Patents

Literature

140results about How to "Small residual magnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

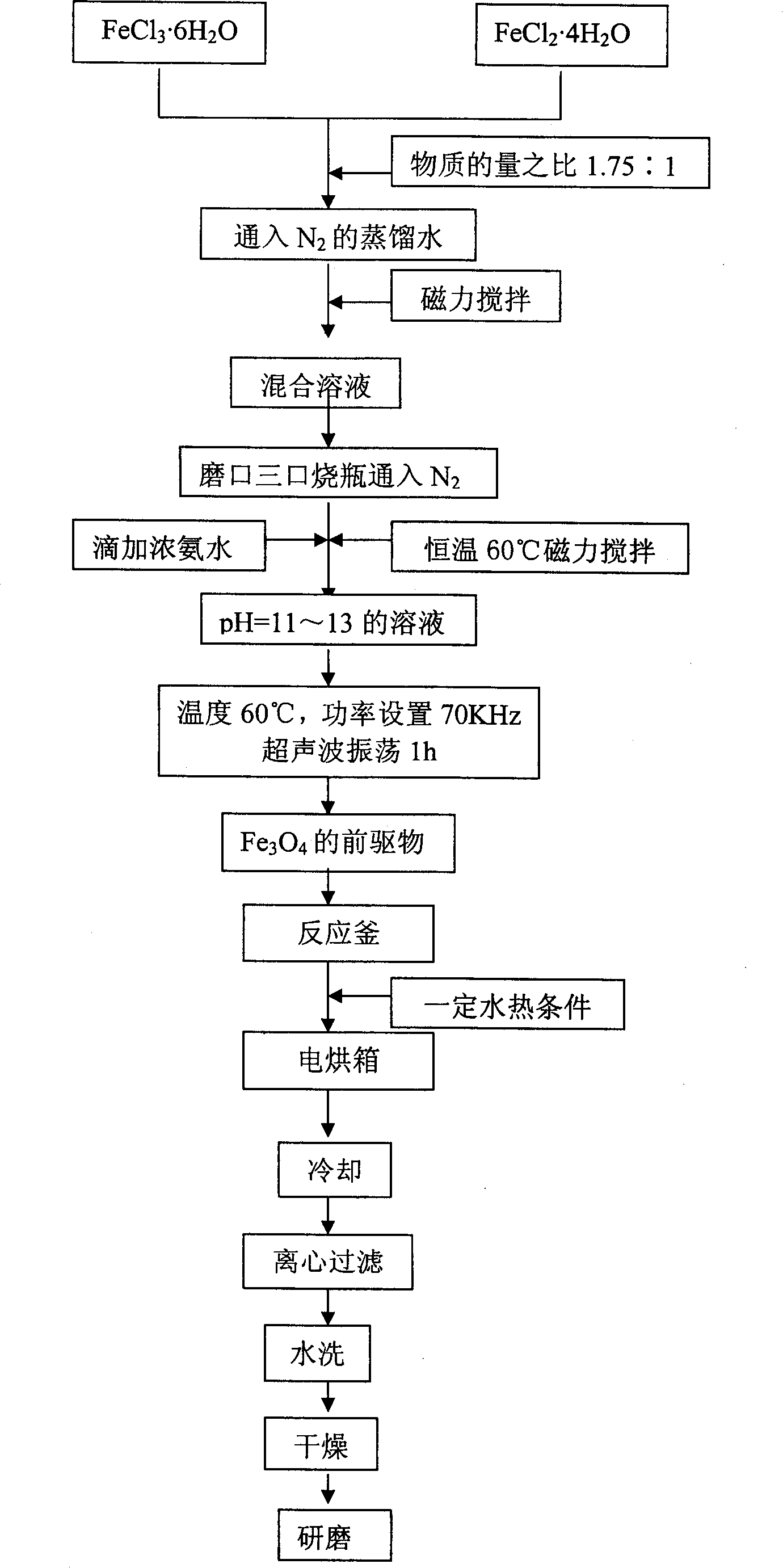

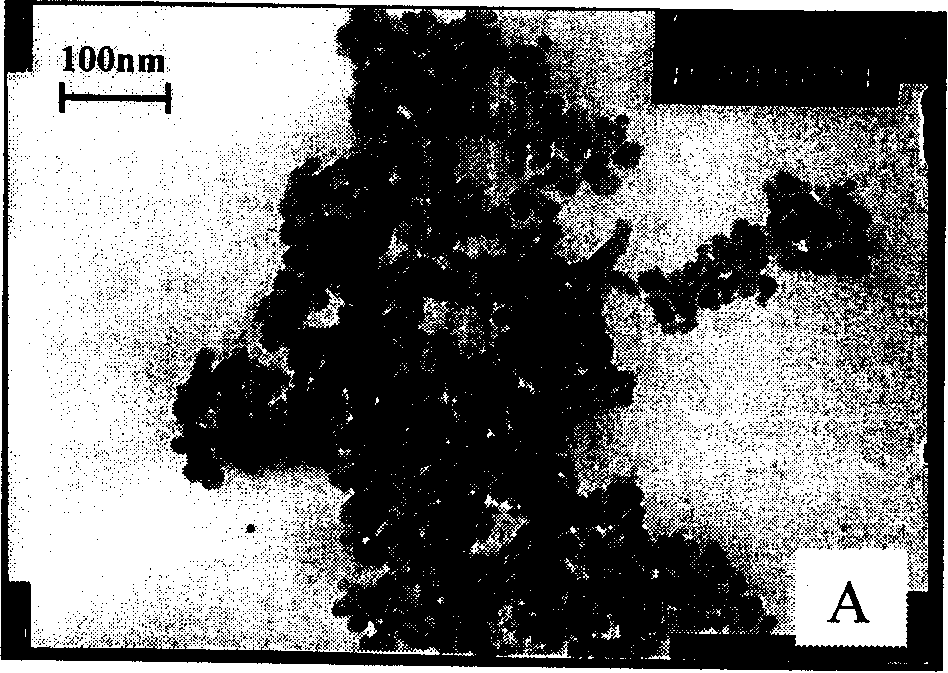

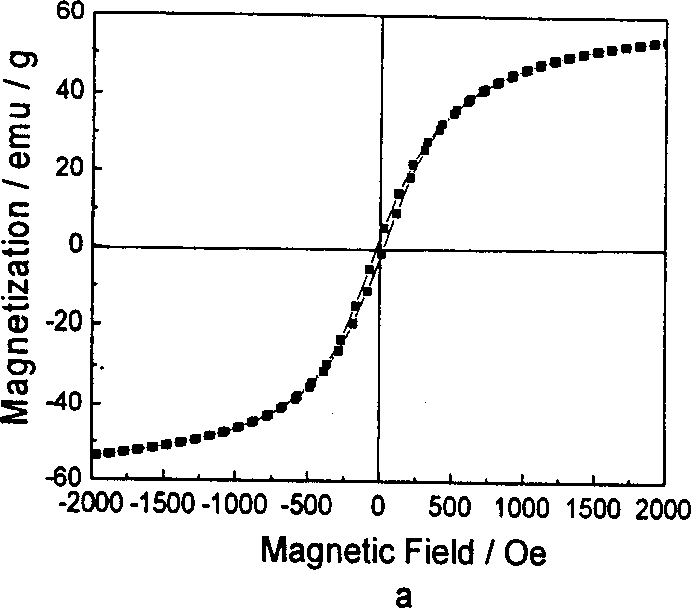

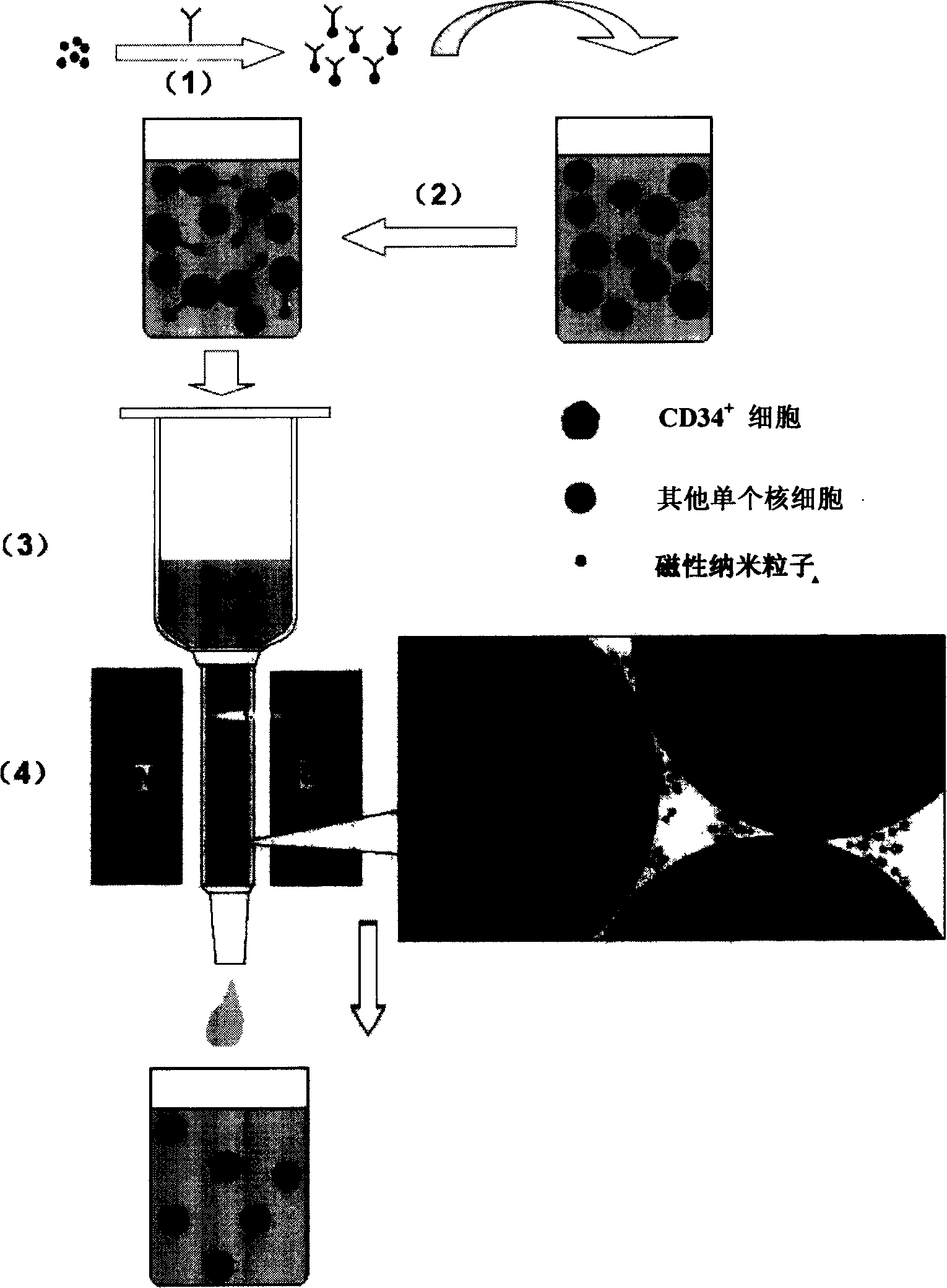

Ultrasound wave auxiliary hydrothermal synthesis technique for magnetic magnetic iron oxide nano ultra-tiny grain

The invention discloses an ultrasonic assistant hydro-thermal synthesis process for magnetic Fe3O4 nanometer super fine grain. The invention solves the problems of impure products and large grain diameter. The invention has the technical proposal that the form of Fe3O4 crystal nucleus is promoted in the cavitation effect of ultrasonic; cavitation gas bubble is produced in mediums; the pH value of strong ammonia is adjusted to 11 to 13; and the nanometer grain diameter size and the magnetic characteristics are controlled by controlling the hydro-thermal synthesis temperature within range from 140 DEG C to 160 DEG C and within time of 3 to 5 hours, and by changing the micro environment of the air bubble chamber, so as to obtain the dry product which is black magnetic Fe3O4 nanometer powder after being milled. The invention comprises no organic solvent, belonging to full green environmental protection which is a break in the field, and the invention is also the first to use the ultrasonic technology for assistant hydro-thermal synthesis. The invention has the advantages of simple technology, low cost, small powder granularity and even grain diameter. The powder not only can be used as duplicate ink powder, but also can be board used in aspects such as medical, biological technology, magnetic immunocyte separation, DNA separation, nucleic acid hybridization, and preparation for magnetic butt directional medicine carrying micron ball.

Owner:CIVIL AVIATION UNIV OF CHINA

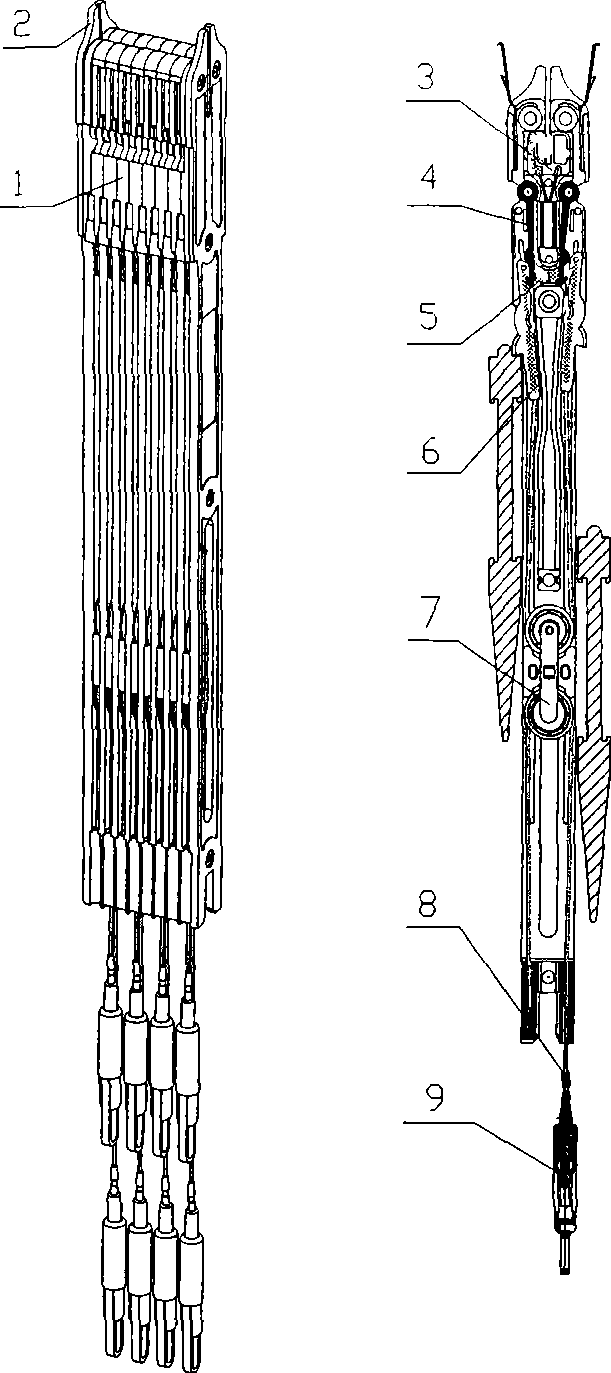

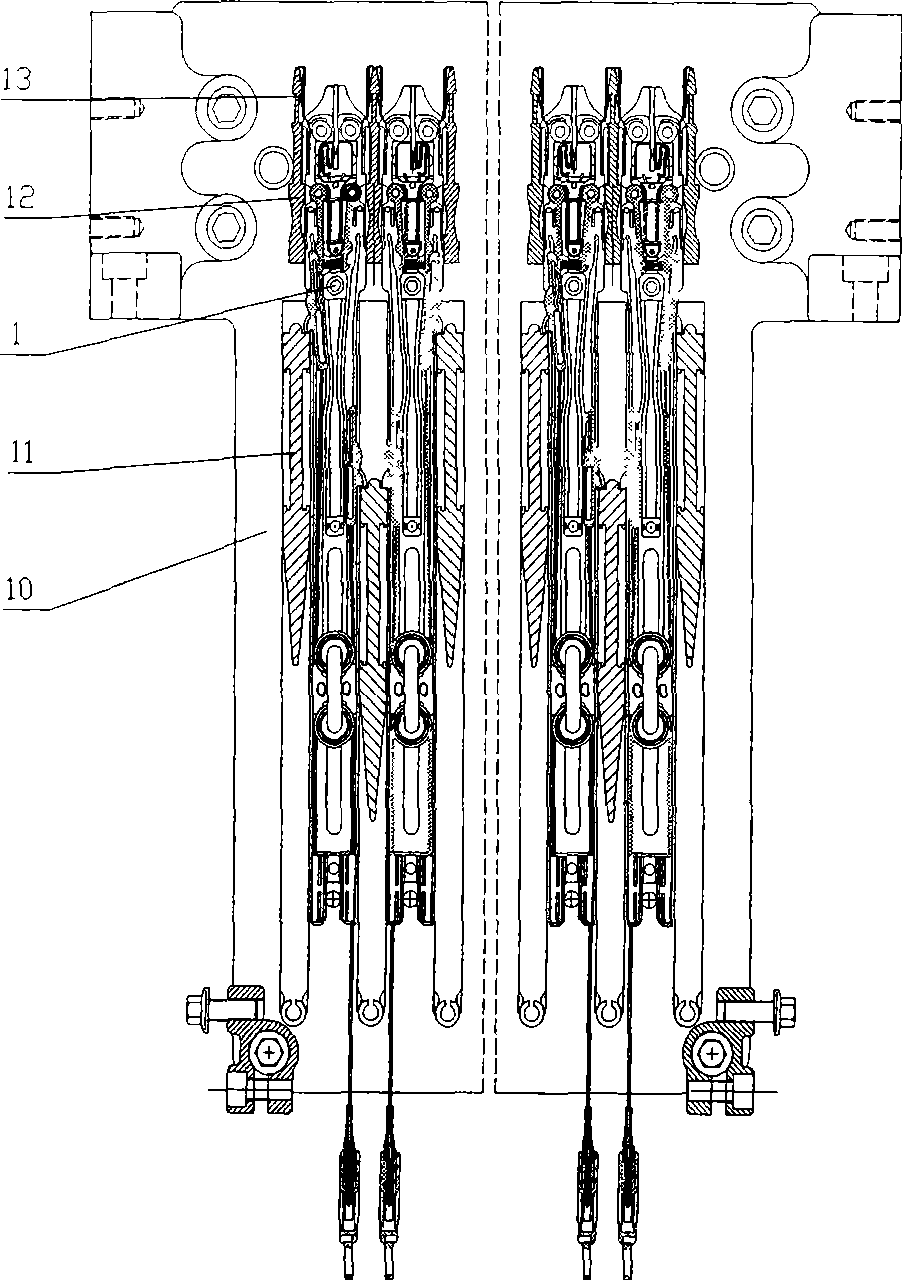

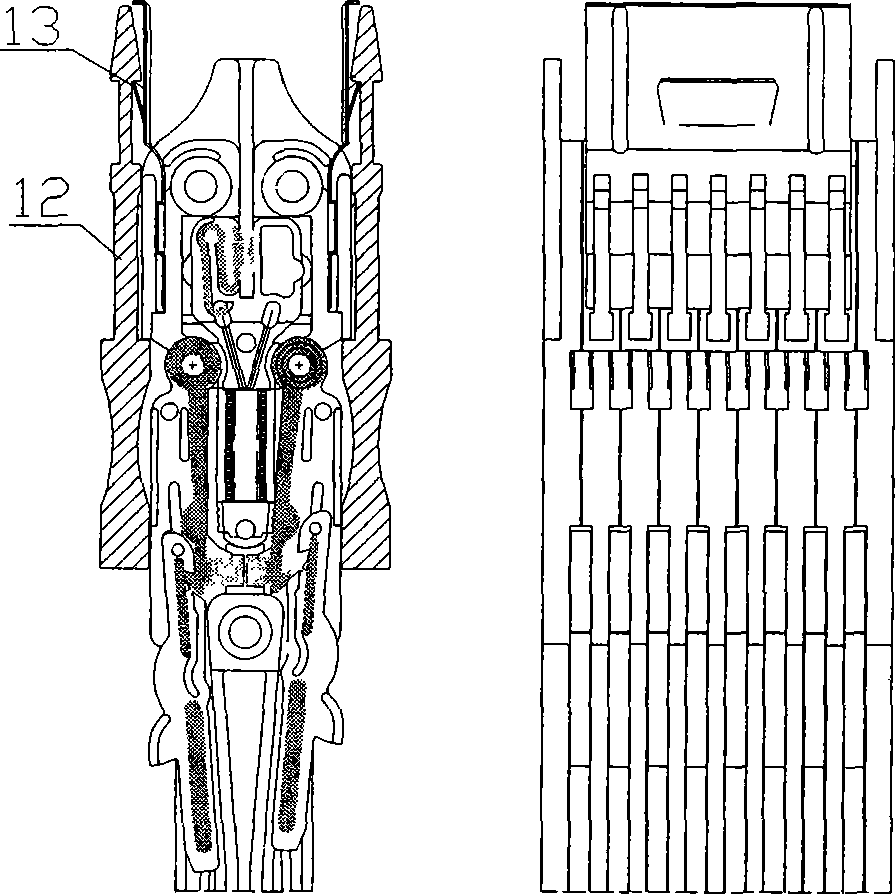

Electromagnetic valve heddle selecting apparatus of electronic jacquard

The invention discloses a heald selecting device for a solenoid valve of an electronic jacquard, which consists essentially of seven pieces of central brackets, two pieces of side brackets, modular solenoid valves, needle selecting hooks, offsetting springs, bidirectional moving hooks, a pulley module, a heald twine hanging cable and a quick coupling, wherein, the modular solenoid valves are arranged among the seven pieces of central brackets as well as between the central brackets and the side brackets; two sides of each modular solenoid valve are provided with a pair of needle selecting hooks, and a pair of offsetting springs and a pair of bidirectional moving hooks are arranged under each modular solenoid valve; and the bidirectional moving hooks, the pulley module, the heald twine hanging cable and the quick coupling are sequentially connected. The heald selecting device for the solenoid valve of the electronic jacquard has small electric power, correct and stable heald selecting and convenient maintenance.

