Patents

Literature

31results about How to "Strong tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

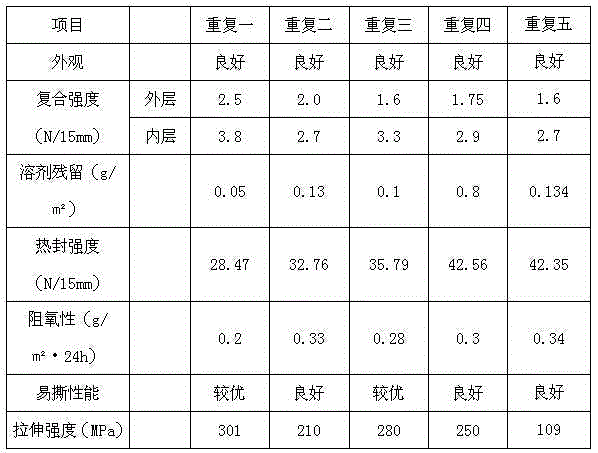

Production process of vacuum aluminum-plated composite films

InactiveCN104589766AGood adhesion to aluminum layerImprove adhesionFlexible coversWrappersAl powderComposite film

The invention discloses a production process of vacuum aluminum-plated composite films. The production process comprises the steps of selecting base materials, carrying out vacuum aluminum plating, coating an adhesive, compositing, rolling up, and carrying out aging treatment, so that a finished product vacuum aluminum-plated composite film is obtained. Compared with the prior art, a composite film prepared according to the invention has the following advantages and effects that experiments prove that a sub-gloss film produced according to the invention has a good aluminum-layer adhesion force, a strong tensile strength (210-301 MPa), good glossiness, and excellent oxygen and moisture permeable barrier properties, the solvent residue is less than or equal to 0.13, the sub-gloss film is environmentally friendly, smooth in surface, bright and clean, safe, sanitary, and easy to recover, the phenomena that the aluminum-layer adhesion force of a composite film prepared in the prior art is poor, aluminum powder is easily removed, and the glossiness of printed patterns is weak are overcome, products are widely used in the packaging industries for foods, cigarettes, gifts, cosmetics, medicines and the like, and the film is a basic raw material used in the printing composite industry.

Owner:NANJING CHENXIANG IND & TRADE

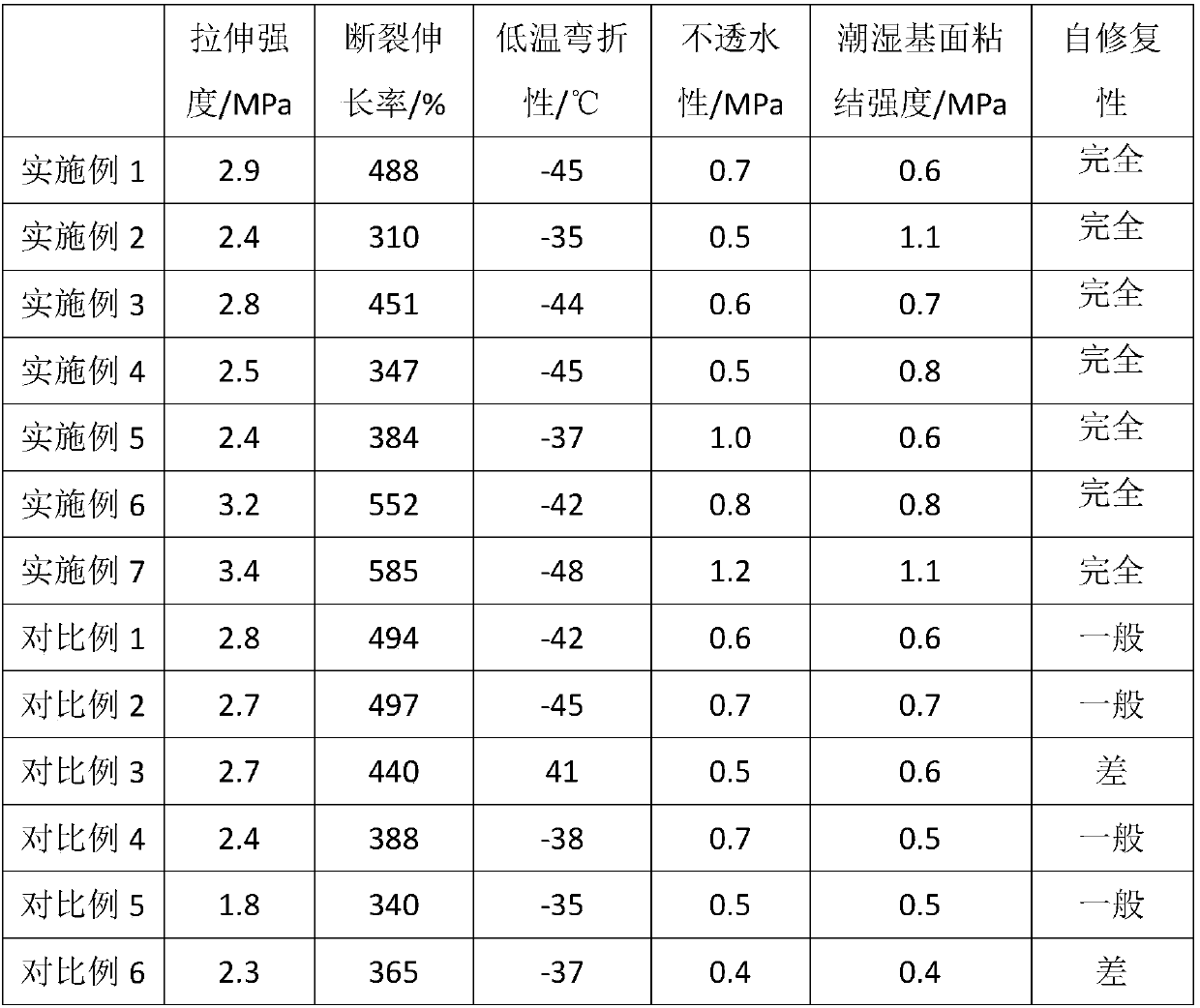

Strong and tough back side waterproof coating

ActiveCN107603455AStrong tensile strengthHigh elongation at breakPolyurea/polyurethane coatingsChemistryEmulsion

The invention relates to the technical field of coating, and particularly relates to strong and tough back side waterproof coating. The strong and tough back side waterproof coating comprises a component A and a component B in a weight ratio of 1:(1-4), wherein the component A is prepared from the following raw materials in parts by weight: 40-95 parts of polyol, 70-80 parts of isocyanate, 3-15 parts of binary oxime, 10-35 parts of polyethyleneimine, 0.2-0.8 part of amino acid and 3-8 parts of acrylic acid; and the component B is prepared from the following raw materials in parts by weight: 15-40 parts of acrylic emulsion, 0.5-4 parts of nano-titanium dioxide, 2-8 parts of nano-silicon dioxide, 1-4 parts of a coalescing agent and 15-35 parts of water.

Owner:盛隆建材(河南)有限公司

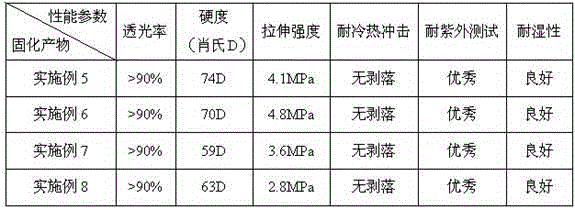

Organic silicon composition with main chain containing phenylene structure and preparation method thereof

The invention provides an organic silicon composition with a main chain containing a phenylene structure. The organic silicon composition is composed of four parts A, B, C and D; each compound of the part (A) contains at least three C-C double bonds, and the structural formula of the part (A) is shown in a general formula (1) which is as shown in the specification, wherein each R is independently a monovalent alkyl or alkoxy with 1-12 carbon atoms, and a, b and c are selected from positive integers between 1 and 20; and the part (B) is a phenylene-structure-containing main chain with two Si-H base heads and straight-chain siloxane with side-group phenyl, and the structural formula of the part (B) is shown in a general formula (2) which is as shown in the specification. The organic silicon composition provided by the invention is high in hardness of cured substances and strong in tensile strength, has no peel-off phenomenon after being subjected to hot and cold impact for multiple times, is heat-resistant and strong in adhesive property, and can be used as a packaging material for various optical components.

Owner:江苏矽时代材料科技有限公司

Asphalt waterproof material

A disclosed asphalt waterproof material is prepared from the following raw materials in parts by weight: 35-50 parts of asphalt, 10-20 parts of an acrylate, 11-14 parts of fly ash, 11-16 parts of slaked lime, 15-25 parts of quartz sand, 3-6 parts of cyclohexanone, 4-8 parts of p-phenylenediamine, 20-35 parts of epoxy resin, 17-28 parts of polyamide, 7-9 parts of tourmalinite powder, 6-9 parts of elastic fiber, 6-9 parts of triethanolamine, 2-5 parts of toluene, 21-29 parts of expanded perlite, 6-10 parts of sodium silicate, 11-19 parts of phenolic resins, 13-18 parts of micaceous iron oxide and 4-8 parts of ethylenediamine. The provided asphalt waterproof material is resistant to high temperature, free of foaming, free of water leakage, high in flexibility, high in anti-bending strength, good in weatherability and high in compressive strength.

Owner:QINGDAO CHENQING INFORMATION TECH

High-strength lightweight concrete

The invention discloses a high-strength lightweight concrete. The raw materials of the high-strength lightweight concrete include the following components in parts by weight: 100 parts of cement, 50 parts of water, 60-70 parts of PC (Poly Carbonate), 30-34 parts of bentonite, 12-16 parts of blast furnace slag, 10-13 parts of borax, 2-5 parts of calcium carbonate and 0.5-2 parts of zinc sulfate. The high-strength lightweight concrete has the advantages that the traditional formula of concrete is broken through in such a manner that the PC is used for taking the place of one part of cement, the concrete which is obtained by activating the calcium carbonate and the zinc sulfate under the action of bentonite is high in compression resistance and stretch resistance, and also low in weight, and therefore, troubles in construction are reduced so that construction can be carried out conveniently.

Owner:六盘水嘉锐商品混凝土有限责任公司

Preparation technology of Chinese chive packaging paper

InactiveCN102943407ABright colorPaper-formingNon-woody plant/crop pulpPaper-making machinesPulp and paper industryPre treatment

The invention discloses a preparation device of Chinese chive packaging paper. The device comprises a Chinese chive pretreatment device, a blanching device, a cooling device, a pulping device, a homogenating device, a degassing device, a curtain coating plate and a drying and molding device. The Chinese chive packaging paper produced by adopting the device has the characteristics of bright colors, paper forming property, tackiness, good uncovering performance, and strong tensile tension.

