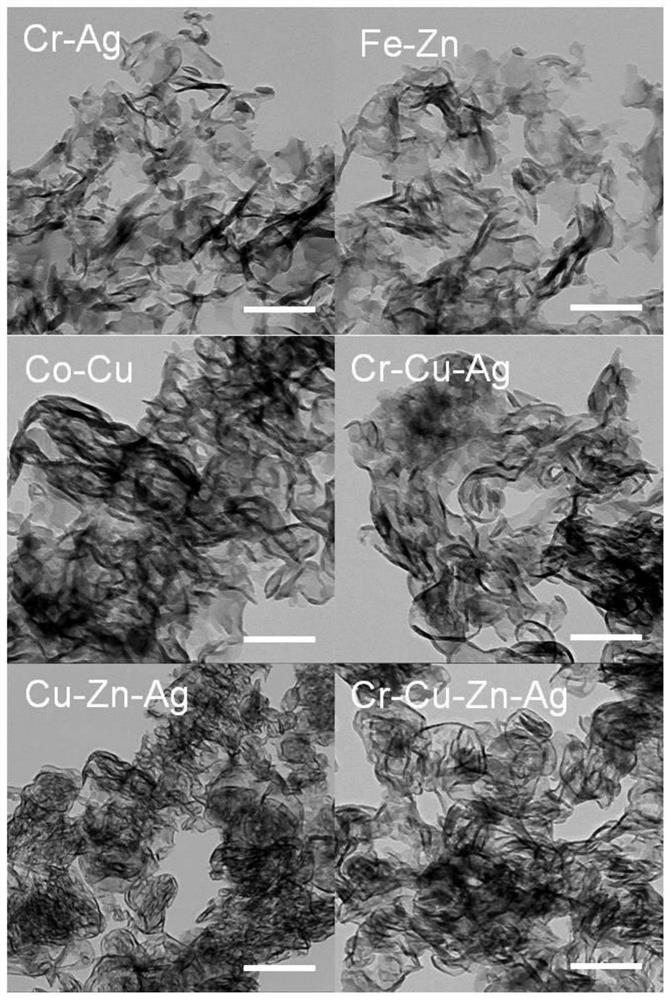

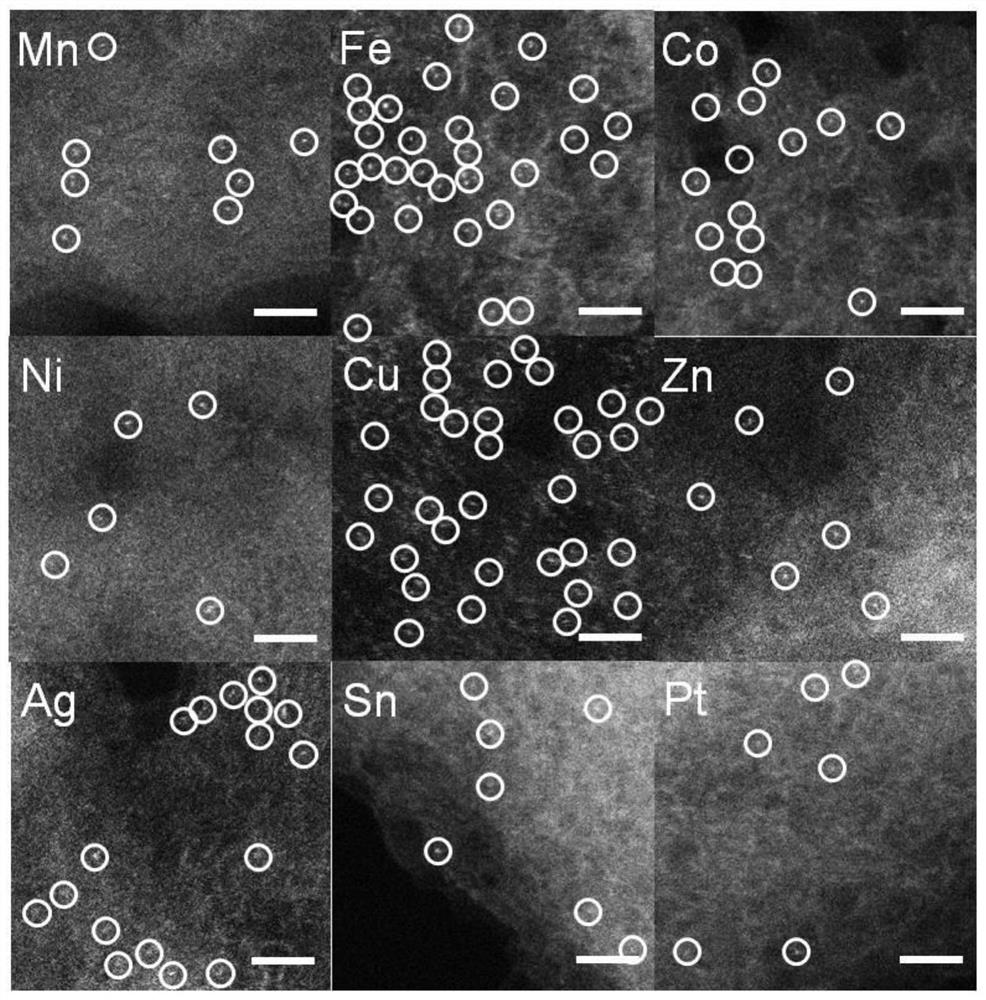

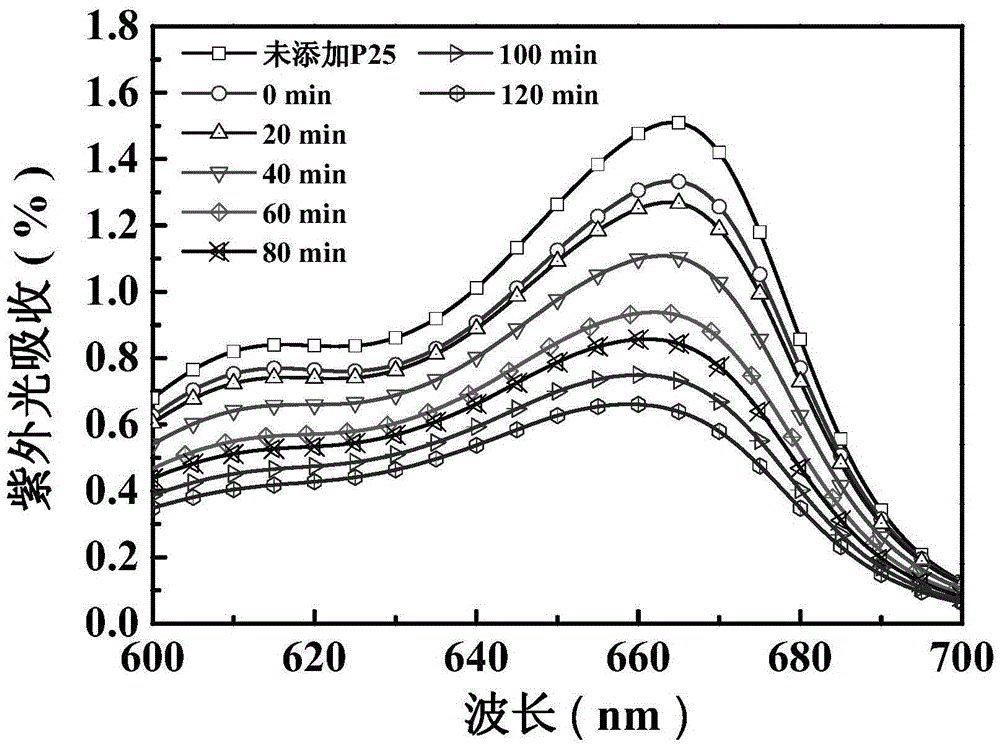

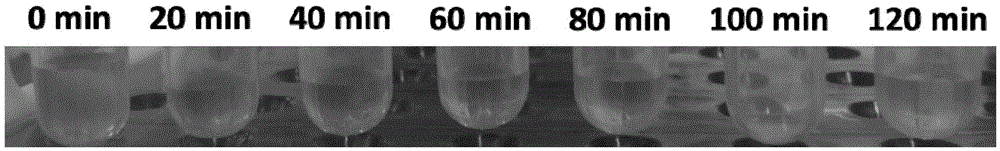

Controllable synthesis method of monoatomic catalyst with low cost and high loading capacity

ActiveCN111939961AIncrease loadThe content is easy to controlPhysical/chemical process catalystsHydrogen productionPhoto catalyticPtru catalyst

The invention discloses a controllable synthesis method of a monoatomic catalyst with low cost and high loading capacity, the monoatomic catalyst prepared by a method takes graphite-phase carbon nitride as a substrate, has the characteristics of low cost, high metal element loading capacity, controllable content and adjustable variety, and meanwhile, the method can be used for preparing the single-metal single-atom catalyst and a multi-metal single-atom catalyst, the single-atom catalyst has excellent catalytic activity and stability, and by taking the silver single-atom catalyst as an example, the visible light hydrogen production rate of the silver single-atom catalyst is 6.2 times that of silver nanoparticle-loaded graphite-phase carbon nitride, and after 60-hour continuous photocatalytic hydrogen production test, the hydrogen production rate is almost unchanged.

Owner:NANCHANG HANGKONG UNIVERSITY

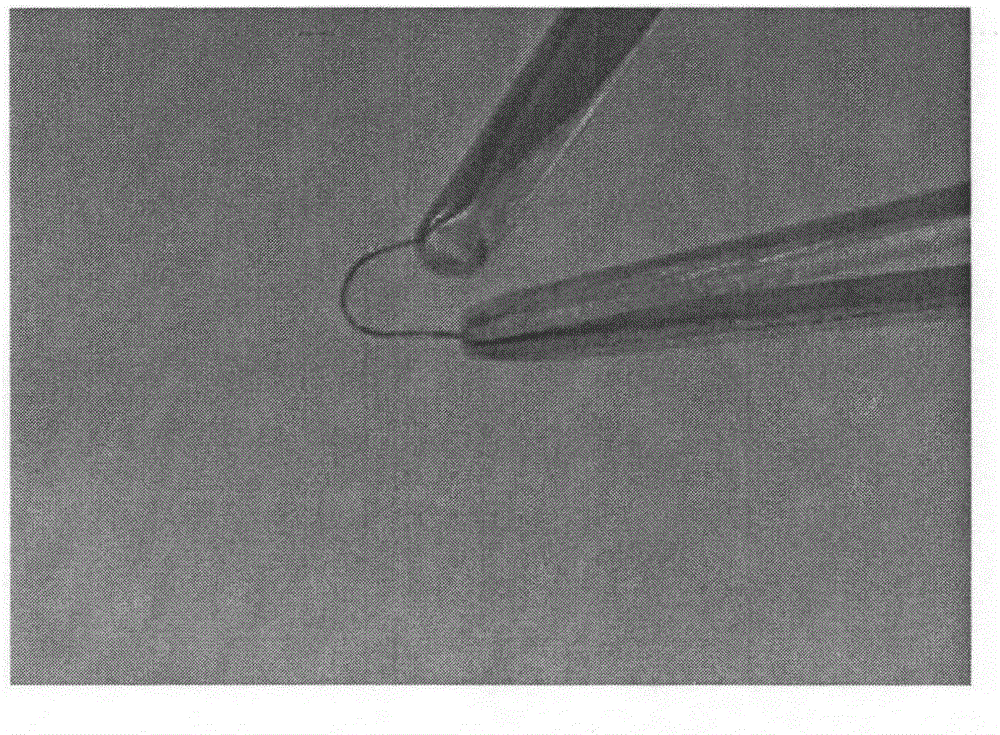

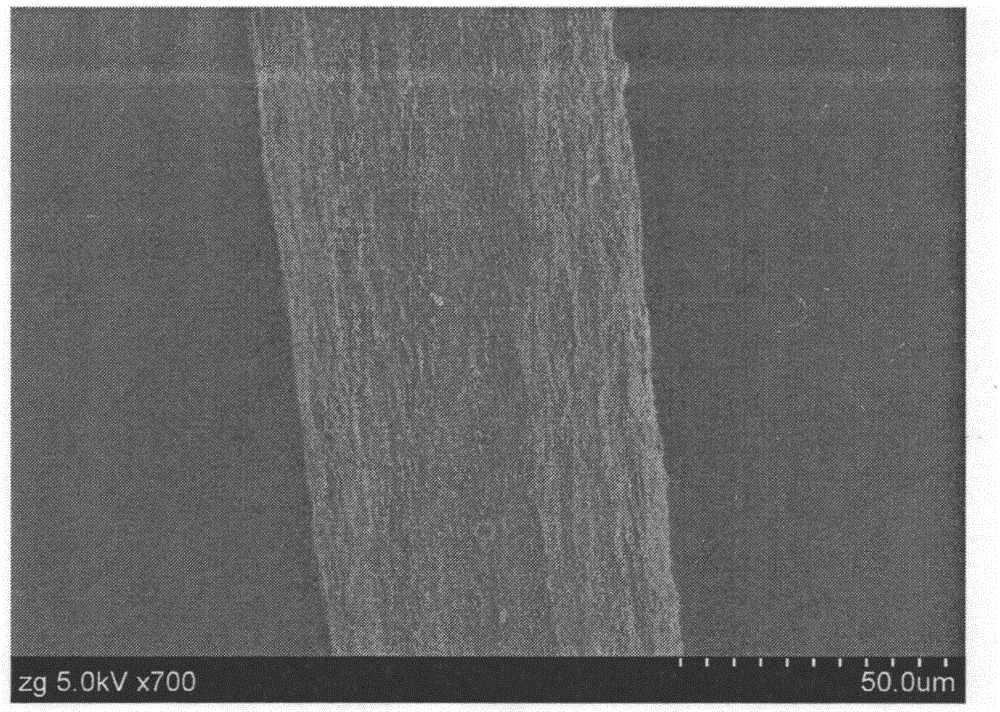

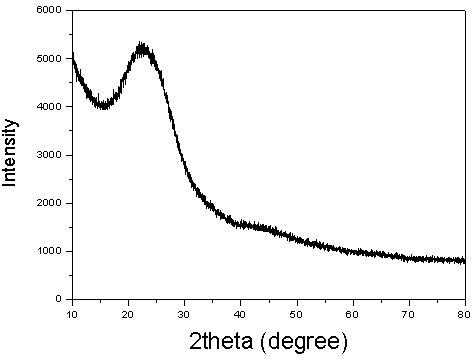

Preparation method of continuous cellulose-carbon nanomaterial composite aerogel fibers

ActiveCN106120007AInnovativePracticalArtificial filaments from viscoseWet spinning methodsCellulose fiberSolvent

The invention provides a preparation method of continuous cellulose-carbon nanomaterial composite aerogel fibers. The method comprises steps as follows: a cellulose dispersion liquid is prepared to serve as a spinning solution, and a carbon nanomaterial is added; an acidic solution, an ethanol solution or an acetone solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution with the carbon nanomaterial added is added to the coagulating bath for wet spinning, and cellulose gel fibers containing the carbon nanomaterial is obtained; the cellulose gel fibers containing the carbon nanomaterial are wound, immersed in an ageing solution to be aged at the normal temperature for 15 min-1 h, washed with deionized water to be neutral, then subjected to solvent replacement with deionized water, ethanol or tertiary butanol and dried, and the continuous cellulose-carbon nanomaterial composite aerogel fibers are obtained. According to the preparation method, the preparation process is simple, the spinnability is good, environmental protection and no pollution are realized, and the prepared continuous cellulose-carbon nanomaterial composite aerogel fibers have good flexibility, rich pores and a large specific surface area.

Owner:DONGHUA UNIV

High-pressure grouting leaking stoppage method for settlement joint of building

ActiveCN107060116AImprove repair efficiencyCost-effectiveBuilding repairsBuilding insulationsStructure and functionEngineering

The invention provides a high-pressure grouting leaking stoppage method for a settlement joint of a building. According to the high-pressure grouting leaking stoppage method for the settlement joint of the building, high complementary between polyurethane modified epoxy resin grouting fluid and acrylamide grouting fluid on core properties is utilized, outer side protection is formed by making use of the polyurethane modified epoxy resin grouting fluid, inner side expansion filler is formed by making use of the acrylamide grouting fluid based on the outer side protection, so that advantages are used to complement to each other, strengths are combined together, advantages are enhanced and disadvantages are avoided, rapid grouting leaking stoppage of the settlement joint of the building is achieved, the leaking stoppage quality is improved, the endurance of leaking stoppage is improved without damaging the original structure and functions of the building, and requirements for development of buildings in the present stage are satisfied.

