Composite body armor

A technology for body armor and bullets, which is applied in protective equipment, offensive equipment, personnel protection equipment, etc. It can solve the problems of poor resistance to deformation, inability to effectively reduce the impact force of bullets and body armor, and easy to produce stray bullets, so as to avoid rib fractures, Reduce stray bullets and impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments.

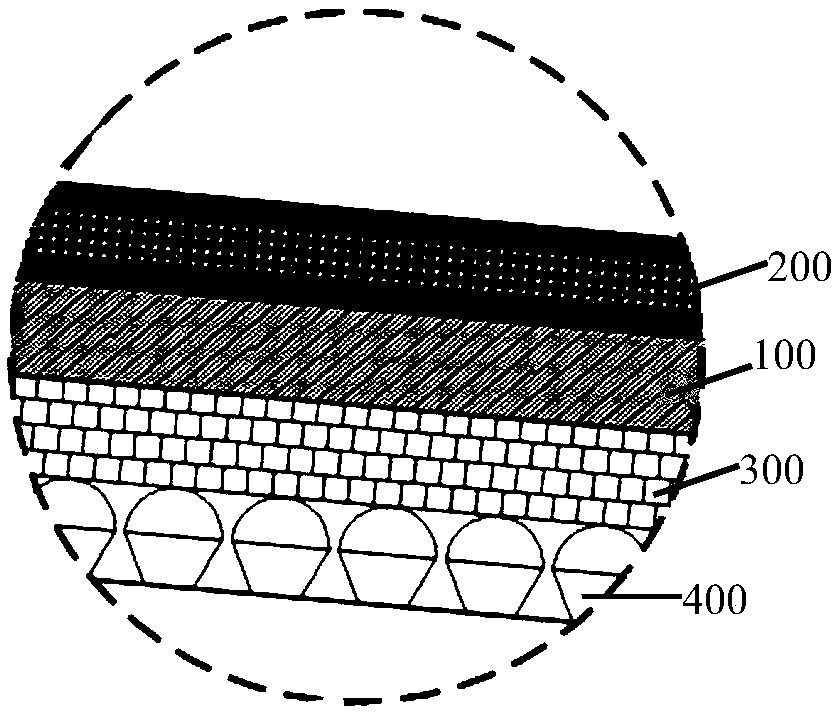

[0024] see Figure 1 to Figure 5 , The body armor with composite structure provided by the present invention mainly includes a bomb-absorbing layer 200, a protective layer, a buffer layer 300, an energy-absorbing layer 400, etc. from the outside and inside, and each layer is glued together.

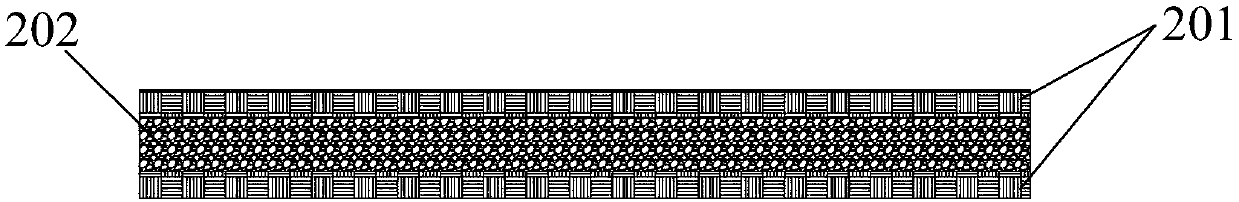

[0025] The bomb-absorbing layer 200 includes two carbon fiber layers 201 and an aluminum foam layer 202 , and the aluminum foam layer 202 is sandwiched between the two carbon fiber layers 201 . Compared with traditional metal materials, carbon fiber has the characteristics of high strength, high modulus, low density, and small linear expansion coefficient. Aluminum foam as a filling material has low density and high impact absorption capacity. The purpose of this layer structure is to make the bullets collide with the body armor, and the body armor can absorb the bullets so as to avoid the genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com