Owner:宁波川一纺织设备有限公司

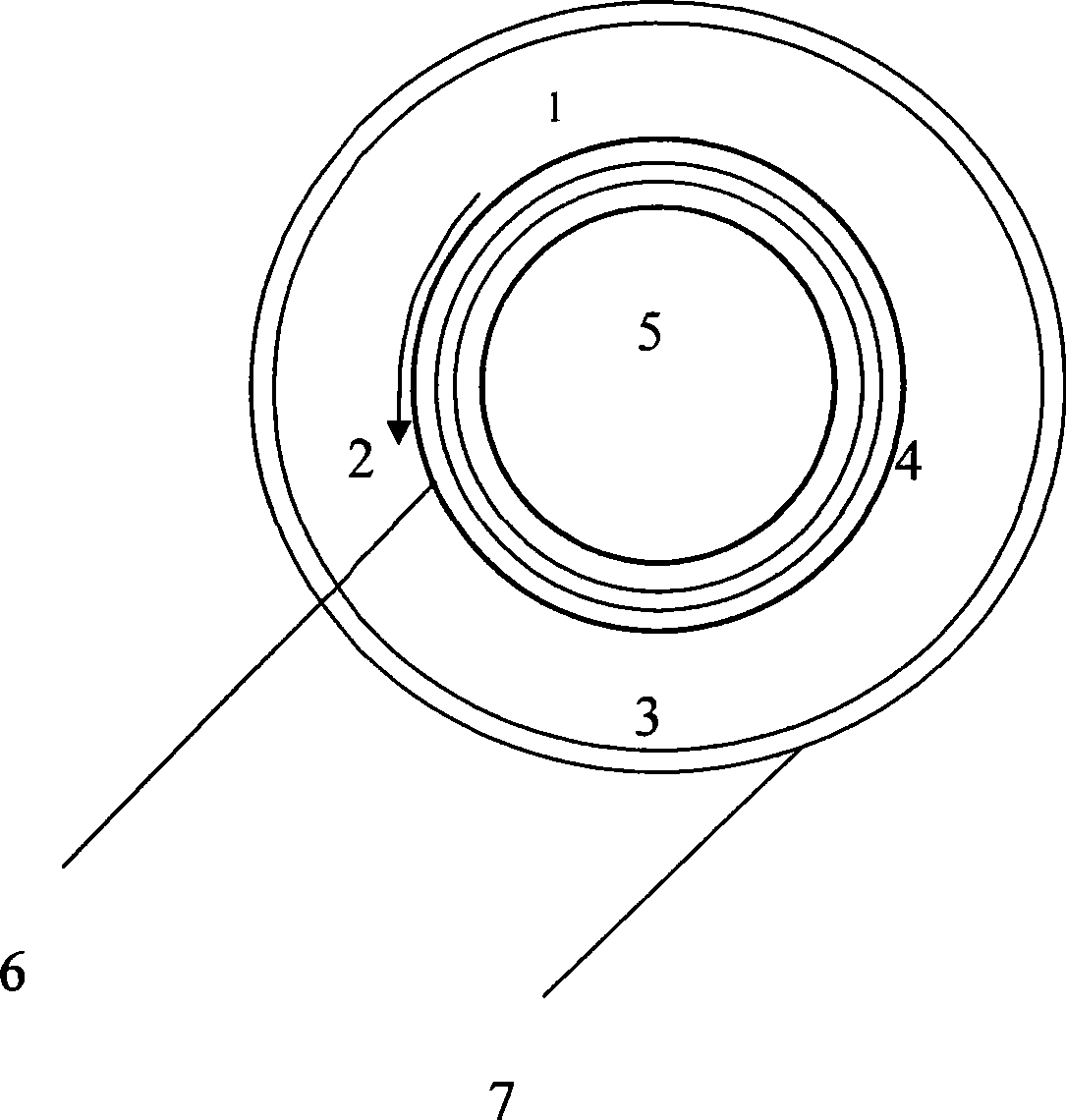

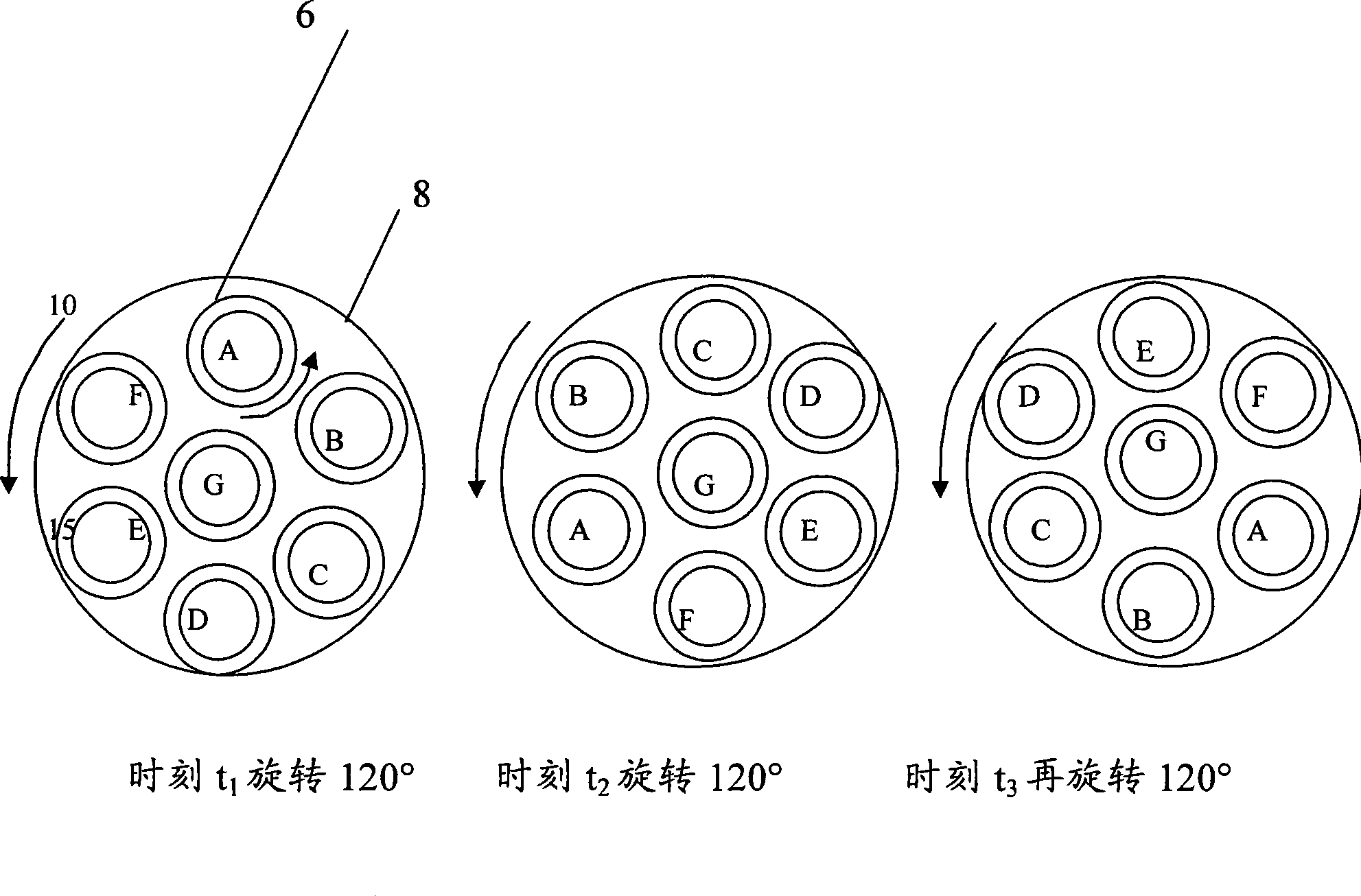

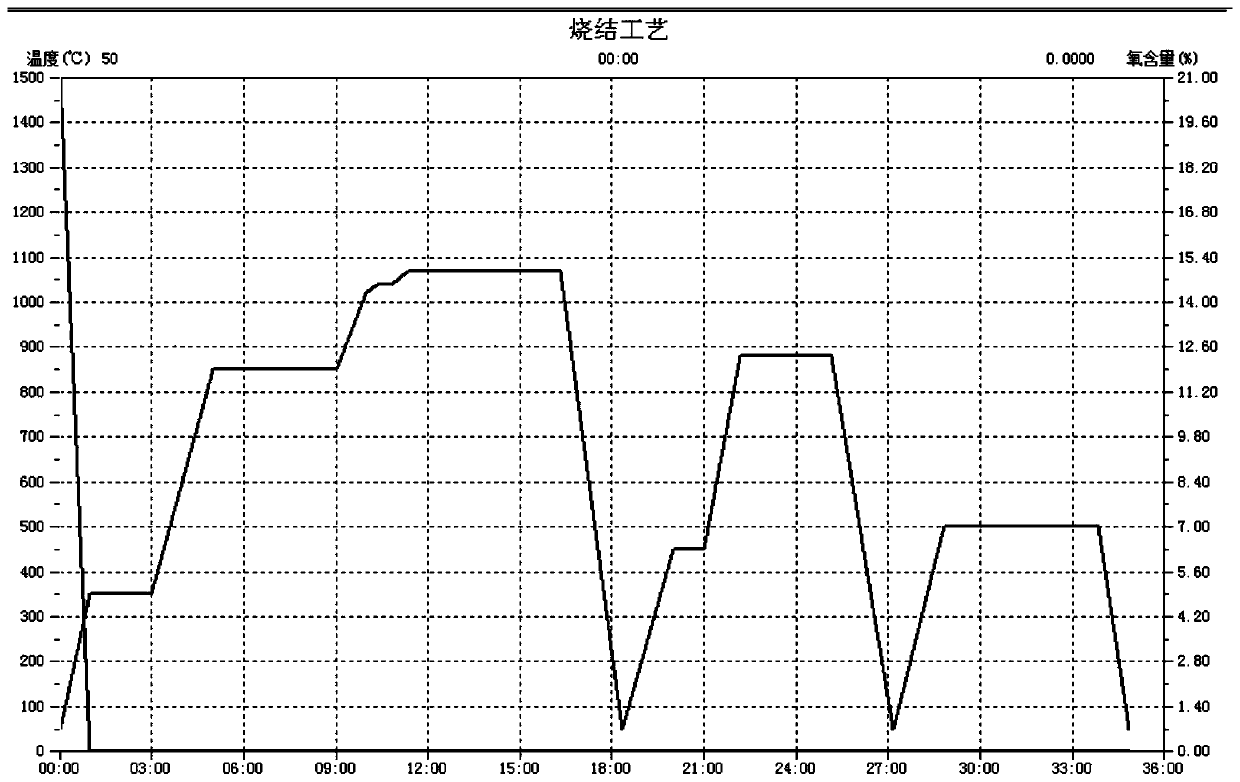

Iron based nanocrystalline magnet core for large power inverter power source and production method

ActiveCN101477868AGood tape making processReduce lossInorganic material magnetismTransformers/inductances magnetic coresPower inverterDownstream processing

The invention relates to a soft magnetic core used for a high-power inverter power supply, and a manufacturing method thereof. The magnetic core is made of an Fe-based amorphous nano-crystalline belt material through winding , and comprises components according to weight percentages as follows: 81%-85% of Fe, 0.01%-5% of Co, 7%-9% of Si, 1.5%-2.5% of B, 1%-2% of Cu, 4%-7% of M, and 0.001%-0.04% of M', wherein M is one or more of Nb, Mo, V, W and Ta, and M' is at least one of Al and Ti. The magnetic core is subjected to anneal in a protective atmosphere or a vacuum; when in anneal, the position of the magnetic core in a furnace is movable or rotatable, a holding temperature is 520-600 DEG C, the holding time is 1-2 hours, and a temperature rise speed is 100 DEG C per hour. The magnetic core manufactured by adopting the method has lower loss, better manufacturing technique properties, and good soft magnetic characteristics; moreover, the downstream processing after the heat treatment is applicable to various technique methods.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

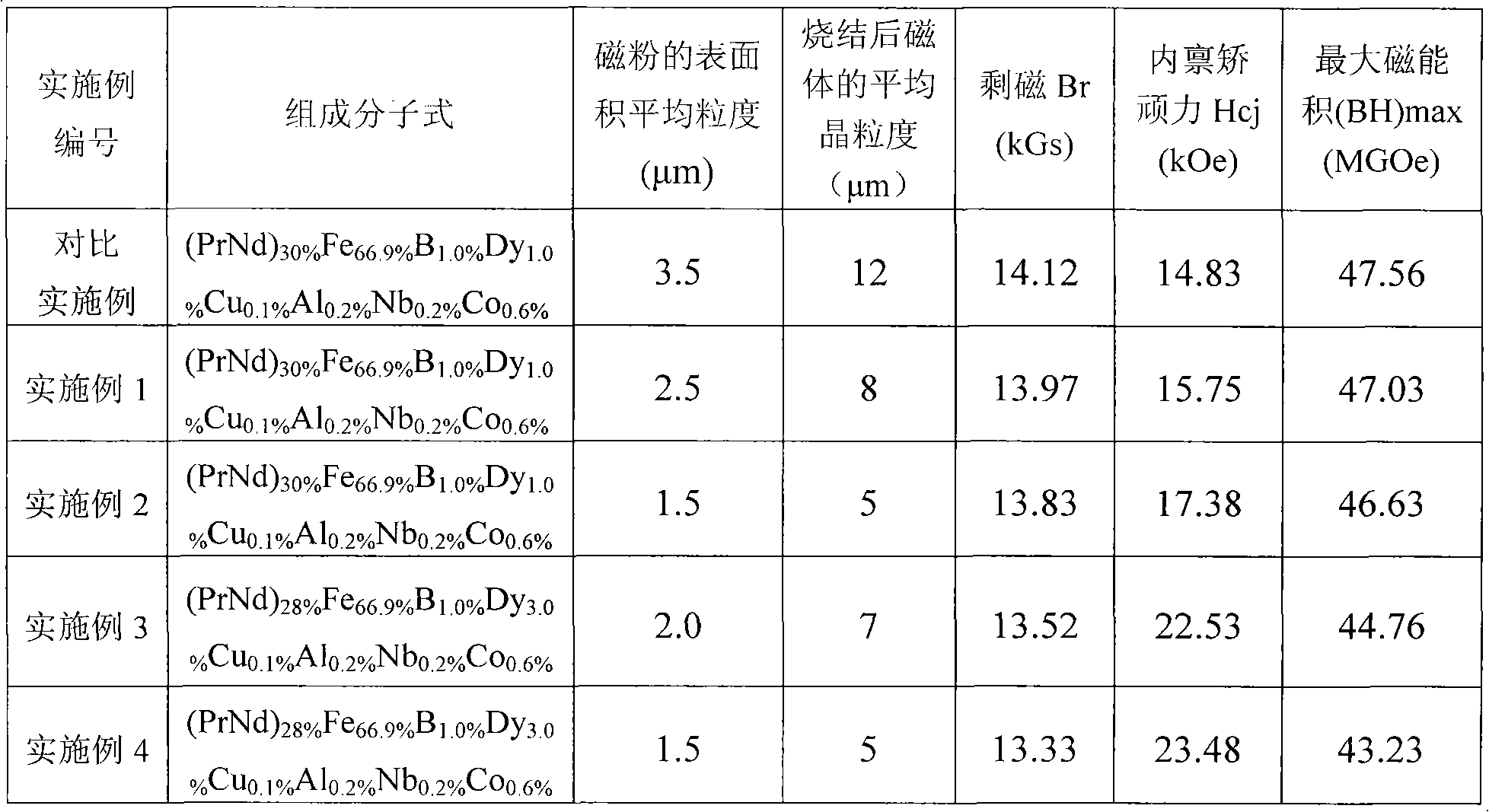

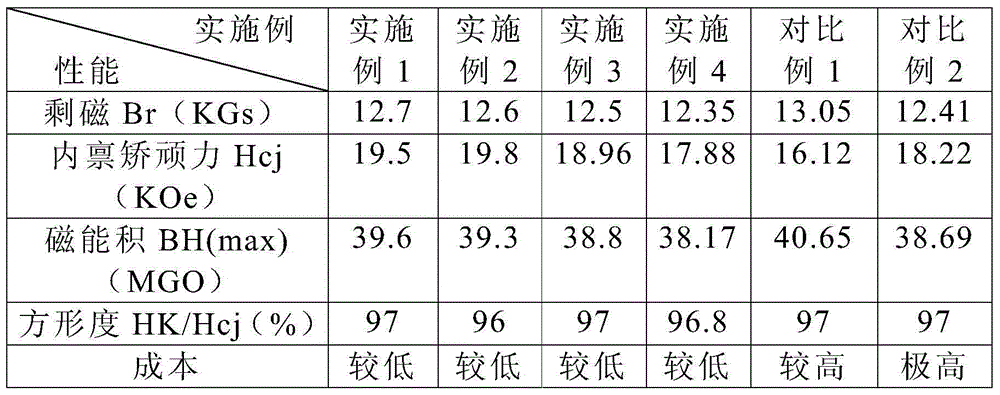

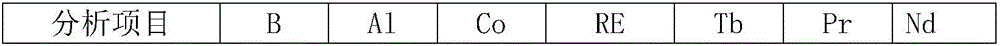

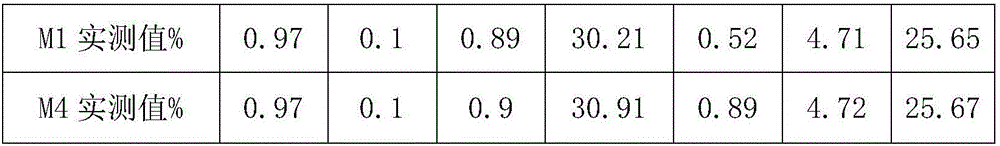

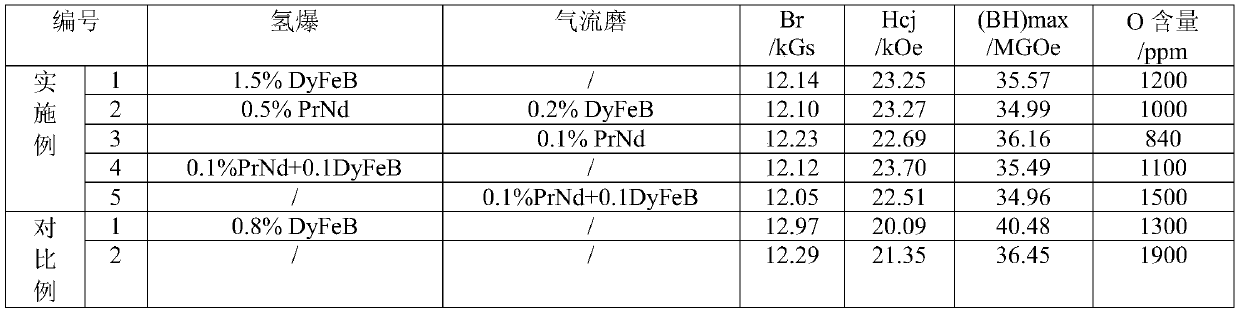

Method for preparing high-magnetic energy product high-coercive force low-cost sintered neodymium iron boron

InactiveCN102031445AReduced Surface Area Average Particle SizeImprove coercive forceMagnetic materialsNeodymium iron boronRaw material

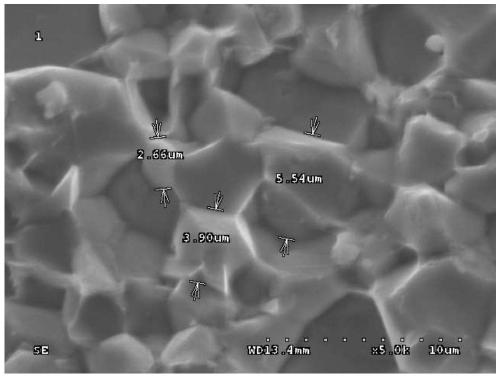

The invention discloses a method for preparing high-magnetic energy product high-coercive force low-cost sintered neodymium iron boron (NdFeB). The method comprises the following steps of: throwing raw materials into a rapid coagulating furnace and smelting in the protective atmosphere of inert gases or nitrogen, and pouring smelting liquid onto a copper roller at a roller speed of 2 to 4m / s to form a rapid coagulating thin strip with the mean thickness of 0.1 to 0.3mm; performing hydrogen breaking and jet milling to obtain magnetic powder with the superficial area mean particle size of 1.5 to 3 mu m, and orientating and molding the magnetic powder in a magnetic field to obtain a blank; and finally, sintering, cooling and ageing to obtain a sintered NdFeB magnet with the mean grain size of 5 to 6 mu m. Compared with the conventional preparation method, by optimizing the rapid coagulating process and combining the adjustment of raw materials, the preparation method makes NdFeB columnar crystals reduced during smelting; therefore, the superficial area mean particle size of the magnetic powder is reduced in the process of performing jet milling, the mean grain size of the sintered NdFeB magnet is reduced finally, and the coercive force of the sintered NdFeB magnet is improved. Therefore, the preparation method is suitable for preparing a high-magnetic energy product and low-cost high-coercive force magnet.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