Owner:HENAN UNIV OF URBAN CONSTR +1

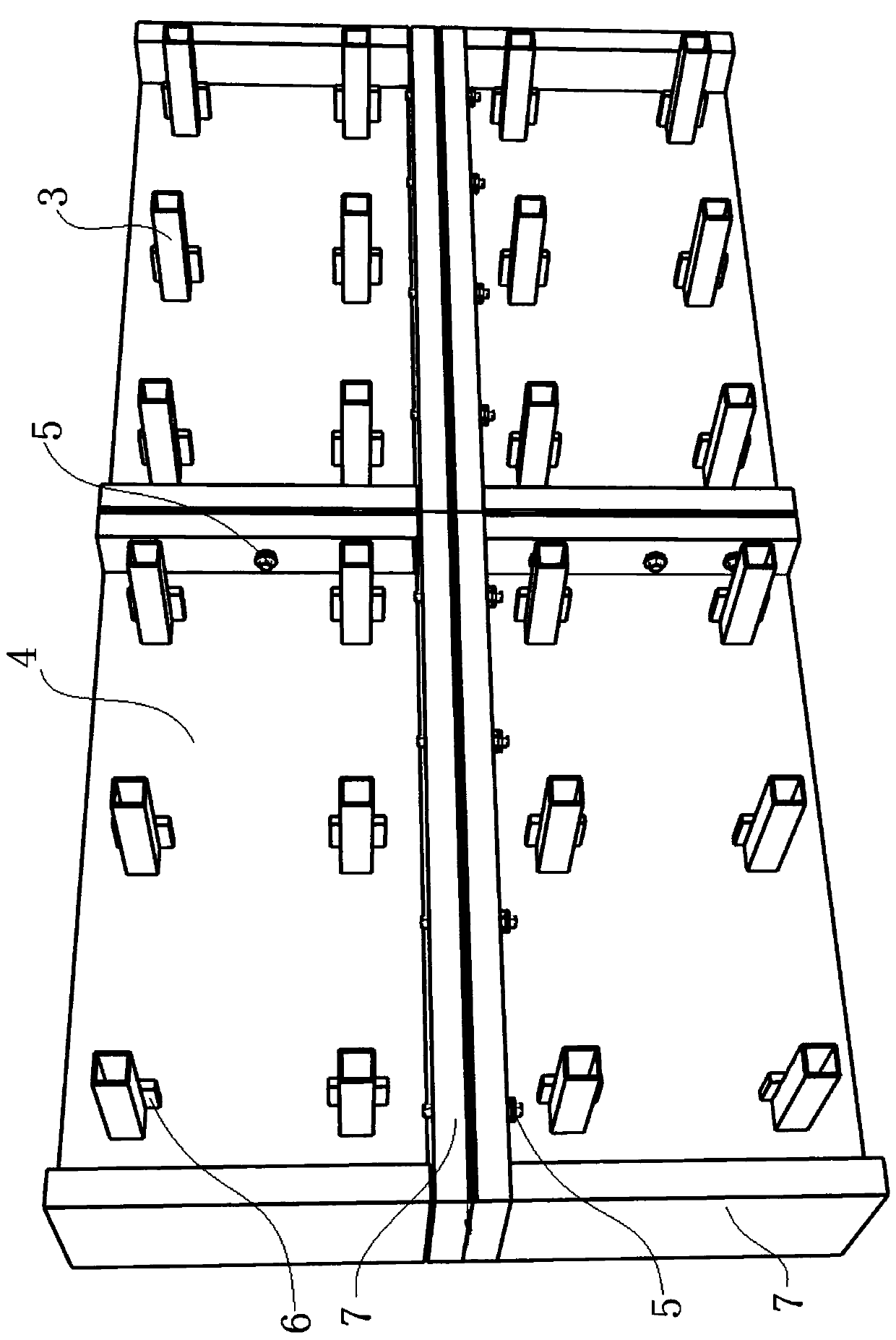

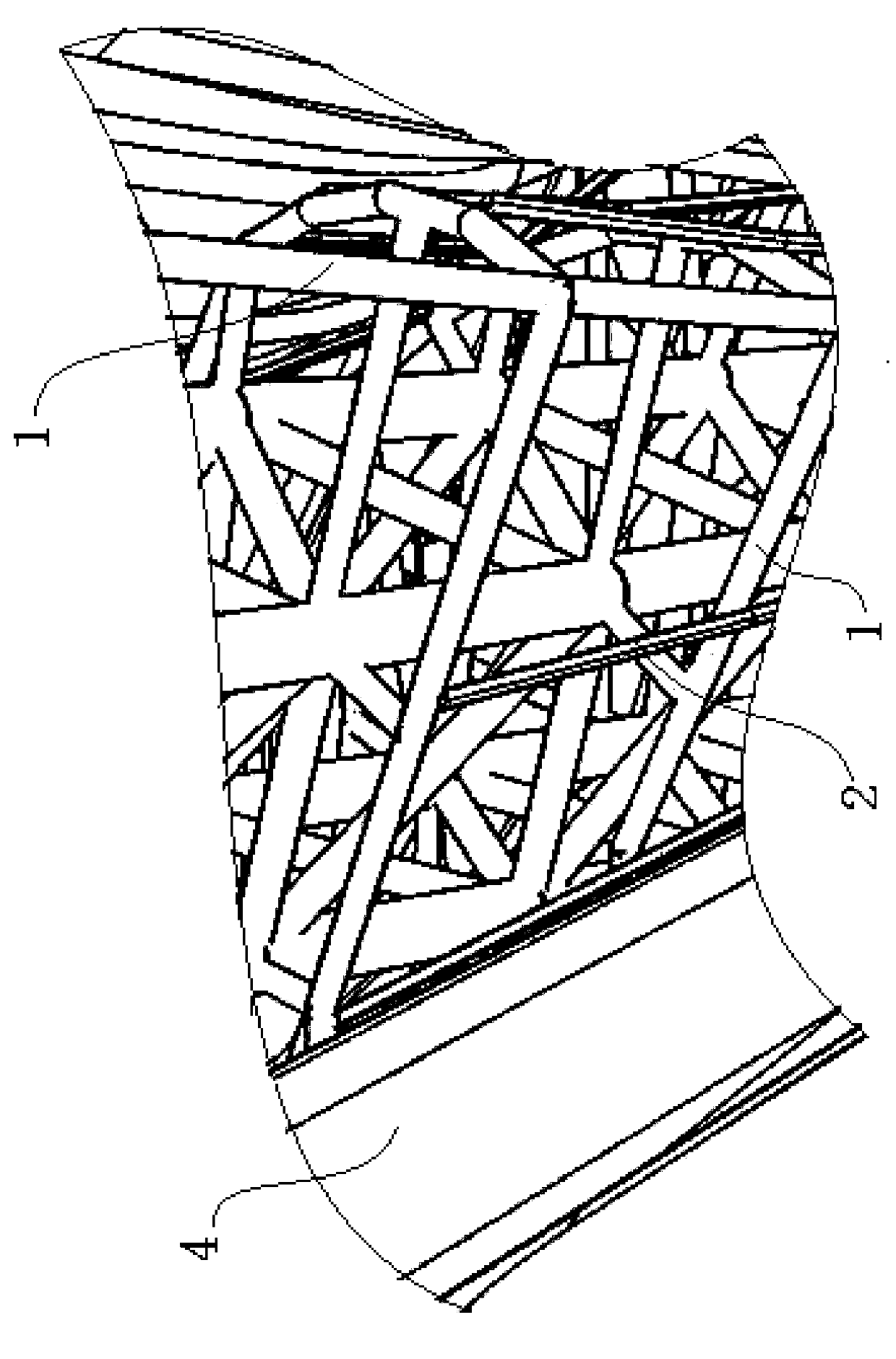

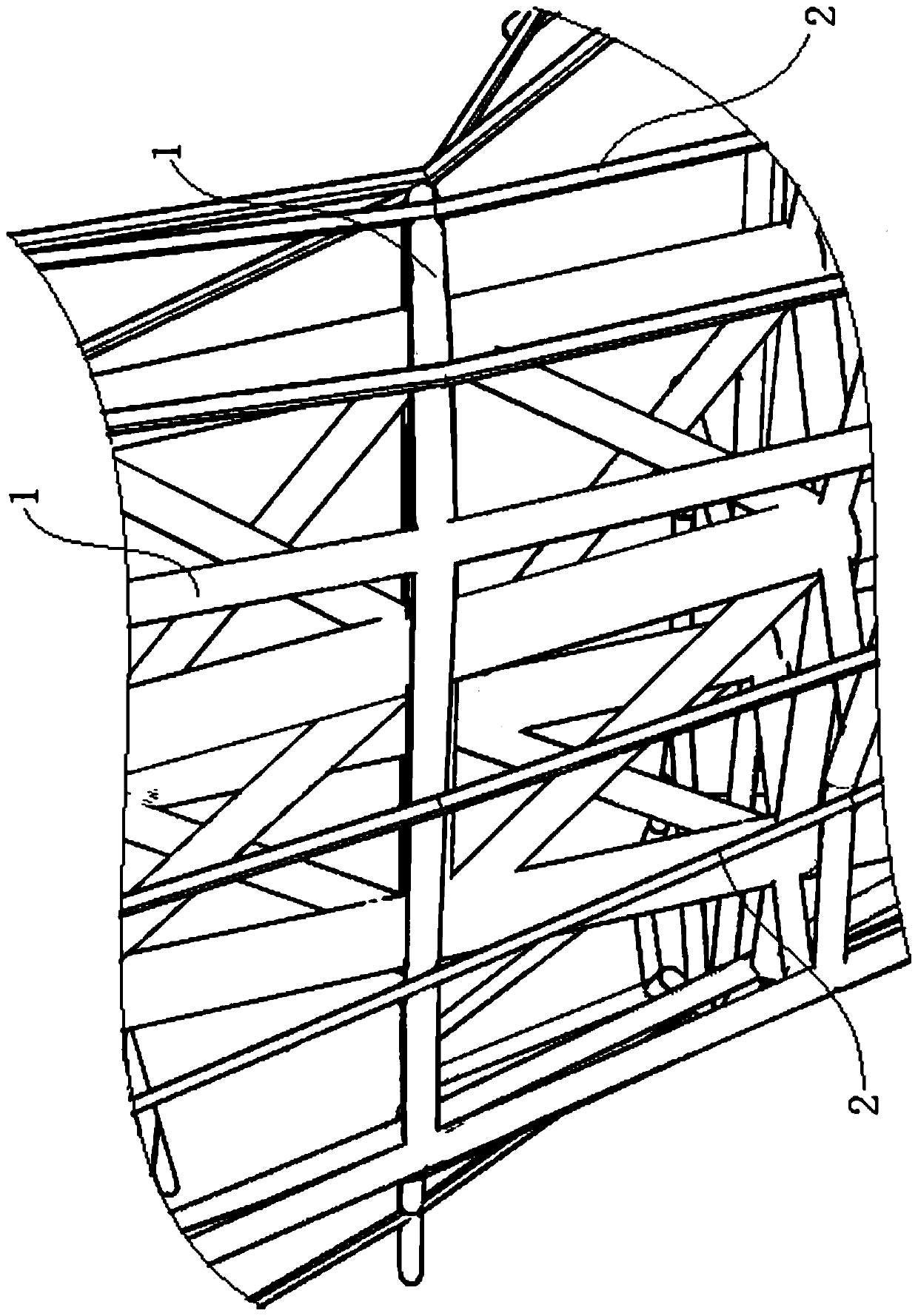

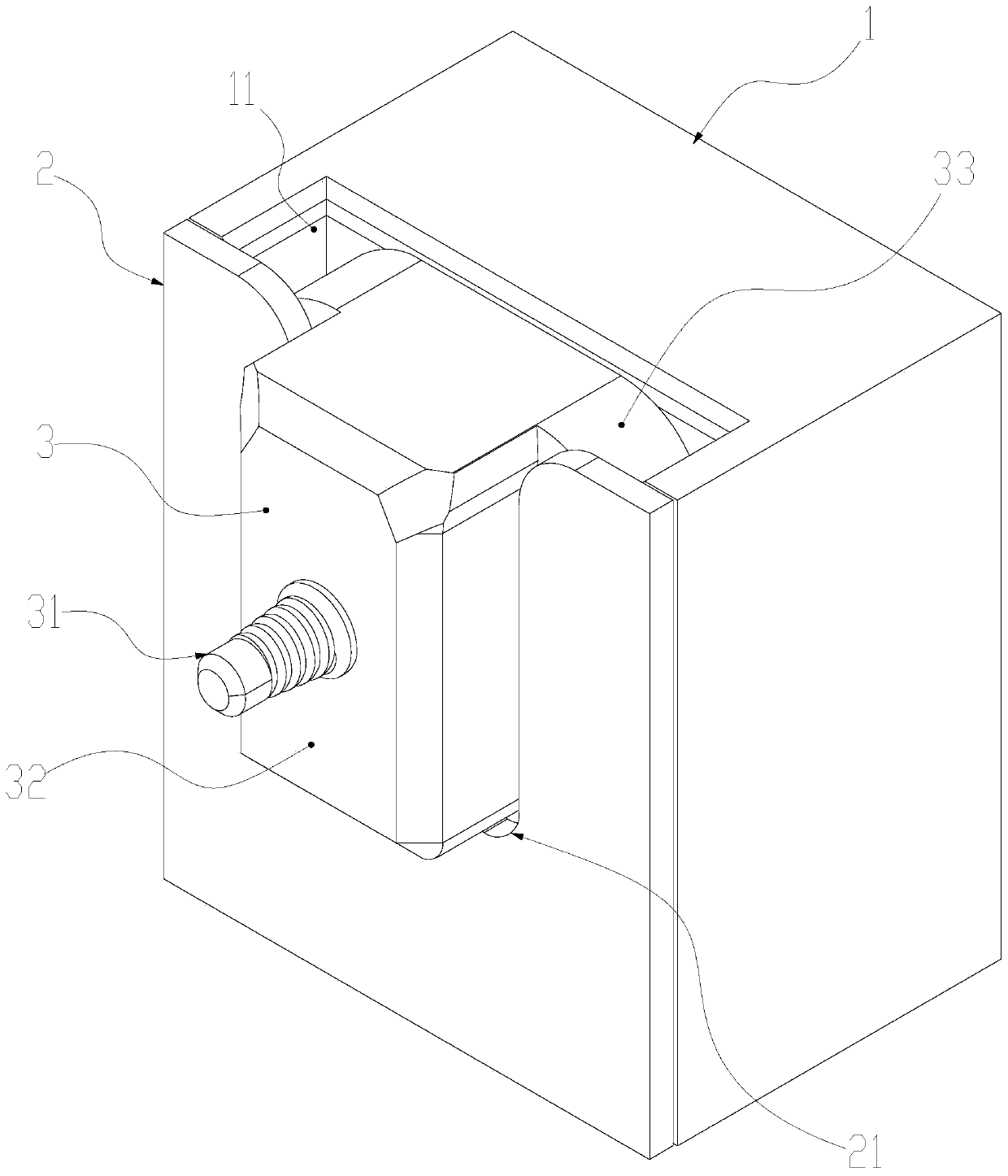

Ultra-large space GRG installation structure

The invention discloses an ultra-large space GRG installation structure. The ultra-large space GRG installation structure comprises a plurality of pre-embedded plates, a connection piece and an auxiliary steel frame, the pre-embedded plates are perpendicularly arranged on the back surface of each glass fiber gypsum plate in a protruding mode, and a main plane of each pre-embedded plate is parallel to a straight line in the vertical direction; the connection piece comprises bolts, flangings perpendicularly turned up facing the back surface are arranged between every two adjacent glass fiber gypsum plates, and the flangings of very two adjacent glass fiber gypsum plates are assembled and connected through the bolts; the auxiliary steel frame comprises a first square tube and a second square tube which are connected perpendicularly, the cross sectional area of the first square tube is larger than the cross sectional area of the second square tube, the first square tube extends in the vertical direction, and the second square tube extends in the horizontal direction; and the main planes of the pre-embedded plates are welded and fixed to the side surfaces of the second square tube. By adopting the ultra-large space GRG installation structure, larger vertical supporting force can be provided, and the ultra-large space GRG installation structure is suitable for a construction scheme of the glass fiber gypsum plates with larger area and large weight.