Owner:天津德砼防腐防水工程有限公司

Preparation method of continuous SiO2/TiO2 aerogel fiber with photocatalytic performance

ActiveCN105597720AHas photocatalytic propertiesInnovativePhysical/chemical process catalystsSpinningSilicic acid

The invention relates to a preparation method of continuous SiO2 / TiO2 aerogel fiber with photocatalytic performance. The preparation method includes the steps of preparing a spinning solution from silicate or silanol sol, adding a TiO2 photocatalyst, adding the spinning solution with the TiO2 photocatalyst to an acid solution coagulating bath to conduct reaction wet method spinning to obtain original silicic acid / silicate fiber with the TiO2 photocatalyst, conducting rolling and ageing, washing the fiber with deionized water to neutral, conducting solvent replacement through deionized water or ethyl alcohol, and conducting drying to obtain the SiO2 / TiO2 aerogel fiber. The method has the advantages that raw materials are low in price and easy to obtain, the reaction process is simple, and spinnability is high; the prepared aerogel fiber has abundant pores, a high specific surface area, high temperature resistance and chemical corrosion resistance, the specific surface area and TiO2 content of the fiber can be adjusted, and the method has application prospects in the field of photocatalysis and the like.

Owner:DONGHUA UNIV

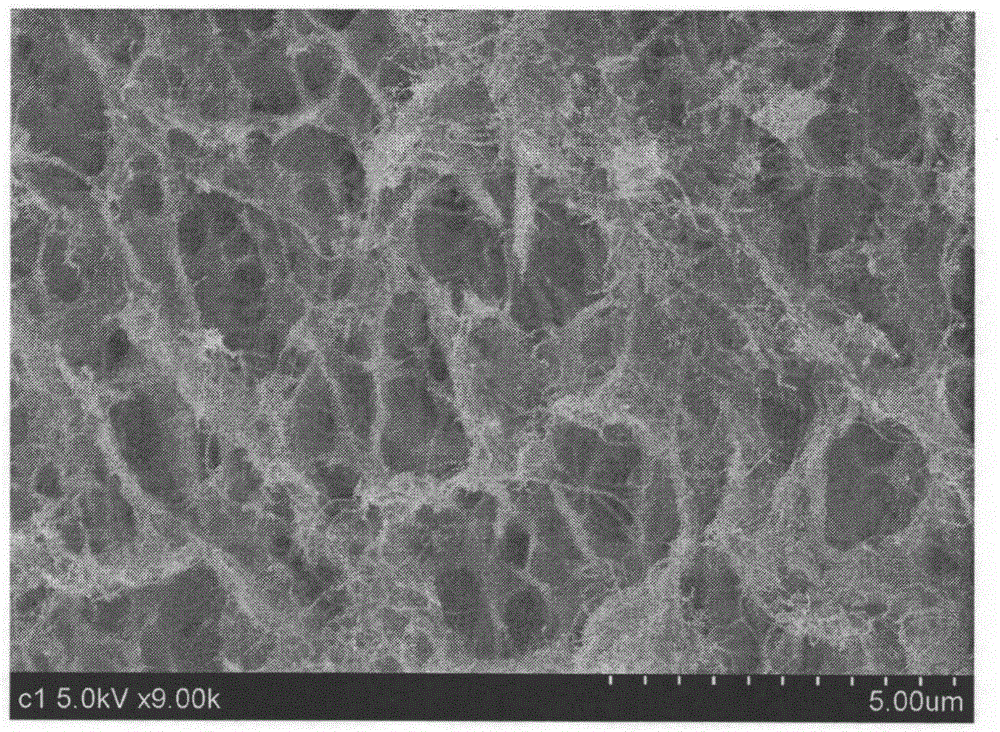

Exotic atom-doped porous carbon material and preparation method and application thereof

ActiveCN110148733ALarge specific surface areaImprove sodium storage performanceCell electrodesCross-linkN dimethylformamide

The invention discloses an exotic atom-doped carbon material and a preparation method and an application thereof. The doped carbon material prepared according to the method is a honeycomb three-dimensional multi-level porous structure material, wherein macropores are constructed by mutually cross-linked flakes, the flakes are stacked by nanoparticles, and random mesopores and micropores are distributed between the nanoparticles. The preparation method comprises the steps of firstly dissolving polyacrylonitrile into an N, N-dimethylformamide solution, then adding one or more reagents containingtarget doping atoms into the solution, conducting a solvothermal reaction to obtain a precursor, placing the precursor in a protective atmosphere for calcination so as to obtain a single or multi-atom doped carbon material with uniform nanometer size and excellent electrochemical performance. Sodium-ion batteries show high specific capacity, excellent rate performance and ultra-long cycle stability when the exotic atom-doped carbon material is used as a negative electrode material of the sodium-ion batteries.

Owner:CENT SOUTH UNIV

Synthetic-leather-used UV solidifying and flame-retarding polyurethane and preparation method thereof

ActiveCN105131227AHigh flame retardant efficiencyEasy to control performanceEnvironmental resistanceSide chain

The invention discloses synthetic-leather-used UV solidifying and flame-retarding polyurethane and a preparation method thereof. The method is characterized by comprising the steps that low-viscosity liquid dihydric alcohol and diisocyanate serve as raw materials, side-group phosphorus / nitrogen-containing dihidroxy acrylate is introduced into the polyurethane structure in the form of chain extender, and then side-group phosphorus-containing monohydroxy acrylate is used for sealing the end. Both a main chain and a side chain of the obtained UV solidifying polyurethane contain photosensitive perssad, through the UV solidification, the crosslinking degree and relative molecular mass of resin can be improved, the contradiction between the fact that photosensitive perssad in traditional UV solidifying polyurethane is low in content and the fact that the molecular weight of coating polymer is high in requirement is reconciled, and meanwhile the comprehensive performance of the polyurethane such as wear resistance, scratch resistance, waterproofness, heat resistance and solvent resistance is improved; phosphorus / nitrogen flame-retarding ingredients are 'suspended'on the macromolecular side chain of the polyurethane, the flame-retarding effect is good, and fire retardant is not migrated or separated out and is resistant to hydrolysis in the storage and using processes; in addition, no organic solvent is used in the preparation process of the polyurethane, and the synthetic-leather-used UV solidifying and flame-retarding polyurethane has the advantages of being prominent in greenness, environment-friendliness, health, safety and the like and can be used in synthetic leather manufacturing and coating materials such as leather and textiles.

Owner:SICHUAN UNIV

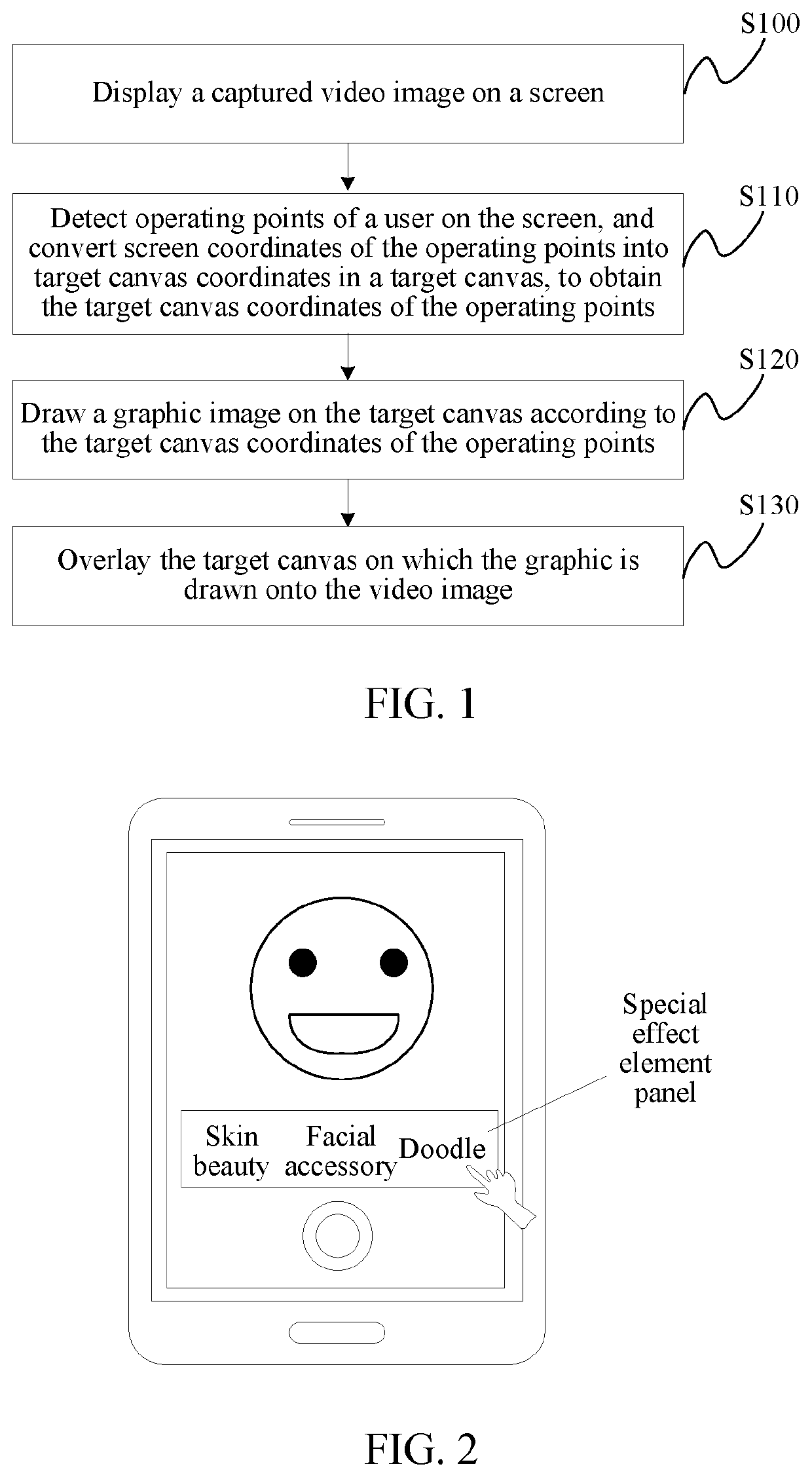

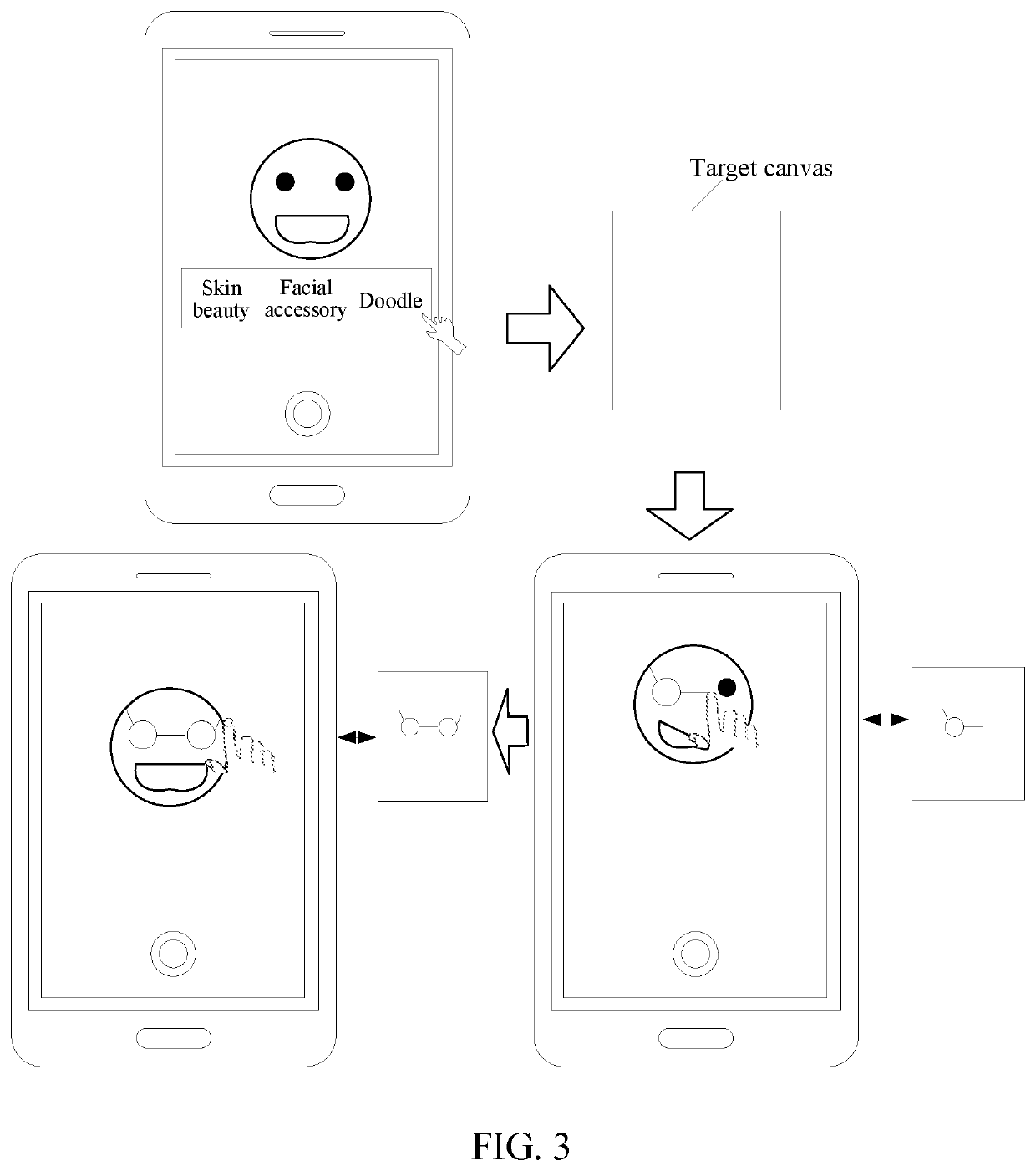

Video image processing method, apparatus and terminal

ActiveUS20200252553A1More imageReduce limitationImage enhancementTelevision system detailsComputer graphics (images)Image processing

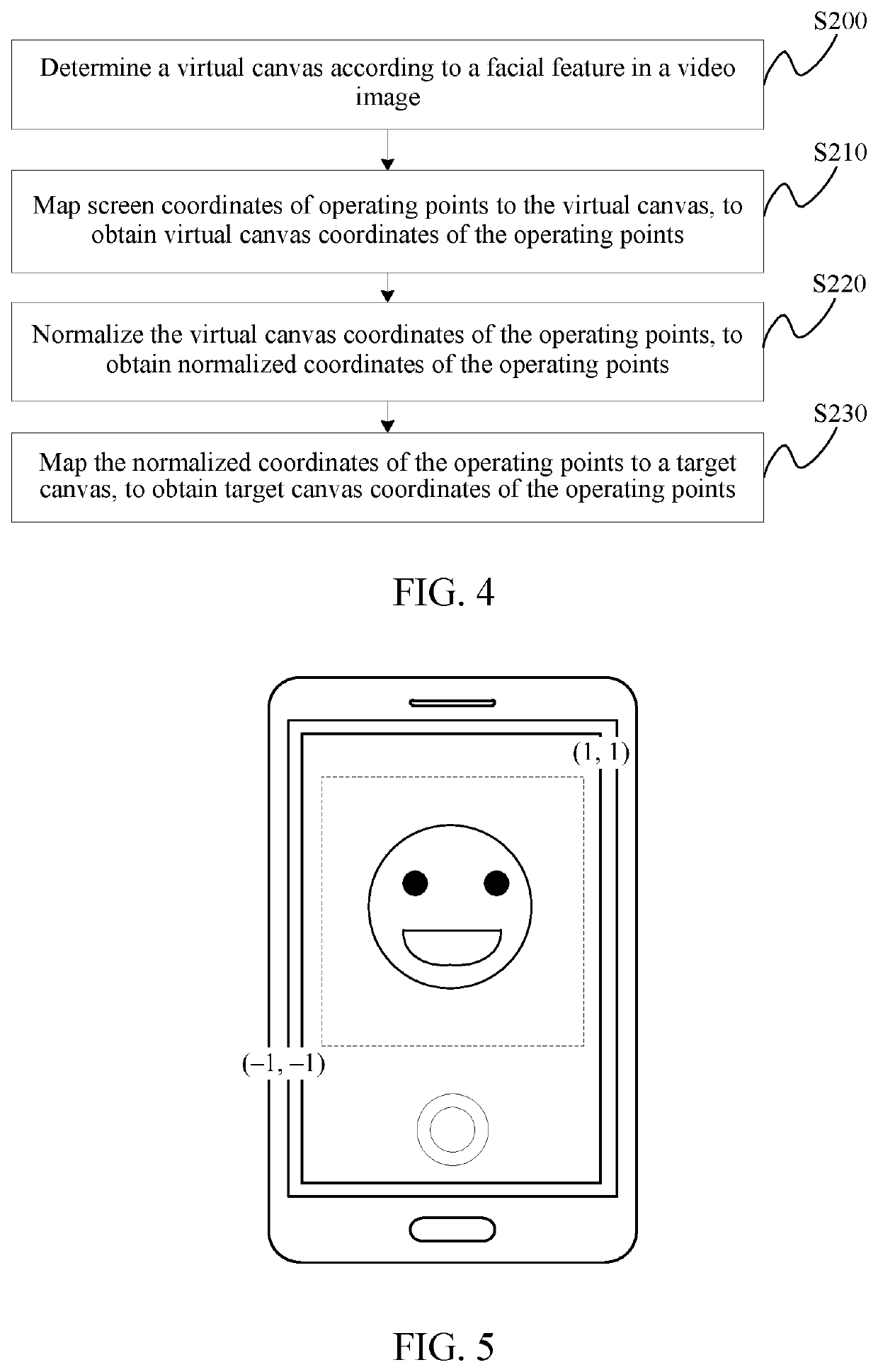

A video image processing method, an apparatus, and a terminal are provided. The method includes: displaying a captured video image on a screen; detecting operating points of a user on the screen, and converting screen coordinates of the operating points into target canvas coordinates in a target canvas; mapping the screen coordinates of the operating points to a virtual canvas, to obtain virtual canvas coordinates of the operating points; mapping the virtual canvas coordinates of the operating points to the target canvas, to obtain target canvas coordinates of the operating points in the target canvas; drawing a graphic image on the target canvas according to the target canvas coordinates of the operating points; and overlaying the target canvas onto the video image.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Method for producing vanadium-nitrogen alloy

The invention relates to a production method for vanadium-nitrogen alloy, which comprises following steps: evenly mixing oxide of powder vanadium or ammonium metavanadate, carbon powder and binder, continuously adding into an external-heating rotary kiln in nitrogen atmosphere after briquetting and forming, and presintering to below 1000 DEG C under the protection of nitrogen; collecting the presintered block product which is cooled to ambient temperature under the protection of nitrogen at a discharge opening, pushing into an improved soft magnetic nitrogen atmosphere furnace kiln, heating to 1000 to 1500 DEG C for carbonization and nitridation reaction, and vanadium-nitrogen alloy product is obtained after discharge. The composition of the vanadium-nitrogen alloy: V is 78 to 83%, N is 16 to 21%, C is 6% max, and silicon, phosphorus and aluminum are less than 0.10%; the apparent density is greater than 3.5g / cm<3>. The production method for vanadium-nitrogen alloy has the advantages of adopting rotary kiln for precalcination, removing harmful impurities and corrosive elements, reducing stacking volume, greatly improving productivity of carbonization and nitridation working procedures, and greatly prolonging service life of nitriding furnace kiln.