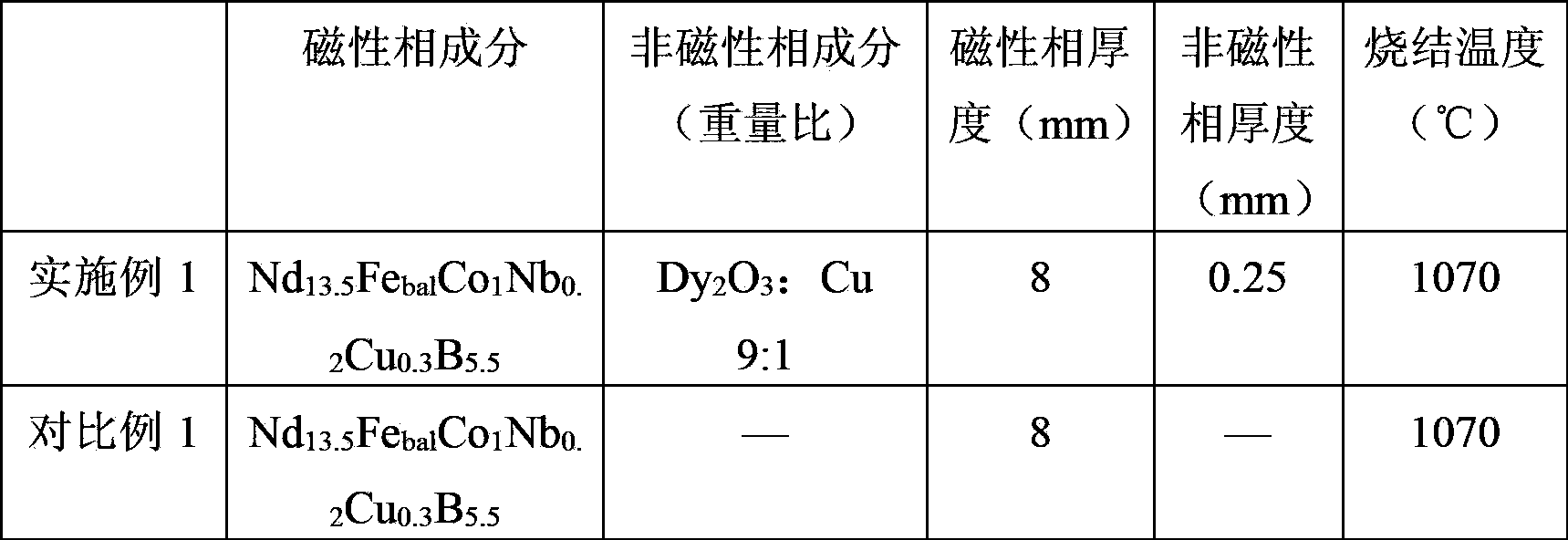

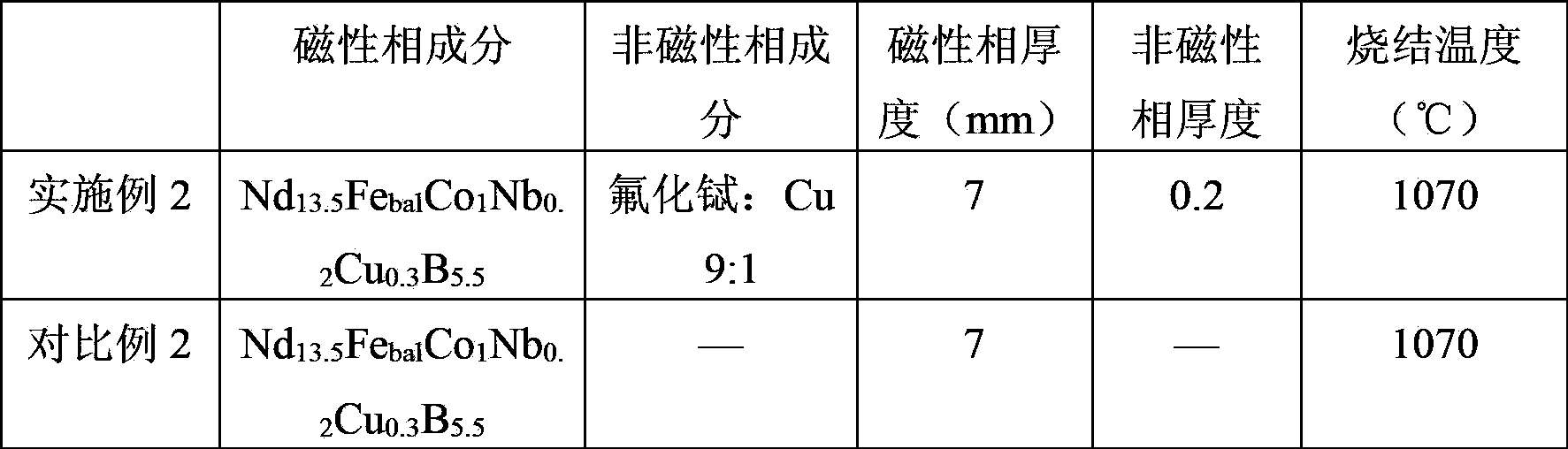

Rare earth permanent magnetic material and preparation method thereof

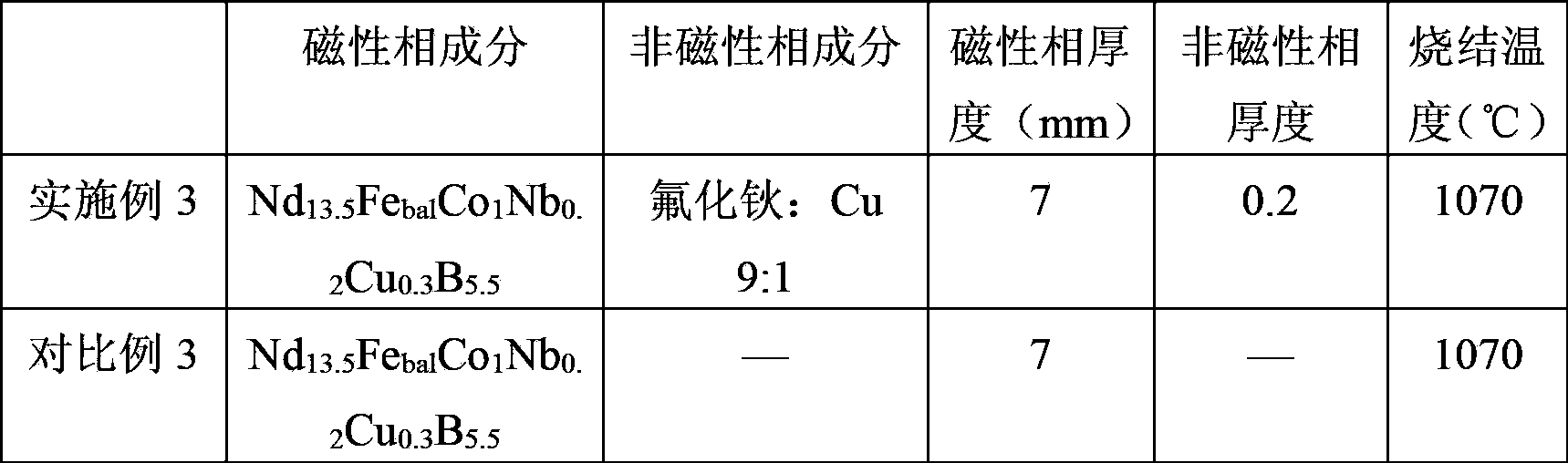

ActiveCN103903823ASimple processImproved production efficiencyInorganic material magnetismRare-earth elementMagnetic phase

The invention provides a rare earth permanent magnetic material and a preparation method thereof. The rare earth permanent magnetic material is characterized in that the rare earth permanent magnetic material is formed in the mode that a composite-structure blank composed of a magnetic phase blank and a non-magnetic phase covering the surface of the magnetic phase blank is pressed and sintered and undergoes tempering heat treatment. During preparation, firstly the magnetic phase blank is prepared in a forming stage, then non-magnetic phase mixtures comprising heavy rare earth compounds are applied to the end face of the blank, then sintering and tempering processing are carried out, and in the heat processing process, by means of grain boundary diffusion, a sintered magnet with low heavy rare earth content and high coercivity is obtained. Compared with an existing grain boundary diffusion technique, production efficiency is improved after the technique is adopted. By means of the method, heavy rare earth elements are in grain boundary of gains in the sintered magnet, and accordingly coercivity is improved and meanwhile residual magnetism is reduced to the smallest degree. By means of the method, a large magnet can be prepared, the defect that a large magnet cannot be prepared in a traditional sintered magnet grain boundary diffusion technique is overcome, and preparation and machining cost of the magnet is reduced.

Owner:宁波金鸡强磁股份有限公司

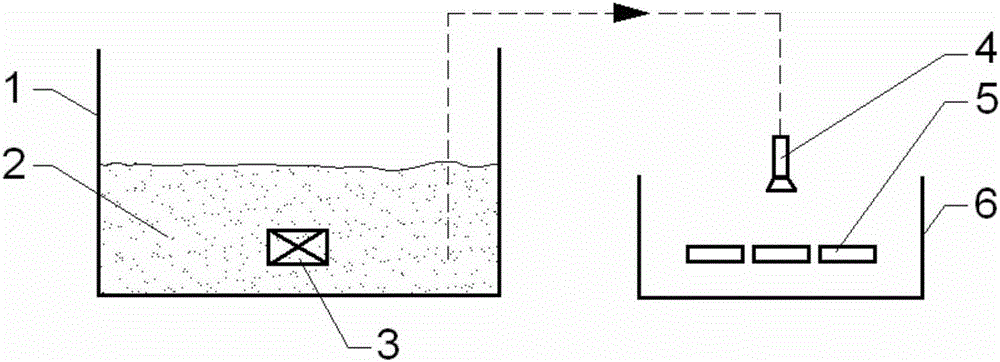

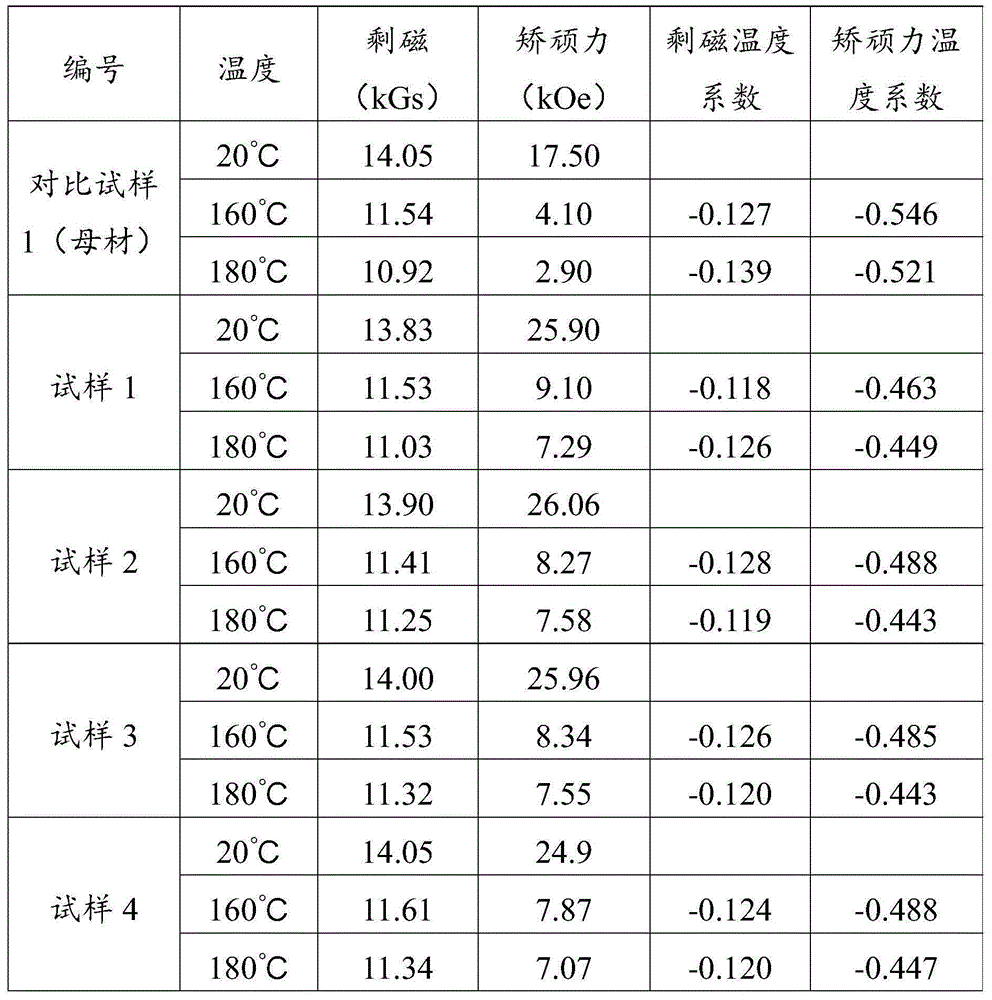

Preparation method of rare-earth permanent magnet material

ActiveCN105185501ACost-effectiveImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementSpray coating

The invention provides a preparation method of a rare-earth permanent magnet material. The preparation method provided by the invention comprises an atomized spray coating process and a permeation process, wherein a sintered rare-earth magnet which is subject to atomized spray coating is put into a closed container before permeation; a solution containing a heavy rare-earth element is subjected to atomized spray coating on the surface of the sintered R1-Fe(Co)-B-A-X-M rare-earth magnet; and heat treatment is carried out after baking, so that the heavy rare-earth element which is subjected to spray coating permeates into a grain-boundary phase of the sintered rare-earth magnet. Compared with a traditional technology, according to the preparation method provided by the invention, the amount of the heavy rare-earth element is reduced; the production cost is reduced; in addition, the coercive force of the magnet can be greatly improved under the premise of slightly reducing the residual magnetism; the residual magnetism temperature coefficient and the coercive force temperature coefficient of the magnet are obviously lowered; and the anti-demagnetization capability of the magnet at high temperature is obviously improved.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

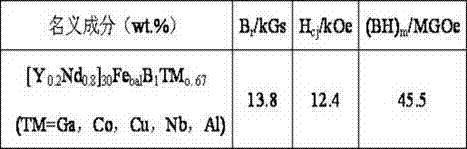

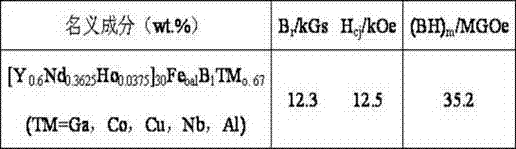

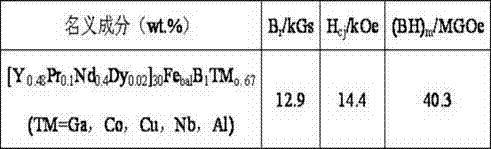

Double-principal-phase yttrium-contained permanent magnet and preparing method of double-principal-phase yttrium-contained permanent magnet

InactiveCN103545079AIncrease dosageReduce manufacturing costPermanent magnetsInductances/transformers/magnets manufactureYttriumCondensed matter physics

The invention discloses a double-principal-phase yttrium-contained permanent magnet, and belongs to the technical field of rare earth permanent magnetic materials. The chemical formula of the double-principal-phase yttrium-contained permanent magnet is (YetaRe1-eta)alphaFe100-alpha-beta-gammaBbetaTMgamma according to the mass percent, wherein the eta is larger than or equal to 0.05 and smaller than or equal to 0.6, the alpha is larger than or equal to 29 and smaller than or equal to 33, the beta is larger than or equal to 0.8 and smaller than or equal to 1.4, the gamma is larger than or equal to 0.5 and smaller than or equal to 3.6, the Re is one or more of elements of Nd, Pr, Dy, Tb and Ho, and the TM is one or more of elements of Ga, Co, Cu, Nb and Al. The double-principal-phase yttrium-contained permanent magnet is of the double-principal-phase structure comprising a (Y, Re)-Fe-B principal phase and a (Nd, Pr)-Fe-B principal phase. According to the double-principal-phase yttrium-contained permanent magnet prepared by a double-principal-phase alloy method, the good magnetic performance is kept, meanwhile, the Nd and the Pr can be greatly replaced by the relatively abundant Y, and the production cost of the double-principal-phase yttrium-contained permanent magnet is greatly reduced.

Owner:赣州诚正稀土新材料股份有限公司 +1

Method for preparing sintered neodymium iron boron by adding nanometre aluminium powder

InactiveCN104575905AImprove performanceImprove coercive forceInorganic material magnetismHydrogenRare earth

The invention relates to a method for preparing sintered neodymium iron boron by adding nanometre aluminium powder, belonging to the technical field of rare earth magnetic material. The method comprises the following steps of: weighting the raw materials according to the following prescription: RxMyBzFe1-x-y-z (x=29-35wt%, y=0-4wt%, z=0.9-1.1wt%), wherein R is selected from one or several of La, Ce, Pr, Nd, Gd, Ho and Dy, and M is selected from one or several of Co, Al, Cu, Nb, Zr and Ga; pouring the smelted raw materials into melt-spinning sheets; hydrogen-smashing the melt-spinning sheets to obtain the powders and airflow-milling the powders into micro powders; adding the aluminium powders with the average grading of 10-100nm into the micro powders according to a proportion of 0.1-1wt% and mixing; pressing and moulding, and isostatic pressing processing the mixed powders into blanks; sintering, tempering to obtain the sintered neodymium iron boron magnets. According to the invention, the residual magnetism fall is relatively little and the production cost is low while the coercive force of the neodymium iron boron magnet is improved.

Owner:NINGBO HONGLEI MAGNETICS

Preparation method of novel magnetism macromolecule hydrogel

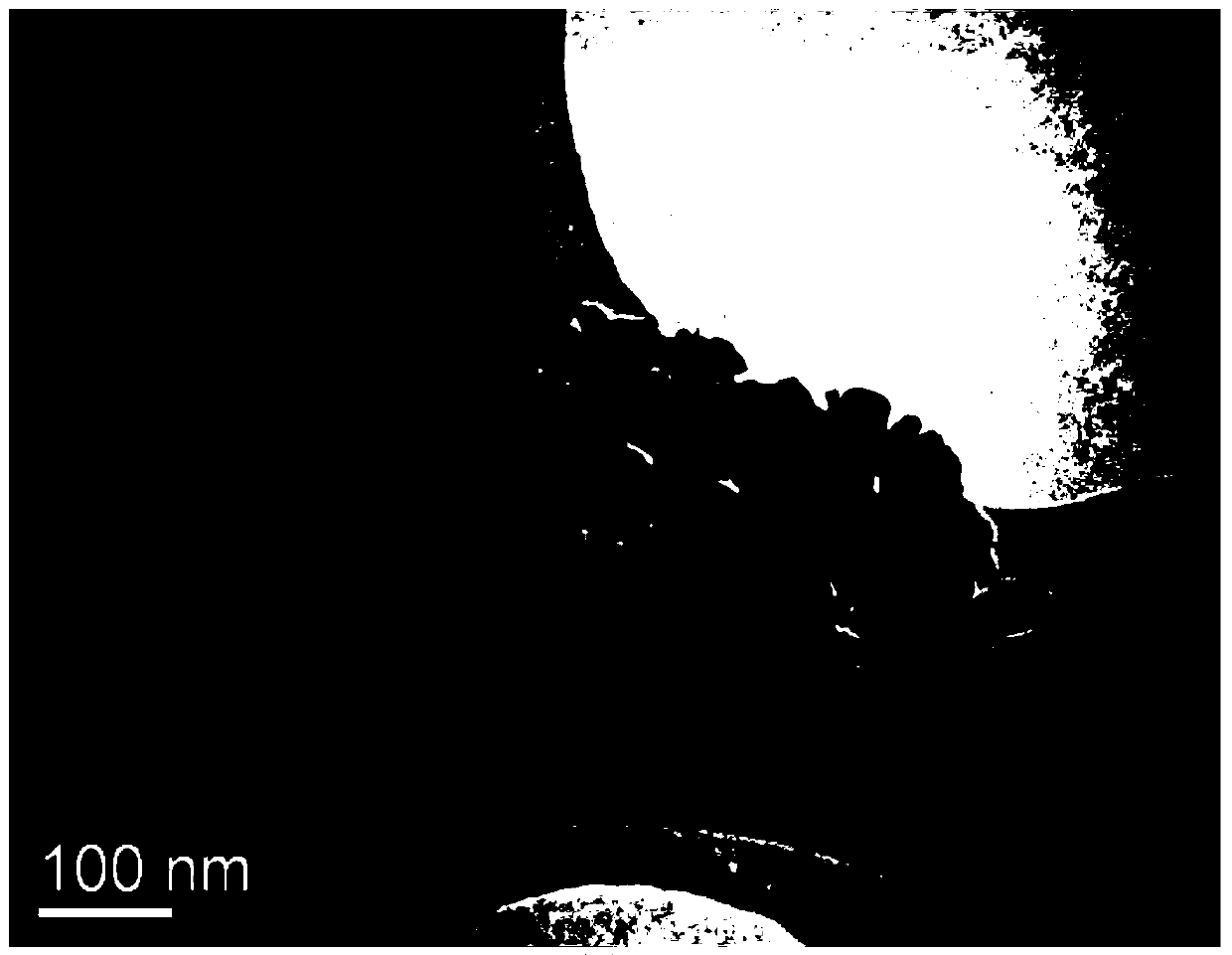

InactiveCN102391603AOvercoming the problem of uneven magnetic distributionSmall residual magnetism2-Methyl propaneCoprecipitation

The invention relates to a preparation method of a magnetism macromolecule hydrogel. In the forming process of the novel magnetism macromolecule hydrogel, iron ions enter a three-dimensional network structure of poly2-acrylamide-2-methylpropane sodium anionic hydrogel through the diffusion action and are adsorbed by sulfonate radicals in the anionic hydrogel through electrostatic interaction and stably to be stably and uniformly distributed in the hydrogel; then the iron ions generate octahedral Fe3O4 magnetic particles with the size of about 50nm to 100nm in situ in a special macromolecule hydrogel network microenvironment by a simple and soft coprecipitation method, thereby obtaining the magnetism macromolecule hydrogel with irregular and uniform-distributed Fe3O4 magnetic particles. The magnetism macromolecule hydrogel prepared by the method overcomes the problem of non-uniform magnetism distribution; and magnetic particles in the hydrogel have the appearance of regular octahedrons with the average size of 50nm-10nm, thereby leading the magnetism hydrogel to have very low residual magnetism.

