Tensile electric wire cable with reinforcement cores

A heating wire and reinforcing core technology, used in insulated cables, power cables with shielding/conducting layers, cables, etc., can solve the problems of inconvenience for people, inability to protect the household electricity consumption of northern people, factory losses, etc., and achieve electrical conductivity. Strong, long service life, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

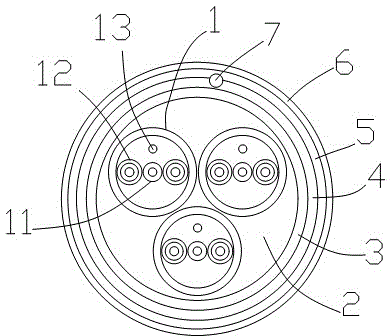

[0009] like figure 1 As shown, a tensile heating wire cable with reinforced core is composed of grounding cable core 1, polyester fiber layer 2, silicon rubber insulating layer 3, copper tape shielding layer 4, copper tape armoring layer 5 and chlorosulfonated Polyethylene sheath layer 6, the control cable core 1 is arranged in two groups, extruded inside the polyester fiber layer 2, and a layer of silicone rubber insulating layer 3 is wrapped outside the polyester fiber layer 2, and the silicon rubber A layer of copper tape shielding layer 4 is wrapped outside the rubber insulating layer 3, and a layer of copper tape armor layer 5 is wrapped outside the copper tape shielding layer 4, and a steel wire reinforcing core 11 is extruded inside the grounding cable core 1, Two sets of nickel conductor cable cores 12 and one copper wire drain wire 13 .

[0010] A copper wire heating wire 7 is extruded between the copper tape shielding layer 4 and the copper tape armor layer 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com