Owner:刘先松 +1

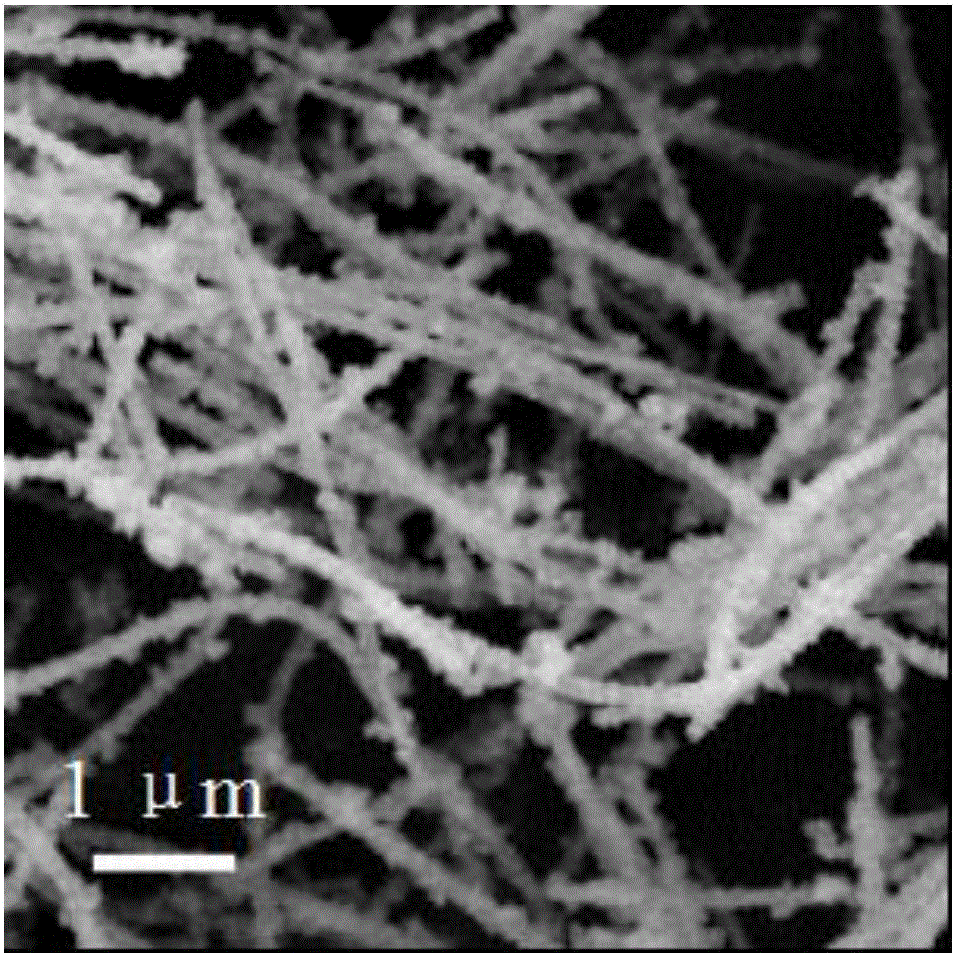

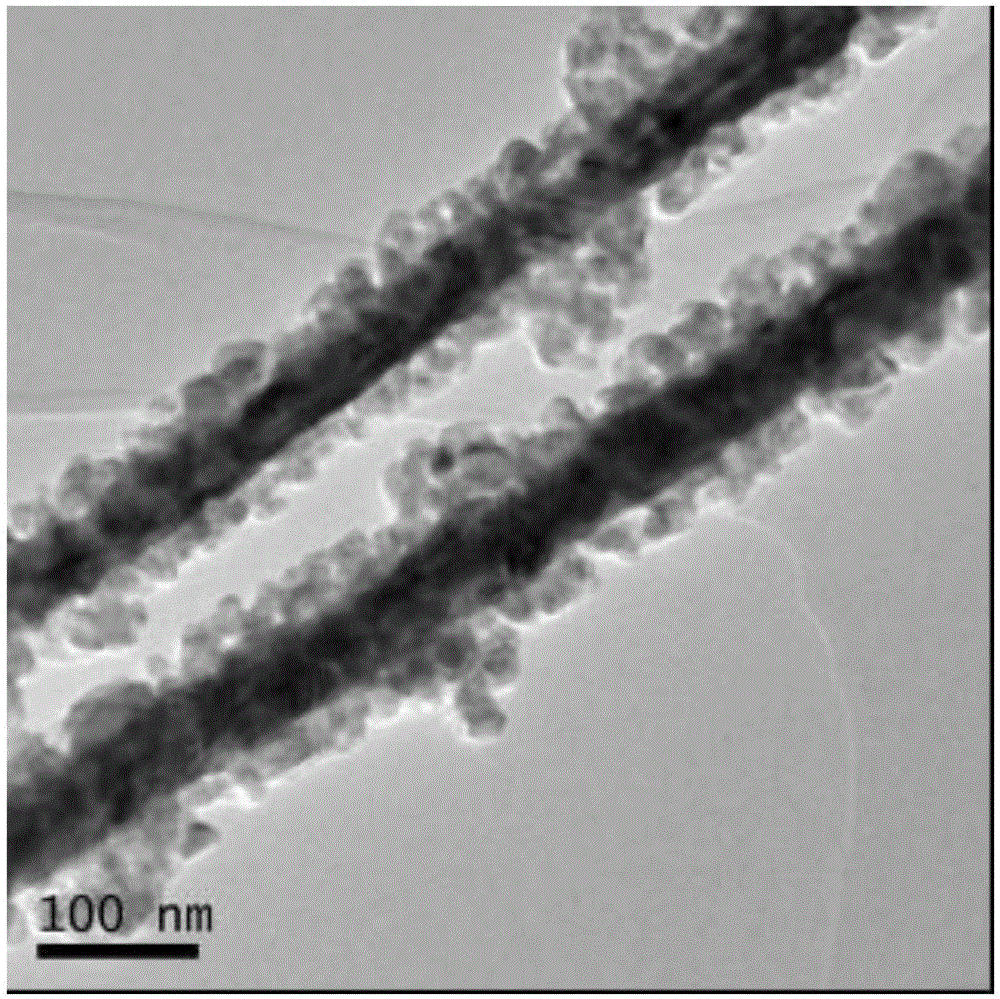

Continuous carbon nanotube-titanium dioxide composite membrane/fiber for electrode material