Owner:扬州爱科新材料科技有限公司

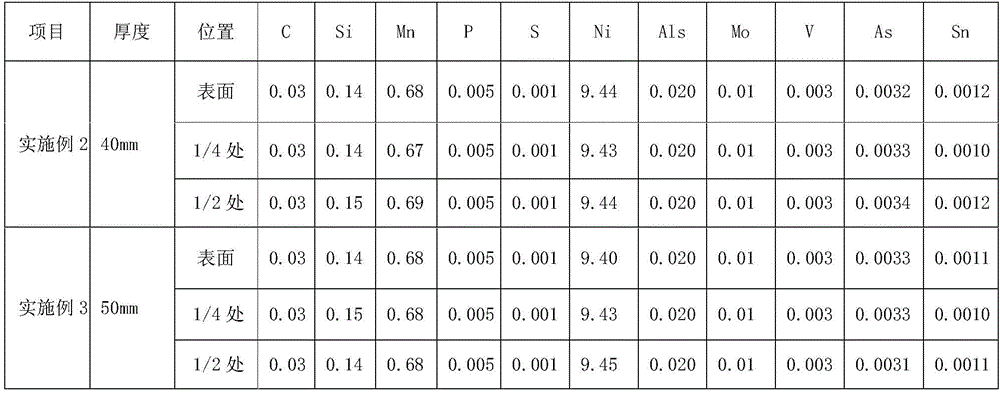

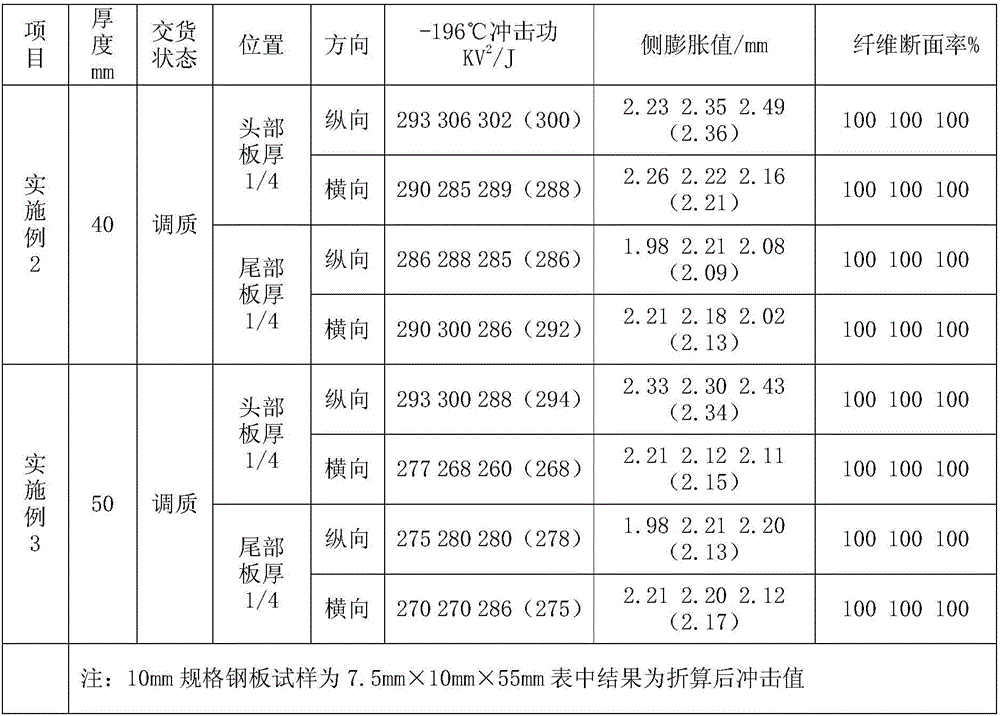

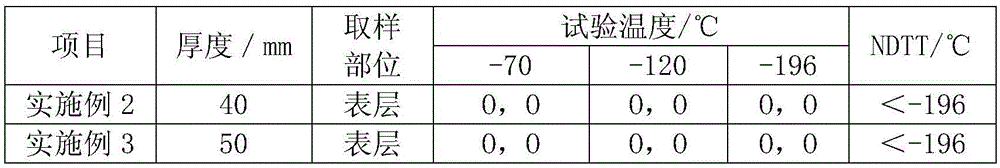

Quenched and tempered high-strength alloy steel 06Ni9DR steel plate used for ultralow-temperature pressure container and preparation method of quenched and tempered high-strength alloy steel 06Ni9DR steel plate

The invention provides a quenched and tempered high-strength alloy steel 06Ni9DR steel plate used for an ultralow-temperature pressure container and a preparation method of the quenched and tempered high-strength alloy steel 06Ni9DR steel plate. The steel plate comprises, by mass percent, 0.01 wt%-0.06 wt% of C, 0.10 wt%-0.20 wt% of Si, 0.50 wt%-0.80 wt% of Mn, smaller than or equal to 0.008 wt% of P, smaller than or equal to 0.002 wt% of S, 8.5 wt%-9.5 wt% of Ni, smaller than or equal to 0.10 wt% of Cu, smaller than or equal to 0.10 wt% of Mo, smaller than or equal to 0.005 wt% of V, smaller than or equal to 0.25 wt% of Cr and the balance Fe and inevitable impurities. According to the quenched and tempered high-strength alloy steel 06Ni9DR steel plate used for the ultralow-temperature pressure container, by means of the reasonable chemical component design, the cleanliness synergistic and effective process of steel is effectively implemented through the RH+LF+RH process, and the prepared steel plate has the beneficial effects of being high in strength, excellent in low-temperature tenacity, good in post-welding performance, and the like.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

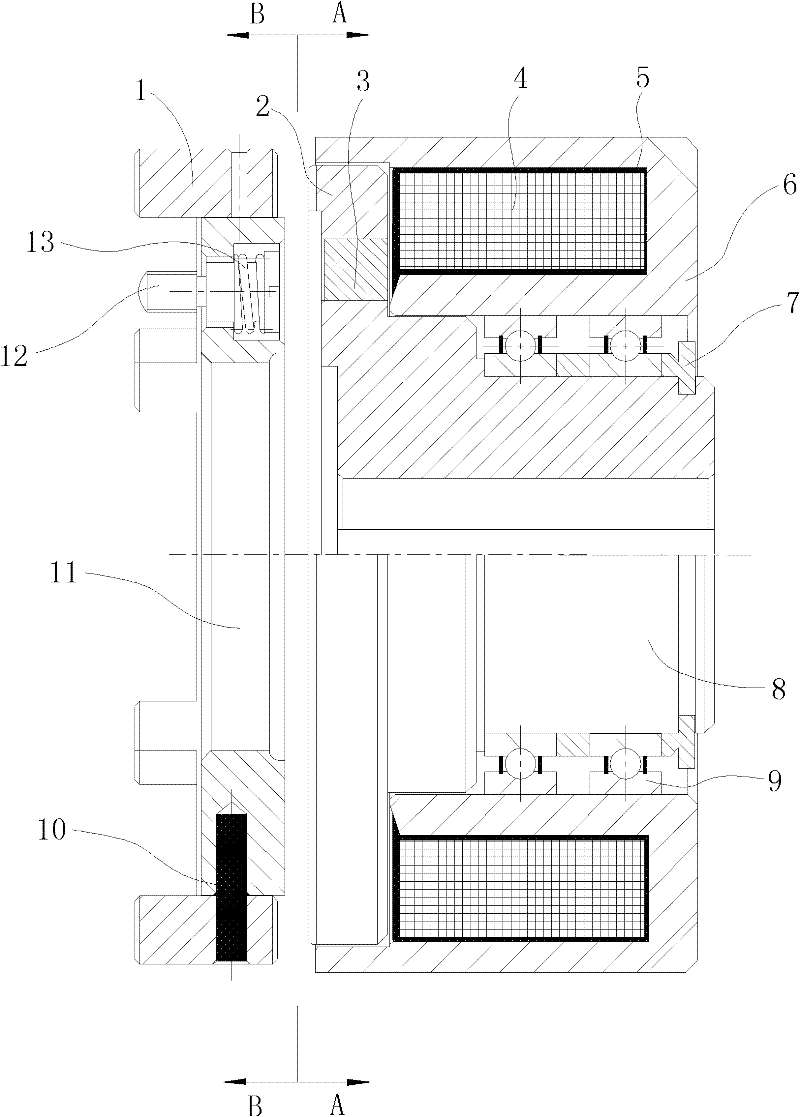

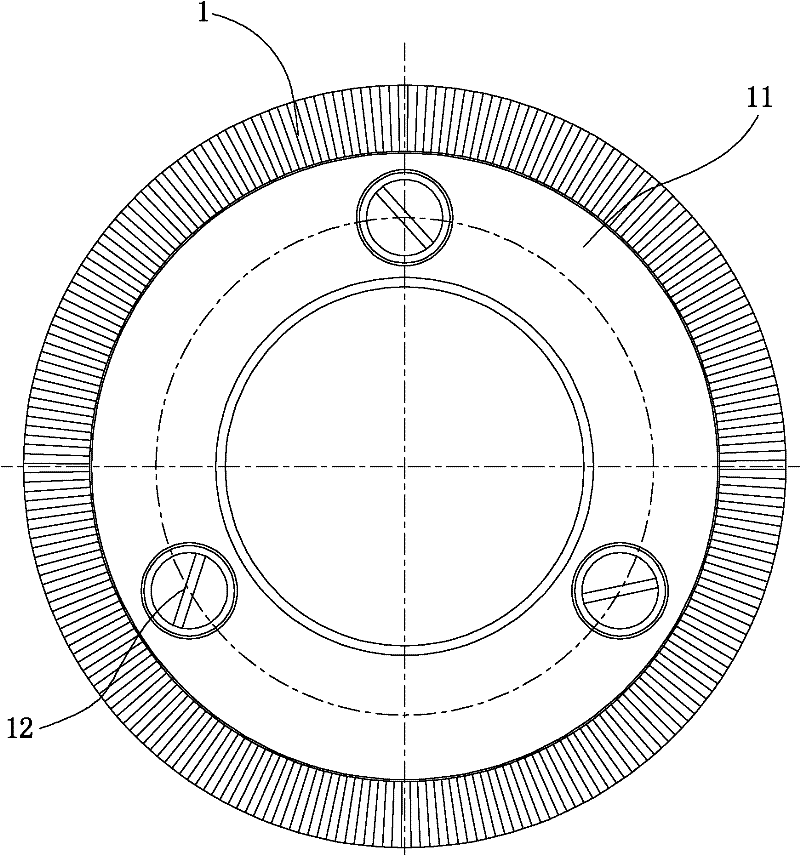

End Tooth Electromagnetic Clutch

InactiveCN102287458AQuick conversionAccurate conversionMagnetically actuated clutchesElectromagnetic clutchTorque transmission

The invention belongs to the technical field of electromagnetic clutches, and relates to an end tooth electromagnetic clutch. The end-tooth electromagnetic clutch includes a driving part and a driven part. The clutch claw, armature flange, and spring are composed of an end gear ring, a magnetic isolation ring, and a core shaft to assemble an end gear shaft, which is set in two 6807 bearings, axially positioned by a retaining ring, and assembled in the inner hole of the yoke. The coil wrapped by insulating paper is placed in the coil groove of the yoke; the armature flange is riveted in the end tooth clutch claw with a hollow pin, and the spring is set on the screw. The end-tooth electromagnetic clutch adopts end-tooth gear connection to transmit power. It has the advantages of simple structure, convenient installation and maintenance, and high transmission ratio precision, which effectively ensures the fast and accurate conversion of mechanical energy in industrial production and the transmission of torque.