Owner:GOLD MANTIS CONSTR DECORATION

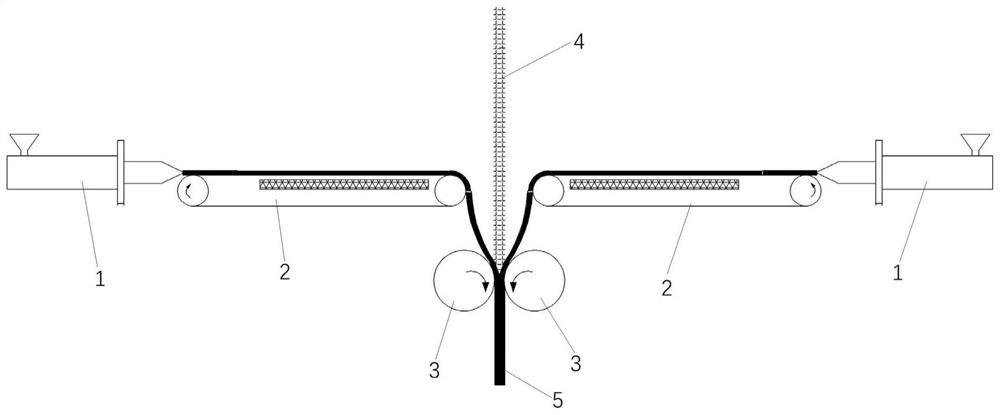

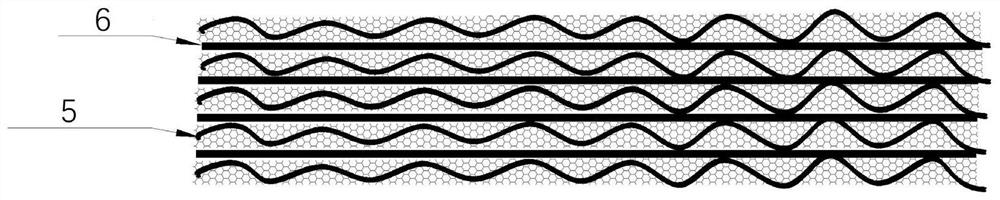

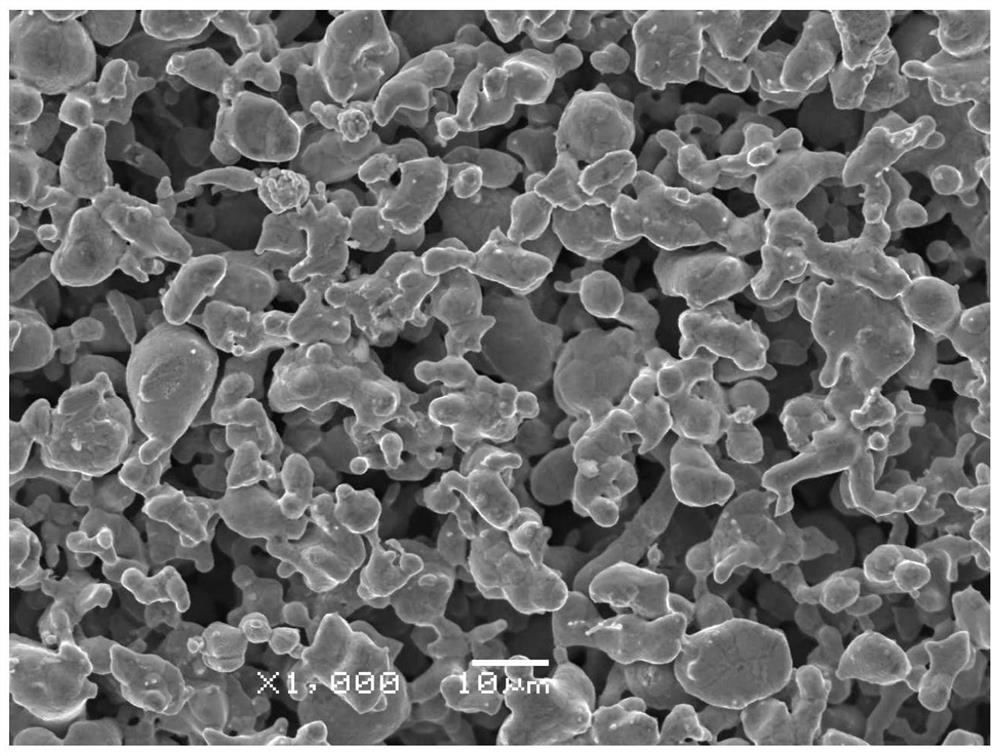

Preparation method of powder net composite porous metal film

PendingCN113181782AHigh filtration precisionStrong tensile strengthSemi-permeable membranesDispersed particle filtrationThin membranePlasticizer

The invention discloses a preparation method of a powder net composite porous metal film, which comprises the steps of 1, uniformly mixing metal powder with a plasticizer, a thickening agent and an organic solvent or deionized water according to a certain proportion to prepare high-viscosity slurry; 2, extruding the high-viscosity slurry into a strip-shaped film blank through a slit-type die opening by using an extruding machine, conveying the strip-shaped film blank to two rolling mills through a conveying belt, and rolling the strip-shaped film blank into a strip-shaped powder net composite porous metal film blank through composite film blanks on the two sides and a composite single-layer metal wire net in the middle; and 3, laying an isolating layer on the strip-shaped powder net composite porous metal film blank through aluminum oxide powder, conducting degreasing and sintering in a hydrogen sintering furnace, and then obtaining the powder net composite porous metal film. The preparation process is simple, the cost is low, the efficiency is high, and the prepared powder net composite porous metal film is uniform in pore size distribution, small in maximum pore size, high in permeability coefficient and capable of being widely applied to the fields of flue gas dust removal, water purification and the like.