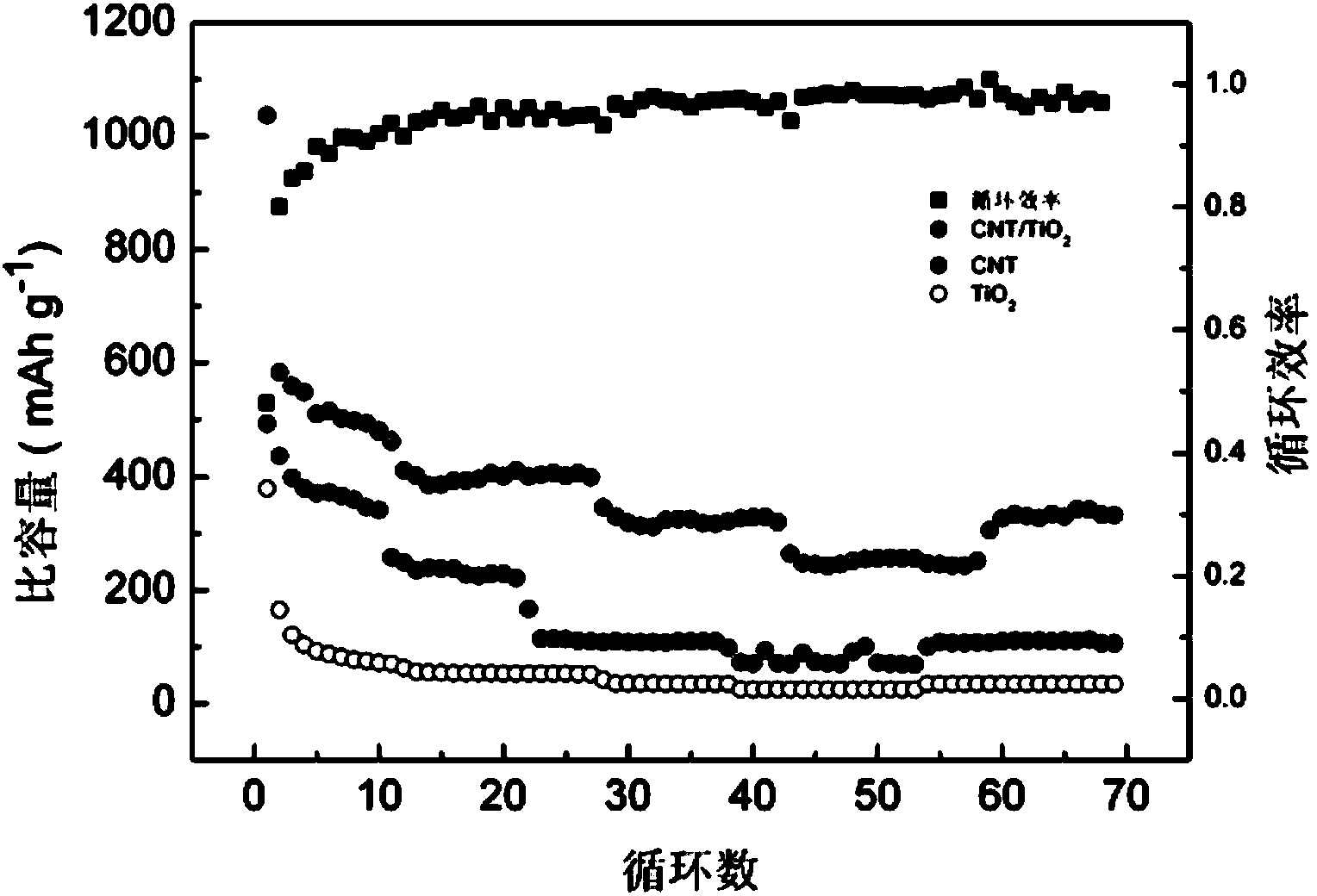

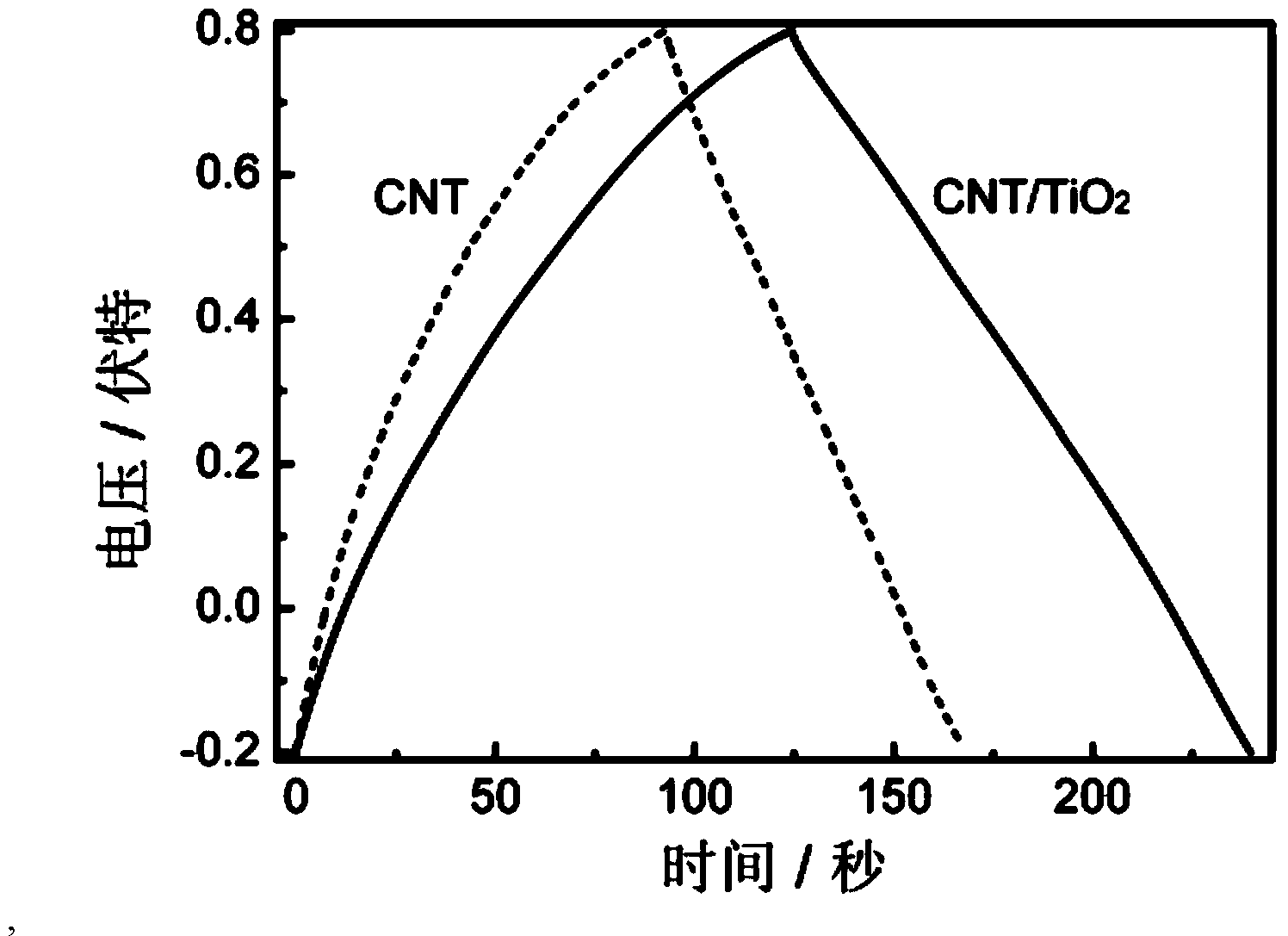

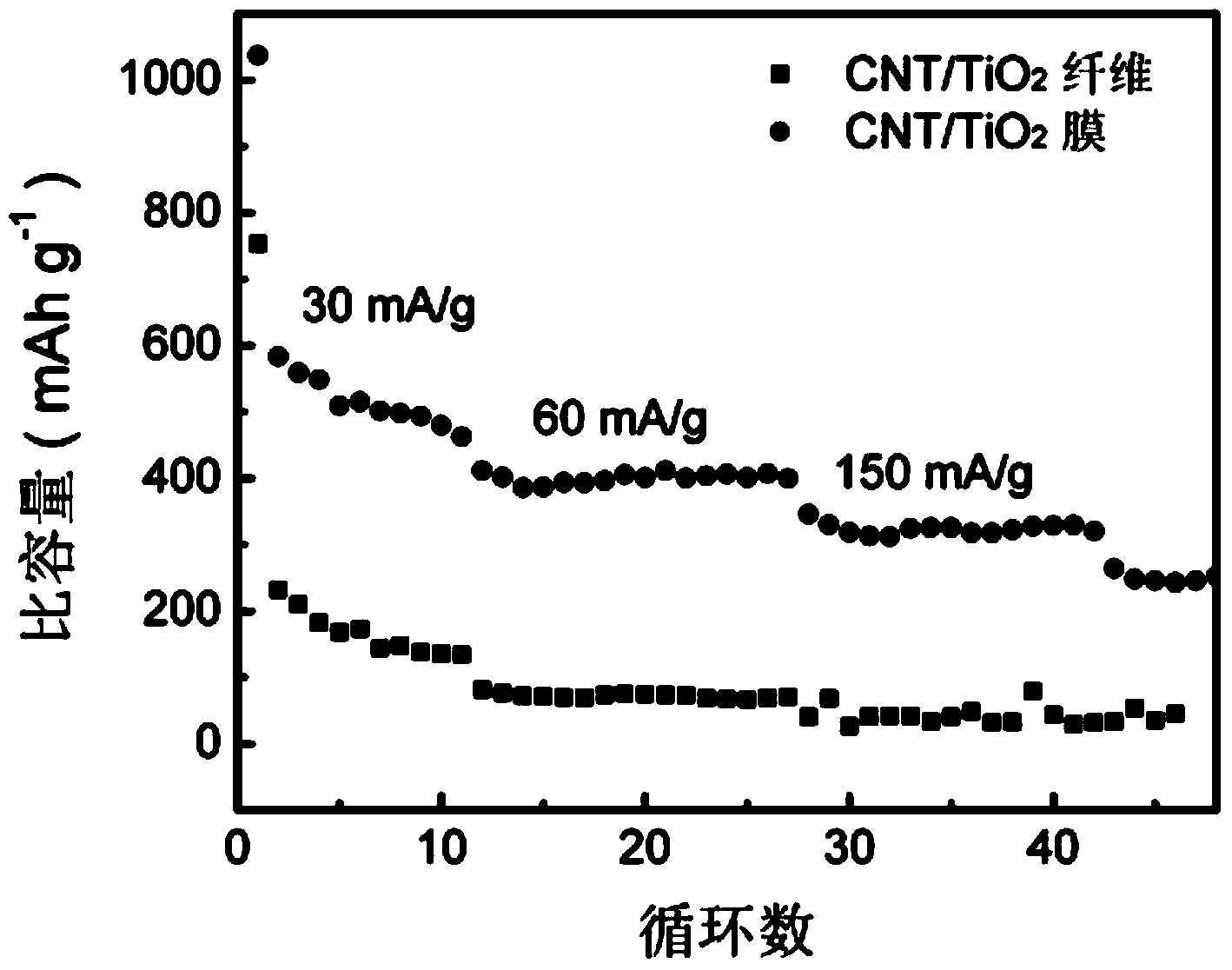

InactiveCN103531753AUniform continuous self-supportingImprove electrochemical performanceHybrid capacitor electrodesCell electrodesFiberGas phase

In the invention, a carbon nanotube-titanium dioxide composite membrane / fiber is prepared in one step by a chemical gas phase method, and the assembly of the carbon nanotube and the nucleation and growth of titanium dioxide are finished at the same time to grow a uniform and continuous carbon nanotube-titanium dioxide composite membrane / fiber. The preparation process is simple, the parameter controllability is strong, and the yield is relatively high; the prepared carbon nanotube-titanium dioxide composite membrane / fiber is uniform and continuous in preparation and realizes self-support and adjustable TiO2 content; with a network structure, the carbon nanotube-titanium dioxide composite membrane / fiber has remarkably strong electrical conductivity and excellent electrochemical properties and does not need the treatment of adding a conductive agent, a binder and the like; after simple cutting, the carbon nanotube-titanium dioxide composite membrane / fiber can be directly applied to a lithium battery cathode material and a super capacitor material.

Owner:TIANJIN UNIV

Method for preparing mineral potash fertilizer with potassium feldspar

The invention discloses a method for preparing a mineral potash fertilizer with potassium feldspar, wherein the method uses potassium feldspar as raw material and phosphates ore as assistant, and comprises crushing, mixing, mechanical force chemical reaction, neutralizing, separating and drying, wherein the mixing is to mix the potassium feldspar powder and phosphates ore, which have a fineness of 100-400 meshes, based on a mass ratio of 1: 0.5-2.5, and add inorganic acid with a mass percentage concentration of 25-60%, and perform the mechanical force chemical reaction for 2-5 h, wherein the liquid to solid ratio of the inorganic acid to the ore powder is 1-5 ml / g (ore powder); the inorganic acid is chosen from phosphoric acid, hydrochloric acid or nitric acid. The method transforms the phosphorus and potassium in the raw material into effective phosphorus and potassium (comprising quick-acting phosphorus and potassium, and long-acting phosphorus and potassium), which can be absorbed by the crops. The quick-acting phosphorus and potassium in the product take up 20-90% of the effective phosphorus and potassium and can be adjusted, wherein the rest is long-acting phosphorus and potassium. The total use ratio of the phosphorus and potassium in the raw material is over 80%.

Owner:安徽物华矿物新材料有限公司

Method and apparatus for controlling a display of multimedia content using a timeline-based interface

ActiveUS9311965B2Content adjustableEasy to controlTelevision system detailsColor television signals processingEvent triggeredTouchscreen

Owner:SAMSUNG ELECTRONICS CO LTD

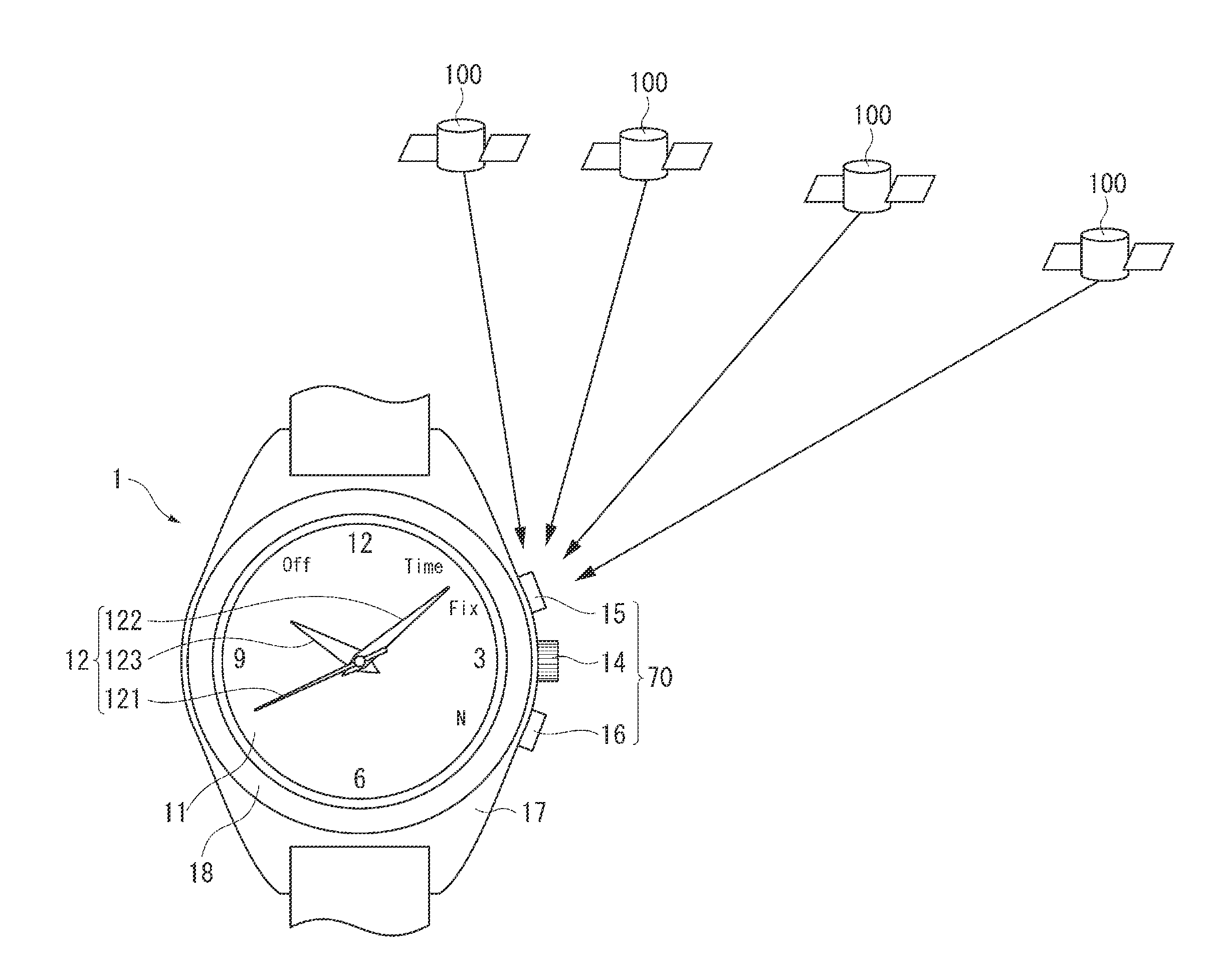

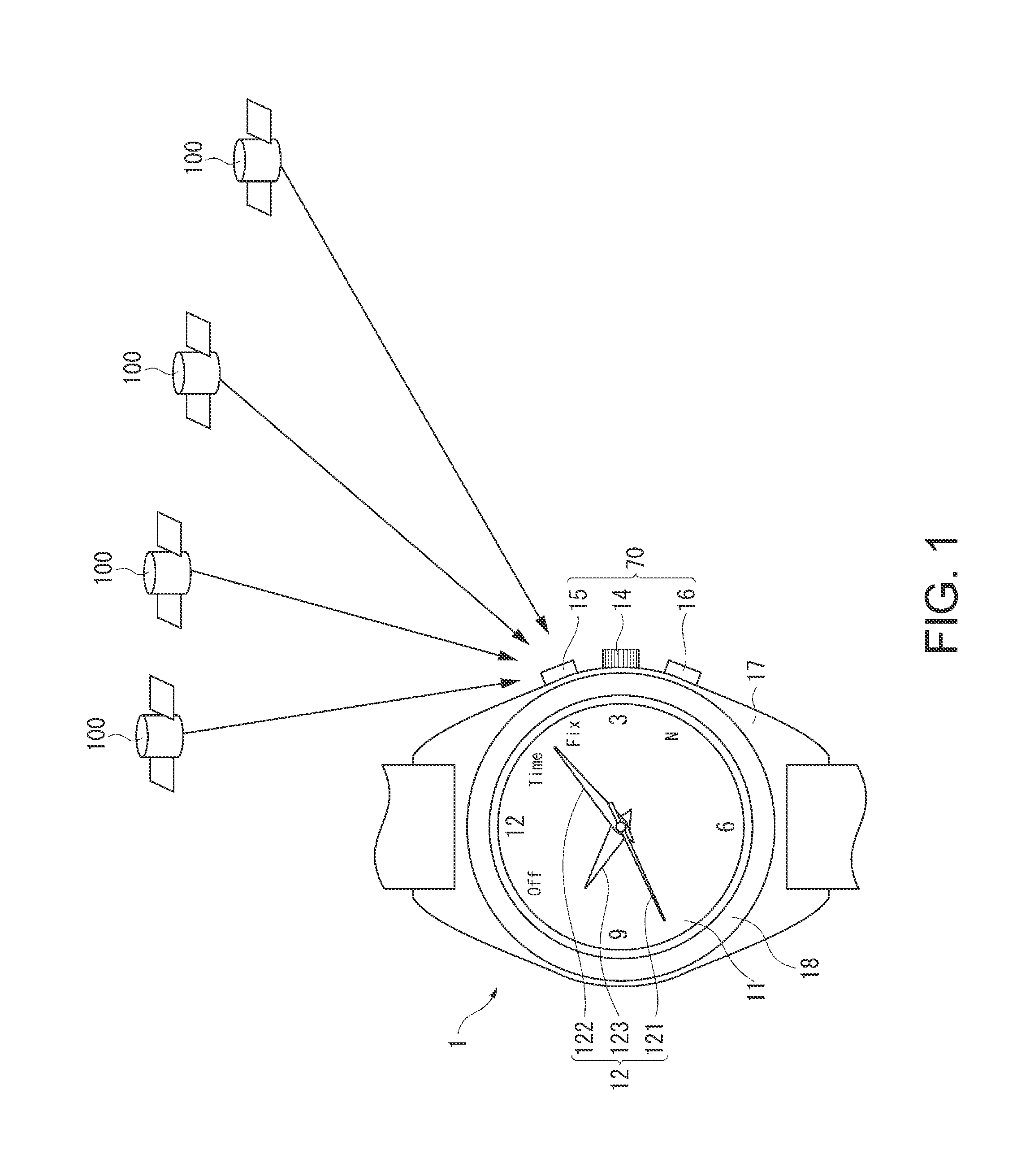

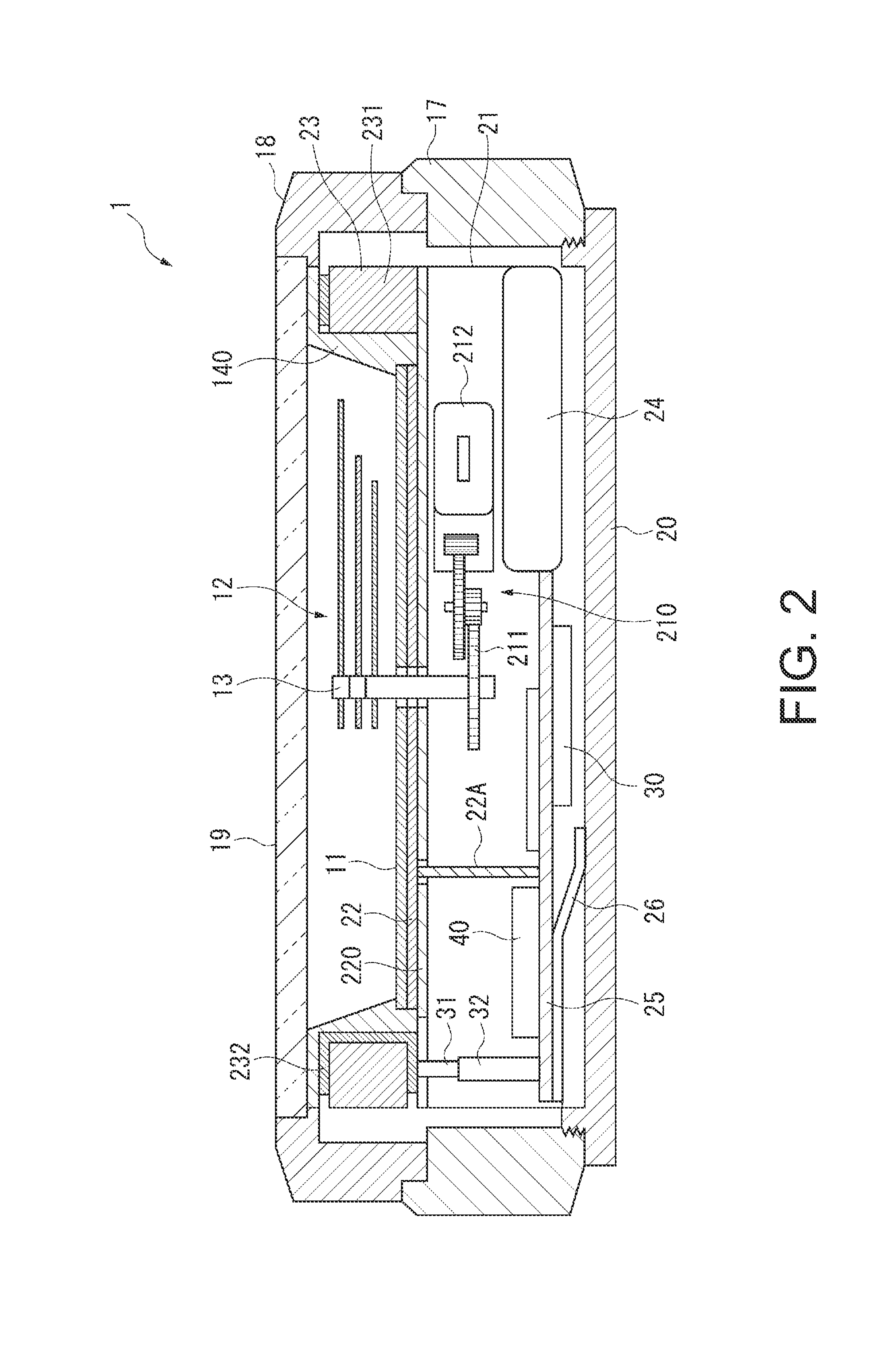

Electronic Timepiece And Method Of Controlling An Electronic Timepiece

InactiveUS20140086021A1Improve probabilityIncrease probabilityElectric windingRadio-controlled time-piecesVIT signalsSatellite

An electronic timepiece has a GPS receiver, outdoor detection device, timekeeping device, control device, and storage device. The control device has an automatic reception control unit that starts reception control when the time kept by the timekeeping device reaches the reception control start time stored in the storage device, and stops reception control until the next reception control start time when a stop reception control condition is met; and a time correction unit that corrects the time kept by the timekeeping device based on time information contained in the satellite signal when satellite signal reception is successful. The automatic reception control unit includes an outdoor reception control unit that executes an outdoor reception process when the outdoor detection device detects being outdoors, and a scheduled reception control unit that executes a scheduled reception process when the time kept by the timekeeping device goes to the scheduled reception time.