Owner:王万年

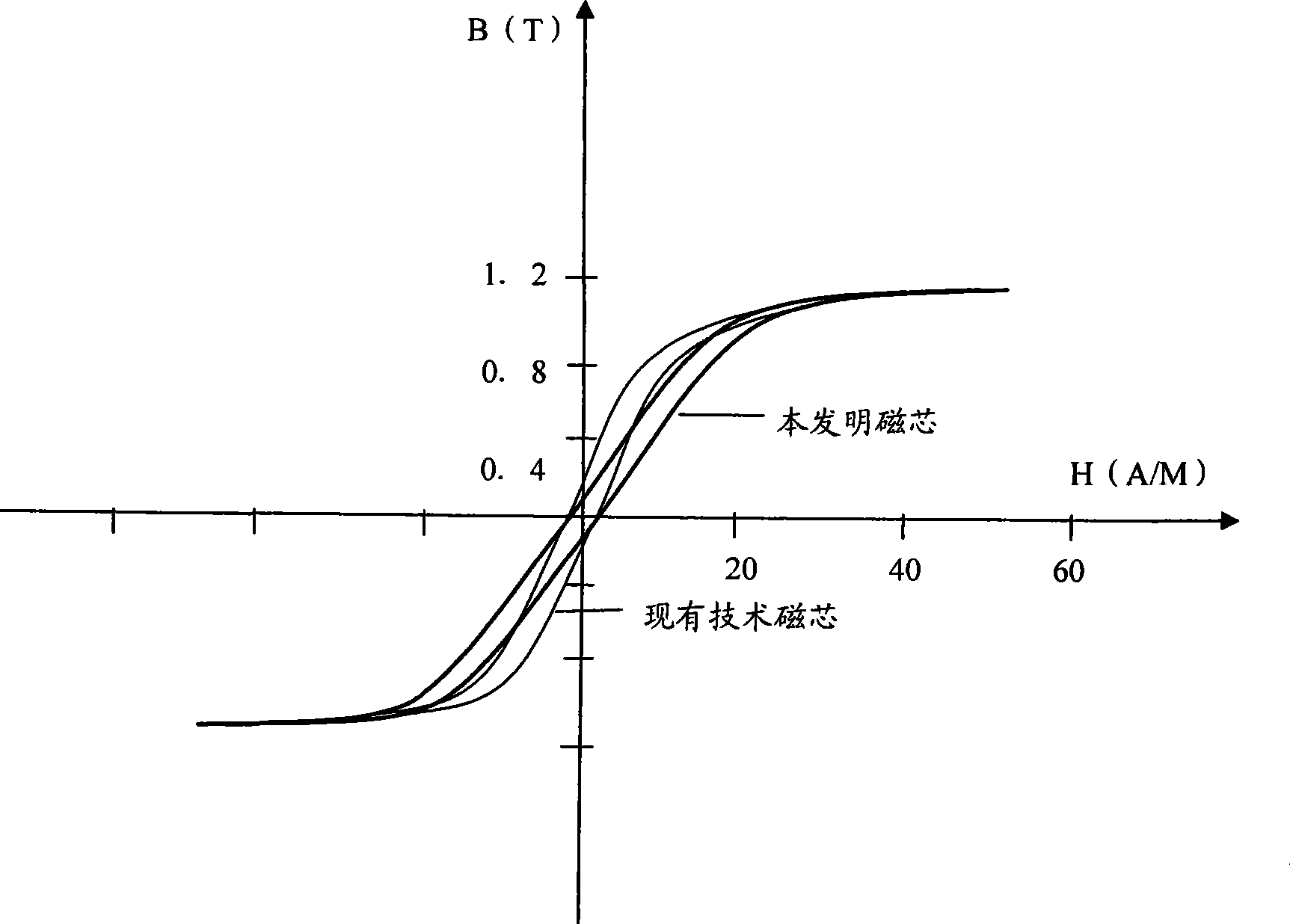

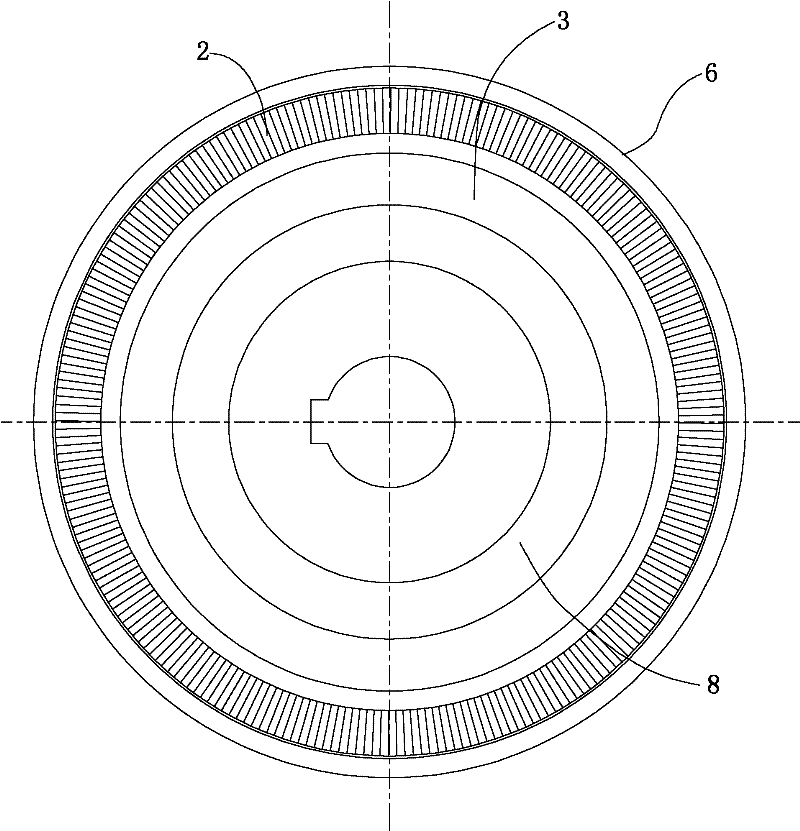

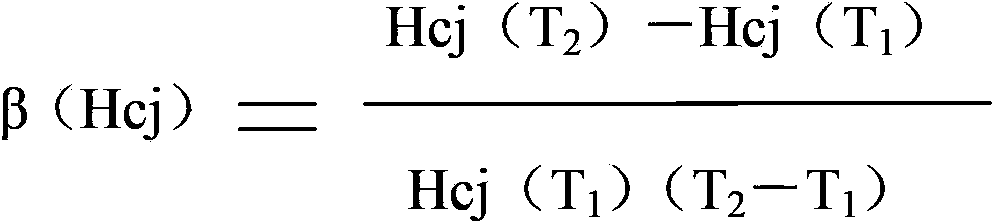

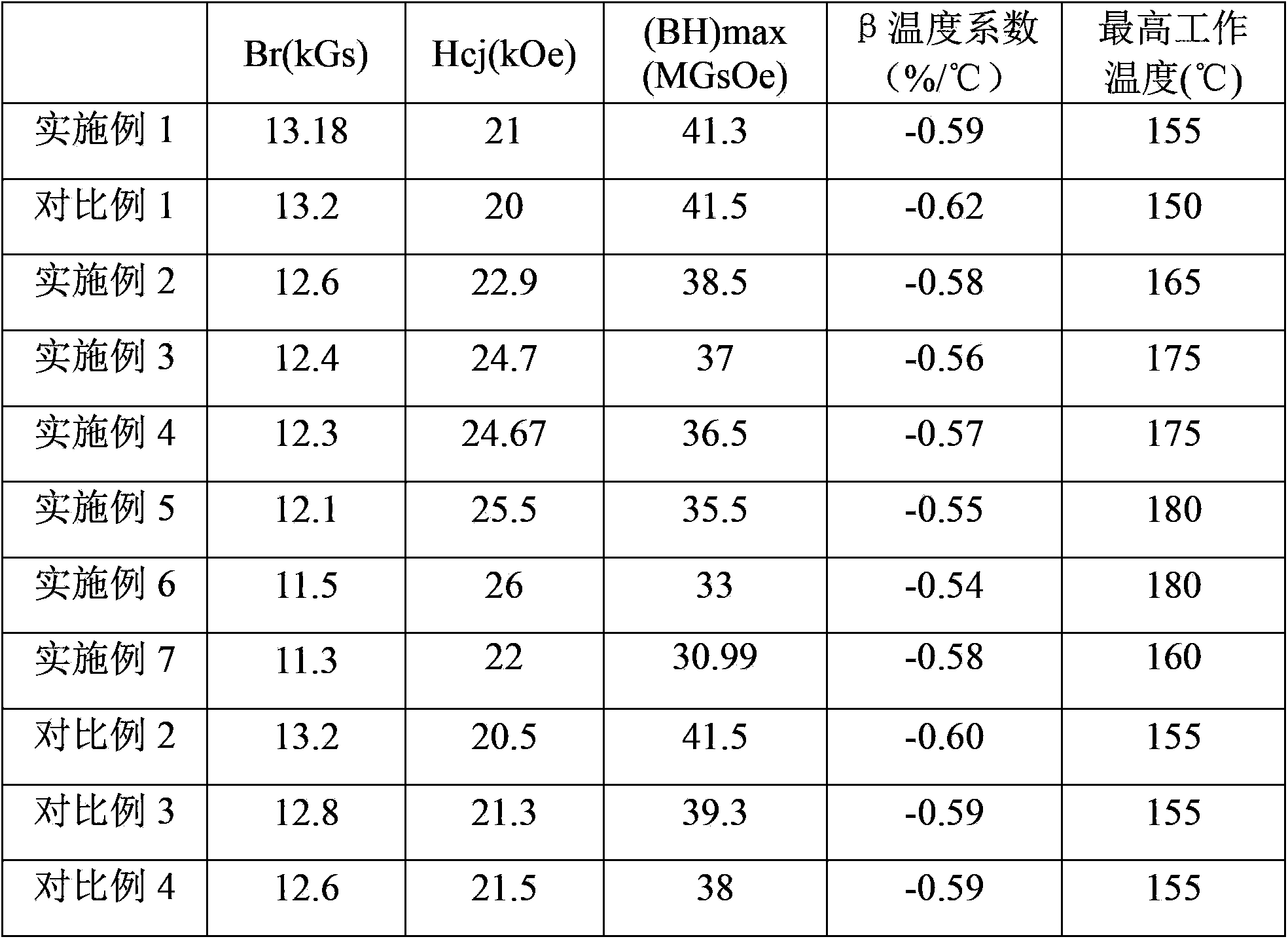

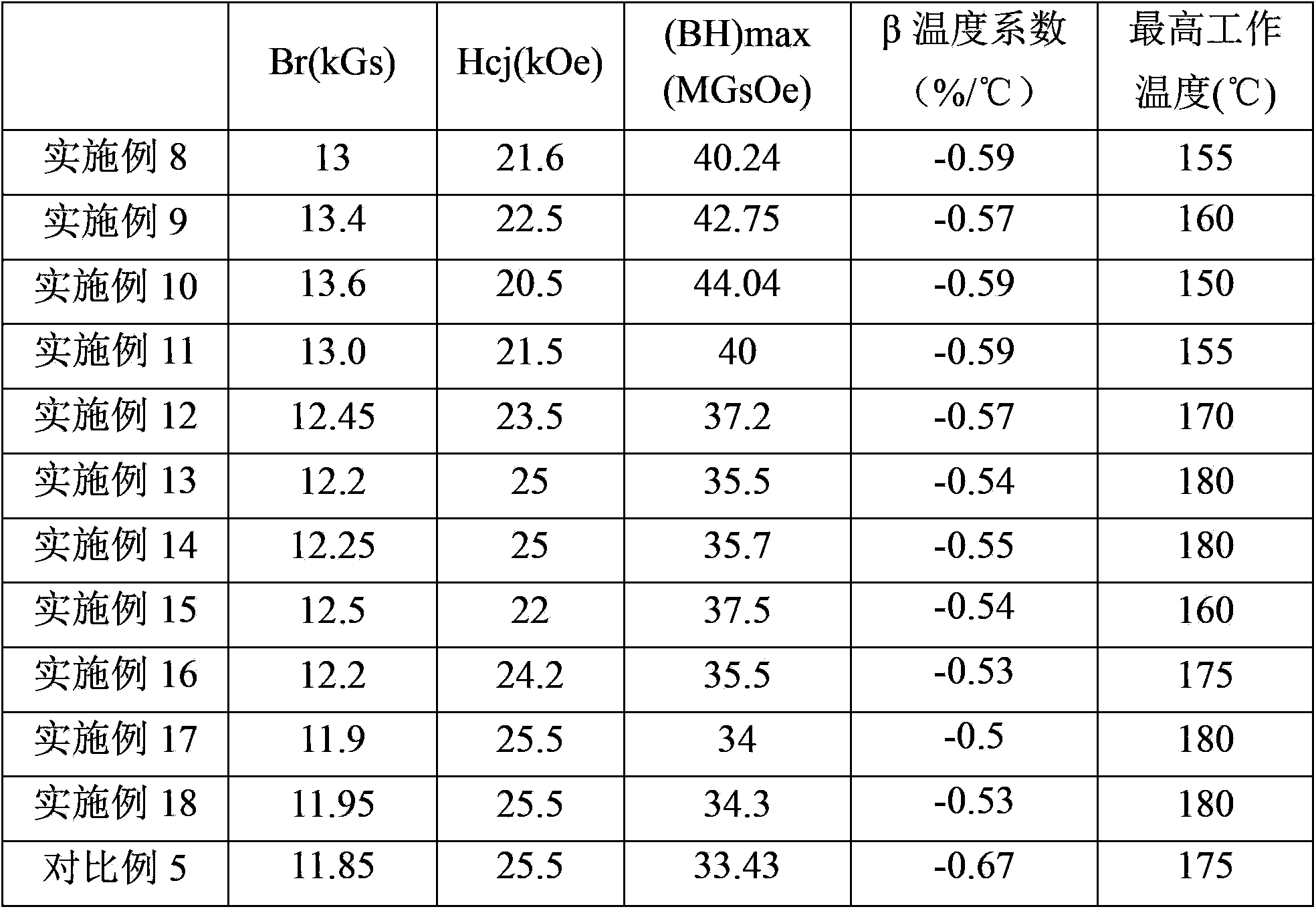

Rare earth permanent magnetic material and preparation method thereof

ActiveCN103903824AImprove coercive forceIncrease working temperatureInorganic material magnetismRemanenceMaterials science

The invention discloses a rare earth permanent magnetic material which comprises a main phase and an auxiliary phase. The rare earth permanent magnetic material is characterized in that the main phase constitutes R1xR2yFe100-x-y-z-uCozBu, the auxiliary phase constitutes R1aR2bFe100-a-b-c-n-vCocBnMv, total mass of the main phase and the auxiliary phase serves as a reference, and the mass content of the auxiliary phase is larger than 0 and smaller than or equal to 20%. The invention further provides a preparation method of the rare earth permanent magnetic material and the rare earth permanent magnetic material prepared in the method. The rare earth permanent magnetic material has high coercivity and a low temperature coefficient under the condition that loss of residual magnetism is little, effectively raises work temperature, obviously reduces content of arrowhead and / or terbium and reduces production cost of the permanent magnetic material.

Owner:BYD CO LTD

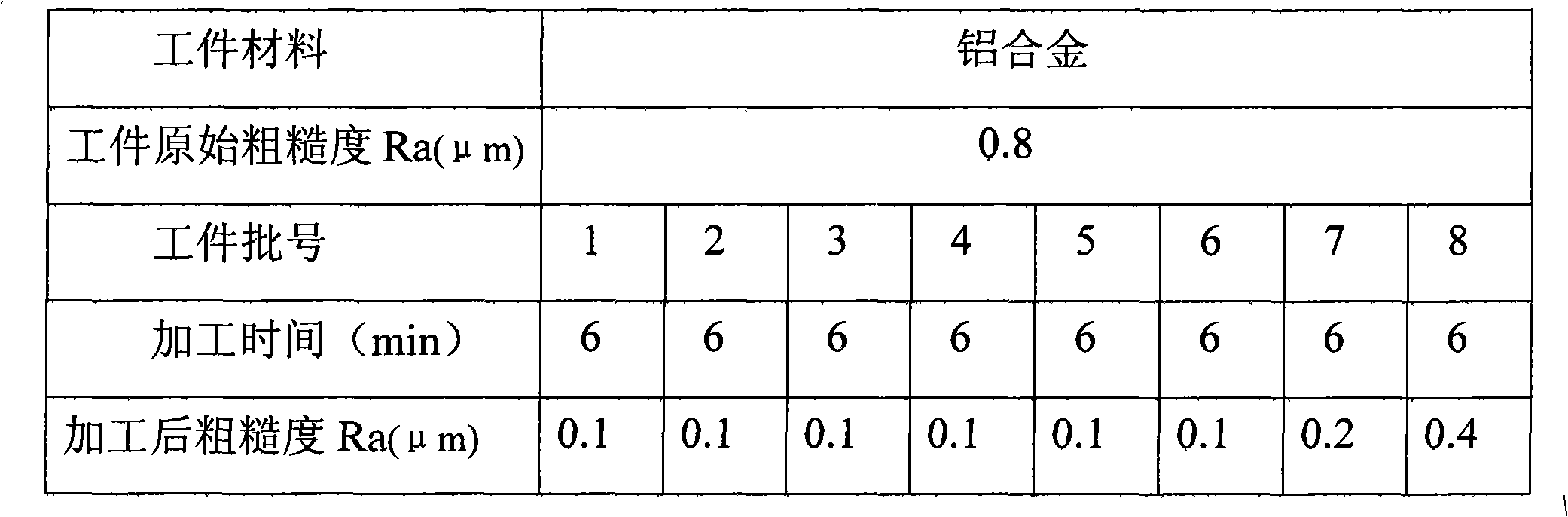

Magnetic grinding abrasive and preparation thereof

InactiveCN101353566AAvoid reunionSolving Polishing ProblemsOther chemical processesSteel ballCeramic

The invention provides a magnetic abrasive material and a method for preparing the magnetic abrasive material. The magnetic abrasive material is an acicular or spherical magnetic abrasive material with the structure of a core and a film, the core is a stainless pin or a stainless steel ball, and the film is ceramics. Through the method for preparing the magnetic abrasive material provided by the invention, a magnetic abrasive material which has strong polishing or grinding capacity and can form an ideal magnetic brush is obtained.

Owner:BYD CO LTD

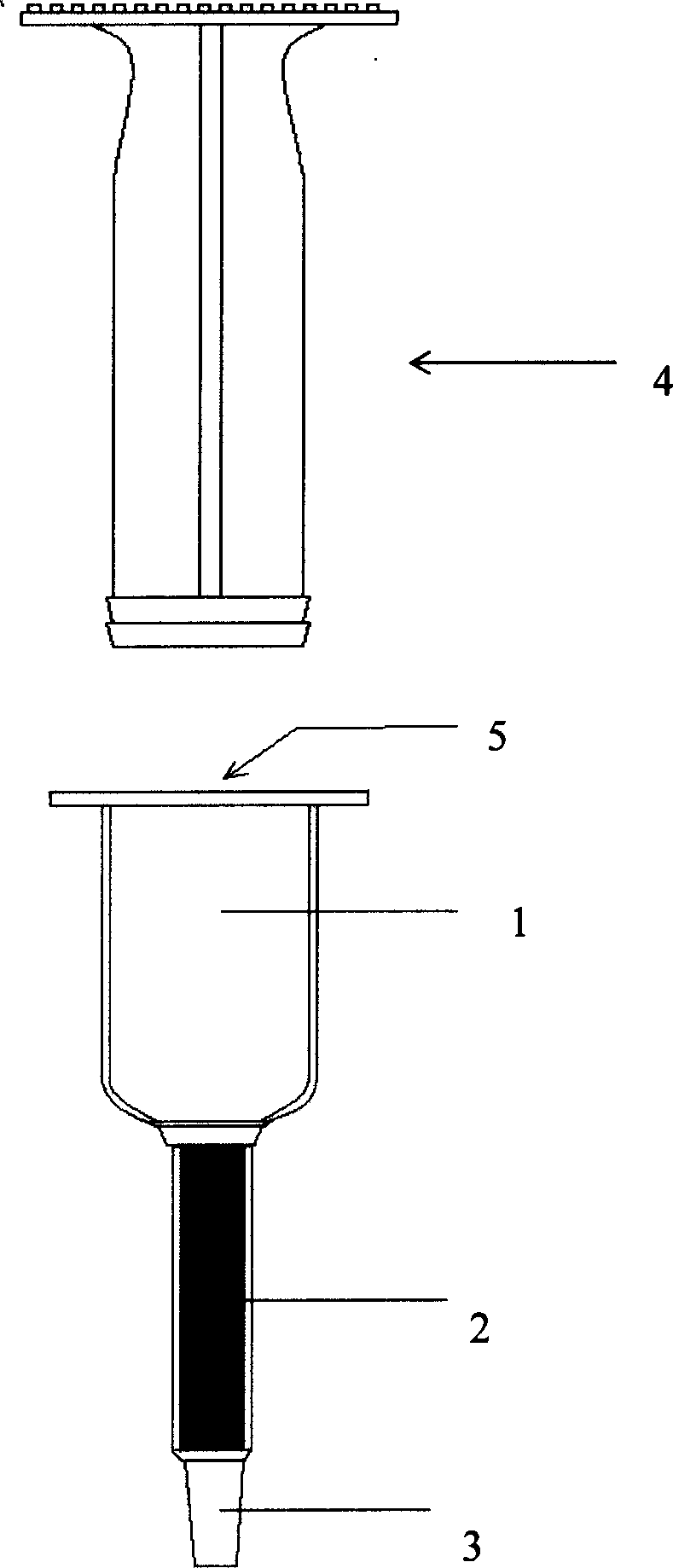

Magnetic separating colume and its use in spearating biological samples

InactiveCN1899698AEasy to makeEase of mass productionLiquid surface applicatorsInorganic material magnetismBiological pumpEngineering

The present invention relates to a kind of magnetic separating column and its application in separating biological samples. The magnetic separating column has structure comprising a material holding section, a filler column, a discharge port and a pushing plug. The filler column is filled with small magnetic soft iron balls of sizes 0.01-0.1mm, 0.1-0.2mm and 0.2-1mm separately. During separation, the sample fed through the inlet in the upper end is made to flow through the filler column and the discharge port under the gravity action, and the pushing plug applies pressure to push out the blocked sample. Under the action of outer magnetic field, the magnetic separating column can generate high gradient magnetic field for effective fast separation of various kinds of cells, subcellular matters, bacteria, viruses, nucleic acids, proteins and other biological samples.

Owner:SHANGHAI NORMAL UNIVERSITY

Low-remanence nanocrystalline magnetic core and preparation method thereof

ActiveCN107256793AAvoid direct contactImprove high temperature stabilityInorganic material magnetismInductances/transformers/magnets manufactureRemanenceWater cooling

The invention relates to the technical field of high frequency inverter power supplies, in particular to a low-remanence nanocrystalline magnetic core and a preparation method thereof. The preparation method includes the following steps: performing vacuum isothermal annealing on a Fe-Ni based nanocrystalline ribbon prepared by the single roller melt rotation rapid quenching method, and water-cooling the Fe-Ni based nanocrystalline ribbon to the indoor temperature; crushing the Fe-Ni based nanocrystalline ribbon into nanocrystalline metallic powder, performing ball-milling and shaping on the nanocrystalline metallic powder, screening the powder into first powder and second powder; evenly mixing the processed first powder and the processed second powder, pressing the mixed powder into a magnetic core; putting the formed magnetic core in a vacuum annealing furnace to perform heat treatment; performing heat treatment again; and performing glue dipping and curing treatment on the nanocrystalline magnetic core. The preparation method is simple in process, and is low in production cost; the acquired magnetic core finished product has high saturation flux density, low a loss value, low coercivity, low remanence, and high temperature resistance, is excellent in comprehensive performance, will not be damaged, and is improved in reliability.

