Core-shell nano-composite material and its preparation method

A nano-composite material and composite material technology, applied in the field of ammonium perchlorate/metal oxide core-shell nano-composite materials, can solve the problem of affecting the actual use effect of nano-catalysts, increasing the cost of nano-catalysts, and the compounding uniformity of mechanochemical methods Limited and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

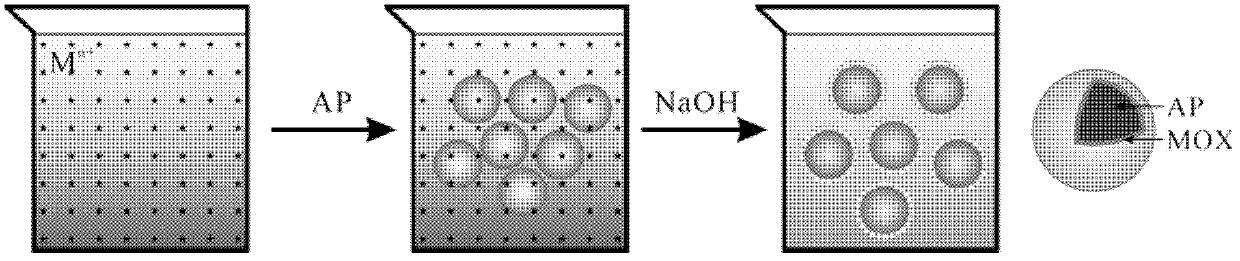

Method used

Image

Examples

Embodiment 1

[0027] AP:ZnO=100:4 core-shell composite material, its preparation steps are dissolving, stirring, titrating, filtering, washing and drying in sequence. The ZnCl configured in it 2 The concentration of ethyl acetate solution is 0.016mol / L, the concentration of NaOH solution for titration is 0.5mol / L, and the volume of NaOH solution for titration is 4.0mL.

[0028] The AP used in the composite material was provided by Shanghai Reagent Company, with an average particle size of 135 μm.

