Strong and tough back side waterproof coating

A waterproof coating and backwater technology, applied in the field of coatings, can solve the problems of water resistance, poor low temperature film formation, dry cracking, deformation cracking, etc., and achieve excellent bending resistance, improved service life, and good self-healing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

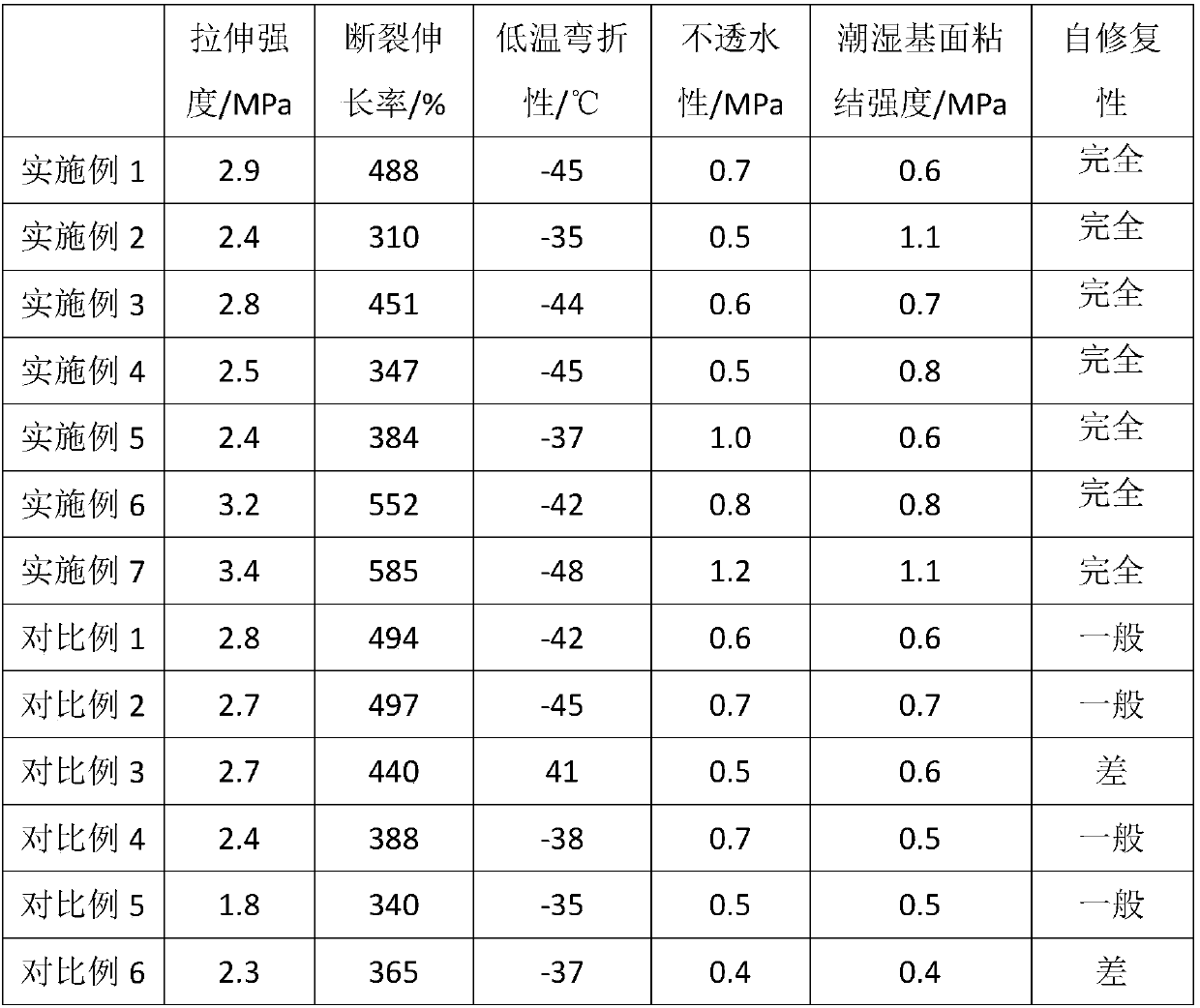

Examples

preparation example Construction

[0076] Second aspect of the present invention provides the preparation method of strong and tough water surface waterproof coating, comprises the steps:

[0077] a: Dehydration treatment of polyols and dioximes, taking specified parts by weight and adding them to a reaction kettle equipped with a stirrer, and adding the first batch of isocyanate, the temperature is controlled at 65 ~ 75 ° C, and in N 2 React in the atmosphere for 1.5 to 3 hours, then add the second batch of isocyanate, polyethyleneimine, amino acid and acrylic acid mixture dropwise, and stir for 30 to 45 minutes to obtain component A;

[0078] b: Take specified weight parts of nano-titanium dioxide, nano-silica, film-forming aids, and water into the high-speed dispersant, stir and disperse evenly for 20-30 minutes; then add acrylic acid emulsion and stir for 10-20 minutes to obtain component B;

[0079] c: Mix and stir components A and B for 15-30 minutes, and filter to obtain a strong and tough water surface ...

Embodiment 1

[0085] Embodiment 1 provides a kind of strong and tough waterproof coating on the back surface, the waterproof coating on the back surface includes two components A and B, the weight ratio of the two components is A:B=1:1;

[0086] The raw materials for the preparation of the A component, in parts by weight, consist of 42 polyols, 76 isocyanates, 3.9 dioximes, 10.5 polyethyleneimines, 0.6 amino acids, and 4.5 acrylic acid; In parts by weight, it consists of 15 acrylic emulsions, 0.5 nano titanium dioxide, 2 nano silicon dioxide, 1 film-forming aid and 15 water.

[0087] Described polyhydric alcohol is polyethylene glycol, is purchased from Sinopharm Chemical Reagent, and trade mark is 30150928; Described isocyanate is L-lysine triisocyanate and hexamethylene diisocyanate, and its molar ratio is L-lysine triisocyanate : Hexamethylene diisocyanate = 1: 3, wherein the CAS number of L-lysine triisocyanate is 69878188, purchased from Hangzhou Yilian Chemical Co., Ltd.; the divalent...

Embodiment 2

[0093] Embodiment 2 provides a kind of strong and tough waterproof paint on the back surface, the waterproof paint on the back water surface includes two components A and B, and the weight ratio of the two components is A:B=1:4;

[0094] The raw materials for the preparation of the A component, in parts by weight, consist of 42 polyols, 76 isocyanates, 3.9 dioximes, 10.5 polyethyleneimines, 0.6 amino acids, and 4.5 acrylic acid; In parts by weight, it consists of 40 acrylic emulsions, 4 nano-titanium dioxide, 8 nano-silicon dioxide, 4 film-forming aids, and 35 water.

[0095] Described polyhydric alcohol is polyethylene glycol, is purchased from Sinopharm Chemical Reagent, and trade mark is 30150928; Described isocyanate is L-lysine triisocyanate and hexamethylene diisocyanate, and its molar ratio is L-lysine triisocyanate : Hexamethylene diisocyanate = 1: 3, wherein the CAS number of L-lysine triisocyanate is 69878188, purchased from Hangzhou Yilian Chemical Co., Ltd.; the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com