Organic silicon composition with main chain containing phenylene structure and preparation method thereof

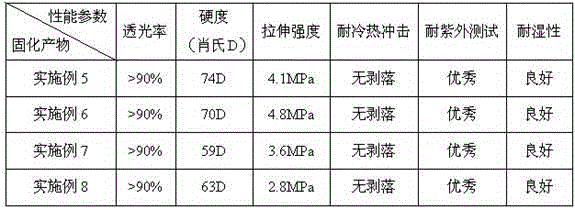

A silicone and composition technology, which is applied in the field of silicone compositions containing phenylene structure in the main chain and its preparation, can solve the problems of poor compatibility, cracks, whitening resin, etc., and achieve strong bonding performance and high hardness , Strong tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The preparation of embodiment 1 A1 component

[0078] (1) Add 150g (0.53mol) of 1,4-bis(dimethylethoxysilyl)benzene, phenyl trimethyl Oxysilane 500g (2.53mol), methylphenyldimethoxysilane 50g (0.27mol), 5-dichloromethylsilylbicyclo[2.2.1]-hept-2-ene 40g (0.19mol) , Vinyldimethylmethoxysilane 44g (0.38mol) and toluene 1000g, stir well and raise the temperature to 60°C;

[0079] (2) At 60°C, add 600g of a mixture of KOH and water dropwise, and the dropping time is controlled within 1 hour;

[0080] (3) After the dropwise addition, the temperature was raised and refluxed for 4 hours;

[0081] (4) Separate the water layer, and wash the polymer and solvent part with water until neutral;

[0082] (5) After removing unreacted raw materials and solvent, the target product A1 component is obtained.

Embodiment 2

[0083] The preparation of embodiment 2 A2 component

[0084] (1) Add 100g (0.35mol) of 1,4-bis(dimethylethoxysilyl)benzene, phenyl trimethyl Oxysilane 500g (2.53mol), phenylmethyldimethoxysilane 80g (0.44mol), vinylmethyldimethoxysilane 15g (0.11mol), vinyldimethylmethoxysilane 44g ( 0.38mol) and toluene 1000g, stir well and heat up to 60°C;

[0085] (2) At 60°C, add 600g of a mixture of KOH and water dropwise, and the dropping time is controlled within 1 hour;

[0086] (3) After the dropwise addition, the temperature was raised and refluxed for 4 hours;

[0087] (4) Separate the water layer, and wash the polymer and solvent part with water until neutral;

[0088] (5) After removing unreacted raw materials and solvents, the target product A2 component is obtained.

Embodiment 3

[0089] The preparation of embodiment 3 B1 component

[0090] (1) Add 100g (0.35mol) of 1,4-bis(dimethylethoxysilyl)benzene, diphenyl Dimethoxysilane 280g (1.15mol), dimethyldimethoxysilane 80g (0.67mol), dihydrotetramethyldisiloxane 28g (0.21mol) and toluene 1000g, stir well and heat it up to 80°C;

[0091] (2) At 80°C, add 500 g of the mixture of HCl and water dropwise, and the dropping time is controlled within 1 hour;

[0092] (3) After the dropwise addition, the temperature was raised and refluxed for 5 hours;

[0093] (4) Separate the water layer, and wash the polymer and solvent part with water until neutral;

[0094] (5) After removing unreacted raw materials and solvent, the target product B1 component is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com