Ultra-large space GRG installation structure

An installation structure and space technology, applied in the field of super-large space GRG installation structure, can solve the problems of large size and complex shape, and achieve the effect of strong bending resistance, strong tensile force and high assembly freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

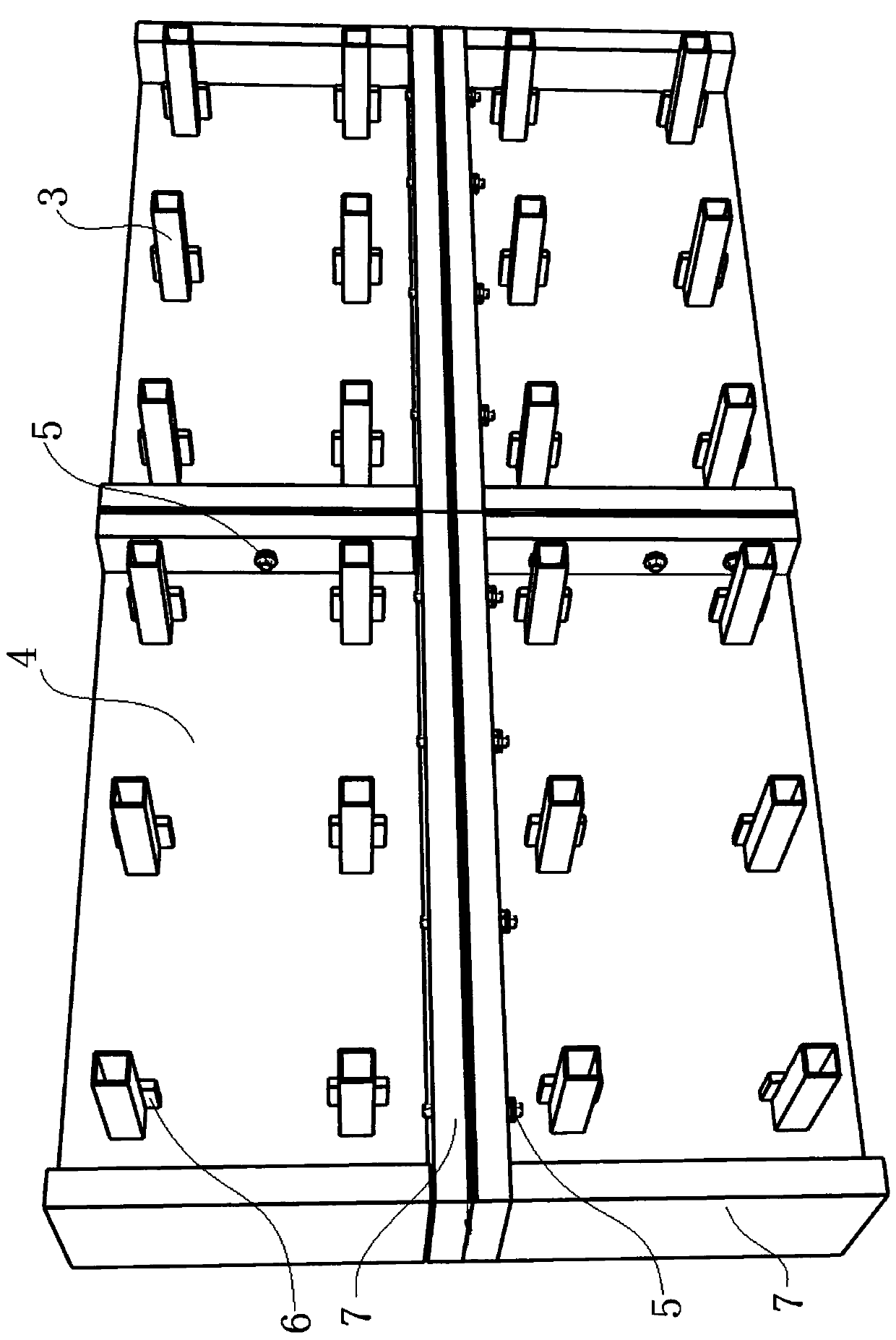

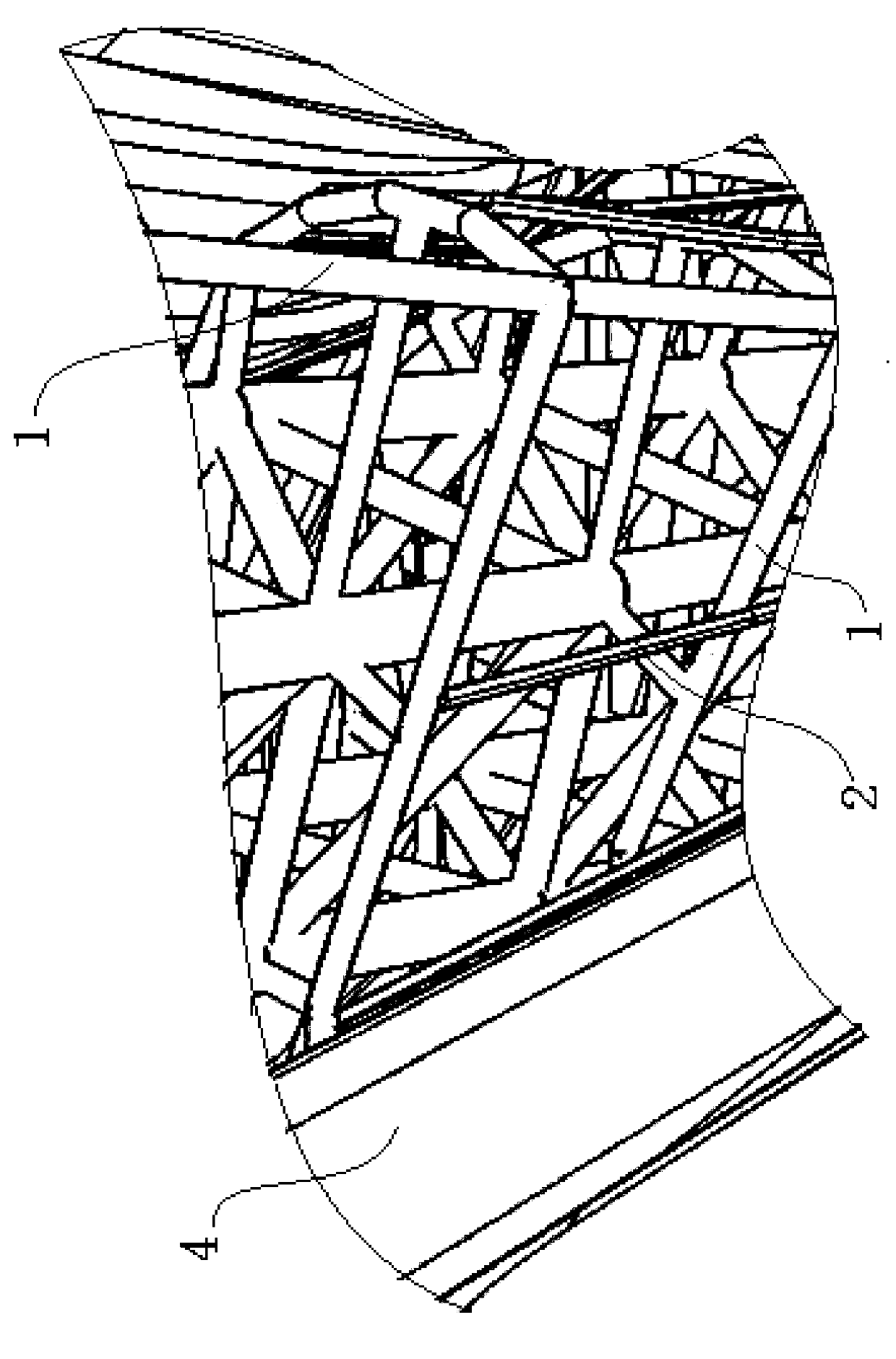

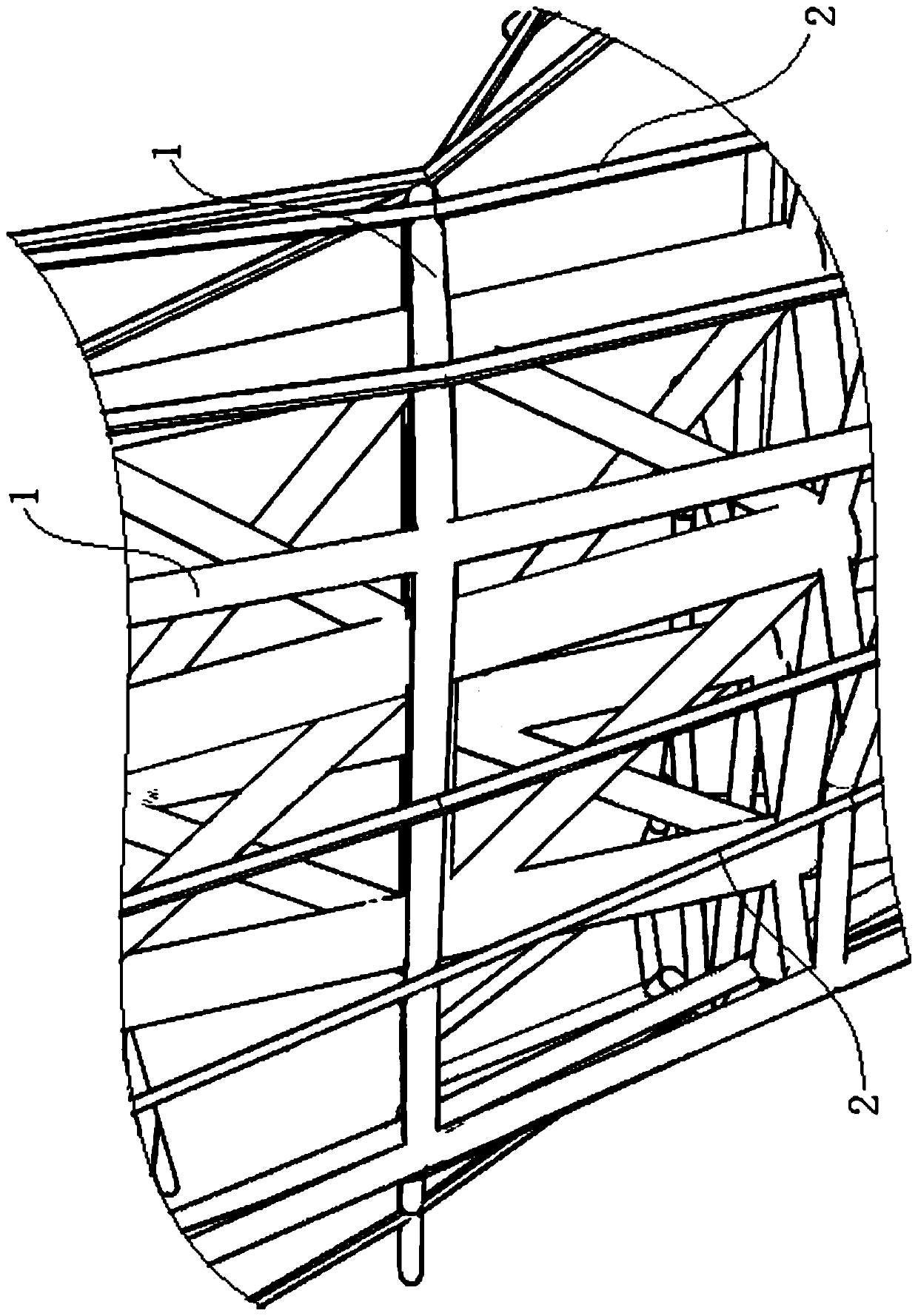

[0031] In order to achieve the purpose of the present invention, the super-large space GRG installation structure includes: embedded boards 6, the back of each glass fiber gypsum board 4 vertically protrudes with several embedded boards 6, and the main plane of each embedded board 6 Straight lines parallel to the vertical direction; connectors, including bolts 5, between 4 adjacent fiberglass gypsum boards are provided with flanges 7 that are turned up vertically toward the back, and bolts 5 connect the respective flanges 7 of adjacent fiberglass gypsum boards 4 Assembly connection; auxiliary steel frame, including the first square tube 2 and the second square tube 3 vertically connected, the cross-sectional area of the first square tube 2 is greater than the cross-sectional area of the second square tube 3, and the first square tube 2 is vertically conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal width | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com