Production process of vacuum aluminum-plated composite films

A technology of vacuum aluminum plating and production process, applied in layered products, metal layered products, flexible coverings, etc., can solve the problems of poor pattern gloss, small solvent residue, poor adhesion of aluminum layer, etc. The effect of smooth surface, excellent oxygen permeability and good adhesion of aluminum layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

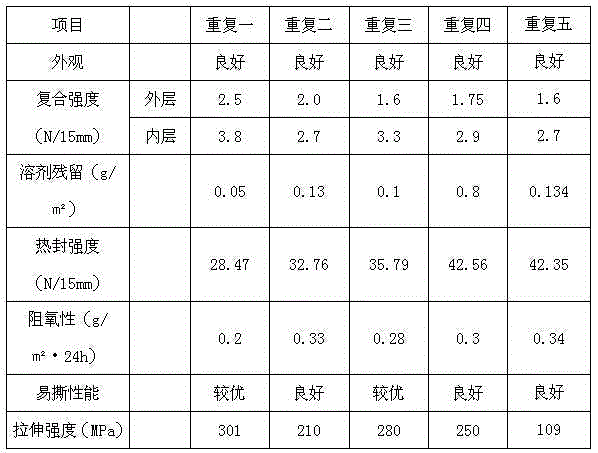

Examples

Embodiment 1

[0020] A kind of production technique of vacuum aluminized composite film, comprises the following steps:

[0021] 1) Selection of base material: select PVC film with low light transmittance as the base material for corona treatment, and the light transmittance of the PVE film is 10-20%;

[0022] 2) Vacuum aluminizing: the PVC film is vacuum aluminized on a vacuum aluminizing machine to form an aluminized film. The vacuum aluminizing process is unwinding the substrate → vacuuming → heating the evaporation boat → sending aluminum wire → evaporation → cooling → Flattening → winding, the vacuum degree is 1.5×10-2Pa, the temperature of the evaporation boat is controlled at 1760°C, the purity of the aluminum wire is not less than 99.99%, the wire feeding speed is 2m / min, and the thickness of the aluminum coating is 380-400 angstroms. The winding speed is 60m / min;

[0023] 3) Apply a solvent-free adhesive to the aluminum surface of the aluminized film at a coating temperature of 60...

Embodiment 2

[0030] A kind of production technology of vacuum aluminized composite film as described in embodiment one, comprises the following steps:

[0031] 1) Selection of base material: select PVC film with low light transmittance as the base material for corona treatment, and the light transmittance of the PVE film is 10-20%;

[0032] 2) Vacuum aluminizing: the PVC film is vacuum aluminized on a vacuum aluminizing machine to form an aluminized film. The vacuum aluminizing process is unwinding the substrate → vacuuming → heating the evaporation boat → sending aluminum wire → evaporation → cooling → Flattening → winding, the vacuum degree is 1.6×10-2Pa, the temperature of the evaporation boat is controlled at 1690°C, the purity of the aluminum wire is not less than 99.99%, the wire feeding speed is 2.3m / min, and the thickness of the aluminum coating layer is 380-400 angstroms , the winding speed is 710m / min;

[0033] 3) Apply a solvent-free adhesive to the aluminum surface of the alum...

Embodiment 3

[0037] A kind of production technology of vacuum aluminized composite film as described in embodiment one, comprises the following steps:

[0038] 1) Selection of base material: select PVC film with low light transmittance as the base material for corona treatment, and the light transmittance of the PVE film is 10-20%;

[0039]2) Vacuum aluminizing: the PVC film is vacuum aluminized on a vacuum aluminizing machine to form an aluminized film. The vacuum aluminizing process is unwinding the substrate → vacuuming → heating the evaporation boat → sending aluminum wire → evaporation → cooling → Flattening → winding, the vacuum degree is 1.7×10-2Pa, the temperature of the evaporation boat is controlled at 1630°C, the purity of the aluminum wire is not lower than 99.99%, the wire feeding speed is 2m / min, and the thickness of the aluminum coating layer is 380-400 angstroms. The winding speed is 730m / min;

[0040] 3) Apply a solvent-free adhesive to the aluminum surface of the alumini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com