Owner:WESTERN BAODE TECH CO LTD

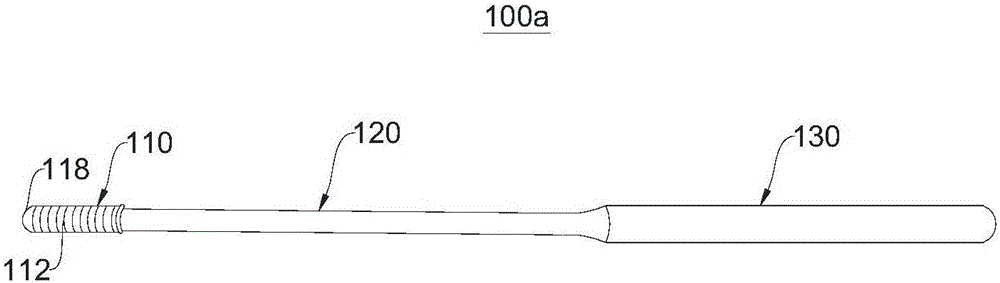

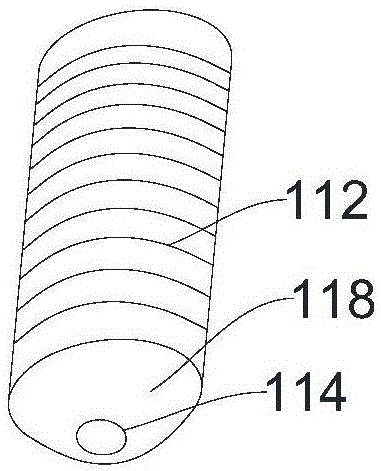

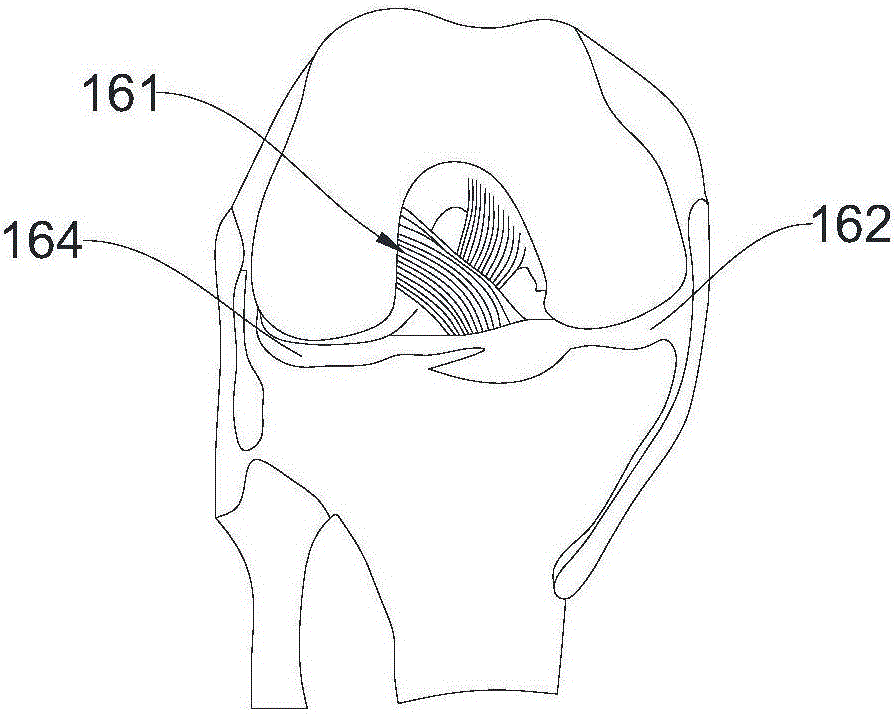

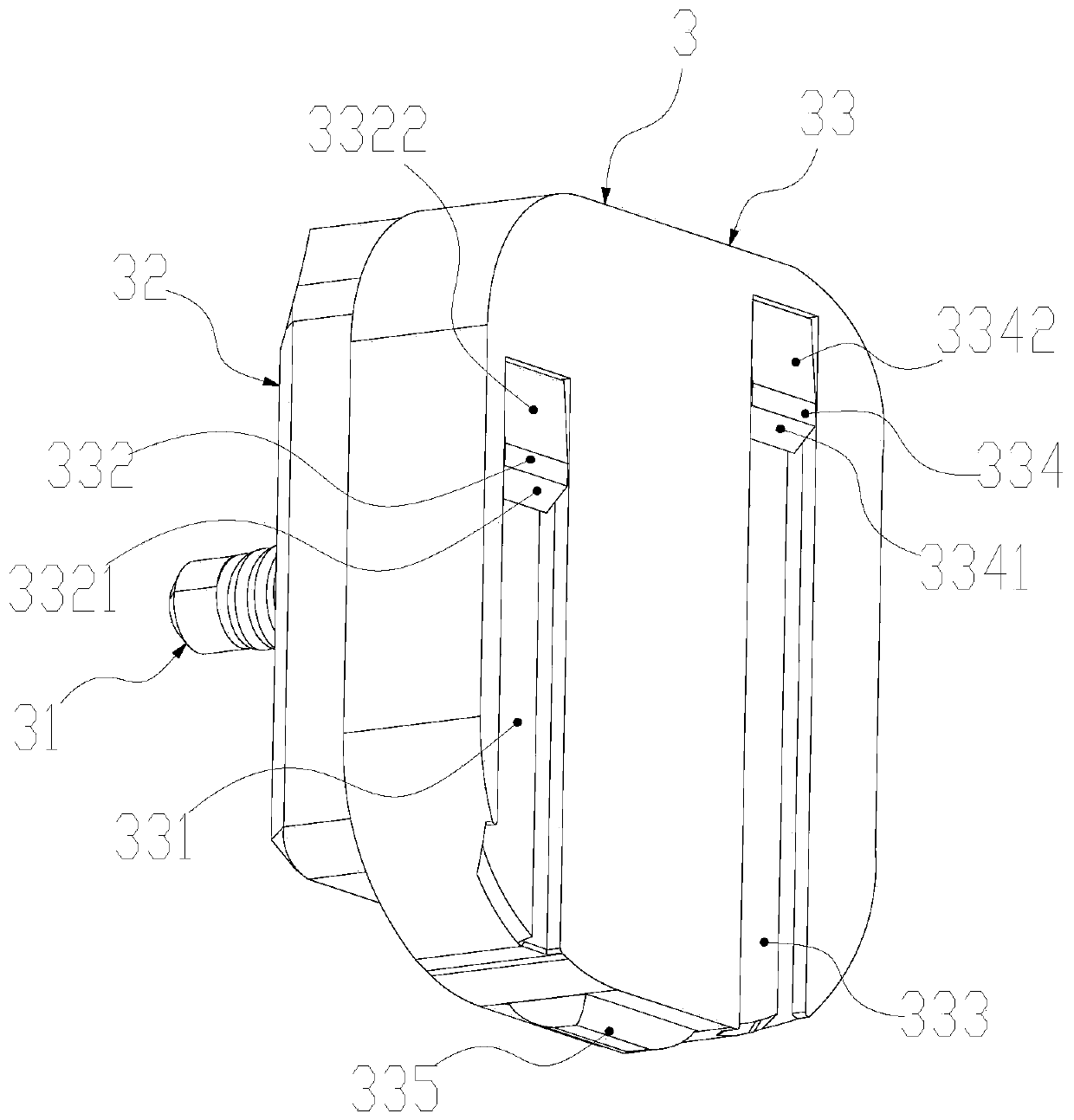

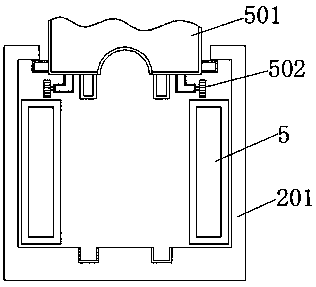

Bone tunnel expander and preparation method of detachable adapter of bone tunnel expander

PendingCN106491179AStrong tensile strengthRestoring anatomical imprintsSurgeryBone tunnelPosterior cruciate ligament

The invention discloses a bone tunnel expander and a preparation method of a detachable adapter of the bone tunnel expander and relates to the field of medical appliances. The bone tunnel expander comprises the adapter, a connecting body and a handle part, wherein the adapter and the handle part are separately arranged at two ends of the connecting body, the cross section of the adapter is elliptical, the elliptical size is matched with that of an elliptical anterior cruciate ligament mark at a thighbone, and a connecting hole which is used for being connected with a guide pin, which is used for perforating the anterior cruciate ligament mark position, is formed in a free end of the adapter. The adapter is in line with the anterior cruciate ligament mark of a human body, so that dissection marks can be restored to greater extent, and physiological restoration is achieved. The preparation method of the detachable adapter of the bone tunnel expander comprises the steps of measuring the size of the anterior cruciate ligament mark of a patient at the beginning of surgery and preparing the adapter of the bone tunnel expander through a 3D printing system. Customized detachable adapters which are in line with sizes of anterior cruciate ligament marks of patients can be manufactured through a 3D printing technique according to individual differences of the patients.

Owner:CHONGQING RONGAN MEDICAL APP CO LTD

Medium-strength aluminum alloy single wire

InactiveCN104894436AHigh conductivityStrong tensile strengthMetal/alloy conductorsRare-earth elementDuctility

The invention discloses a medium-strength aluminum alloy single wire. An aluminum alloy rod for shielding consists of the following components in parts by weight: 0.3-0.5% of iron, 0.3-0.3% of magnesium, 0.1-0.2% of silicon, 0.03-0.5% of rare earth mixture, 0.02-0.04% of copper, 0.08-0.12% of beryllium, and aluminum not lower than 98.4%; the sum of all the components is 100%; the rare earth element consists of lanthanum, cerium and scandium; the lanthanum, the cerium and the scandium are mixed in proportion by weight parts of 14: 5-7: 0.9-1.2 to form the rare earth element; the model number of aluminum is LHA3-GD; and the lanthanum, the cerium and the scandium are mixed in proportion by weight parts of 14: 6: 1 to form the rare earth element. The medium-strength and high-electric-conductivity aluminum alloy material is high in electric conductivity; the tensile strength is high up to achieve a purpose of providing a high-performance and medium-strength aluminum alloy lead to the construction of the state grid corporation of China; the electric conductivity reaches above 69.2% IACS; the tensile strength is 240-255 MPa; and the ductility reaches 2.0-3.5%.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