Owner:SEIKO EPSON CORP

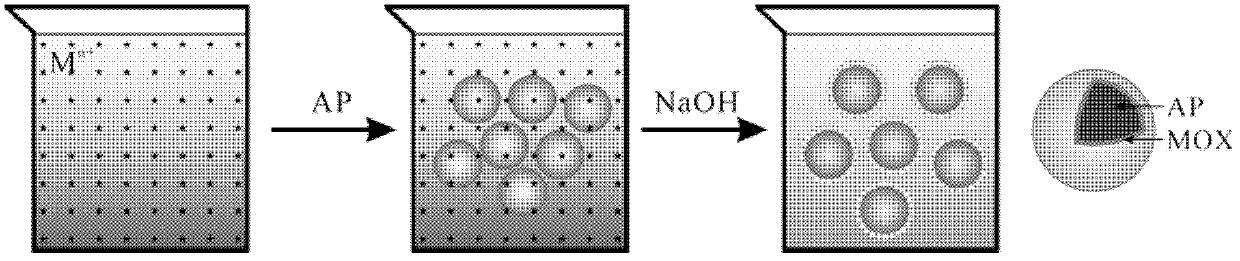

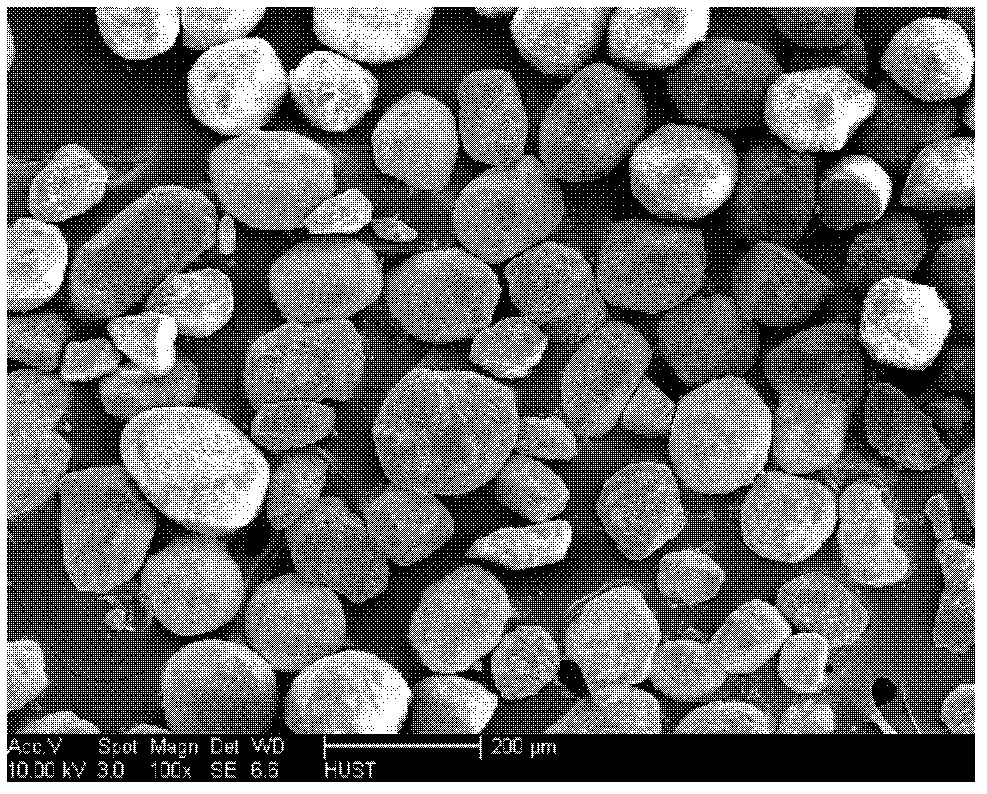

Core-shell nano-composite material and its preparation method

InactiveCN102515984ASolving Dispersion ProblemsEasy reunionNon-explosive/non-thermic compositionsAmmonium perchlorate explosive compositionsEthyl acetateUltrasonic oscillation

The invention discloses a core-shell nano-composite material and its preparation method. The composite material is formed by compounding ammonium perchlorate (AP) and a nano-metal oxide which accounts for 0.1-10% by mass. The preparation comprises: (1) dissolving a metal salt in ethyl acetate, and conducting ultrasonic oscillation to make it fully dissolved so as to obtain a metal salt solution, in which the molar concentration of the metal salt is 0.0004-0.04mol / L; (2) adding ammonium perchlorate into the metal salt solution in an undissolved state, and carrying out stirring at room temperature so as to make the ammonium perchlorate dispersed uniformly; (3) using an alkaline solution with an OH<-> ion concentration of 0.1-1mol / L for titration at a constant speed so as to make the metal ions in the metal salt converted to a precipitate completely; and (4) filtering the obtained precipitate and conducting washing, and drying the obtained powder, thus obtaining the core-shell nano-composite material. The metal salt can be ZnCl2, FeCl3, Co(NO3)2.6H2O or CuCl2. In the invention, the dispersion problem of a nano-oxide catalyst in AP is solved; an oxide catalyst is generated on AP in situ, and the oxide content is adjustable; the nano-composite material of the invention has self-catalysis property, and the catalysis effect is substantial.

Owner:HUAZHONG UNIV OF SCI & TECH

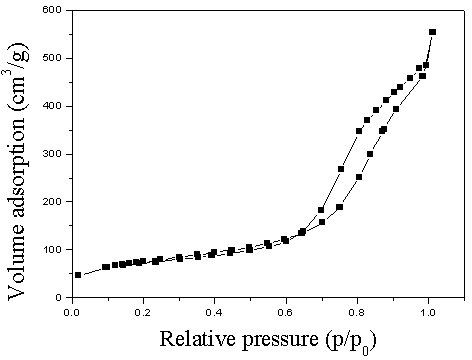

Alumino silica gel and preparation method thereof

ActiveCN108046280AUniform structureUniform strengthMaterial nanotechnologyAluminium silicatesMolecular sieveCompressive strength

The invention discloses alumino silica gel and belongs to the technical field of alumino silica gel. In the alumino silica gel, mass content of Al2O3 is 3-8%, and mass content of SiO2 is not lower than 82%; specific surface area of the alumino silica gel is 300-550m2 / g, pore volume is 0.6-1.0mL / g, and compressive strength is not lower than 50N. The invention further discloses a preparation methodof the alumino silica gel. The preparation method includes: subjecting sodium silicate, aluminum salt and raw material acid to sol-gel process, aging, exchange acid treatment, water washing, ammoniumtreatment and drying to obtain the alumino silica gel. The alumino silica gel is wide in silicon-aluminum ratio adjusting range, large in pore volume and specific surface area, high in compressive strength, uniform in framework structure and strength and stable in quality; the preparation method is simple in process and convenient in operation and can be widely used in the field of catalyst and catalyst carriers, adsorption and separation and molecular sieve preparation.

Owner:QINGDAO MAKALL GROUP CO LTD

Preparation method of catalytic material of nitrogen-doped mesoporous carbon-silicon dioxide-based strongly-acidic multi-phase ion liquid

InactiveCN103464199AHigh specific surface areaSimple methodFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselBiological materials

The invention provides a preparation method of a catalytic material of nitrogen-doped mesoporous carbon-silicon dioxide-based strongly-acidic multi-phase ion liquid. The preparation method comprises the steps of taking P123 or F127 as a template agent, cyanamide as a carbon source and tetraethoxysilane as an inorganic source, and obtaining a primary product by volatilized self assembly under the condition of acidic room temperature and heat treatment; then under the protective condition of inert gases, baking at the high temperature to obtain a nanocomposite with open hole channels; and then carrying out quaternized reaction, and obtaining the catalytic material of the nitrogen-doped mesoporous carbon-silicon dioxide-based strongly-acidic multi-phase ion liquid by further acid exchange. The preparation method provided by the invention has the advantages that tested by catalytic reaction, the catalytic activity in reaction for preparing biodiesel by catalyzing biomass to carry out conversion-ester exchange is very excellent, and the regenerating capability of the catalyst is strong, so that the preparation method has certain industrial significance for improving the preparation efficiency of the biological material on large scale.

Owner:SHAOXING UNIVERSITY

Pneumatic tire and laminate

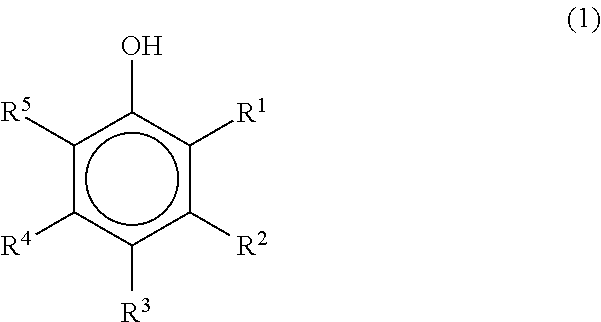

ActiveUS9539859B2Content adjustableImprove adhesionSynthetic resin layered productsSpecial tyresHydrogenPolymer science

In a pneumatic tire containing as an inner liner material a laminate of a film of a thermoplastic resin or a thermoplastic elastomer composition and a layer of a rubber composition for improving the adhesive strength between the film and the rubber composition, the rubber composition comprises 100 parts by weight of a rubber component, 0.5 to 20 parts by weight of a condensate between a compound expressed by formula (1):wherein R1, R2, R3, R4 and R5 are hydrogen, a hydroxyl group or a C1 to C8 alkyl group, and formaldehyde, 0.25 to 200 parts by weight of a methylene donor, and a vulcanizing agent; and a weight ratio of the methylene donor content to the condensate content is 0.5 to 10.

Owner:THE YOKOHAMA RUBBER CO LTD

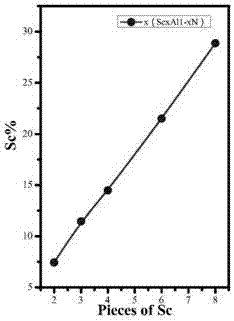

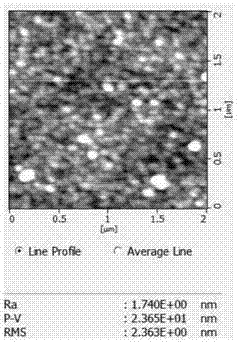

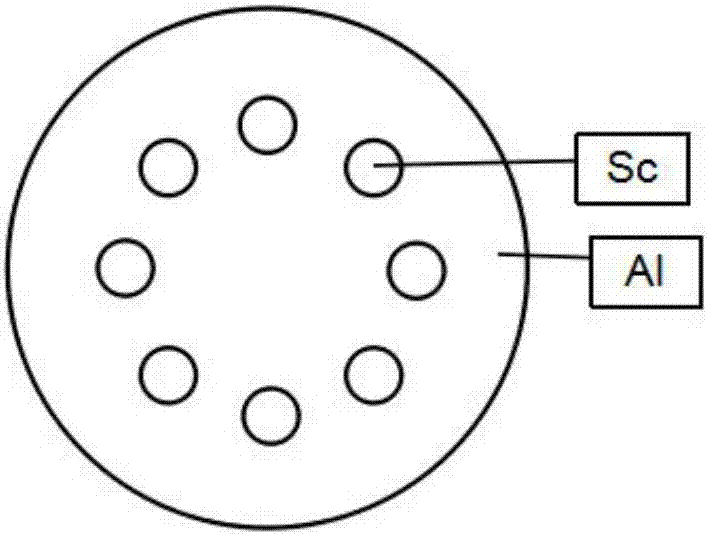

Process for preparing high-C-axis-orientation ScAlN thin film

InactiveCN106917088AShorten the timeExperiment operation is simpleVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringDesalination

The invention discloses a process for preparing a high-C-axis-orientation ScAlN thin film and a preparation manner for lowering the process difficulty. In the vacuum environment, N2 gas is ionized through radio frequency so that local plasmas can be generated on a substrate, and a nitride layer is formed on the substrate mentioned above through the plasmas; by means of a radio frequency magnetron sputtering manner, a Sc-doped AlN thin film is prepared and formed on the substrate with a desalination layer under the room temperature condition, and the relative molecule content of the doping amount of the element Sc in the ScAlN thin film ranges from 0% to 28.87%; and regulation and control are achieved according to requirements, the relative molecule content values of the doping amount of the element Sc in the prepared thin film include 0, 7.45%, 11.45%, 14.49%, 21.50% and 28.87%. By means of the process, orientation of the ScAlN thin film can be optimized, and meanwhile the preparation difficulty is lowered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