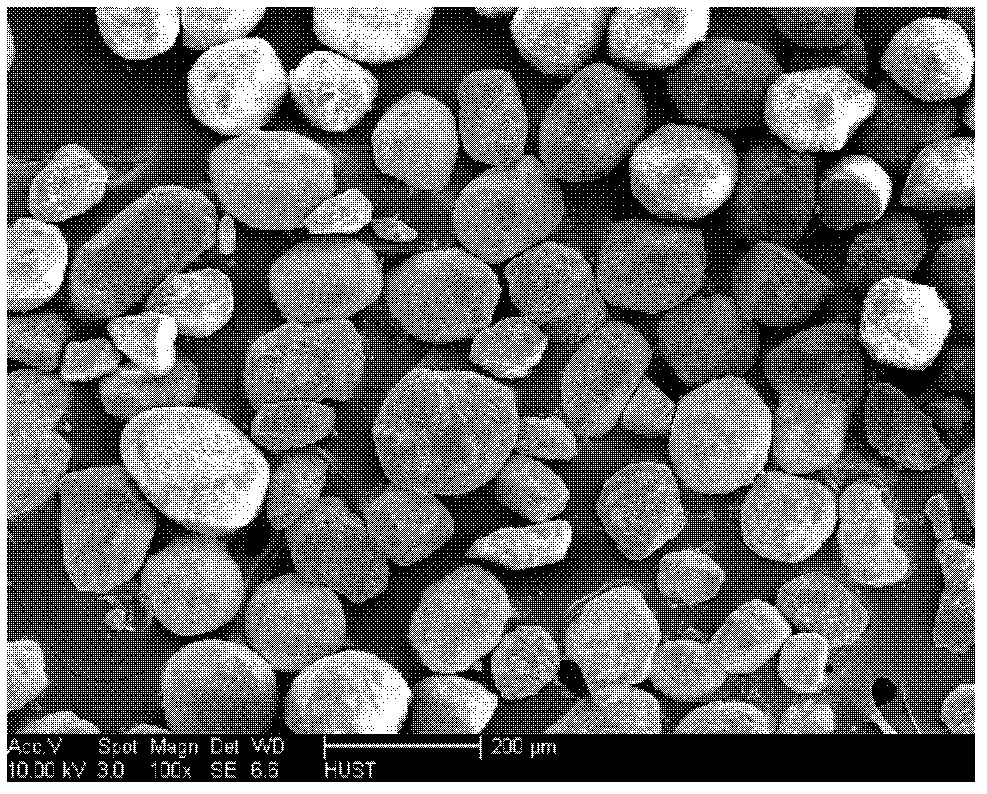

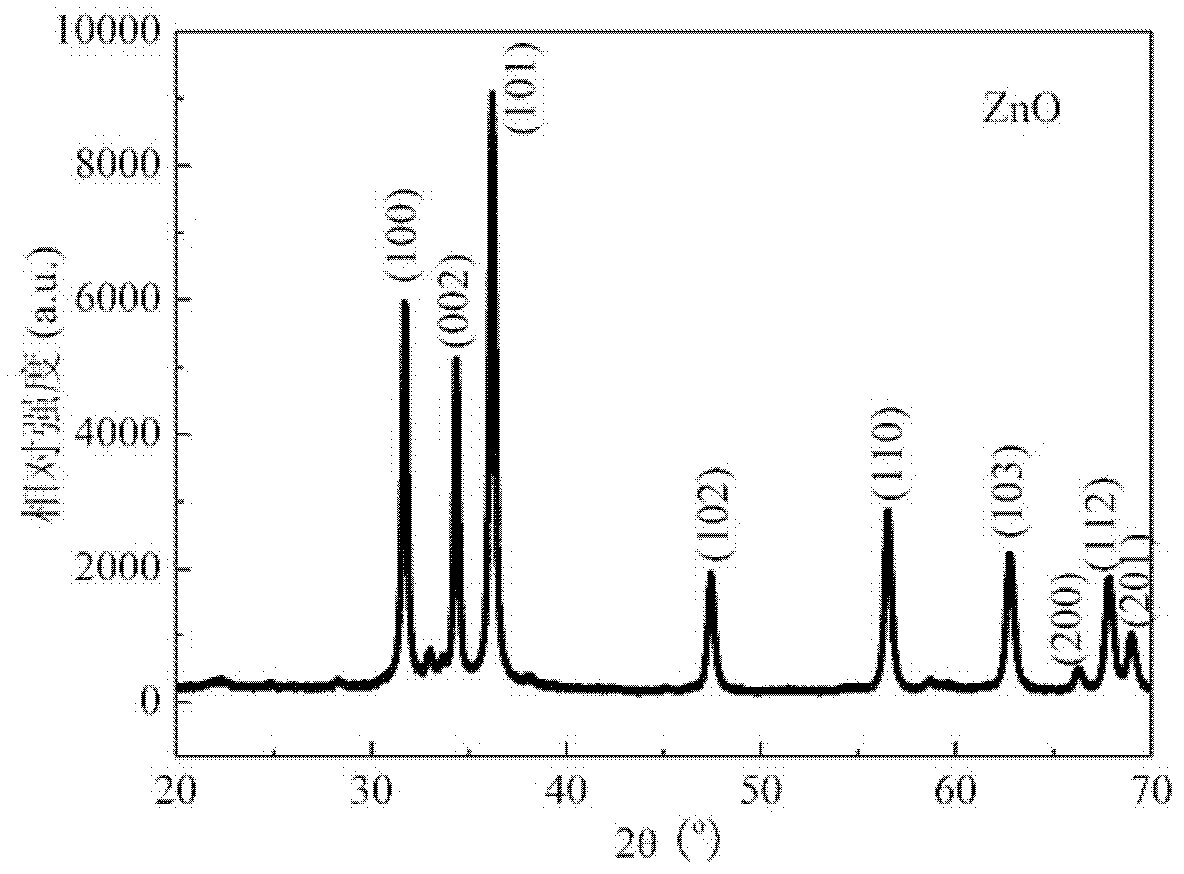

[0029] In order to use a scanning electron microscope (FESEM FEI Sirion 200) to observe the coating effect of the obtained powder, its morphology is shown in the attached figure 2 shown. The surface of AP is evenly covered with a layer of particles with a particle size of about 100nm, forming a core-shell structure. In order to analyze the elemental composition of the obtained core-shell powder, EDX analysis was carried out on the composite particles. The constituent elements include N, O, Cl...

Embodiment 2

[0031] AP:ZnO=100:0.1 core-shell composite material, its preparation steps are dissolving, stirring, titrating, filtering, washing and drying in sequence. The ZnCl configured in it 2 The concentration of ethyl acetate solution is 0.0004mol / L, the concentration of KOH solution for titration is 0.1mol / L, and the volume of KOH solution for titration is 0.5mL.

Embodiment 3

[0033] AP:ZnO=100:1 core-shell composite material, its preparation steps are dissolving, stirring, titrating, filtering, washing and drying in sequence. The ZnCl configured in it 2 The concentration of ethyl acetate solution is 0.004mol / L, the concentration of NaOH solution for titration is 0.2mol / L, and the volume of NaOH solution for titration is 2.5 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com