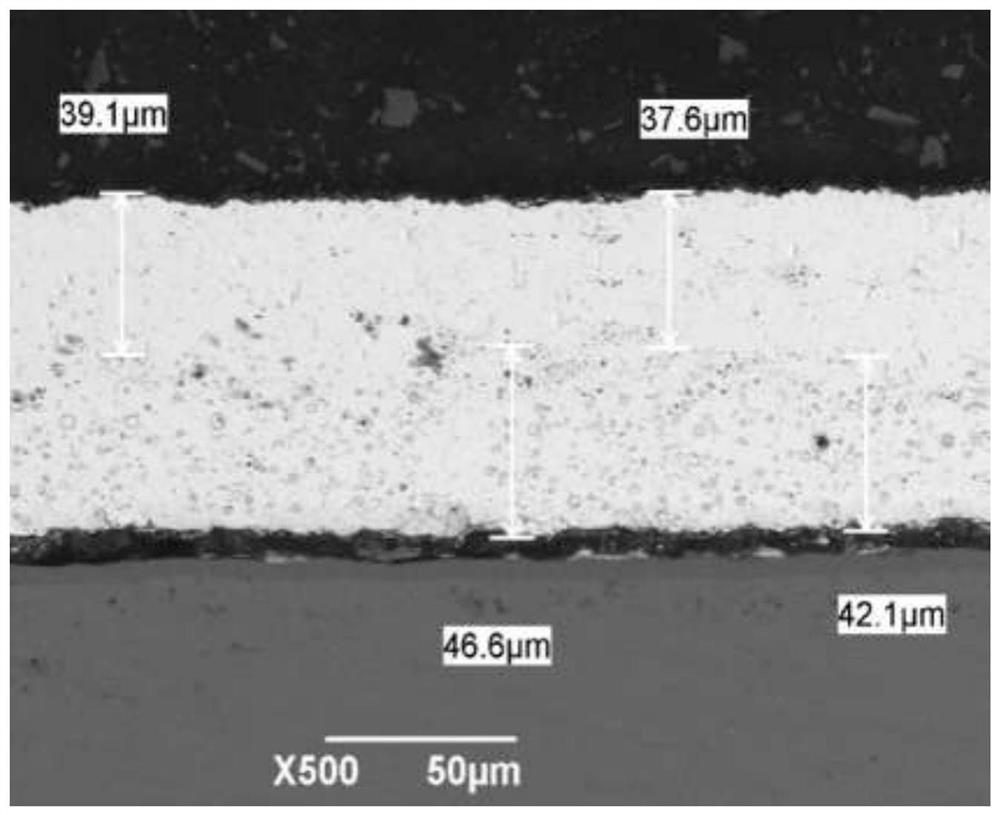

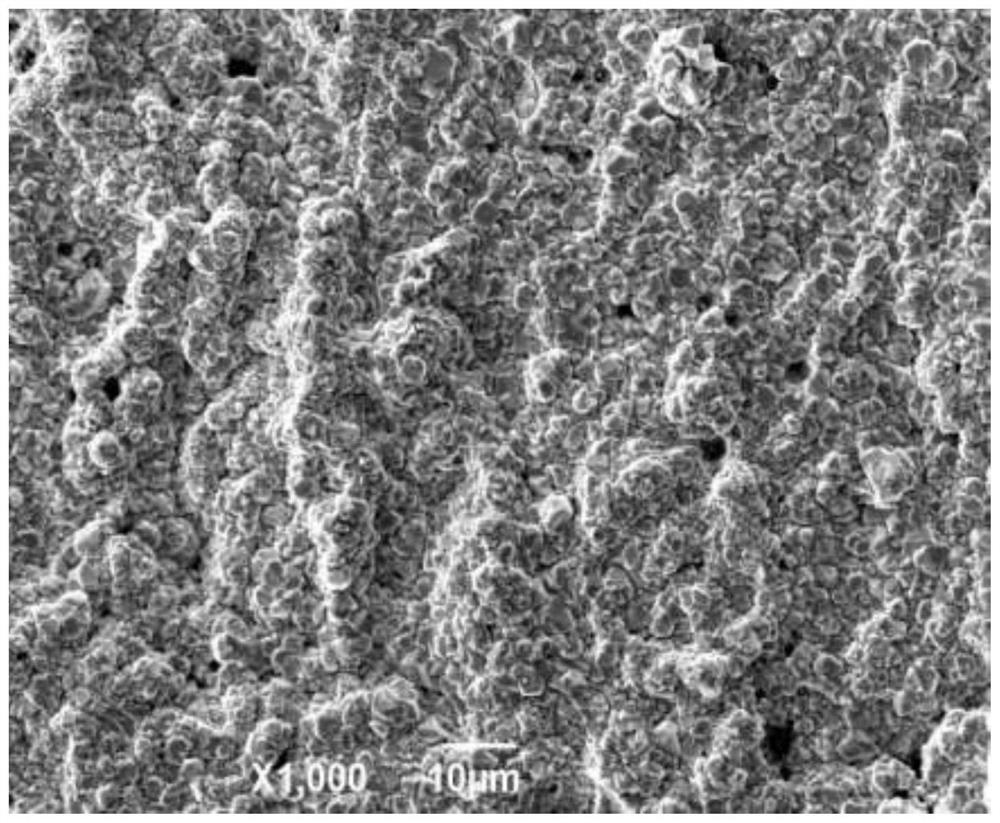

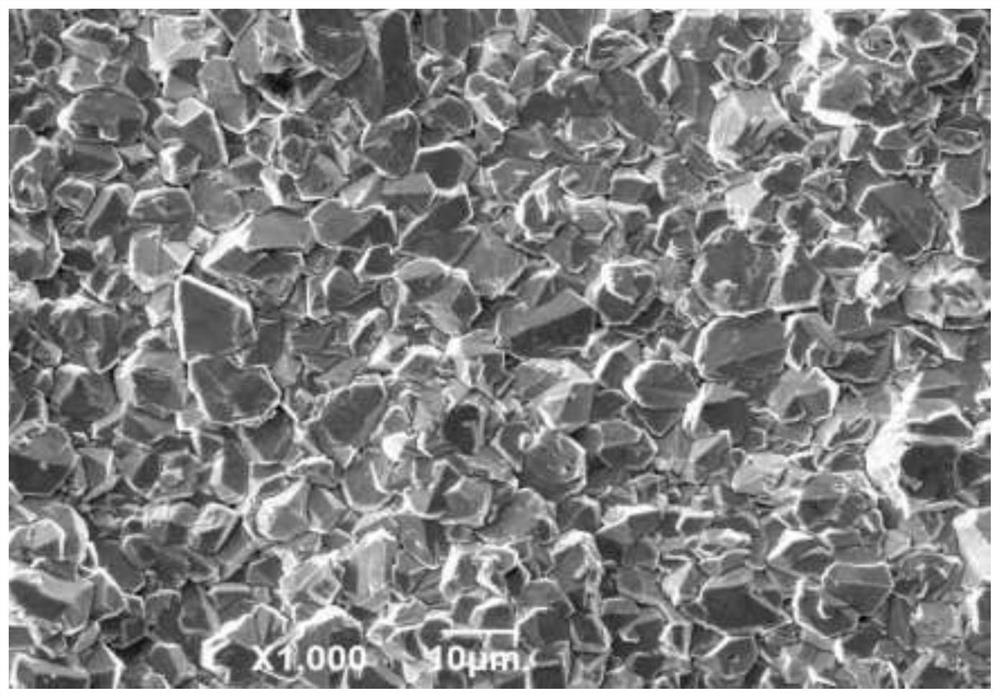

Preparation method of titanium-based composite PbO2 anode for water treatment

PendingCN112830554AStrong tensile strengthStrong wear resistanceElectrolytic inorganic material coatingWater/sewage treatmentSteel platesComposite material

The invention belongs to the technical field of preparation of lead dioxide dimensionally stable anodes, and particularly relates to a preparation method of a titanium-based composite PbO2 anode for water treatment. According to the preparation method of the titanium-based composite PbO2 anode for water treatment, pretreated porous titanium serves as an anode, a stainless steel plate with the same area serves as a cathode, the anode and the cathode are placed in a lead nitrate solution, active particles Ta2O5 and SnO2 are added, anode co-deposition is carried out to obtain a beta-PbO2 composite middle layer, beta-PbO2-Ta2O5 and a beta-PbO2-SnO2 composite middle layer, then anode electrode position is carried out to obtain a PbO2 active layer, and finally, the coating dimensionally stable anode (DSA) with the structure of Ti / beta-PbO2-Ta2O5 / PbO2 and the structure of Ti / beta-PbO2-SnO2 / PbO2 is obtained. The problems that a titanium-based lead dioxide electrode is poor in electrode stability, short in service lifetime and low in electrode electrocatalytic activity in the water treatment use process are solved.

Owner:西安泰金新能科技股份有限公司

High-strength easily-degradable plastic sealing film for battery and preparation method of plastic sealing film

The invention discloses a high-strength easily-degradable plastic sealing film for a battery and a preparation method of the plastic sealing film. The method comprises the following steps: 1) mixing polypropylene resin, polycarbonate resin, polyethylene terephthalate, diatomaceous earth, a plasticizer, a heat stabilizer and a flame retardant, and performing extrusion granulation to obtain a masterbatch M; and 2) performing film blowing on the master batch M to obtain the high-strength easily-degradable plastic sealing film for the battery. The high-strength easily-degradable plastic sealing film for the battery disclosed by the invention has excellent tensile strength and telescopic properties, can well seal the surface of the battery and ensure the long-term safe use of the battery; andthe surface plastic sealing film is easy to degrade and facilitates environmental protection.

Owner:WUHU ZHEXIN NEW ENERGY

Articles of manufacture made from agave residue, and methods for making such articles

InactiveUS20060222719A1Reduce amount of waterStrong tensile strengthBiocideAnimal repellantsThermosetting polymerAgave

Articles of manufacture are produced from a composition comprising agave plant residue and a thermosetting polymer resin.

Owner:TANG EAMAN OCHUN +1

High toughness polystyrene pipe

The invention provides a high toughness polystyrene pipe. The high toughness polystyrene pipe is prepared from the following raw materials in parts by weight: 60 to 70 parts of polystyrene, 20 to 35 parts of polystyrene butadiene copolymer, 5 to 15 parts of polyisobutene, 5 to 15 parts of vegetable fibers, 1 to 3 parts of polycarbamate, 1 to 3 parts of polyurethane, 0.1 to 0.5 part of a coupling agent and 0.1 to 0.5 part of a cross-linking agent. The high toughness polystyrene pipe provided by the invention has the advantages of excellent tensile resistance, high toughness, capability of meeting the requirements of health and environmental protection and wide application range.

Owner:句容沣润塑料制品有限公司

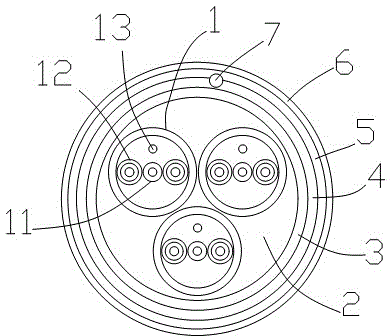

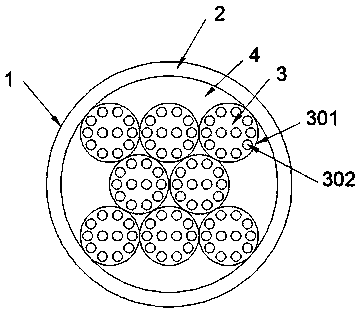

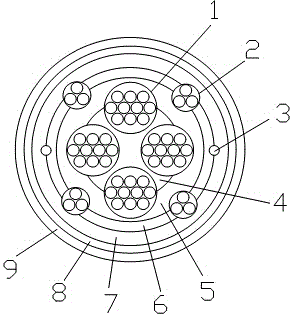

Tensile electric wire cable with reinforcement cores

InactiveCN103915210AExtended service lifeStrong tensile strengthPower cables with screens/conductive layersInsulated cablesFiber layerPolyester

The invention discloses a tensile electric wire cable with reinforcement cores. The tensile electric wire cable with the reinforcement cores is composed of ground cable cores, a polyester fiber layer, a silicone rubber insulation layer, a copper tape shielding layer, a copper tape armoring layer and a chlorosulfonated polyethylene sheath layer. Two sets of control cable cores are provided and extruded and wrapped inside the polyester fiber layer; the polyester fiber layer is wrapped with the silicone rubber insulation layer; the silicone rubber insulation layer is wrapped with the copper tape shielding layer; the copper tape shielding layer is wrapped with the copper tape armoring layer. The cable is long in service life, high in tensile strength, firm, not prone to cracking and resistant to aging and cold, and has the advantages of being resistant to acid and alkali corrosion and high in electrical conductivity.