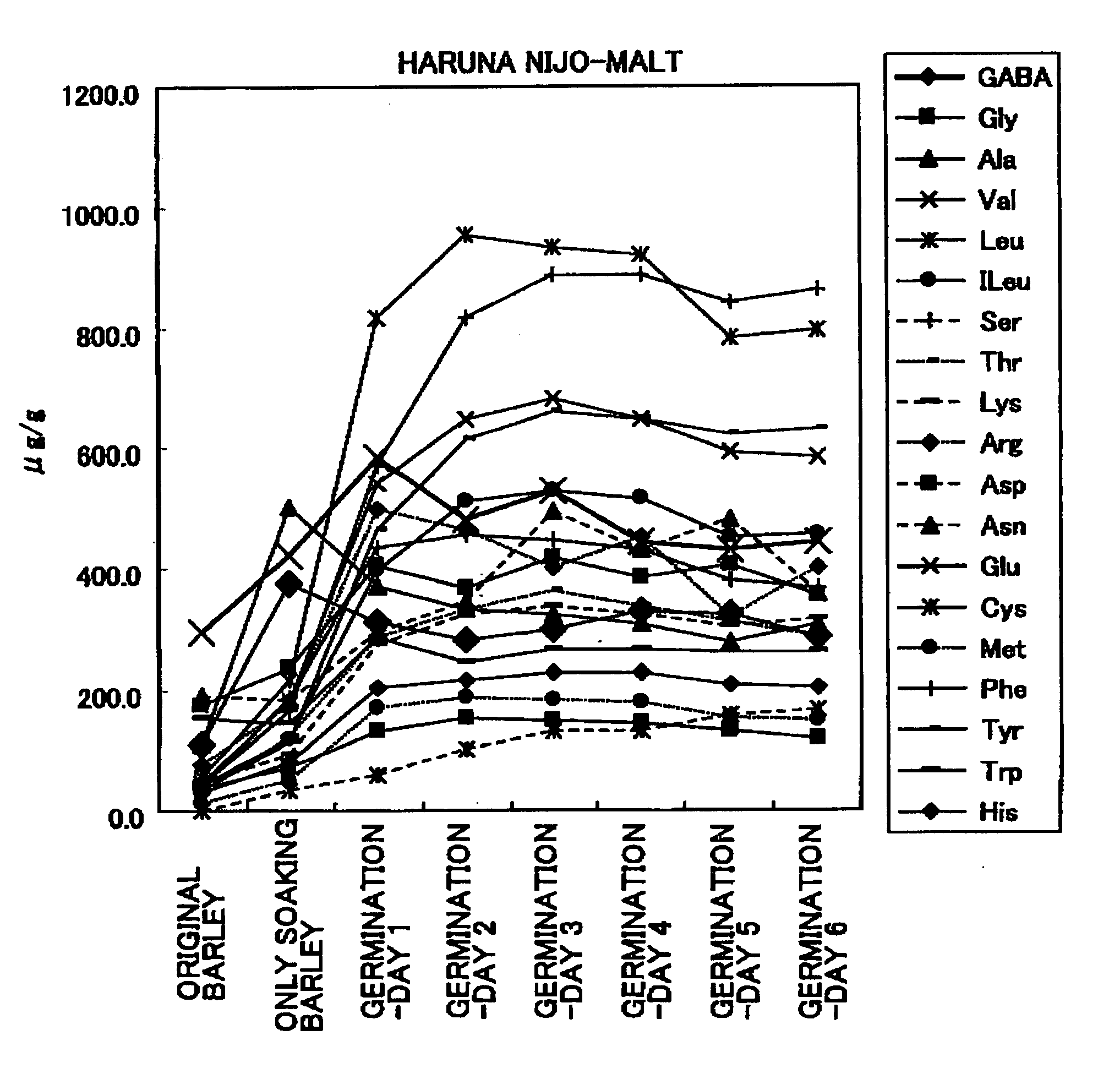

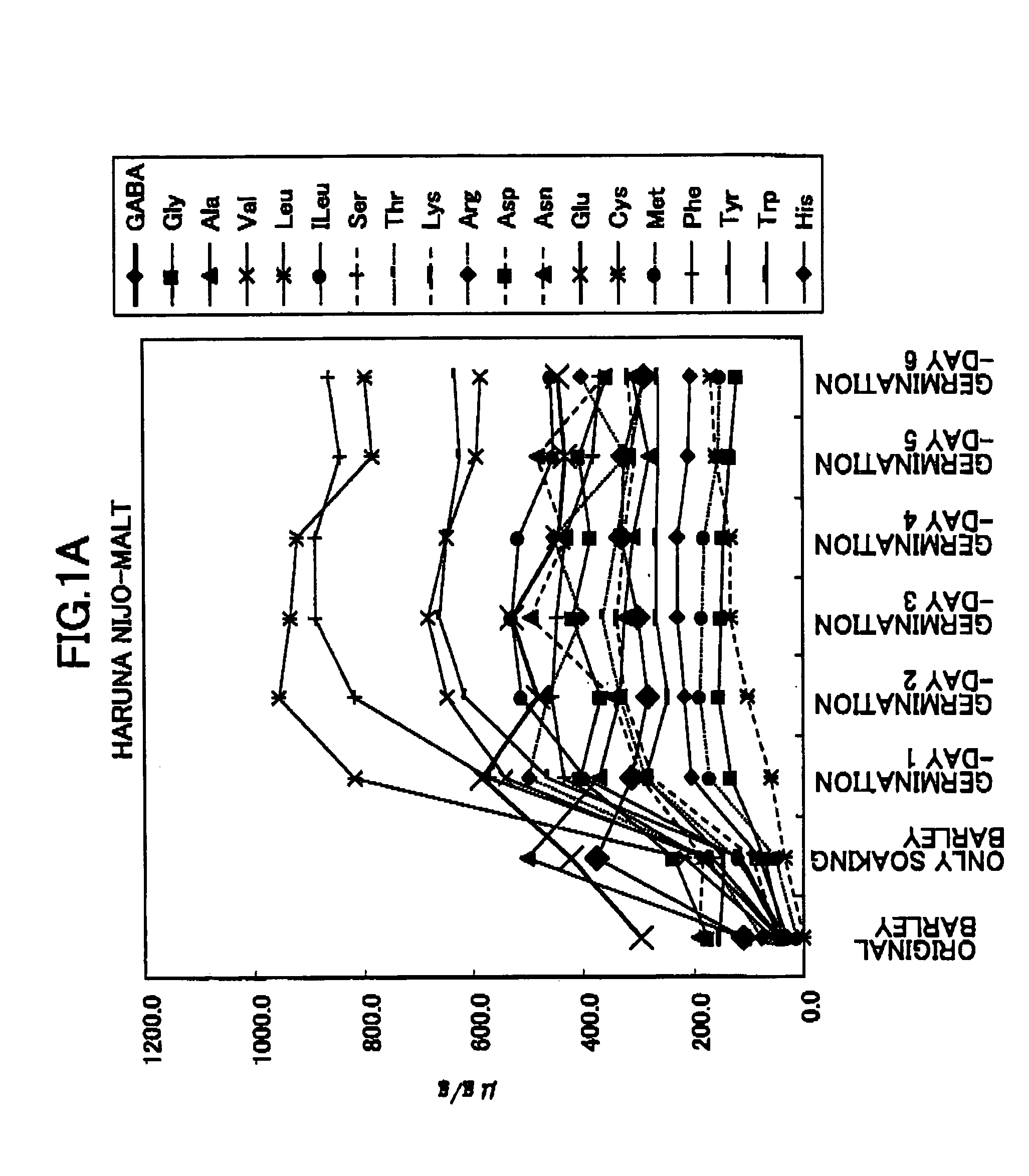

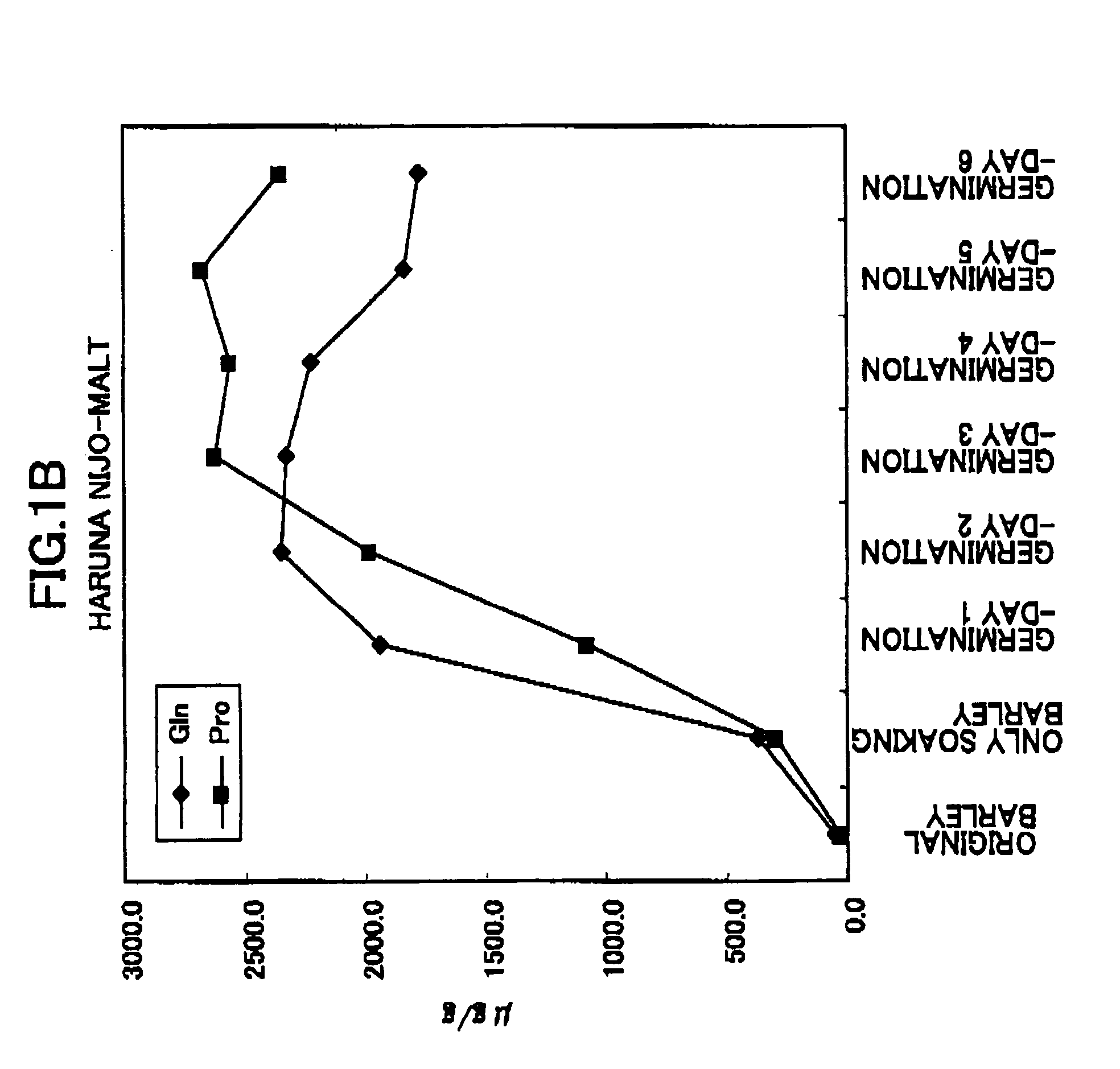

Processed wheat product containing functional components in elevated amounts and processing method therefor

InactiveUS20070141216A1Content adjustableReduced activityFood shapingNatural extract food ingredientsAdditive ingredientHordeum vulgare

It is intended to provide processed products of wheat, barley, oats and rye and its processing method, in which any functional ingredients are increased with balanced, and originally physical properties and quality that are demanded by inhibiting activity of an unnecessary enzyme are held. Depending on functional ingredients condition of targeted free amino acids like GABA or dietary fibers, by soaking process of seeds of wheat, barley, oats and rye, controlling germination days after soaking, controlling the drying temperature and controlling the gibberellin process, then wheat, barley, oats and rye, in which functional ingredients contents such as GABA, free amino acids and dietary fibers can be increased, can be obtained. Then, the extraction process from seeds of wheat, barley, oats and rye in controlled and the extraction method is suited for extracting the targeted functional ingredients like GABA and β-glucan. Thus, the method for increasing functional ingredients contents and processed products by its method can be provided. Therefore, foods comprising increased functional ingredients contents such as GABA and β-glucan can be provided by including wheat, barley, oats and rye or processed products of wheat, barley, oats and rye which has increased functional ingredients contents as raw material in foods.

Owner:SAPPORO BREWERIES

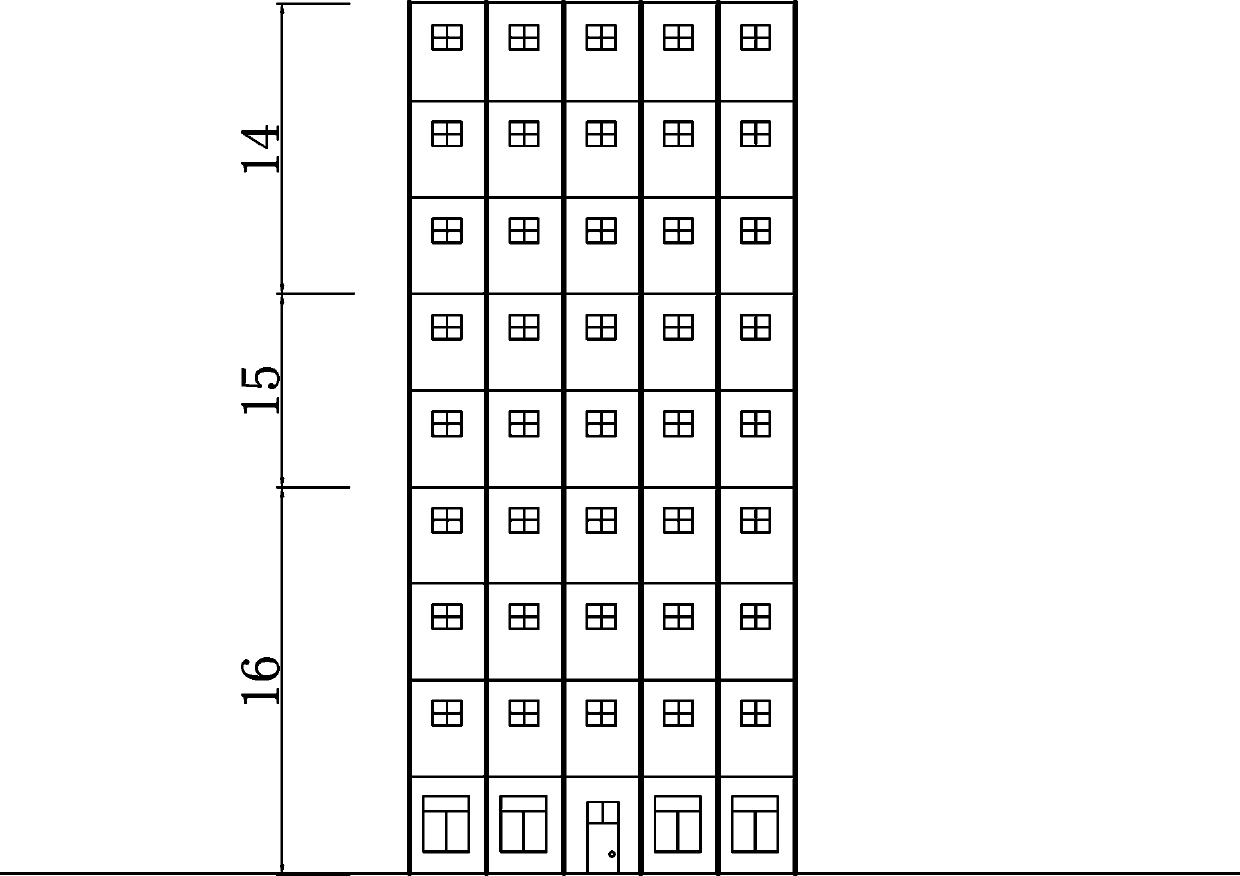

Building demolition method using self-expansion effect of expansion agent

The invention discloses a building demolition method using a self-expansion effect of an expansion agent. The building demolition method using the self-expansion effect of the expansion agent comprises the following steps that step 1, the number of falling layers, destruction layers and destroying layers of a building to be demolished is calculated; step 2, stand columns of the destruction layersare marked; step 3, pouring holes are formed; step 4, oil storage holes are formed; step 5, expansion agent mixtures are prepared; step 6, the expansion agent mixtures are poured; step 7, openings ofthe pouring holes are closed by sealing devices; and step 8, burning devices are arranged to burn the stand columns, the stand columns are completely destroyed, and the demolition of the building is realized. According to the building demolition method using the self-expansion effect of the expansion agent, the problems of long demolition cycle, high demolition cost and high danger can be solved,and the momentum generated by the self-weight falling from the upper part of the building is used for destroying the entire building, the demolition of the building is realized in safety and controllability modes, the demolition cycle is short, the operation is simple, the demolition cost is low, and the safety and reliability are achieved.