Owner:DONGGUAN DAZHONG ELECTRONICS

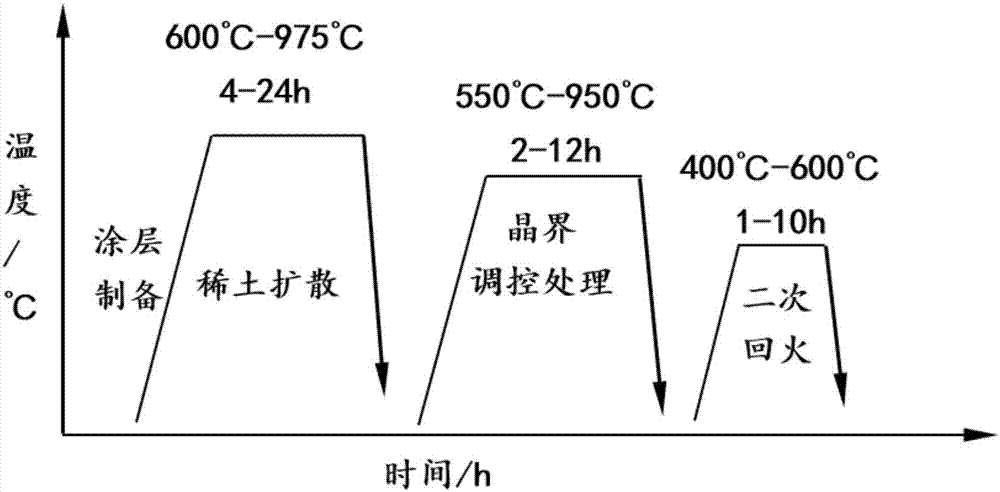

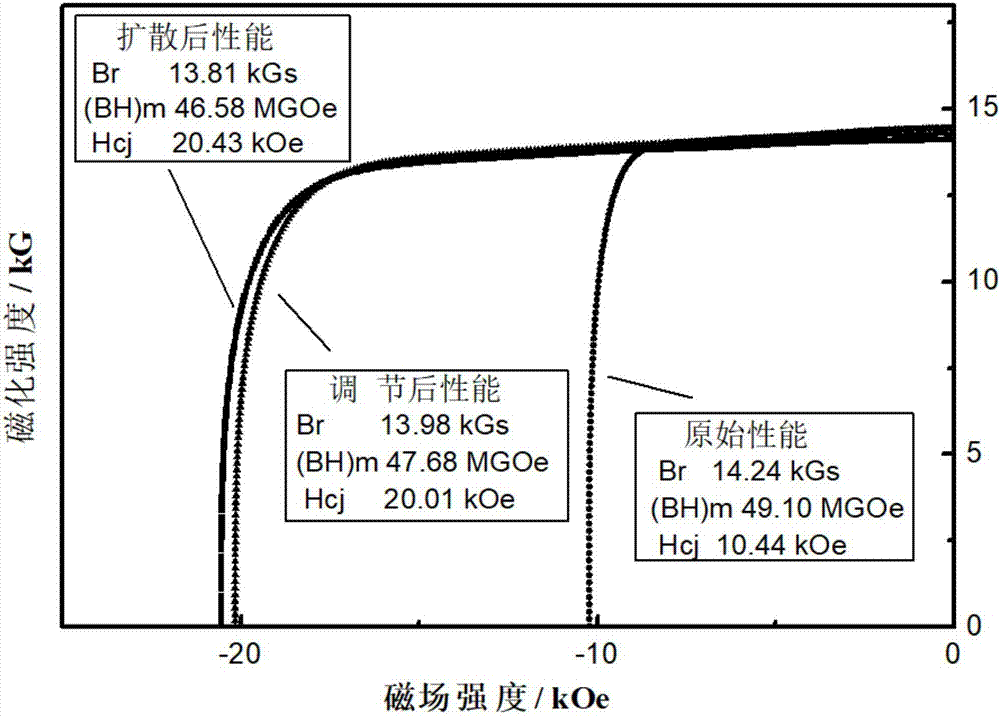

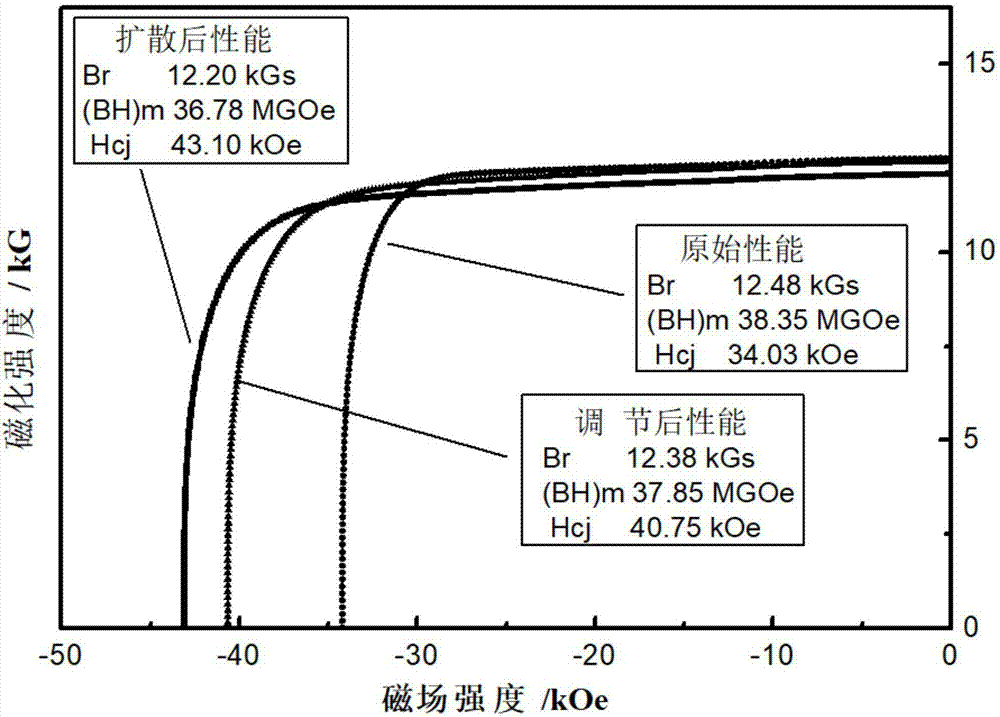

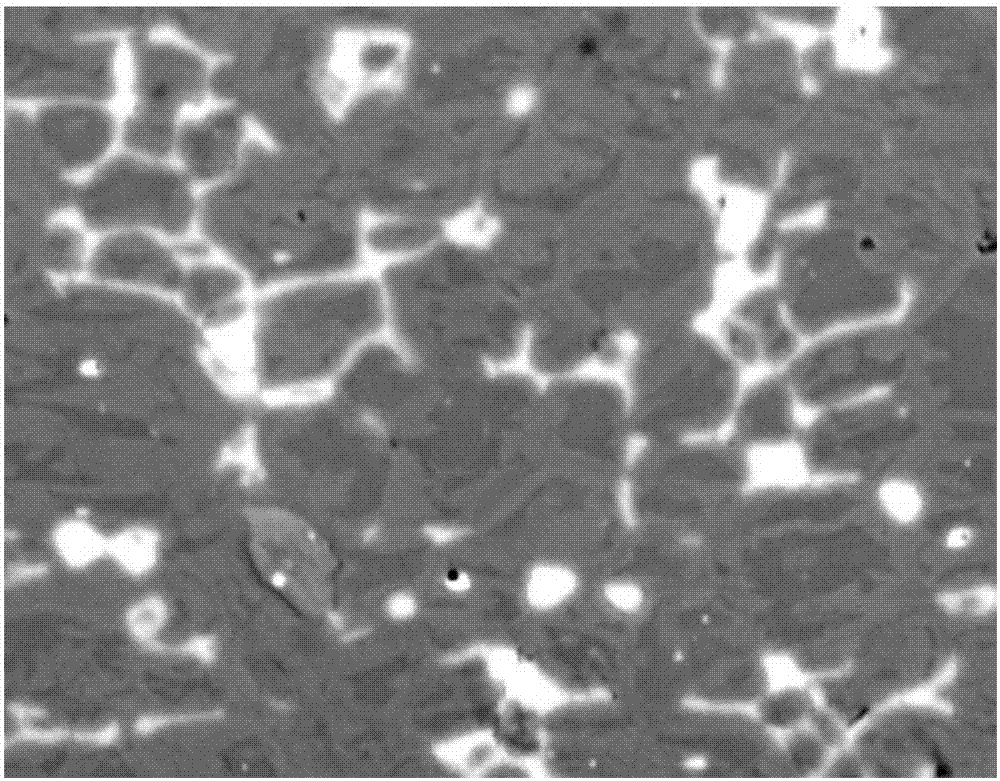

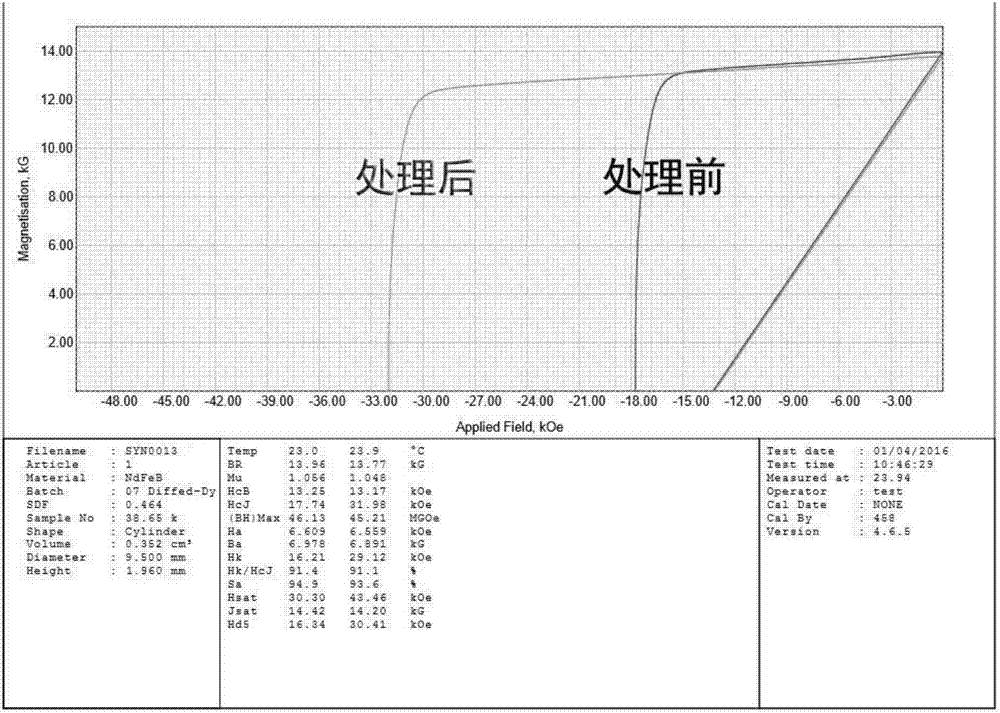

Interface control method of grain boundary diffusion neodymium-iron-boron magnet

ActiveCN107275028ASmall residual magnetismAlleviate or even eliminate remanence reduction problemsInductances/transformers/magnets manufactureMagnetic materialsDiffusionRemanence

The invention discloses an interface control method of a grain boundary diffusion neodymium-iron-boron magnet, and belongs to the technical field of rare earth permanent magnetic materials. By interface control treatment, the grain boundary structure of the neodymium-iron-boron magnet is improved, distribution of rare earth at a grain boundary and diffusing into grains is optimized, and high residual magnetism is obtained in the diffused magnet. By interface control treatment, distribution of heavy rare earth Dy and Tb inside the magnet can be controlled, the heavy rare earth Dy and Tb is only distributed on surface layers of main phase NdFeB grains, and finally, residual magnetism of the magnet reduced by rare earth diffusion treatment is restored to be approximate to level before diffusion. The method has the advantages that the problem of residual magnetism reduction caused by coercive force increased by grain boundary diffusion is solved, the magnet with high residual magnetism and super-high coercivity can be prepared and produced, and the method has a wide market prospect and remarkable economic benefits.

Owner:CENT IRON & STEEL RES INST

Neodymium-iron-boron magnet material, raw material composition, preparation method and application

ActiveCN110957091AImprove coercive forceImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementRemanence

The invention discloses a neodymium-iron-boron magnet material, a raw material composition, a preparation method and application. The raw material composition of the neodymium-iron-boron magnet material is prepared from the following components in percentage by mass: 29.5 to 32 percent of R' which is a rare earth element and comprises Pr and Nd, wherein Pr is greater than or equal to 17.15%; 0.25to 1.05 percent of Ga; 0.9 to 1.2 percent of B; and 64 to 69 percent of Fe. According to the neodymium-iron-boron magnet material disclosed by the invention, on the premise of not adding heavy rare earth elements, the residual magnetism and coercive force of the obtained neodymium-iron-boron magnet material are relatively high.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

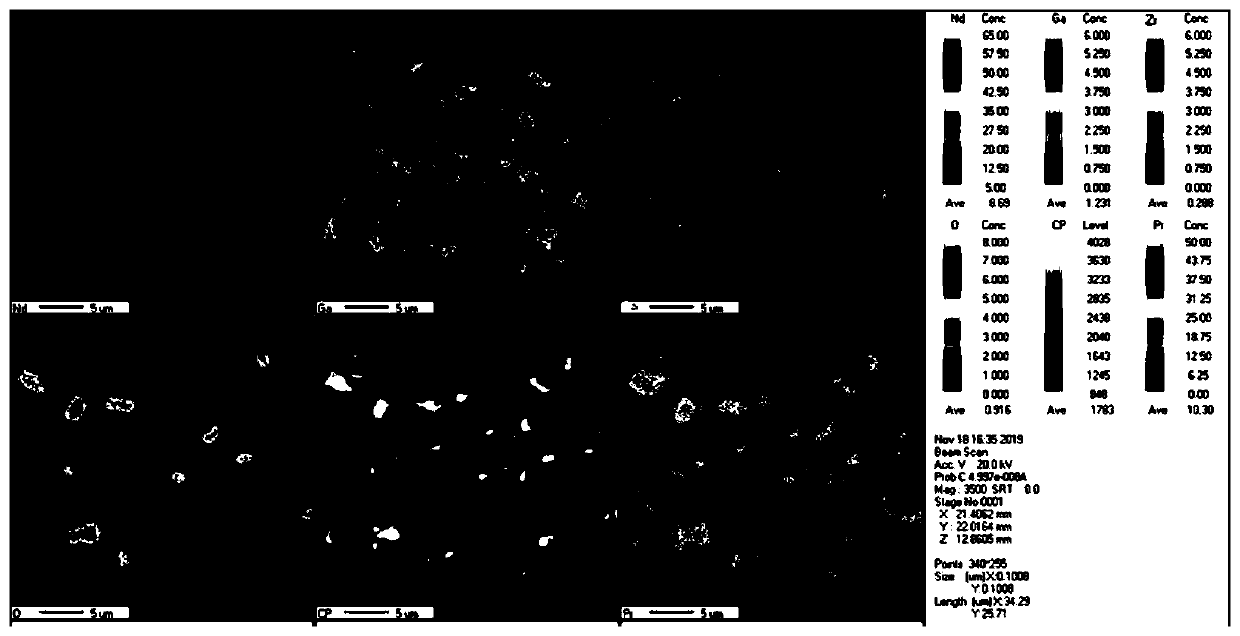

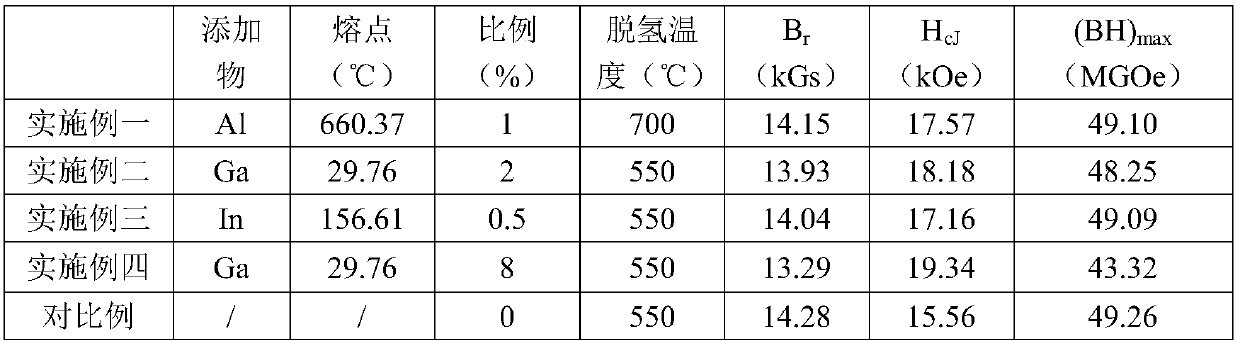

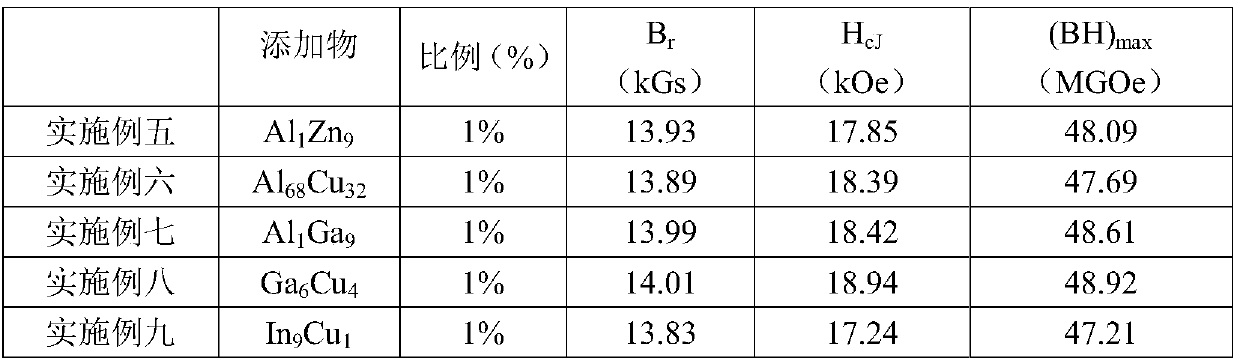

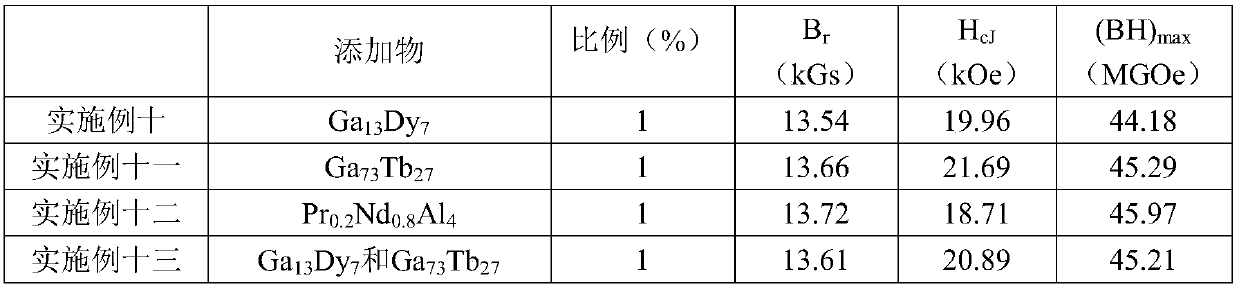

Preparation method of a sintered NdFeB magnet

InactiveCN109585113ALow heavy rare earth contentLess heavy rare earth contentInductances/transformers/magnets manufactureMagnetic materialsHydrogenRare earth

The invention discloses a preparation method of sintered NdFeB magnet. The method comprises the steps of: mixing a NdFeB alloy with a low melting point metal material to perform hydrogen crushing, andobtaining a sintered NdFeB magnet by powdering, forming, sintering and low temperature heat treatment. The sintered NdFeB magnet prepared by employing the method is high in coercive force and high inthe maximum magnetic energy product and excellent in the comprehensive magnetic properties, can save the amount of heavy rare earth and can reduce the cost.

Owner:NINGBO YUNSHENG +2

Preparation method of permanent magnet material

ActiveCN105185500AImprove coercive forceUniform penetrationMagnetic materialsRare-earth elementPressure - action

The invention provides a preparation method of a permanent magnet material. The preparation method provided by the invention comprises a coating process and a permeation process, wherein a material containing a rare-earth element coats the surfaces of sintered neodymium-iron-boron magnets; the thickness of each sintered neodymium-iron-boron magnet in one direction is at least less than 10mm; the sintered neodymium-iron-boron magnets are regularly arranged; with respective surfaces with the maximum area as contact surfaces, the sintered neodymium-iron-boron magnets tightly contact one another under the pressure action; and then the sintered neodymium-iron-boron magnets are subjected to heat treatment. By the preparation method provided by the invention, the rare-earth element can permeate evenly and the permeability is high. In addition, by the preparation method provided by the invention, the coercive force of the permanent magnet material can be greatly improved while the residual magnetism is reduced slightly.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

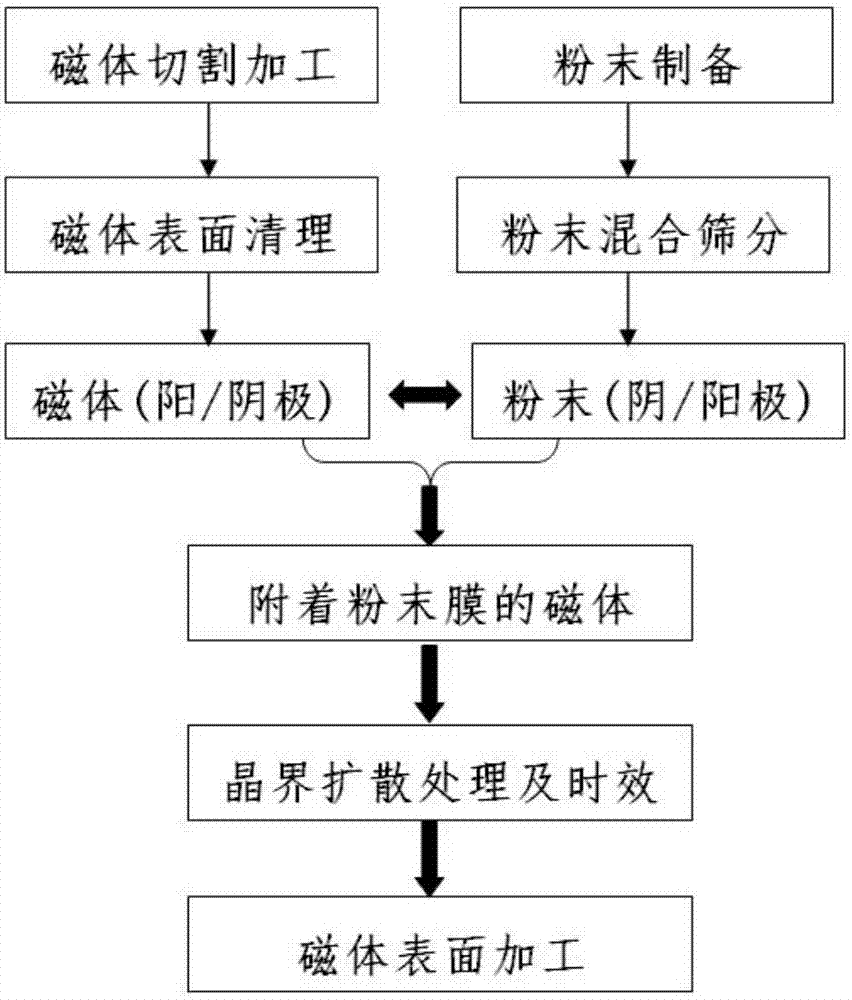

Preparation method for rare earth permanent magnet material

PendingCN107146670AReduce usageImprove performanceSolid state diffusion coatingInductances/transformers/magnets manufactureRare-earth elementSurface cleaning

The invention relates to a preparation method for a rare earth permanent magnet material. The preparation method comprises the steps of weighing powder of three kinds of raw materials of H, M and Q according to atomic percentage contents in a general formula of H<100-x-y>M<x>Q<y>, and performing mixing and screening processing in nitrogen or other oxygen-less environment to obtain composite powder; next, performing mechanical processing on a sintered NdFeB magnet to obtain specific shapes and dimensions, and performing surface cleaning and drying to obtain a to-be-processed NdFeB magnet; next, enabling the composite powder to be attached to the surface of the to-be-processed NdFeB magnet through static in an oxygen-less environment; and performing vacuum heat treatment and tempering treatment in sequence to obtain the rare earth permanent magnet material. By adoption of the method, high efficiency, high binding force between heavy rare earth element attachment and the base magnet, and convenience in residual powder recycling are realized; and the coercivity of the prepared NdFeB magnet can be improved by 4,000-14,000Oe, the residual magnetism is only reduced by 1-2%, and the heavy rare earth usage amount can be saved by 30% compared with that of the equivalent-performance magnet.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