Owner:ANHUI HUAYUAN CABLE GROUP

Ammonia-free elastic antibacterial polylactic acid fabric and preparation method thereof

InactiveCN112895638AStrong antibacterial abilityStrong tensile strengthLamination ancillary operationsSynthetic resin layered productsAnti bacterialPolylactic acid

The invention discloses an ammonia-free elastic antibacterial polylactic acid fabric and a preparation method thereof. The ammonia-free elastic antibacterial polylactic acid fabric comprises a fabric body, wefts and warps; a fabric outer layer is connected with the outer side face of a fabric antibacterial layer in a heat bonding mode, and the outer side face and the inner side face of a fabric middle layer are coated with a first coating layer and a second coating layer respectively; and the fabric antibacterial layer is connected with the outer side face of the fabric middle layer in a heat bonding mode, and the fabric middle layer is connected with the outer side face of the fabric inner layer in a heat bonding mode. The first coating layer, the second coating layer and the fabric antibacterial layer are arranged in the fabric body; the first coating layer and the second coating layer are both made of nano-silver coating materials; the nano-silver coating materials have anti-radiation, antibacterial and dirt-inhibiting functions and are soft, breathable and washable; and the fabric antibacterial layer is made of bamboo fiber fabric, the bamboo fiber fabric has the characteristics of good air permeability, instant water absorption, strong wear resistance, good dyeing property and the like, and has the functions of natural antibiosis, bacteriostasis, acarus killing, deodorization and ultraviolet resistance.

Owner:苏州盟红新材料科技有限公司

Multifunctional dishwashing towel and manufacturing method thereof

InactiveCN111394209AStrong tensile strengthNot easy to breakInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWoven fabricAlkene

The invention discloses a multifunctional dish washing towel and a manufacturing method thereof, and belongs to the technical field of washing products and manufacturing methods. The multifunctional dish washing towel comprises a non-woven fabric body, a washing substance layer is attached to the non-woven fabric body, and the washing substance layer comprises the following substances in parts byweight: 50 to 60 parts of deionized water, 10 to 15 parts of sodium laureth sulfate, 0.05 to 0.2 part of an environment-friendly chelating agent, 5 to 10 parts of sodium lauryl sulfate, 1 to 5 parts of fatty alcohol ether, 1 to 5 parts of alkyl glucoside, 5 to 10 parts of C12-14 olefin sulfonate; 1-5 parts of cocamide DEA, 3-8 parts of potassium cocoyl hydrolyzed oat protein, 0.5-2.5 parts of polyglyceryl ether 26, 0.5-2 parts of a residue-free cleaning agent and 0.05-0.2 part of a preservative. The problem that traditional dishwashing liquid can only exist in a liquid state is solved, dishwashing liquid does not need to be used additionally, only one piece of the multifunctional dish washing towel needs to be drawn out and used for wiping objects after being wetted with water in the usingprocess, carrying and transportation are convenient, and more cost is saved compared with liquid transportation.

Owner:YIWU KELI TECH CO LTD

A touch socket

ActiveCN109378640BImprove securityStrong tensile strengthEngagement/disengagement of coupling partsCoupling contact membersPhysicsGround line

The present invention relates to a socket, and more particularly to a touch socket including a touch socket body, a detachable protective board and a circuit module; wherein the touch socket body is formed by a slot and an internal mounting chamber between which a live wire slot, a neutral line through hole and a ground line through hole are arranged; the detachable protective board is fixedly fitted with the slot to form an insertion cavity; the circuit module comprises a live wire module, a neutral line module, a ground line module and an external connector; the live wire module is composedof a touch live wire, a connection live wire and a master live wire; one end of the touch live wire is disposed in the live wire slot, and the other end of the touch live wire and one end of the connection live wire are close to each other, have a gap threrebetween and are not in contact with each other; the other end of the connection live wire and one end of the master live wire are close to each other, have a gap threrebetween and are not in contact with each other; the other end of the master live wire is connected to the external connector; and the circuit module is placed in the internal mounting chamber.

Owner:潘晓丹

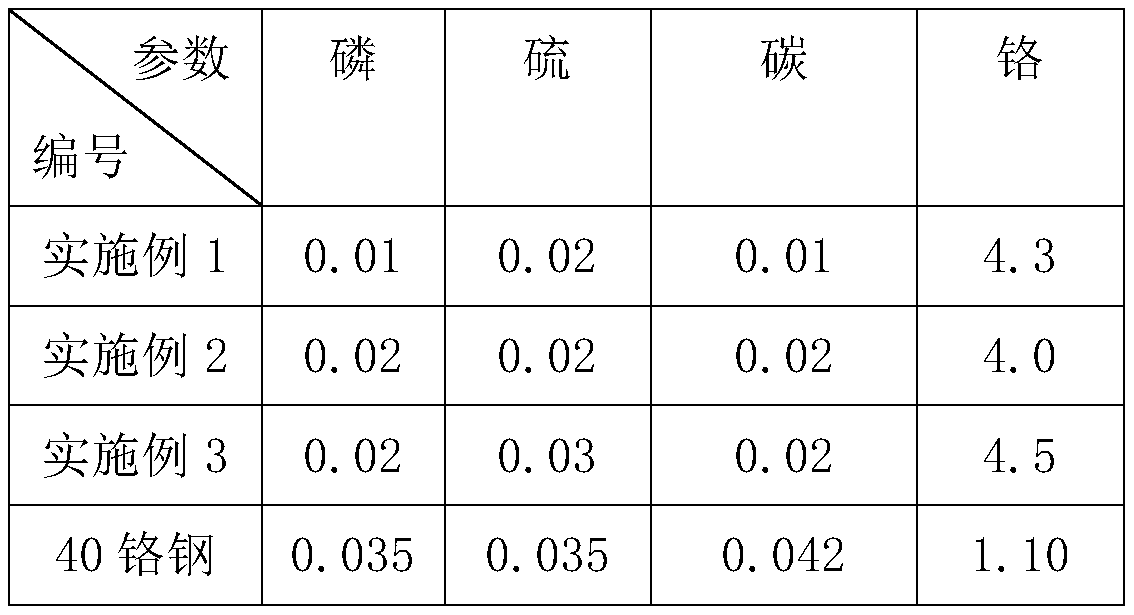

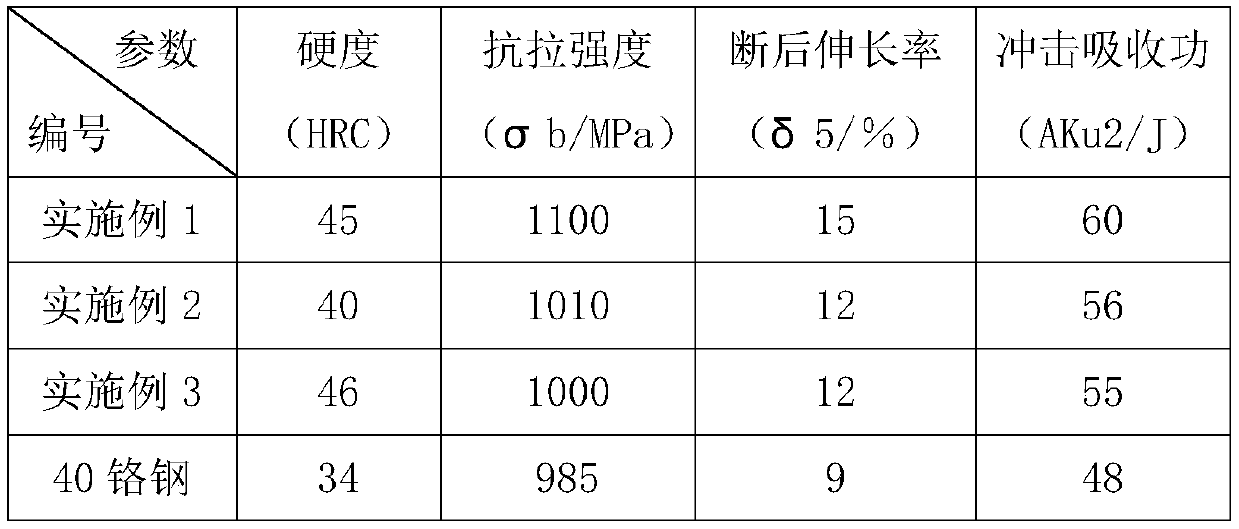

Smelting method of chromium steel

The invention discloses a smelting method of chromium steel, and relates to the technical field of smelting. The smelting method includes the steps of de-phosphorization, desulfurization, rotating boiler boiling steel tapping, steel ladle transporting to the RH furnace station after the steel tapping, steel ladle transporting back to an LF furnace after transported out of a RH furnace, and chromium ferroalloy adding. By means of the smelting method, the phosphorus, sulfur and carbon containing content of the chromium steel is lower, the chromium containing content is improved, the hardness isimproved, the tensile strength, the elongation rate after breaking and the value of impact absorption power are greater than 40 chromium steel, wherein, the embodiment of the example 1 is the best, the thermal brittle phenomenon of the chromium steel is reduced, the pore and looseness of the gas due to SO2 in the welding metal during welding are reduced, the plasticity and impact toughness of chromium steel from the high temperature to below 0 DEG C are improved, and the welding performance and cold bending performance of the chromium steel are optimized.

Owner:马鞍山市鑫龙特钢有限公司

Polypropylene zippered bag and production process thereof

PendingCN113787640ALiquidityStrong tensile strengthBag making operationsPaper-makingMaleic anhydridePelletizing

The invention discloses a polypropylene zippered bag and a production process thereof. According to the technical scheme, the production process comprises the following steps of 1, material preparation: preparing polypropylene (PP), maleic anhydride and ethylene bisstearamide (EBS) according to a ratio of 90%-98%: 3%-5%: 1%-2% to obtain to-be-mixed materials; 2, mixing and granulating: putting the to-be-mixed materials in the step 1 into a high-speed mixer, mixing for 5 minutes at the temperature of more than or equal to 60 DEG C, then putting the to-be-mixed materials mixed in the high-speed mixer into a cold mixer, carrying out cold mixing for 2 minutes, spirally feeding the to-be-mixed materials subjected to cold mixing into a double-screw granulator for granulating, so as to obtain a flexible polypropylene modified material. In the casting process, the EBS is added, so that the flowability is high, the tensile strength of the product is high, the thickness is uniform, and the thickness is only 3-15 filaments compared with a traditional casting film.

Owner:温州银润包装有限公司

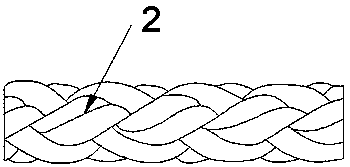

High-performance PP (polypropylene) fiber rope

InactiveCN108677572AStrong tensile strengthExtended service lifeTextile cablesPolypropyleneEngineering

The invention discloses a high-performance PP (polypropylene) fiber rope, comprising a rope body. The rope body includes outer skin and eight rope strands; a filling layer is arranged between the ropebody and the rope strands; the rope strands include an upper layer of three strands, a middle layer of two strands and a bottom layer of three strands; each rope strand is composed of a covering layer and rope cores; any rope strand is formed by twisting 12 rope cores; the high-performance PP fiber rope is composed of the eight rope strands; each rope strand is formed by twisting 12 rope cores, with 10 rope cores around 2 rope cores, wherein the rope cores are twisted in pairs in opposite directions; rotation of the rope can be prevented through such manner; the high-performance PP fiber ropeis more convenient to use; steel wires in the rope cores can provide shaping; the covering layers made of acrylic material allow less water to enter the rope cores, and therefore, rusting of the steel wires is avoided.

