Process for preparing high-C-axis-orientation ScAlN thin film

A film and orientation technology, which is applied in the process of preparing highly C-axis oriented ScAlN films, can solve the problems of reducing the selection range of substrate materials, high-power vacuum space, unfavorable industrial production, etc., and achieves the elimination of heating and cooling bases. The effect of slice time, energy saving, time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The processing steps in the present embodiment are as follows:

[0031] Step 1: Using Si(100) as the substrate, first soak the substrate in a mixed liquid of concentrated sulfuric acid and hydrogen peroxide (liquid volume ratio H 2 SO 4 :H 2 o 2 =1:1) for 30 minutes to remove stubborn stains on the surface, then ultrasonically clean the substrate in acetone for 20 minutes, ultrasonically clean in alcohol for 10 minutes to remove surface organic pollutants, and finally use high-purity argon to dry it and place it in a sputter The ejaculation room is spare.

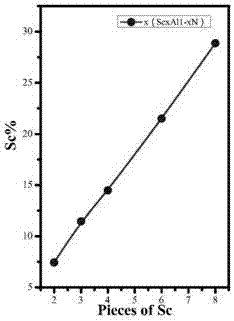

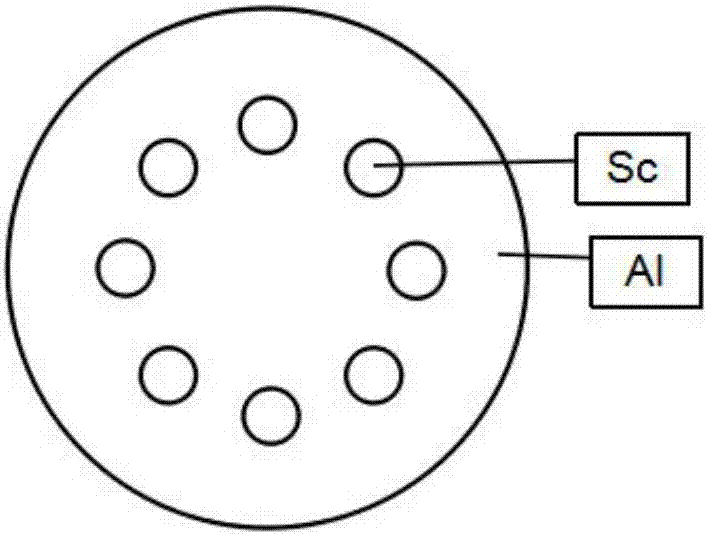

[0032] Step 2: Polish the surface of the Al target (99.999%) with a diameter of Φ=75mm and the Sc target (99.999%) with a diameter of Φ8mm until the surface is bright with 1000-mesh sandpaper, clean the surface stains with alcohol, and dry them with high-purity nitrogen. The sputtering track of the target is divided into four areas equally. One side of the 4 pieces of Sc target is coated with silver paste and pas...

Embodiment 2

[0040] The processing steps in the present embodiment are as follows:

[0041] Step 1: Si (100) is used as the substrate, and the processing method of the substrate is the same as that in the first embodiment.

[0042] Target processing:

[0043] Step 2: Al target (99.999%) and Sc target (99.999%) chip targets are used as sputtering targets, and chip target materials are implemented in the same way as in Example 1.

[0044] Step 3: Treat the Si(100) substrate in the same way as in Step 1 and grow a layer of Si on the surface of the substrate 3 N 4 layer, put the processed substrate into the PECVD instrument, and Table 2 sets the process parameters.

[0045] Table 2 Partial experimental conditions of SiN prepared by PECVD

[0046] Power / W Pressure / mT Si / Ar / sccm N2 / sccm Time / s 60 400 250 200 100

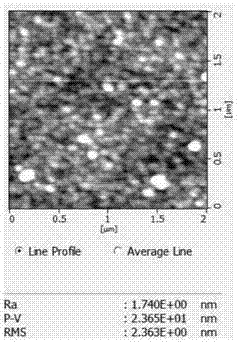

[0047] Step 4: Put the target processed in step 2 and the Si3N4 / Si substrate prepared in step 3 into the vacuum chamber. The pre-sputtering condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com