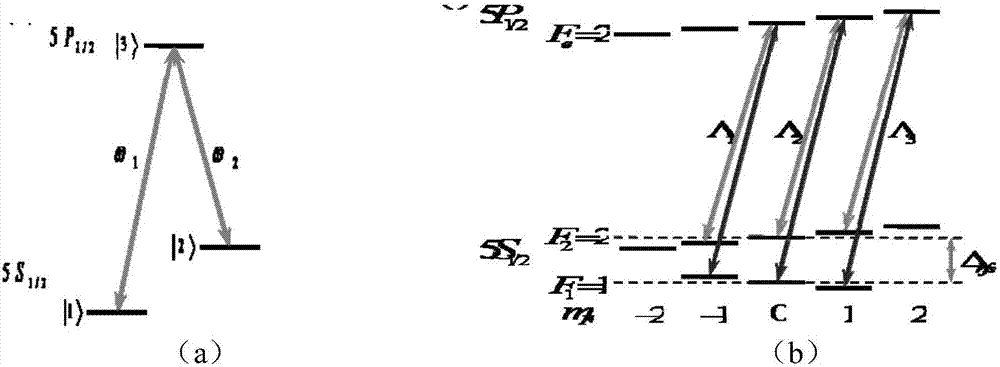

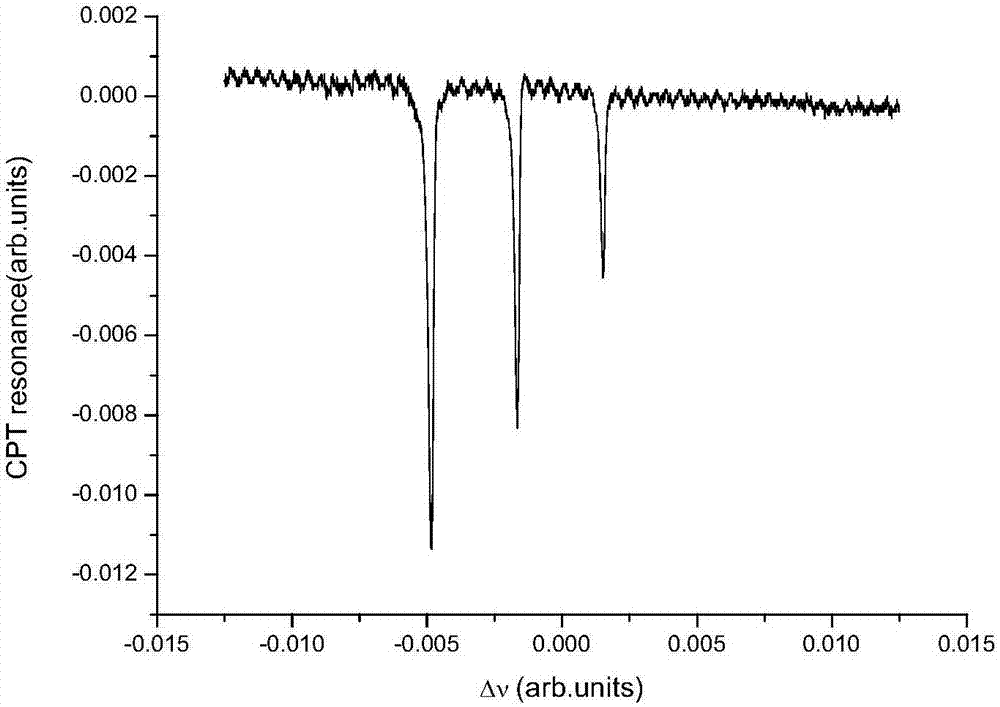

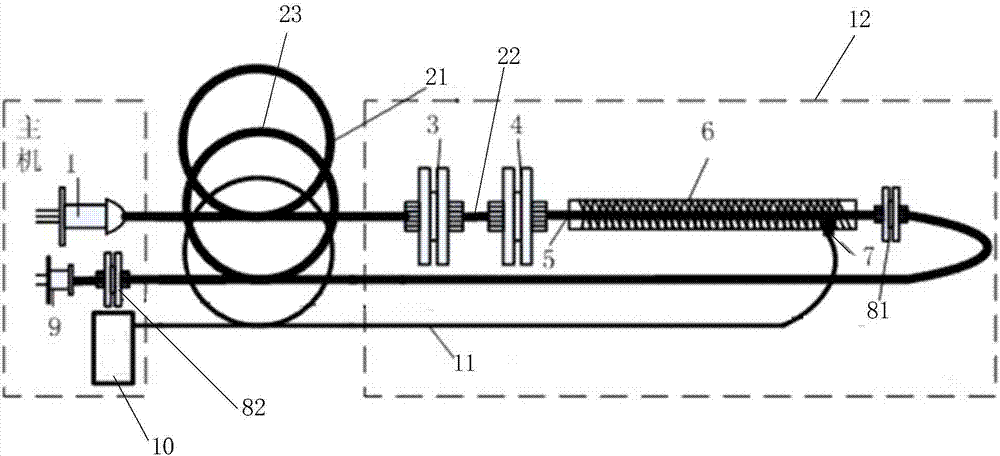

Optical fiber type CPT atomic magnetometer physical system

InactiveCN106932738ASmall residual magnetismHigh precisionMagnitude/direction of magnetic fieldsPigtailPolarization-maintaining optical fiber

The present invention provides an optical fiber type CPT atomic magnetometer physical system which comprises a host machine, a first single-mode polarization-maintaining fiber, a fiber polarizer, a second single-mode polarization-maintaining fiber, a fiber 1 / 4 waveplate, an atomic gas chamber, a twisted heating wire, a temperature sensor, a first optical fiber connector, and a third single-mode polarization-maintaining fiber, wherein the host machine comprises a pigtail VCSEL laser, an optical fiber photoelectric detector, a second optical fiber connector and a temperature control unit, the twisted heating wire is wound around the outer surface of the atomic gas chamber, the temperature sensor is arranged at the outer surface of the atomic gas chamber, the twisted heating wire and the temperature sensor are connected to the temperature control unit through temperature control cables, the twisted heating wire is used for generating heat in the atomic gas chamber, and the temperature control unit controls the temperature of the atomic gas chamber through the temperature sensor. According to the system, the difficulty of installing and debugging an optical path is reduced, the stability of outputting a CPT signal is improved, the size is reduced, the power consumption is reduced, and the precision of measuring a magnetic field is improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

A preparation method of high-performance sintered Nd-Fe-B permanent magnet material

InactiveCN109192493AStrong combinationFacilitate grain boundary diffusion processInductances/transformers/magnets manufactureMagnetic materialsAlloy elementRare-earth element

The invention relates to a preparation method of a high-performance sintered Nd-Fe-B permanent magnet material, belonging to the field of rare earth permanent magnet material. The quaternary and abovequaternary rare earth alloy films are deposited on the surface of pretreated Nd-Fe-B magnet by magnetron sputtering. The homogenization, grain boundary diffusion and low temperature tempering are used as diffusion sources to improve the boundary structure of the magnet, so that the coercivity of the magnet is greatly increased and the remanence is kept basically unchanged. The composition of thequaternary and above quaternary rare earth alloy film is LRE 100-X-Y-ZHRExMyAlz (1 <= x <= 40, 1 <= y <= 20, 1 <= z <= 20), wherein LRE is one or more of the light rare earth elements such as Y, La, Ce, Pr, Nd, HRE is one or more of the heavy rare earth elements such as Tb, Dy, Ho, and M is one or more of the alloy elements such as Cu, Fe, Co, Ga, Zr, Zn, Mn, and Mg. The rare earth alloy thin filmprepared by the invention is uniform, compact and strong in adhesion as diffusion source, the quantity is continuously controllable, and the consistency of magnetic properties of the magnet after diffusion treatment is good; It can reduce the amount of rare earth and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

R-Fe-B type sintered magnet manufacturing method

ActiveCN106298135APrevent oxidationAvoid stickingMagnetic materialsPermanent magnet manufactureRemanenceRare earth

The invention discloses an R-Fe-B type sintered magnet manufacturing method. The method mainly includes the steps that an R-Fe-B type sintered magnet is prepared as a matrix; a heavy rare earth RHX layer comprising at least one of metal dysprosium, dysprosium hydride, terbium and terbium hydride is distributed on the surface of the matrix, and an RLF layer comprising at least one of praseodymium fluoride, neodymium fluoride, praseodymium oxide and neodymium oxide is distributed on the RHX layer; heat treatment is conducted in a diffusion furnace, the heavy rare earth RHX is diffused into the magnet through the surface of the matrix. By arranging the RLF layer with praseodymium fluoride, neodymium fluoride, praseodymium oxide and neodymium oxide coatings outside the heavy rare earth RHX layer of the magnet, on one hand, magnets can be stacked in the diffusion process and the adhesion is prevented; on the other hand, the heavy rare earth RHX layer is protected against oxidation in the diffusion process, the situation that the heavy rare earth RHX layer is oxidized on the surface of the magnet and influences the diffusion effect is affected, besides, volatilization of the R element in the R-Fe-B type magnet matrix can be prevented in the diffusion process, and it is guaranteed that remanence of the magnet hardly reduces.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

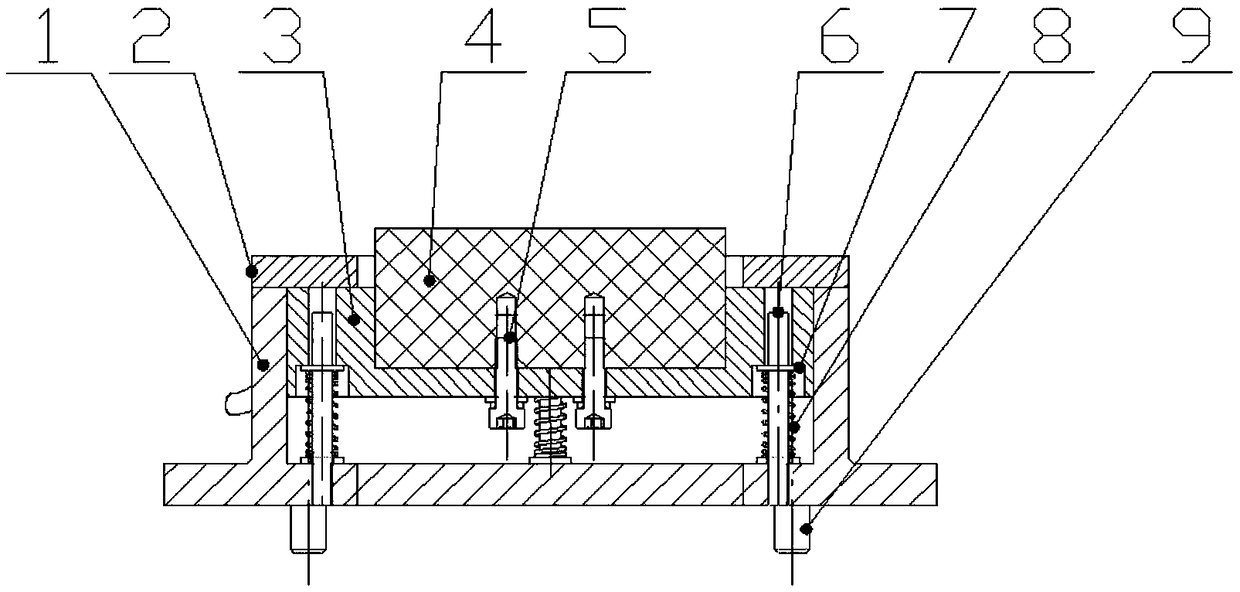

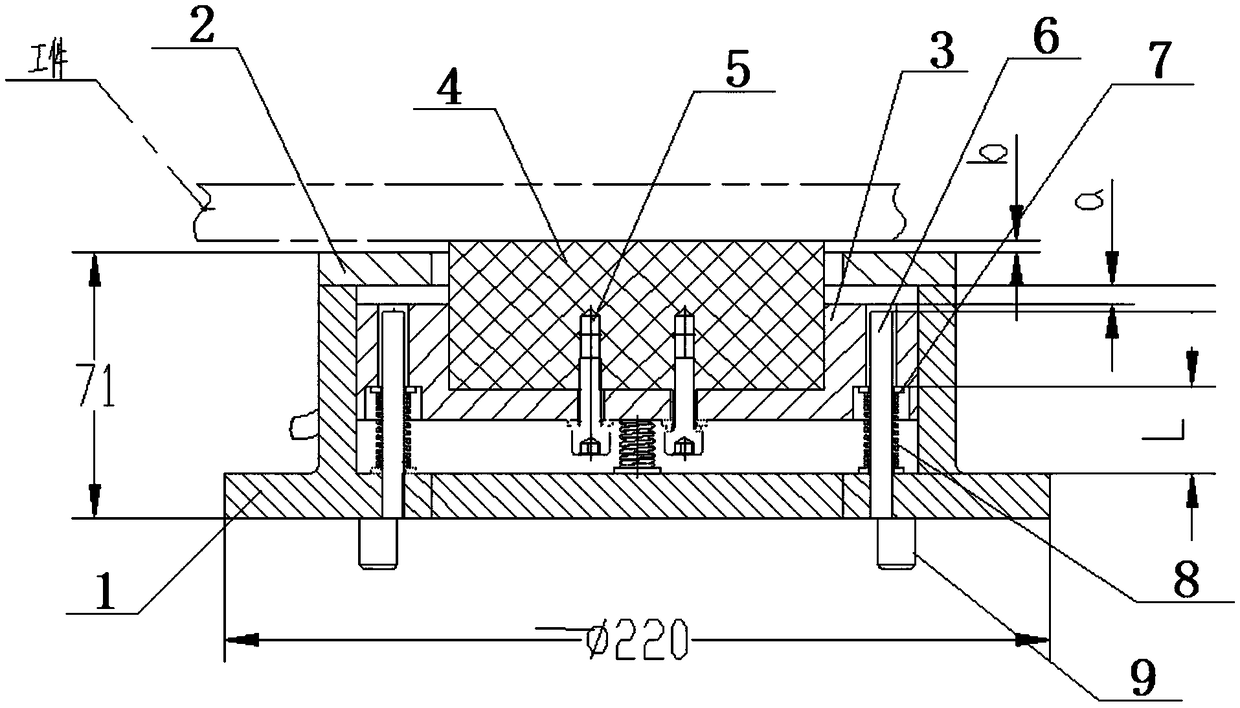

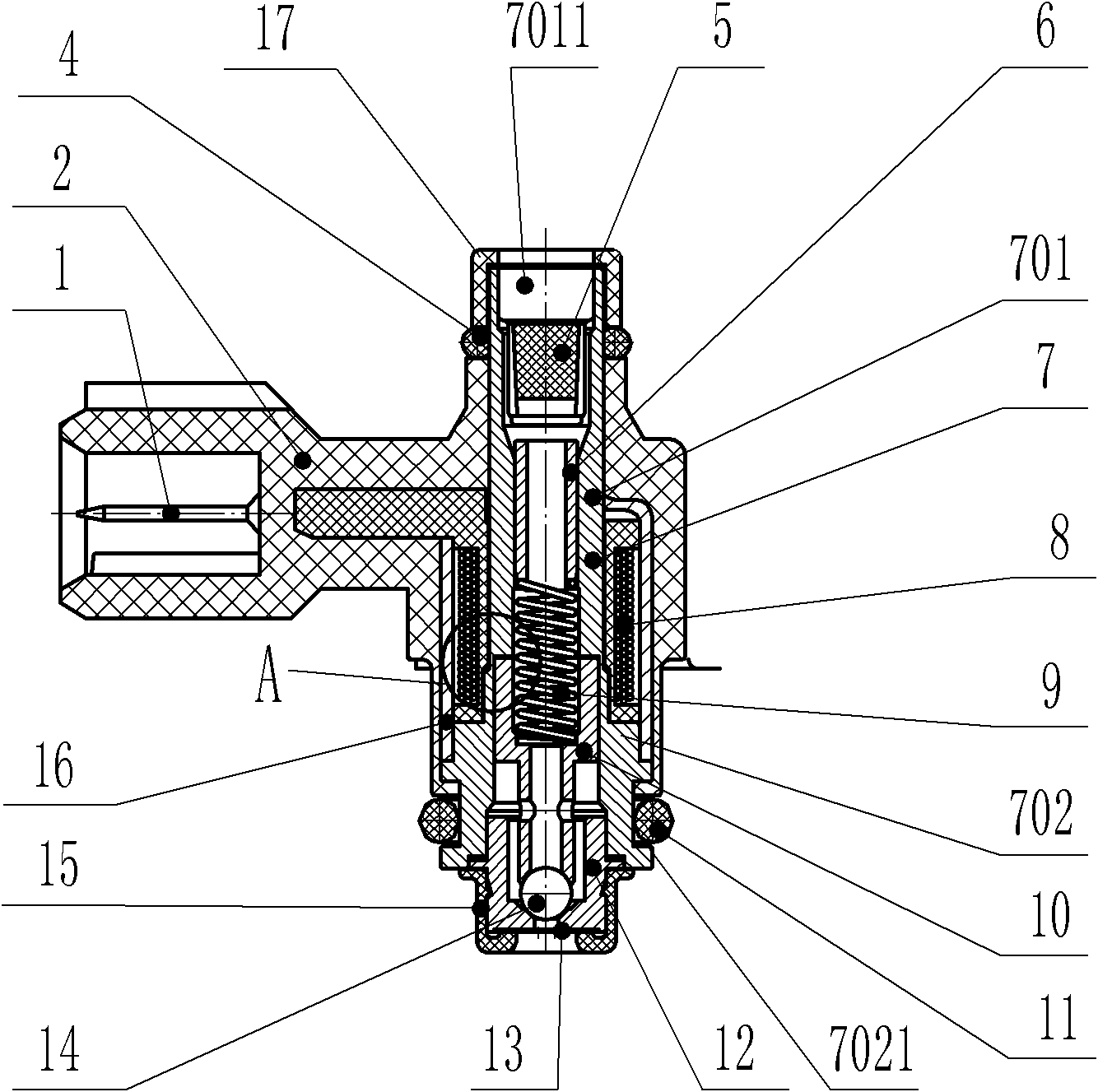

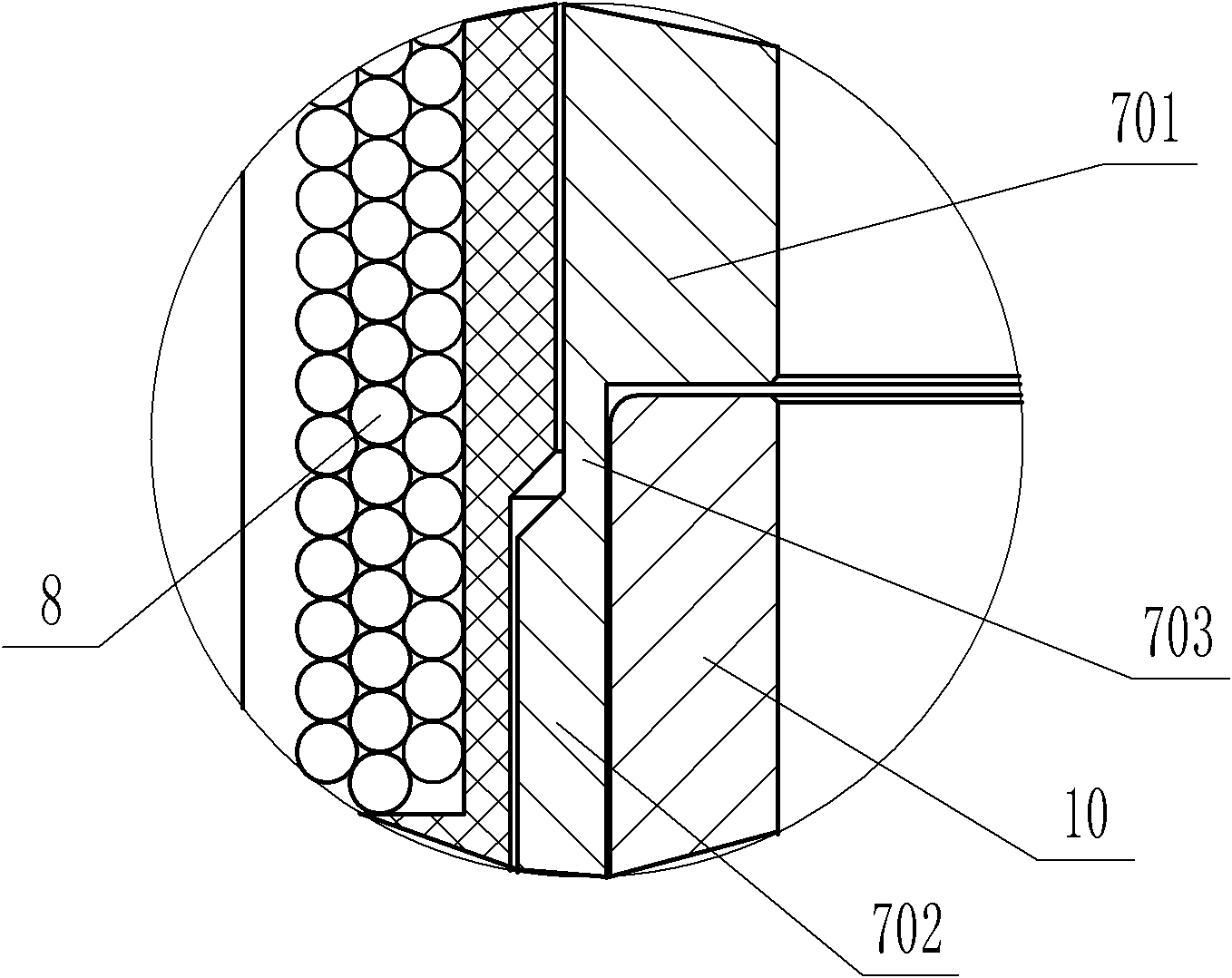

Magnetic attraction type locking and positioning device

PendingCN108953311ACompact structureEasy to installSecuring devicesFastening meansLow voltageEngineering

The invention discloses a magnetic attraction type locking and positioning device. The magnetic attraction type locking and positioning device comprises a base, a cover plate, an electromagnetic suction cup, an electromagnetic suction cup supporting base, spring guiding rods and supporting type compression springs. The electromagnetic suction cup is arranged on the electromagnetic suction cup supporting base, and the electromagnetic suction cup supporting base bearing the electromagnetic suction cup is arranged in the base. The spring guiding rods sleeved with the supporting type compression springs are arranged between the electromagnetic suction cup supporting base and the base, and the cover plate is arranged on the base. The device can adjust the pre-tightening force, low-voltage direct current power supply is utilized, and the beneficial effects of stability, strong attraction force and small residual magnetism after the power failure are achieved; and functions are safer and morereliable, the structure is simple and economical, and mounting, dismounting, maintaining and component replacement are convenient.

