Reinforced square steel tube

A square steel pipe, reinforced technology, applied in the direction of slender elements, building elements, etc., can solve the problems of not having a beautiful appearance, easy deformation, insufficient shear and bending strength of the square steel pipe, and achieve a beautiful structural appearance , the effect of strengthening the anti-bearing capacity and increasing the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

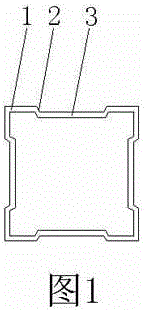

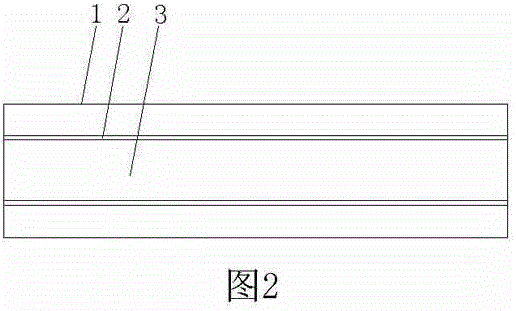

[0012] The specific embodiment of the present invention is, with reference to figure 1 , figure 2 , including the square steel pipe body and the reinforcement ribs 3 on the four walls of the square steel pipe body, the reinforcement ribs 3 are longitudinally arranged on the square steel pipe, and the reinforcement ribs 3 on the four walls of the square steel pipe are concave toward the inner cavity of the square steel pipe Further, the reinforced ribs 3 recessed in the inner chamber walls of the four walls of the square steel pipe constitute the trapezoidal inner chamber wall, and the trapezoidal sides 2 of the inner chamber wall of the trapezoidal shape form the supporting surfaces of the four corners 1 of the square steel pipe. The four corners 1 are parallel, and the four corners 1 of the parallel square steel pipes and the reinforcing ribs 3 recessed toward the inner wall of the square steel pipe form a convex-concave square steel pipe wall;

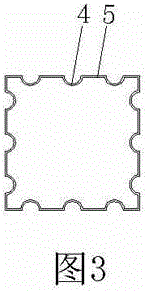

[0013] refer to image 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com