Device for coating external insulation of 1200 DEG C high-temperature-resistant cable and use method

A technology of high temperature resistance and external insulation, applied in the direction of insulating conductors/cables, etc., can solve the problems of large cable hardness, large bending radius, large space occupation, etc., and achieve the effect of excellent tensile strength and high conductor strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

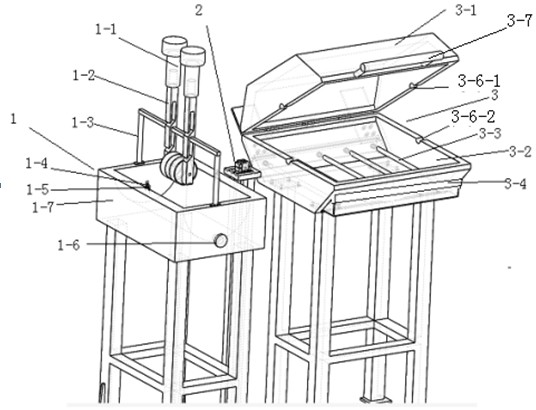

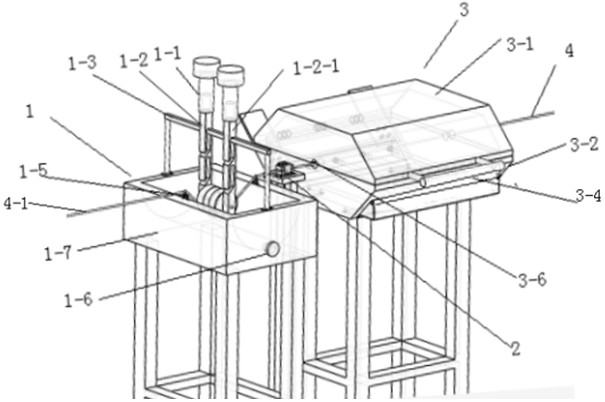

[0024] Such as Figure 1 to Figure 5 As shown, a device for coating the outer insulation of high temperature resistant cables at 1200 °C, including a glue pot 1, a mold frame 2 and a dryer 3;

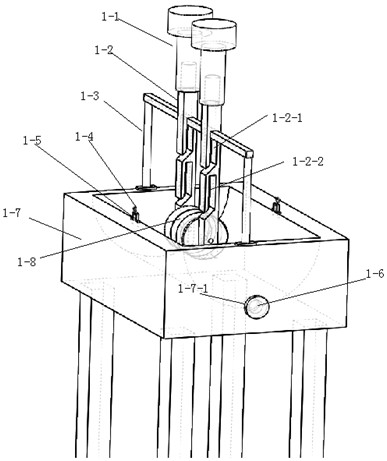

[0025] The glue pot 1 includes a handle 1-1, a crimping wheel rod 1-2, a pot rack 1-3, a wire hook 1-4, a wire hook bracket 1-5, a rubber leakage plug 1-6, and a glue pot body 1- 7 and the crimping wheel 1-8; the glue pot body 1-7 is a rectangular groove fixed on the workbench, and a glue leakage plug hole 1-7-1 is set on the side wall of the glue pot body 1-7, The leaking plug 1-6 is set in the leaking plug hole 1-7-1; the pot rack 1-3 is set across the pot body 1-7 on the two opposite side plates of the pot body 1-7, The two wire hook brackets 1-5 are respectively arranged on the other two opposite side plates of the glue pot body 1-7, and the two wire hooks 1-4 are respectively arranged on the two wire hook brackets 1-5; There are two rods 1-2, an open upper card slot 1-2-1 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com