Owner:JIANGSU XIANGCHUANG ROPE TECH

Plastic formula containing phosphite ester

InactiveCN107189440AStrong chemical stabilityStrong tensile strengthTemperature resistanceAntimony oxide

The invention discloses a plastic formula containing phosphite ester. The plastic formula containing phosphite ester comprises, by weight, 40 to 70 parts of a polysulfone resin, 10 to 15 parts of a phosphite ester, 6 to 8 parts of toluene diisocyanate, 3 to 10 parts of antimony oxide, 1 to 4 parts of a lubricant, 13 to 19 parts of polypropylene, and 13 to 17 parts of a compatilizer. The beneficial effects are that: plastic prepared based on the plastic formula is nontoxic, is high in chemical stability, possesses high temperature resistance, high tensile strength, antistatic properties, and oxidation resistance; no environmental pollution is caused; and the plastic formula is friendly to the environment.

Owner:郭瑞

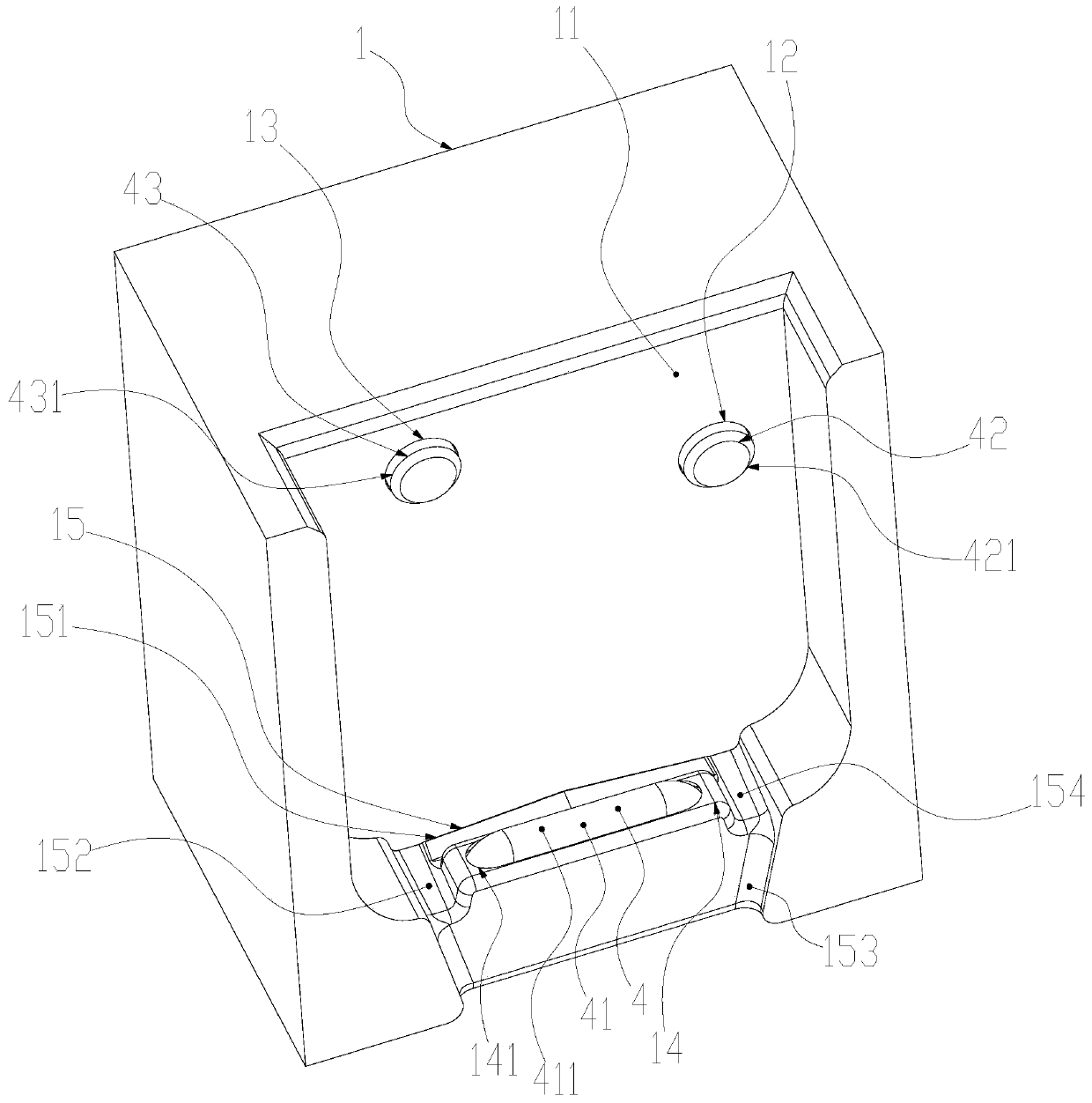

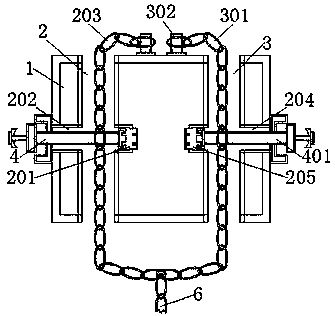

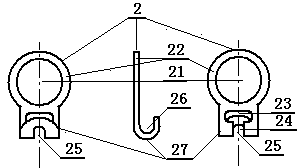

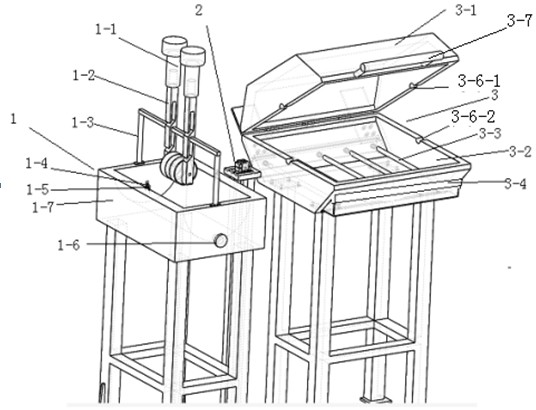

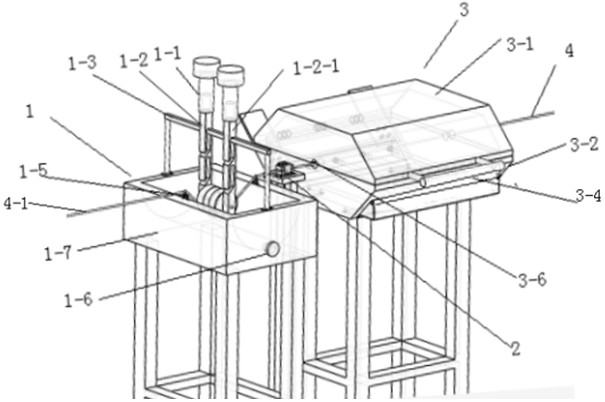

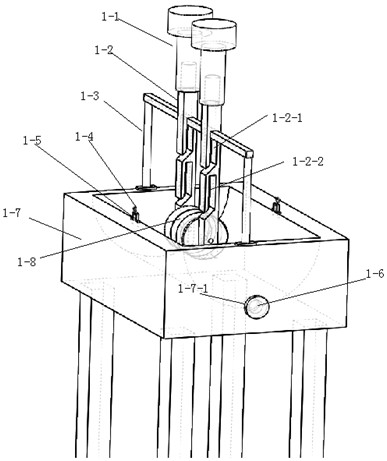

A rear trailer hook device for an airport trailer

InactiveCN109203880AEven by forceHigh pulling efficiencyTowing devicesEngineeringMechanical engineering

The invention discloses a rear trailer hook device for an airport trailer, and relates to the technical field of towing hook devices. The device includes a body. The first passage and the second passage are respectively arranged on the inner two sides of the trailing hook device. The first passage and the second passage have the same structure, one side of the first passage and one side of the second passage are respectively provided with a first engaging groove and a second engaging groove, and the other side of the first passage and the other side of the second passage are respectively provided with a first mounting port and a second mounting port. On the one hand, the trailer is connected by one end of the third trailer chain, the other end of the third trailing chain is connected withone end of the first trailing chain and the second trailing chain. When the trailer is moved forward, the trailing hook device simultaneously provides pulling force for the third trailing chain through the first trailing chain and the second trailing chain. The first trailing chain and the second trailing chain are uniformly forced, and the overall pulling efficiency is much higher than that of the conventional trailing hooks.

Owner:宿迁泰达空港设备有限公司

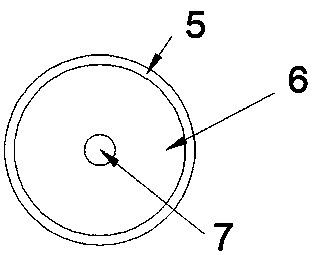

Cable with metal hoses for coal

InactiveCN104637614AGood electrical conductivityStrong tensile strengthPower cables with screens/conductive layersInsulated cablesChemical industryFluorinated ethylene propylene

The invention discloses a cable with metal hoses for coal. The cable comprises two conductor cores, two metal hoses and six protective layers. The two conductor cores are respectively a galvanized annealing copper conductor core and a galvanized annealing nickel conductor core; the metal hoses are galvanized aluminum alloy metal hoses; from inside to outside, the six protective layers are a galvanized aluminum wire shielding layer, a fluorinated ethylene-propylene insulation layer, a silver-plated nickel tape armored layer, a polyvinyl chloride insulation layer, a polychloroprene sheathed layer and a copper-plastic aluminum tape polyethylene sheathed layer in sequence; the galvanized aluminum wire shielding layer is adopted as the core layer of the cable. The cable has the characteristics of best conductivity, oxidation resistance and ageing resistance; meanwhile, the cable can be widely applied to the fields of coal, petroleum and chemical industry.

Owner:安徽万博电缆材料有限公司

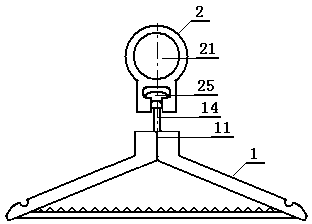

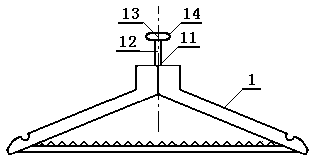

Part combining type clothes hanger

InactiveCN103750710ASafe and reliable workReasonable structureApparel holdersEngineeringClothes hanger

The invention relates to a part combining type clothes hanger. According to the part combining type clothes hanger, a body is split type and is formed by mutual matched combination and buckling of two independent components which are a hanger body and a hook, a T-shaped metal hanging rod which is composed of a vertical rod and an outward-protruding chuck which are connected with each other is arranged on the hanger body, the body of the hook is composed of a bent metal thin steel sheet, and the metal thin steel sheet is composed of a straight hanging end provided with a closed hanging hole and a bent hanging and holding end provided with a T-shaped stretching guide hole and a limiting clamping groove; when the part combining type clothes hanger is used, the hook is movably arranged on a clothes hanging cross rod in a sleeved mode and can move leftwards and rightwards, the hanger body is buckled at the bent hanging and holding end of the hook through the outward-protruding chuck and can be dismantled freely, in order to enable the hanger body to be separated from or buckled with the hook, a user just needs to lift the hanger body to enable the outward-protruding chuck and a transverse strip hole to be aligned, the size of the outward-protruding chuck is small, the surface of the outward-protruding chuck is smooth, the influence of resistance is quite small when the outward-protruding chuck touches clothes around, and the situation that the clothes around the outward-protruding chuck are scratched by the outward-protruding chuck can not occur; the part combining type clothes hanger has the advantages of being reasonable in structure, safe and reliable in work, convenient to use, long in service life, high in practicability and broad in market application prospect.