Owner:CHINA THREE GORGES UNIV

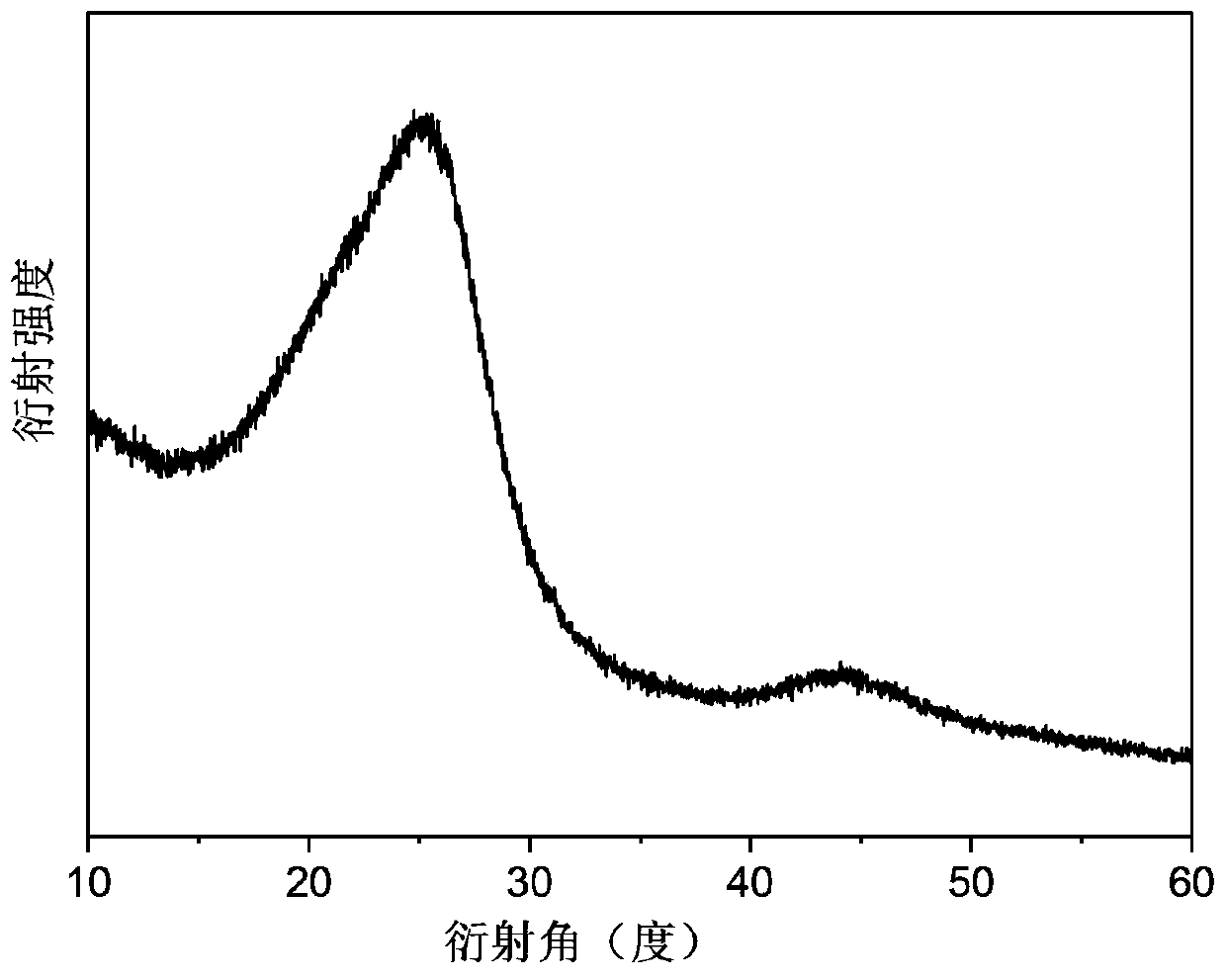

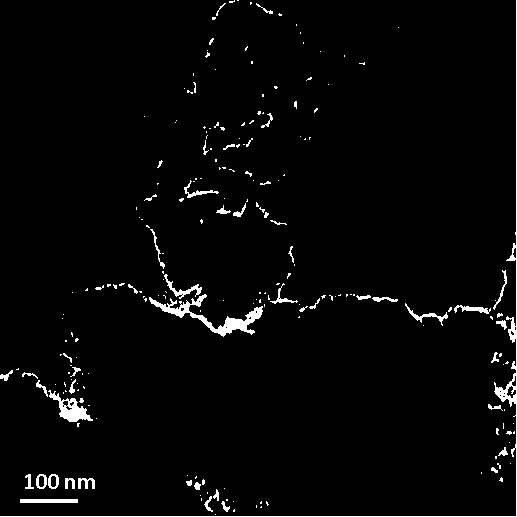

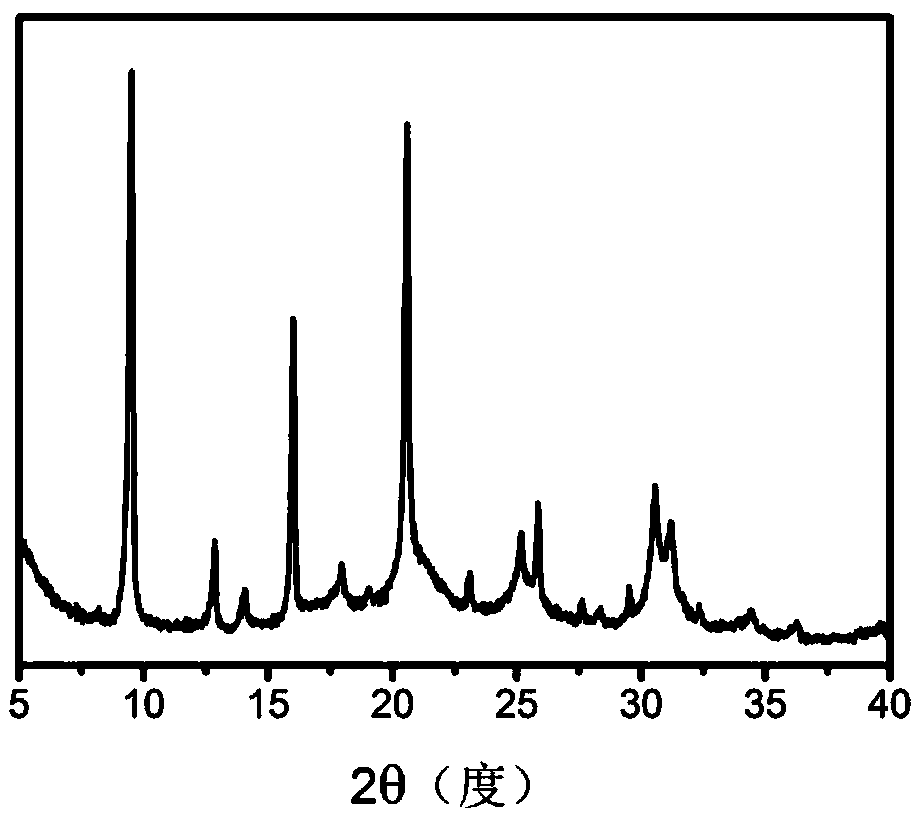

Two-dimensional ultra-thin SAPO-34 molecular sieve sheeting material and preparation method thereof

ActiveCN108975345AContent adjustableHuge external areaMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesMolecular sieveCrystal structure

The invention discloses a two-dimensional ultra-thin SAPO-34 molecular sieve sheeting material. The thickness is 1-25 nanometers, and a crystal structure is a SAPO-34 molecular sieve, wherein a silicon / aluminium atom ratio is 0.05-0.3. The two-dimensional ultra-thin SAPO-34 molecular sieve sheeting material is characterized in that cheap easy-to-get aluminium phosphate, a silicon source and organic amine are used as reactants, through a chemical method, a layered precursor is exfoliated, and then gaseous phase crystallization is conducted to prepare the two-dimensional ultra-thin SAPO-34 molecular sieve sheeting material. The two-dimensional ultra-thin SAPO-34 molecular sieve sheeting material has a an enormous surface area, the silicon content is adjustable in a certain range, and a method is pervasive; the material has multiple advantages and can be subjected to industrial large-scale production; the method is little in template usage, suitable for industrial large-scale production and low in cost, and basically, no environmental pollution is generated. The invention discloses the preparation method of the two-dimensional ultra-thin SAPO-34 molecular sieve sheeting material.

Owner:NANJING UNIV

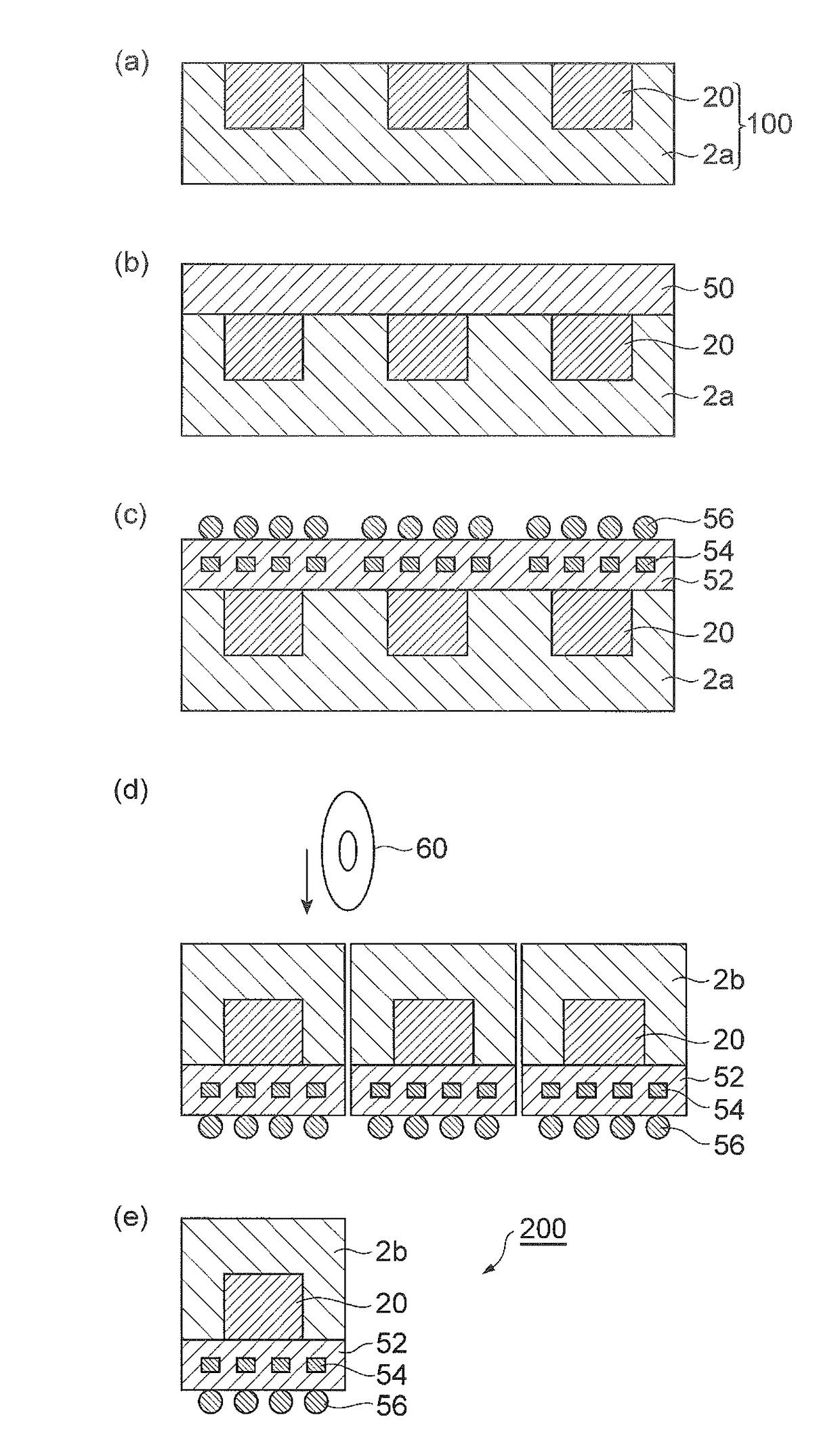

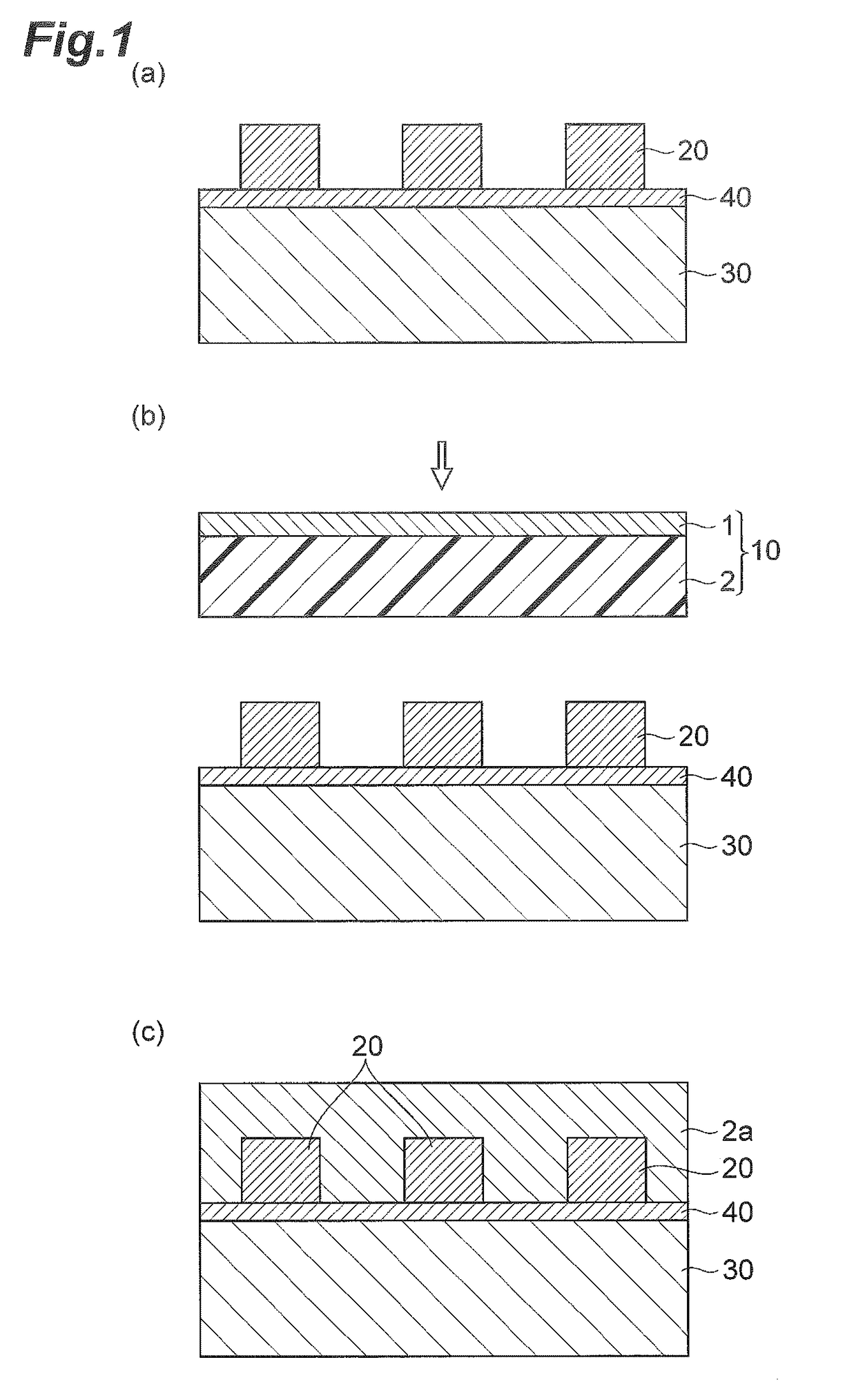

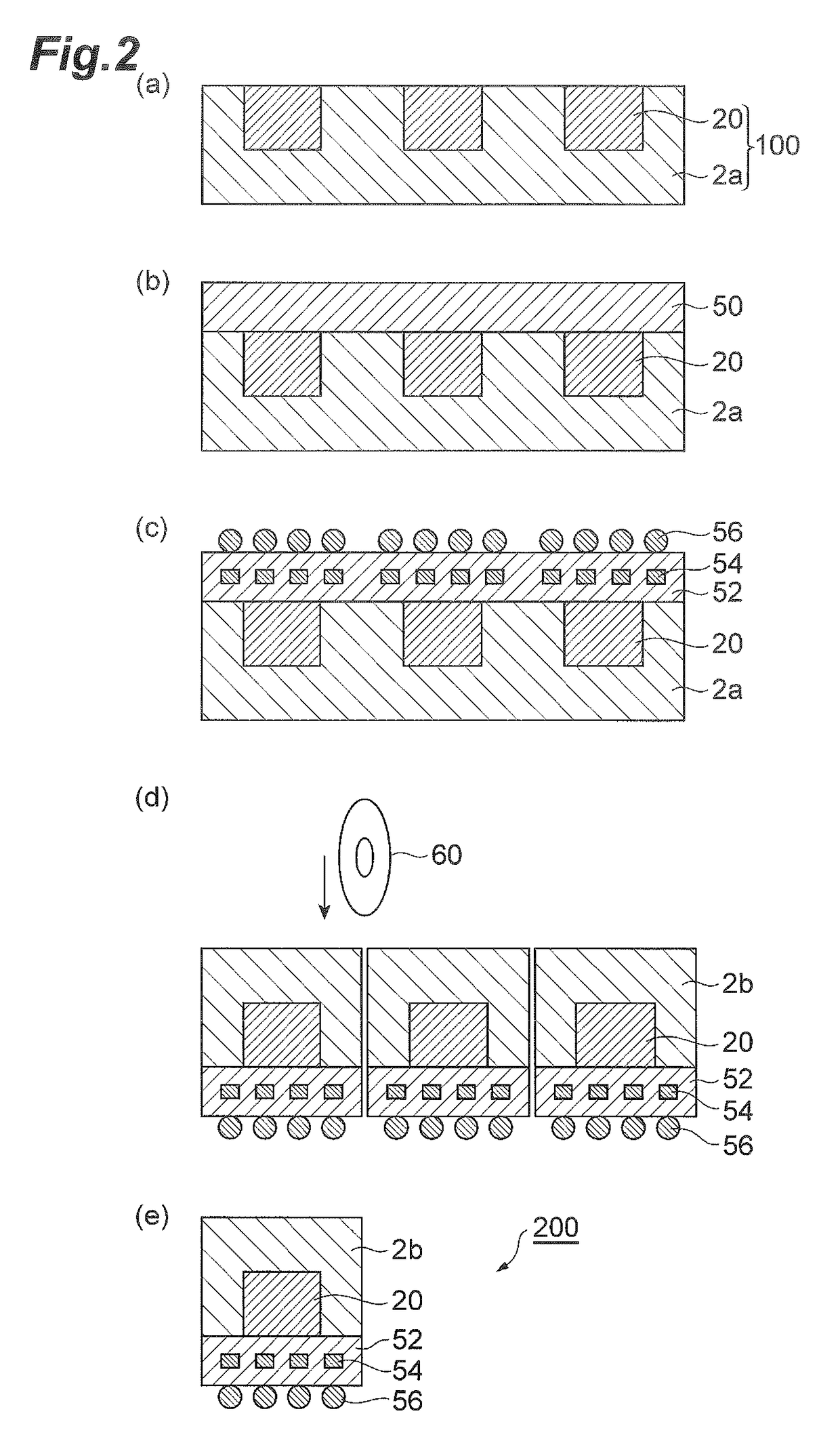

Film-like epoxy resin composition, method of producing film-like epoxy resin composition, and method of producing semiconductor device

ActiveUS20170073481A1Inhibition formationPrevents excess drying occurringSemiconductor/solid-state device detailsSolid-state devicesEpoxyOrganic solvent

Provided is a film-like epoxy resin composition including an epoxy resin (A); a curing agent (B); a cure accelerator (C); an inorganic filler (D); and an organic solvent (E) and satisfying all the following requirements (1) to (4): (1) at least one of the epoxy resin (A) and the curing agent (B) contains a component being a liquid at 25° C. in an amount of 30% by mass or more based on the total mass of the epoxy resin (A) and the curing agent (B); (2) the content of a volatile portion that volatilizes by being heated at 180° C. for 10 minutes is 0.2% to 1.5% by mass based on the total amount of the epoxy resin composition; (3) the minimum melt viscosity in temperature rising from 40° C. to 200° C. is 800 Pa·s or less; and (4) the film thickness is 50 to 500 nm.