Owner:南京奥特自动化有限公司

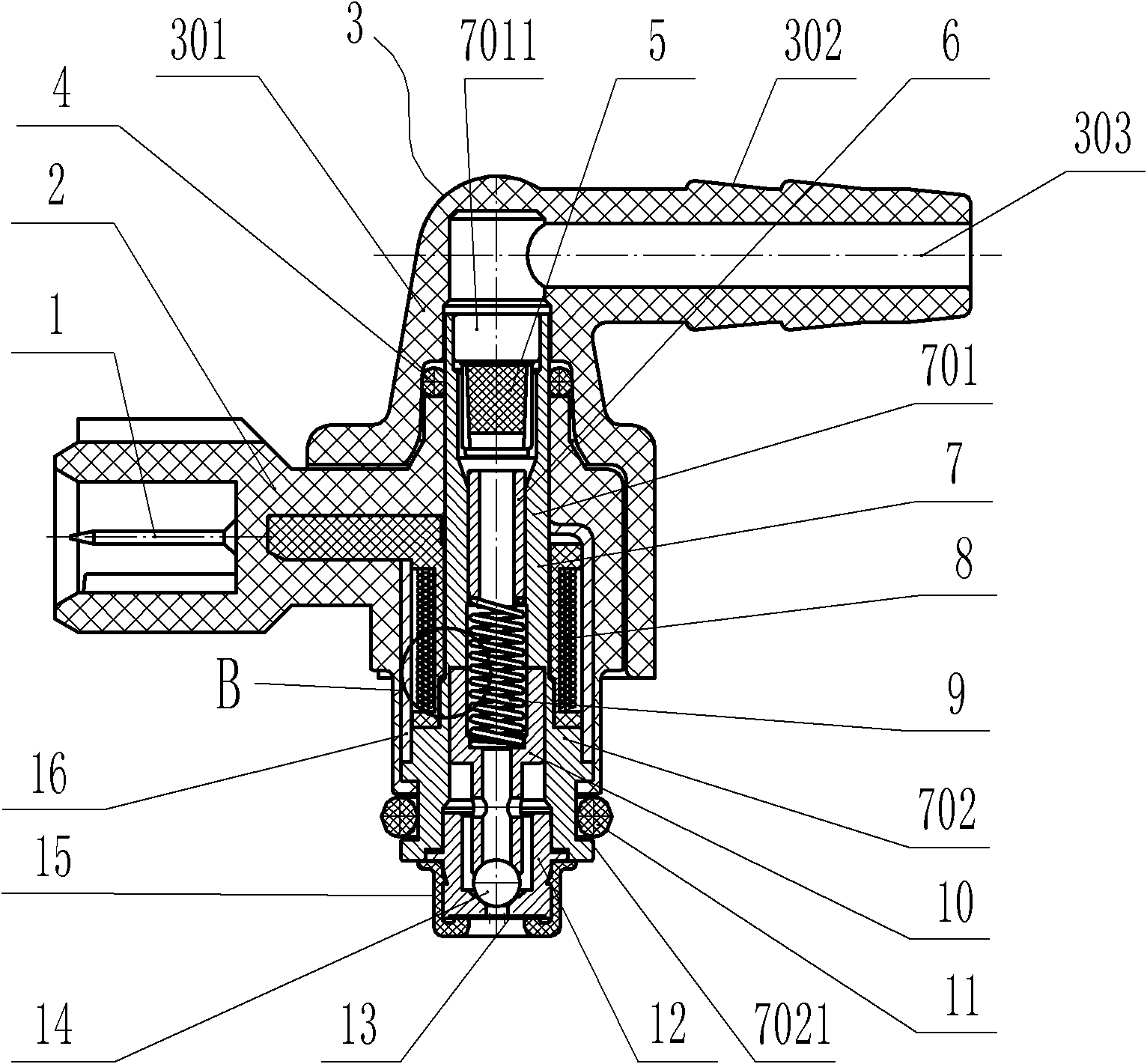

High-speed response electromagnetic valve type fuel injector for motorcycle

ActiveCN102102608AQuick responseIncrease magnetic fluxFuel injection apparatusMachines/enginesSuction forceEngineering

The invention relates to a high-speed response electromagnetic valve type fuel injector for a motorcycle, in particular relating to a fuel injector which comprises a shell, a limit pipe, an electromagnetic coil, a return spring, a valve plug, a valve seat, seal steel balls, a fuel injection pore plate and a flux sleeve, wherein the shell is internally provided with a main shaft of an integrated type turbular structure; the small end inner bore of the main shaft is sequentially provided with the limit pipe and the return spring; the large end inner bore of the main shaft is sequentially provided with the valve plug and the valve seat; the small end and large end of the main shaft are transitionally integrated at the end surface coordination part of the main shaft and the valve plug; the high-speed response electromagnetic valve type fuel injector provided by the invention is also provided with a rotary fuel cap capable of rotating by 180 degrees; and one side of the shell is provided with a mounting hole,and the other side of the shell is provided with a locating pin. According to the invention, the main shaft and a magnectic shield are designed to be integrated, not only can the magnetic flux of an electromagnetic return circuit be increased effectively, but also the residual magnetism of the electromagnetic return circuit is reduced, and the suction force of the valve plug is improved greatly, thus the resoponse speed of the fuel injector is improved, and the high-speed response electromagnetic valve type fuel injector provided by the invention has the advantages of simple structure and low manufacturing cost, and can be adaptive to the mounting requirement of the narrow space of the motorcycle.

Owner:LIUZHOU YUANCHUANG EFI TECH

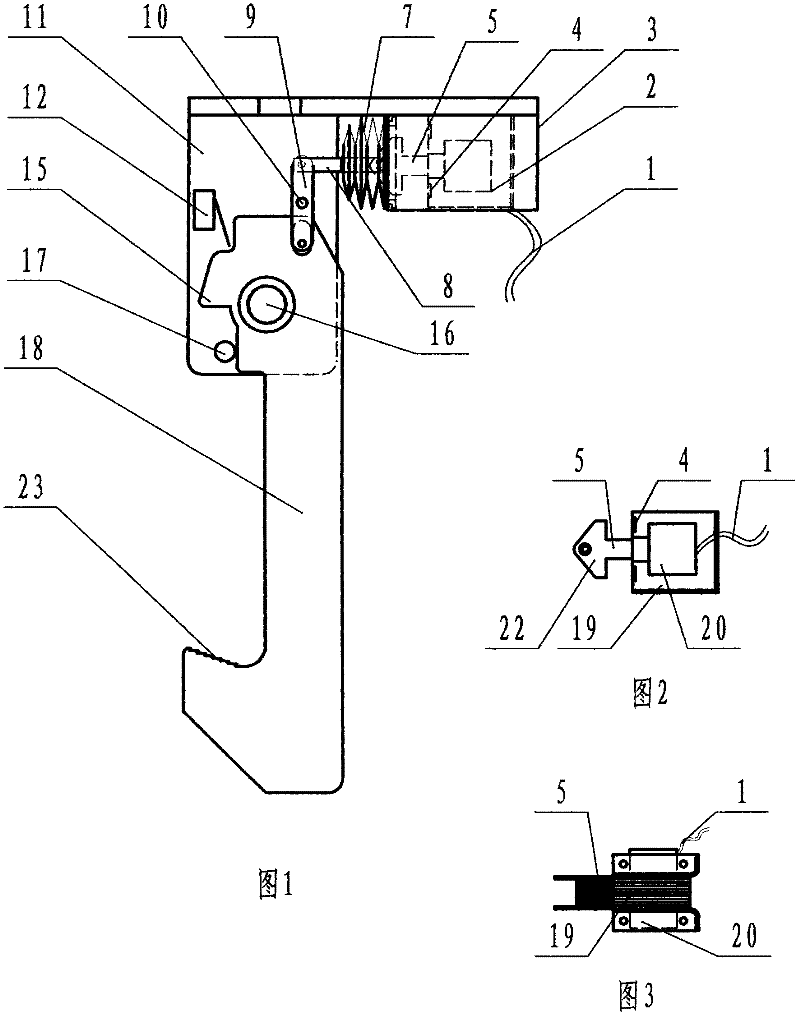

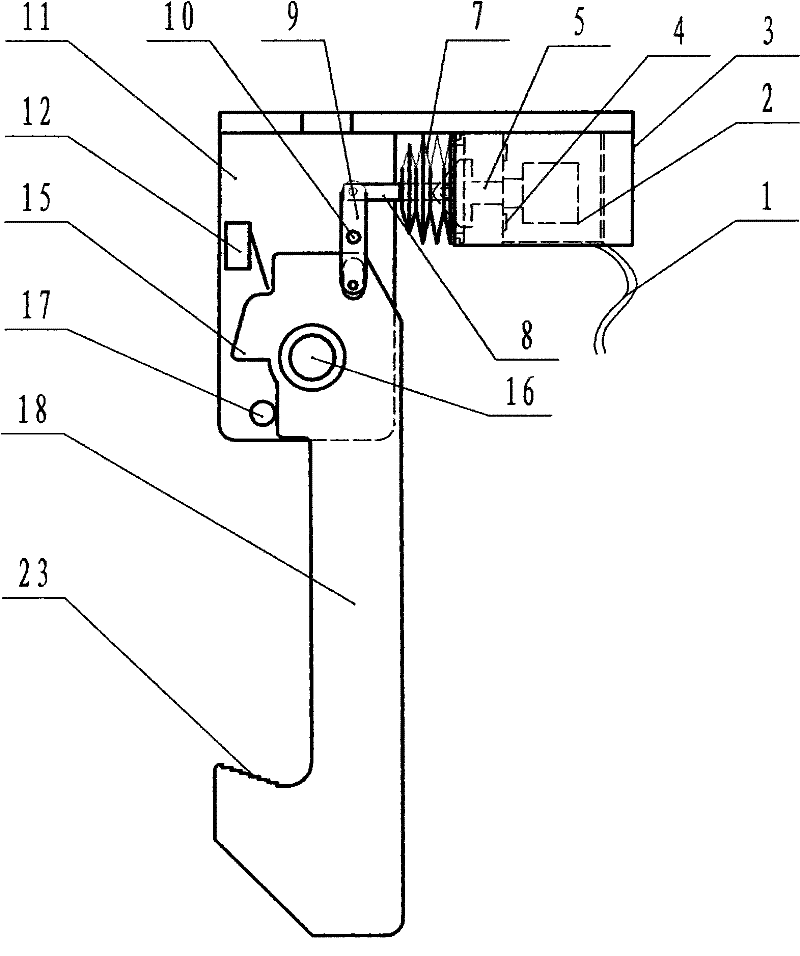

Solid garage falling protector

The invention relates to a solid garage falling protector. The falling protector is characterized in that one end of a pull rod is flexibly connected with an armature connector in a hinged mode, a fulcrum pin is fixed on a support, and the middle of a linkage lever is rotatablely matched with the fulcrum pin; one end of the linkage lever is flexibly connected with the other end of the pull rod in the hinged mode, the other end of the linkage lever is a flexibly connected with a connecting pin of a hook connector in the hinged mode, and the other end of the linkage lever is rotatablely connected to the connecting pin on the right upper part of the hook connector; and the support arranged on the left upper side of the hook connector is provided with a signal switch, and a trigger end of the signal switch is matched above the left upper side step of the hook connector. The pull rod of the falling protector provided by the invention is formed by connecting elastisch Oxford rods through the active linkage lever, therefore, the collision of the falling protector does not deform and bend through the collision. The falling protector provided by the invention has the advantages of restoration in time, good sensitivity, safety and waterproof properties, and prolongs the service life.

Owner:袁志年

Iron-cobalt alloy and preparation method of magnetizing pole head of iron-cobalt alloy

ActiveCN103834862AImprove magnetic propertiesImprove mechanical propertiesMagnetic bodiesQuenching agentsDry iceIngot

The invention discloses an iron-cobalt alloy and a preparation method of a magnetizing pole head of the iron-cobalt alloy. The iron-cobalt alloy comprises the following substances in percentage by weight: 29-34.5% of Co, 0.05-0.15% of rare earth, 0.15-0.40% of Nb, 0.10-0.25% of Zr and the balance of Fe. The preparation method of the magnetizing pole head of the iron-cobalt alloy comprises the following steps: 1) smelting the alloy by virtue of a vacuum furnace and casting the alloy into alloy ingot; 2) after forging and molding, directly quenching in a mixed solution of dry ice and water; 3) processing the forge piece into the magnetizing pole head; 4) subsequently carrying out three times of treatment containing pre-heating treatment and multiplex heat treatment by using a protective atmosphere heat treatment furnace and a vacuum heat treatment furnace so as to ensure excellent comprehensive properties of a finished product. The magnetizing pole head produced by virtue of the preparation method has the advantages of strong saturation flux density, low coercive force, small residual magnetism, good mechanical property, high compressive strength, long service life and good quality stability and can meet operating requirements on high property of the magnetizing pole head in the electron industry.

Owner:梅州市嘉晟工贸有限公司

Sintered neodymium iron boron magnet

ActiveCN109732046AEvenly distributedImprove effective utilizationInductances/transformers/magnets manufactureMagnetic materialsHydrogenRare earth

The invention relates to the technical field of rare earth permanent magnets, in particular to a sintered neodymium iron boron magnet and a preparation method thereof. The sintered neodymium iron boron magnet is characterized in that according to the mass percentage composition, the general formula of the sintered neodymium iron boron magnet is ReaDybFe100-a-b-c-dBcMd; Re is one or more of Pr, Nd,La, Ce, Gd and Ho; M is one or more of Co, Cu, Al, Nb, Ga, Zr, Ti and Cr; and a is larger than or equal to 27 and smaller than or equal to 33, b is larger than or equal to 1.0 and smaller than or equal to 2.0, c is larger than or equal to 0.9 and smaller than or equal to 1.1, and d is larger than or equal to 0 and smaller than or equal to 5. Through the optimized process, smelting, single hydrogen breaking and powder making are not needed, and the using amount of heavy rare earth can be reduced to 1.5wt% or even 1.2wt%, so that rare earth is more uniformly distributed in the grain boundary, and the effective utilization ratio of the rare earth is improved; and according to the sintered neodymium iron boron magnet prepared through the process, while cost is reduced, the excellent magneticproperties are achieved.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

Preparation method of nano-micron pyrrhotite soft magnetic material

ActiveCN104192915AAdequate responseHigh purityInorganic material magnetismIron sulfidesRemanenceIron powder

The invention provides a preparation method of a nano-micron pyrrhotite soft magnetic material. The preparation method comprises the following steps: by using reduced iron powder (Fe) and sublimed sulfur as main raw materials, and grinding the two raw materials in a certain proportion until the two raw materials are uniformly mixed; heating for a certain time under a certain temperature condition; performing heat preservation and cooling, thereby finally obtaining the ash black pyrrhotite soft magnetic powered material with crystals developing well. The material has the characteristics of low residual magnetism and low coercivity. The basic expression of the components is Fe1-xS (x is greater than or equal to 0 but less than or equal to 0.223). By using materials which are low in price and simple and easily available, the pyrrhotite soft magnetic material which is high in purity, uniform in granular distribution and low in coercivity and residual magnetism is manually prepared by virtue of an iron-sulfur compound method and can be used for satisfying the actual demand of the magnetic material. The soft magnetic material is the magnetic material with low residual magnetism and low coercivity, has the characteristics of easiness for magnetization and easiness for demagnetization, can be widely applied to electrical equipment and electronic equipment and has actual application value.

Owner:NORTHEASTERN UNIV

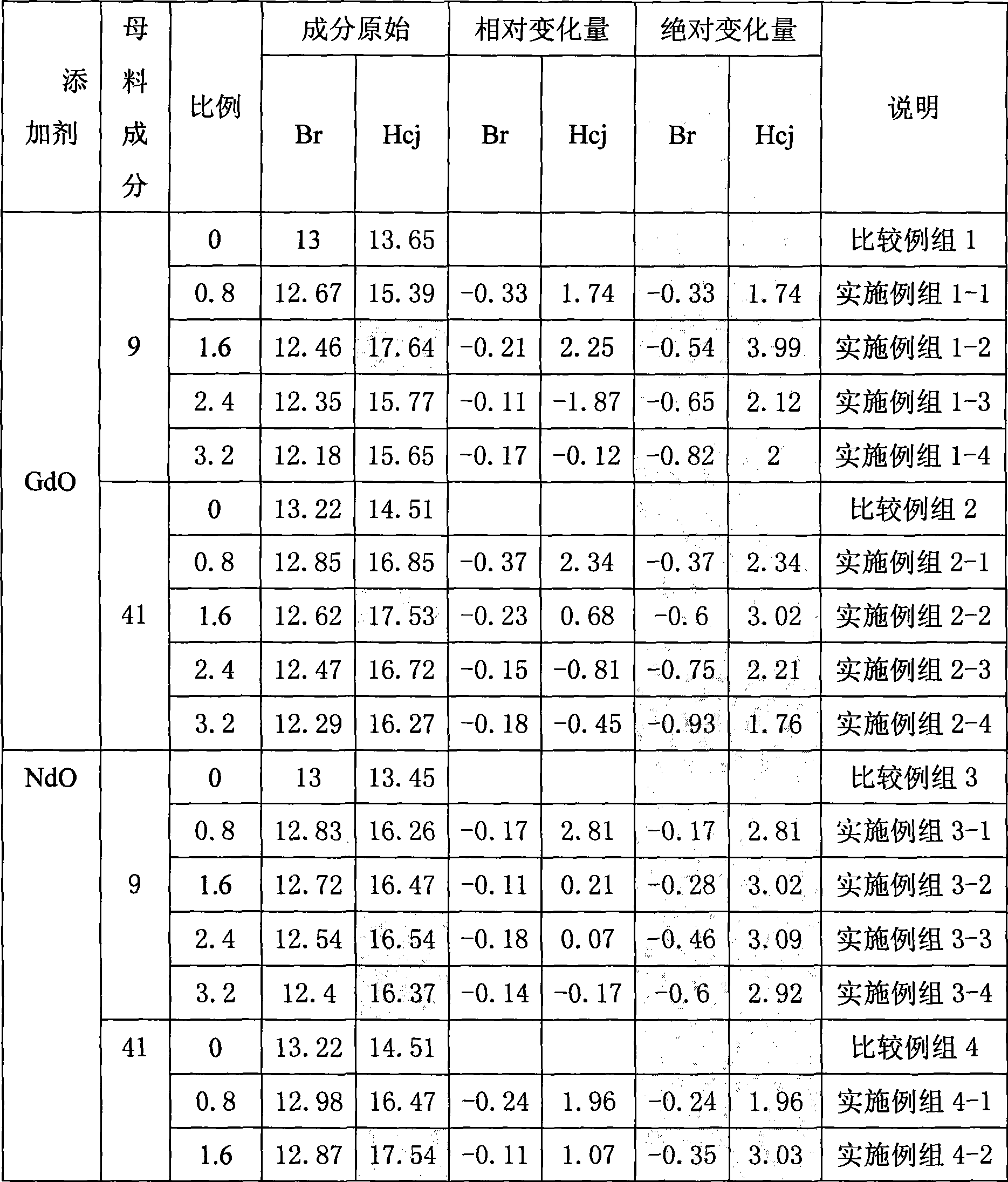

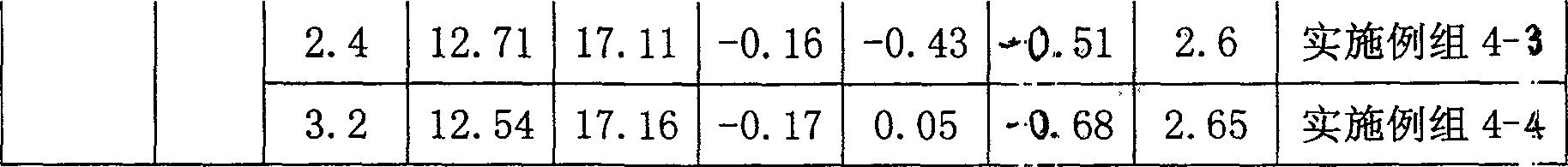

Method for improving rare earth permanent magnet coercive force

ActiveCN101499345ALow priceLow costPermanent magnetsInductances/transformers/magnets manufactureRemanenceRare earth

The invention discloses a method for improving coercive force of a rare-earth permanent-magnet, which is characterized in that in the process of manufacturing the rare-earth permanent-magnet, other rare-earth oxides except DyO and TbO are added into and fully mixed with prepared powdered alloy, and then the mixture is molded in an oriented way and sintered; and the added rare-earth oxides are NdO and / or GdO, and are treated by dehydration at the temperature of over 500 DEG C, and the doping proportion is 0.8-3.2% of the weight of the prepared powdered alloy. The rare-earth oxides with lower price are added into the prepared powdered alloy, and other processes are not changed, serial tests prove that when about 0.8% of rare-earth oxides are added, the coercive force is increased by 1900-3900KOe, and the remanence of the product is reduced by 200-300Gs. When the adding proportion is more than 1.6%, the remanence of the product is reduced, and the significance is significantly lowered. The method has simple technique, lower cost and remarkable effect.

Owner:SINO MAGNETICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com