Owner:李文祥

Fluorinated ethylene propylene copolymer tensile cable

InactiveCN107964177AImprove tensile strengthStrong tensile strengthPlastic/resin/waxes insulatorsInsulated cablesPolypropyleneFluorinated ethylene propylene

The invention discloses a fluorinated ethylene propylene copolymer tensile cable, comprising: at least one conductor core, an insulating layer wrapped around the conductor core, a shielding layer wrapped around the insulating layer, The sheath layer wrapped around the shielding layer; the sheath layer includes an inner sheath, an inner lining layer, an armor layer and an outer coating layer; the outer coating layer is made of modified fluorinated ethylene propylene copolymer The modified fluorinated ethylene propylene copolymer material is prepared from the following raw materials in parts by weight: 20-30 parts of basalt fiber, 8-12 parts of modifier, 20-30 parts of poly Propylene, 35-45 parts of fluorinated ethylene-propylene copolymer, 0.3-0.8 parts of coupling agent, 0.1-0.3 parts of cross-linking agent; The fluorinated ethylene propylene copolymer material is used as the outer layer in the cable sheath layer, which improves the tensile resistance of the fluorinated ethylene propylene copolymer cable, makes the fluorinated ethylene propylene copolymer cable better adaptable, and has a wider application range.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

Latex powder containing plastic formula

The invention discloses a latex powder containing plastic formula. The plastic formula comprises raw materials including, by weight, 40-70 parts of polysulfone resin, 10-15 parts of phosphite, 6-8 parts of toluene diisocyanate, 3-10 parts of antimony trioxide, 1-4 parts of a lubricant, 13-19 parts of latex powder and 13-17 parts of a compatibilizer. The latex powder containing plastic formula has advantages that plastic produced according to the formula is nontoxic, high in chemical stability, resistant to high temperature, high in tensile strength and free of environment pollution and has antistatic and anti-oxidation properties, and the formula is an environment-friendly plastic formula.

Owner:郭瑞

Device for coating external insulation of 1200 DEG C high-temperature-resistant cable and use method

PendingCN113192704AHigh conductor strengthStrong tensile strengthInsulating conductors/cablesQuartz fiberManufacturing engineering

The invention relates to a device for coating external insulation of a 1200 DEG C high-temperature-resistant cable and a use method. The device comprises a gluing pot, a mold frame and a dryer, wherein the center lines of a wire hook on the gluing pot, a die hole on the lower die and a lower wire groove on a dryer base are on the same horizontal plane and on the same straight line. The method comprises the steps of manufacturing the high-strength nickel-plated copper alloy conductor, wrapping the high-purity quartz fiber woven inner insulator, preparing the mica coating, coating and sintering. The high-purity quartz fiber woven inner insulation and the high-temperature-resistant mica coating outer insulation can be sintered into a whole to form an insulation layer, the insulation layer is coated on the outer surface of the high-strength nickel-plated copper alloy conductor, the 1200 DEG C high-temperature-resistant cable is manufactured, the 1200 DEG C high-temperature-resistant cable can resist the high temperature of 1050 DEG C for a long time and can resist the high temperature of 1700 DEG C for a short time, and the 1200 DEG C high-temperature-resistant cable has the advantages of being soft, small in outer diameter and the like. The device provided by the invention is matched with various types of machines such as horizontal cable winches, wrapping machines, rewinding machines and the like for use.

Owner:天津六0九电缆有限公司

Formula of plastic containing polysulfone resin

InactiveCN107141801AStrong chemical stabilityStrong tensile strengthTemperature resistancePolypropylene

The invention discloses a plastic formula containing polysulfone resin, which comprises the following raw materials in parts by weight: 40-70 parts of polysulfone resin, 10-15 parts of glass fiber, 6-8 parts of toluene diisocyanate, and 3 parts of plasticizer ‑10 parts, lubricant 1‑4 parts, polypropylene 13‑19 parts, compatibilizer 13‑17 parts. The beneficial effects of the invention are: the plastic produced by the formula is non-toxic, has strong chemical stability, high temperature resistance, strong tensile force, anti-static, anti-oxidation, and has no pollution to the environment, and belongs to the environment-friendly plastic formula.

Owner:郭瑞

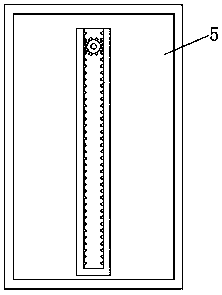

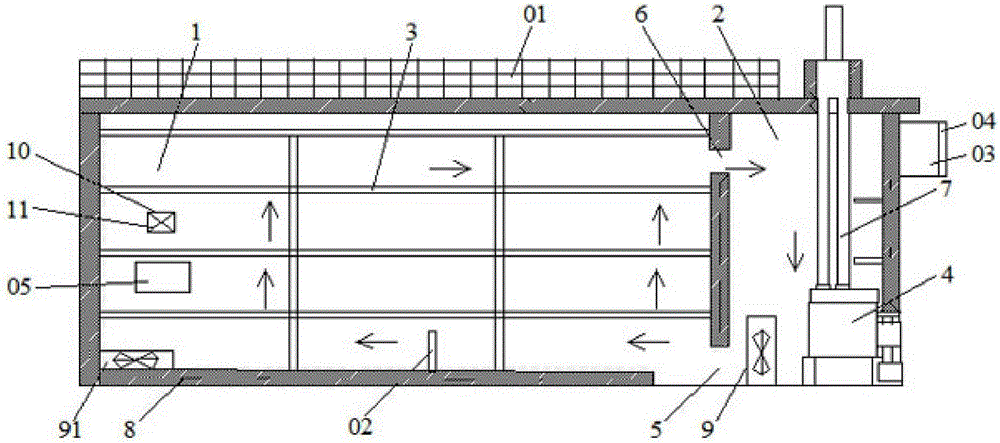

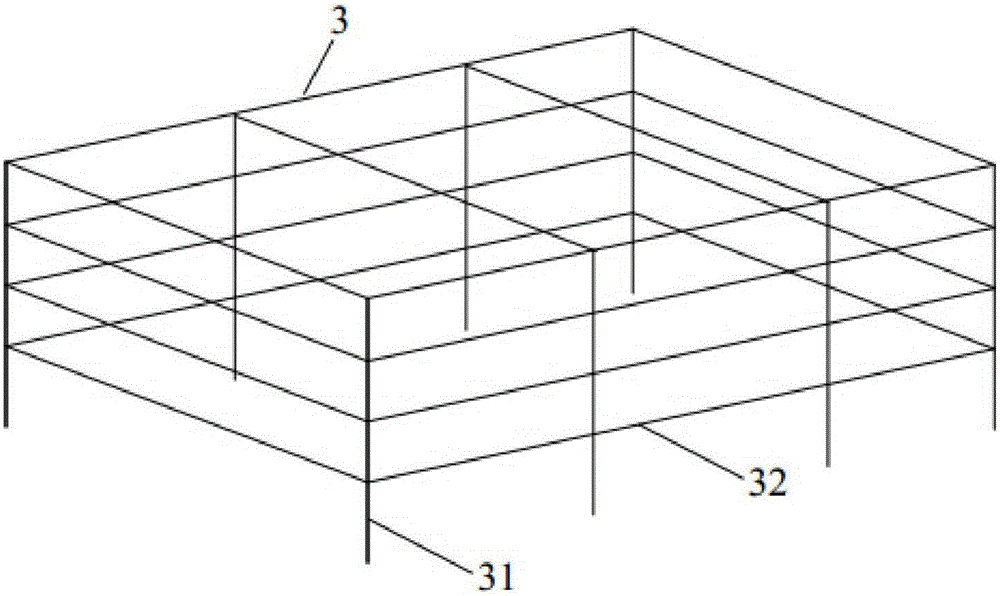

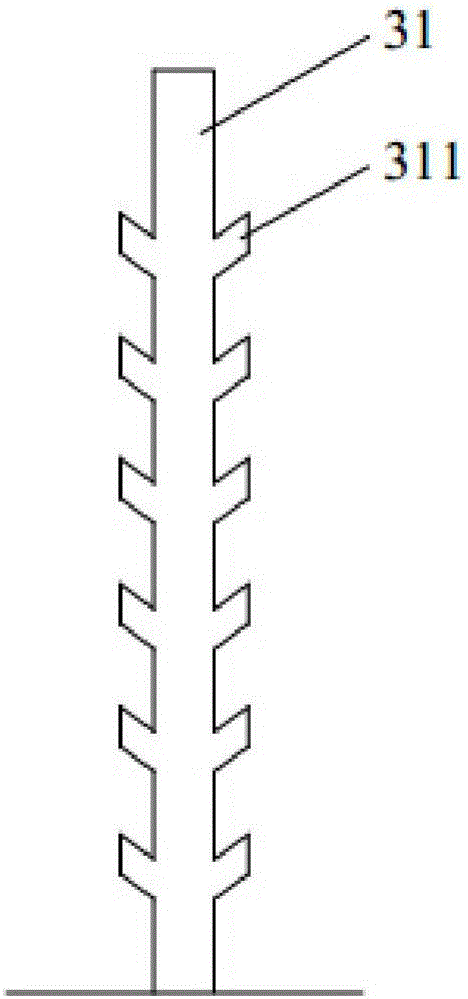

Insulation full-automatic solar tobacco curing barn

InactiveCN105661612AStrong tensile strengthSpeed up the cycleTobacco preparationSolar power systemMeasurement device

The invention discloses a heat-preserving full-automatic solar-powered tobacco flue-curing room. A first fan is arranged at the lower part of the hot air chamber near the air inlet, and a second fan blowing upward is arranged at the lower part of the flue-cured room opposite the first fan. The tobacco hanging rack includes a vertical The vertical bar and the horizontal bar are set, and the vertical bar is provided with a plurality of clamping parts for clamping the horizontal bar; a solar power generation device is also installed on the roof of the flue-cured room; a temperature and humidity detection device is installed in the flue-cured room, and the flue-cured room There is also a control host on the top, and the control host is respectively connected with the temperature and humidity detection device, the heating device, the first fan, the second fan, and the solar power generation device through cables; a control panel is also arranged outside the control host, and a There are viewing windows. The solar power generation device can provide power for electrical equipment in the flue-cured room, reducing investment in electrical equipment and reducing comprehensive electricity costs. Moreover, it can be automatically controlled to realize fully automatic intelligent flue-cured tobacco. At the same time, the flue-cured tobacco room is also equipped with a humidity collection system to facilitate the management and control of humidity.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com