Owner:RESONAC CORP

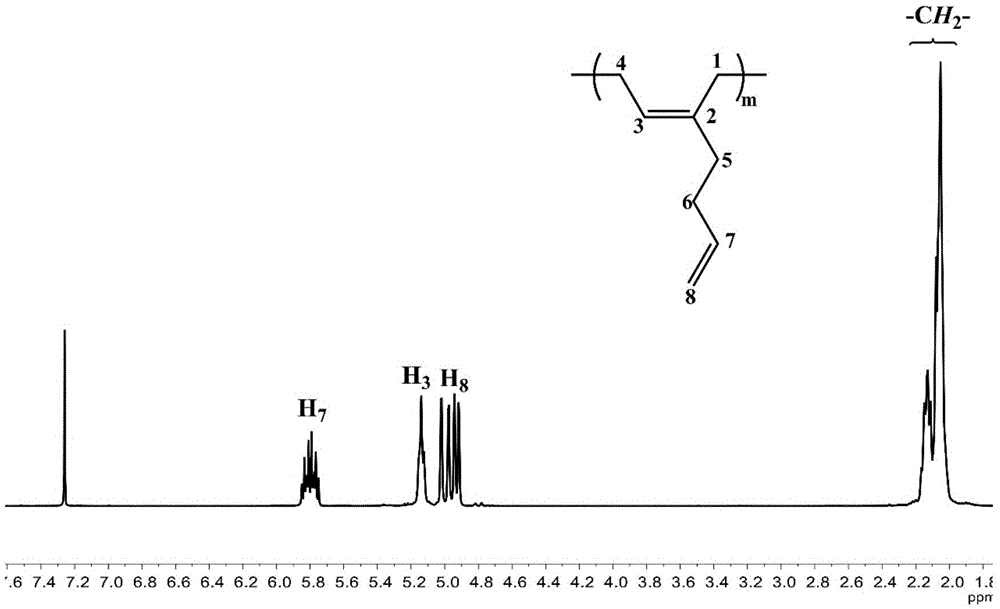

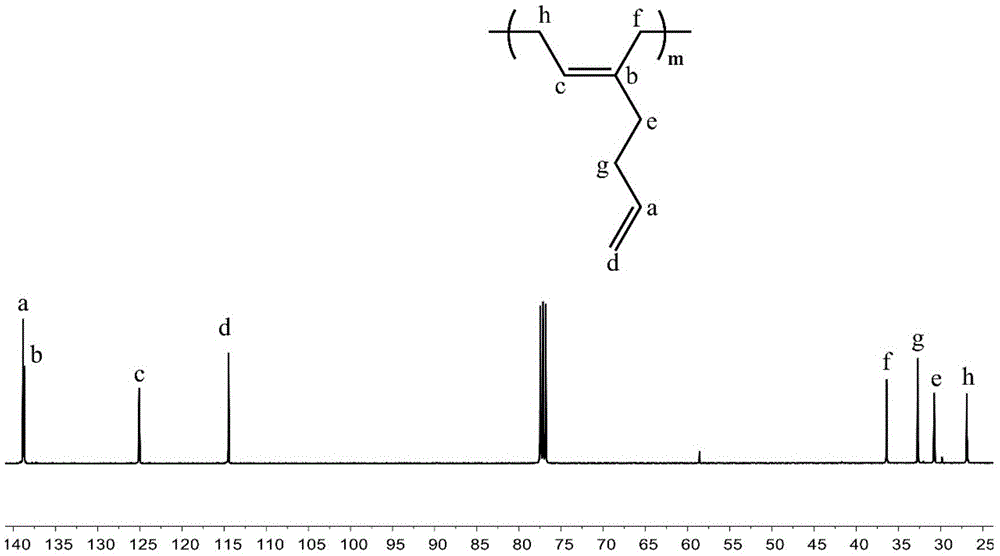

High CIS-1,4 conjugated diene polymer with double bonds on side arm and preparation method thereof as well as high CIS-1,4 conjugated diene polymer with functional groups on side arm and preparation method thereof

ActiveCN105542049AControllable structural qualityControllable relative molecular massPolymer scienceRare earth

The invention relates to a high CIS-1,4 conjugated diene polymer with double bonds on a side arm and a preparation method thereof as well as a high CIS-1,4 conjugated diene polymer with functional groups on a side arm and a preparation method thereof, belongs to the field of conjugated diene polymers and solves the technical problem in the prior art that a high-stereo-tacticity conjugated diene polymer containing polar functional groups cannot be obtained. The invention first provides the high CIS-1,4 conjugated diene polymer with the double bonds on the side arm and the preparation method thereof, and based on the polymer, a functional high CIS-1,4 conjugated diene polymer is synthesized. The high CIS-1,4 conjugated diene polymer with the double bonds on the side arm is prepared by homopolymerization of a conjugated diene monomer with double bonds on the side arm or copolymerization of the conjugated diene monomer with the double bonds on the side arm and non-functional conjugated diene under catalytic action of a catalytic system formed by a tridentate carbazolyl rare earth complex and organic boron salt, so that the polymer prepared by adopting the method is controllable in both molecular structure and relative molecular mass. The polymer with the double bonds on the side arm reacts with various sulfhydryl compounds to obtain the high CIS-1,4 conjugated diene polymer with the functional groups on the side arm.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Nano silicon-carbon composite material and preparation method thereof

ActiveUS9666863B2Improve cycle stabilityNo pollution in the processMaterial nanotechnologyElectrolysis componentsCarbon compositesLithium-ion battery

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Manufacturing method of silver nanowire and manganous-manganic oxide one-dimensional core-shell composite nanomaterial

InactiveCN106710894AHigh specific capacityImproved magnification performanceHybrid capacitor electrodesHybrid/EDL manufactureEnvironmental resistanceArgon atmosphere

A manufacturing method of a silver nanowire and manganous-manganic oxide one-dimensional core-shell composite nanomaterial is disclosed. The method comprises the following steps of 1) adding thick-silver nanowire-ethanol dispersion solution into absolute ethyl alcohol, carrying out magnetic stirring till that uniform dispersion is reached, and acquiring a mixed liquor; 2) adding a potassium permanganate solution dropwise into the above mixed liquor, under a room temperature, maintaining magnetic stirring for 12 hours, using deionized water and the absolute ethyl alcohol to carry out centrifugal washing for 3 times, at a 60 DEG C, drying for 12 hours in a vacuum state, and acquiring brown powder; and 3) putting the above brown powder into a tube furnace, calcining under an argon atmosphere, naturally cooling to the room temperature, and acquiring a target object. The method has advantages that the manufacturing method of the composite nanomaterial is simple and is easy to operate, and energy consumption is reduced; product components and contents can be adjusted; the composite material has a high specific capacity, a good rate capability and a good cycle performance; during a manufacturing process, an environment pollution is not made, green and environmental protection are achieved, and the method is suitable for large scale production.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

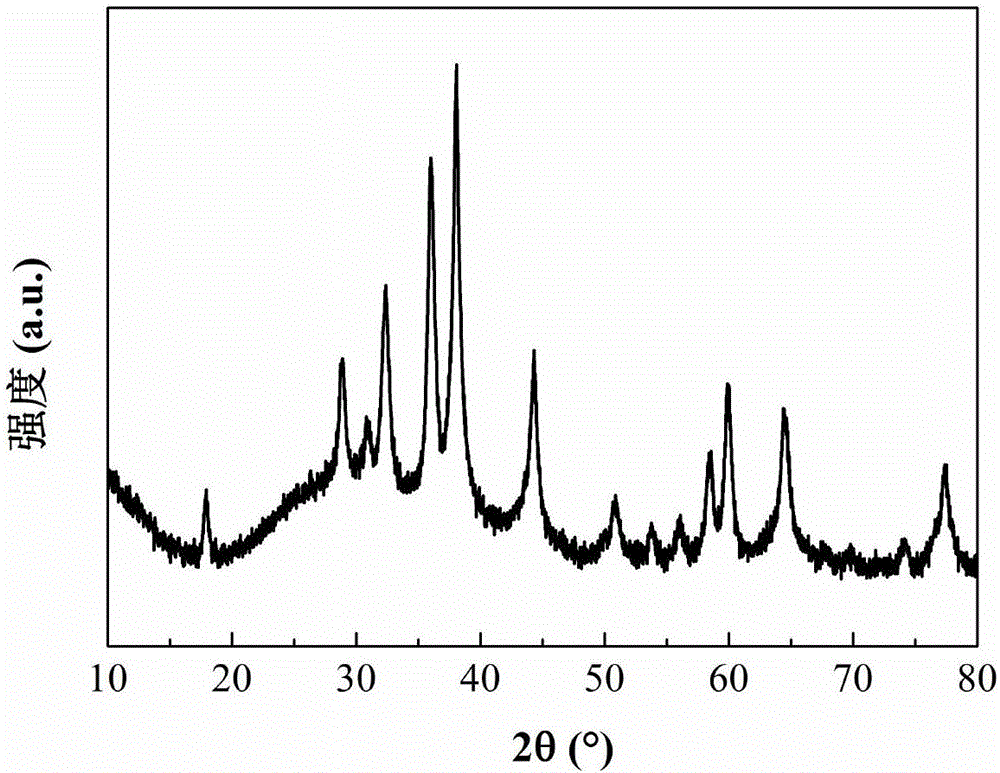

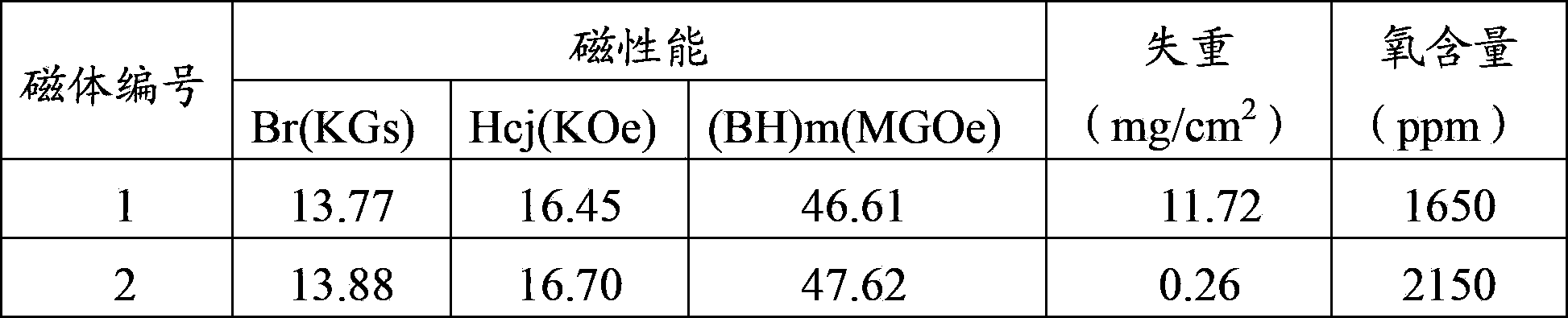

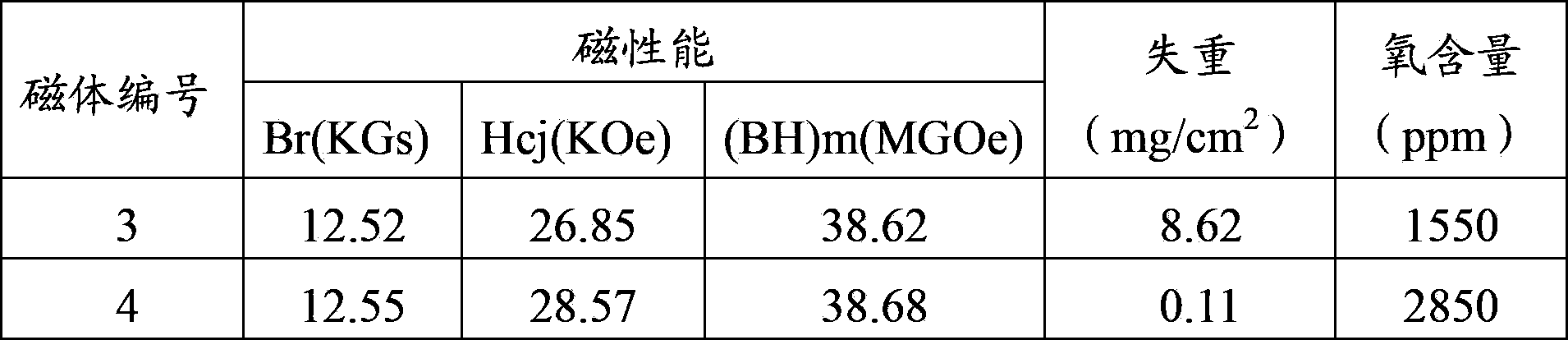

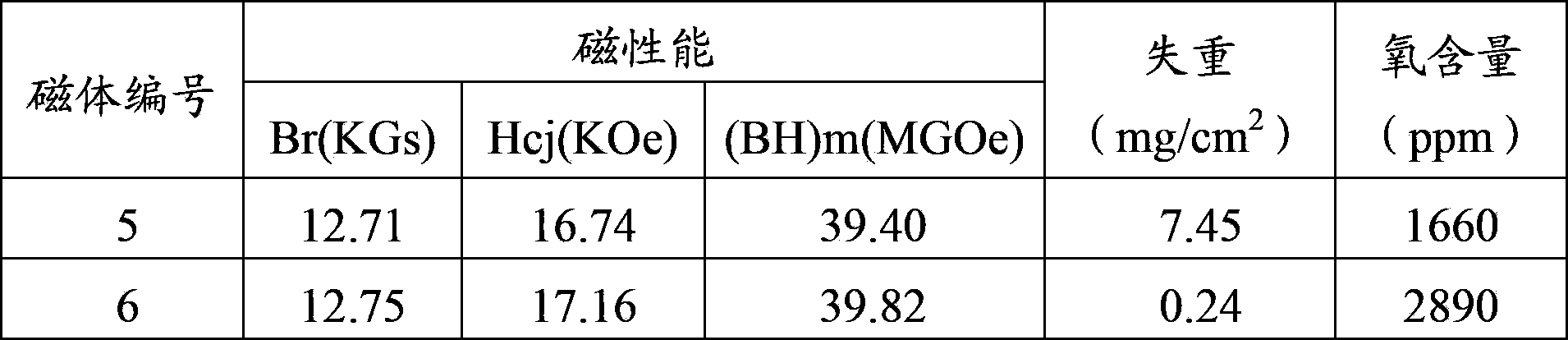

Oxygen-bearing Re-(Fe, TM)-B based sintering magnetic body and manufacturing method thereof

ActiveCN103779062ASmall residual magnetismAdd lessMagnetsInorganic material magnetismRare earthOxygen content

The invention discloses a manufacturing method of an oxygen-bearing Re-(Fe, TM)-B based sintering magnetic body. The manufacturing method comprises the steps of 1 smelting and then coarsely crushing the Re-(Fe, TM)-B based magnetic body, performing secondary crushing to obtain a powder material with 0.5mm average grain diameter, wherein the Re is one or more of Pr-Nd, Nd, Dy, Tb, Gd and Ho, the TM is one or more of Al, Nb, Cu, Ga, Co and Zr; 2 adopting air-flow milling to further grind the powder material obtained in the step 1 till the grain diameter of the powder material is smaller than 5mum; 3 performing magnetic field forming, vacuum sintering and aging treatment on the powder material obtained in the step 2 to obtain a product with 2100-2900ppm oxygen content, wherein the powder material obtained in the steps 1 and 2 are mixed evenly before the next treatment, and rare earth oxide e with average grain diameter smaller than 45mum is added into the powder material when one or more of the secondary crushing, the grinding and mixing treatment is performed. The invention further provides the oxygen-bearing Re-(Fe, TM)-B based sintering magnetic body manufactured by the manufacturing method.

Owner:SINO MAGNETICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com