Patents

Literature

74results about How to "Strong fracture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

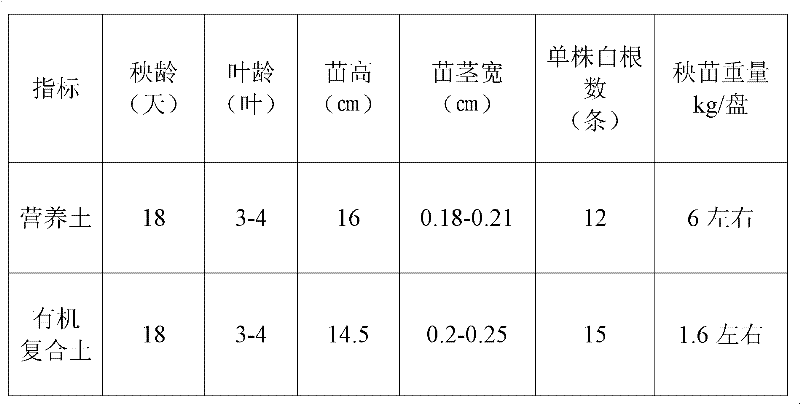

Preparation method of organic compound soil for rice seedling raising

ActiveCN102503652ASeedling raising effect is goodGood fracture resistanceBio-organic fraction processingOrganic fertiliser preparationEffective microorganismSoil organic matter

The invention discloses a preparation method of organic compound soil for rice seedling raising. The method comprises the following steps of: collecting and treating raw materials, selecting a raw material formula, composting organic matters and adding auxiliary materials. The water content of the organic compound soil is less than or equal to 50%, the organic matter content (dry basis) is more than or equal to 40%, the total nutrient content (dry basis) is 2.2% to 2.8%, the pH value is 5.5 to 7, the EC value is less than or equal to 3, and the particle size is less than or equal to 5 mm. The mushroom leftovers and other organic waste are used as raw materials to provide complete nutrients, and the organic matters are fermented with effective microorganisms and then the auxiliary materials are added, resulting in extremely good effects. The organic waste is adopted as matrix to replace the conventional nutritional soil, so as to eliminate the need of collecting farmland surface soil, effectively protect farmlands and facilitate sustainable development of agriculture. The organic compound soil made by the method is very suitable for rice seedling raising, can promote robust growth of rice seedlings and can be promoted and applied all over the country.

Owner:江苏培蕾基质科技发展有限公司

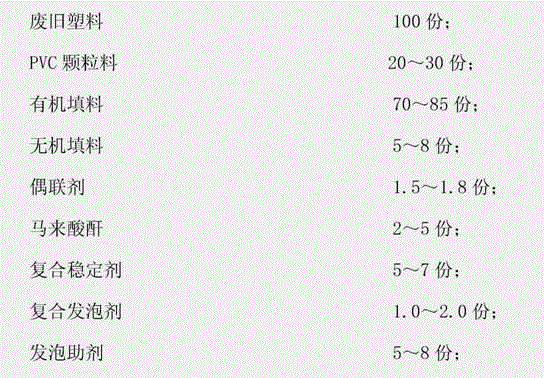

Highly filled wood-plastic foaming material and preparation method thereof

The invention discloses a highly filled wood-plastic foaming material and a preparation method thereof and belongs to the technical field of wood-plastic materials. The highly filled wood-plastic foaming material is prepared from the following raw materials: 100 parts of waste plastic, 20-30 parts of PVC particles, 70-85 parts of organic filler, 5-8 parts of inorganic filler, 1.5-1.8 parts of a coupling agent, 2-5 parts of maleic anhydride, 5-7 parts of a composite stabilizer, 1.0-2.0 parts of a composite foaming agent, 5-8 parts of a foaming aid, 2-3 parts of baking soda and 3-5 parts of epoxy soybean oil. The preparation method comprises the following steps of treating the organic filler with the coupling agent and a compatilizer and mixing the treated organic filler and other components and carrying out extrusion molding with an extruder. Compared with the existing wood-plastic composite material, the proportion of the filler in the wood-plastic foaming material is higher and thus the wood-plastic foaming material has good processing performance as well as lightweight, high specific strength, waterproof property, corrosion resistance, thermal insulation and the like.

Owner:李银亭

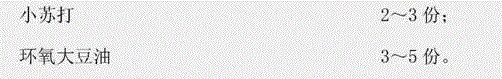

Preparation method of fully biodegradable copolyester

The invention discloses a preparation method of fully-biodegradable copolyester, relates to the technical field of fully-biodegradable copolyester preparation, and solves the problems of poor tensileyield strength, tearing resistance and light transmittance of the existing fully-biodegradable copolyester. According to the preparation method, main raw materials contain aromatic dibasic acid, aliphatic diol and aliphatic dibasic acid, wherein the aromatic dibasic acid is one of terephthalic acid or isophthalic acid; the aliphatic diol is one of C4-C10 saturated diols, and the aliphatic dibasicacid is adipic acid. The disclosed copolyester has strong fracture resistance, excellent elasticity, good processability and strong light transmission, and can hardly be snapped.

Owner:四川中科兴业高新材料有限公司

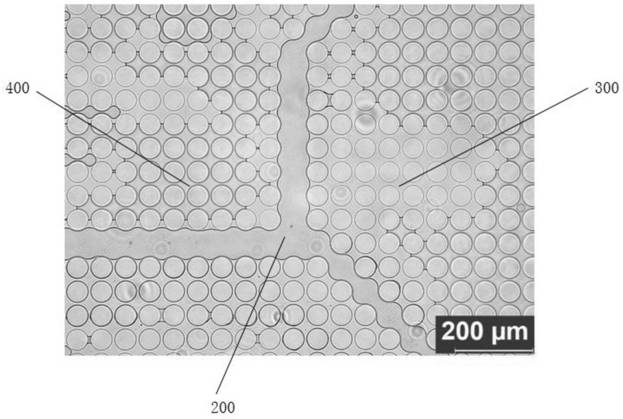

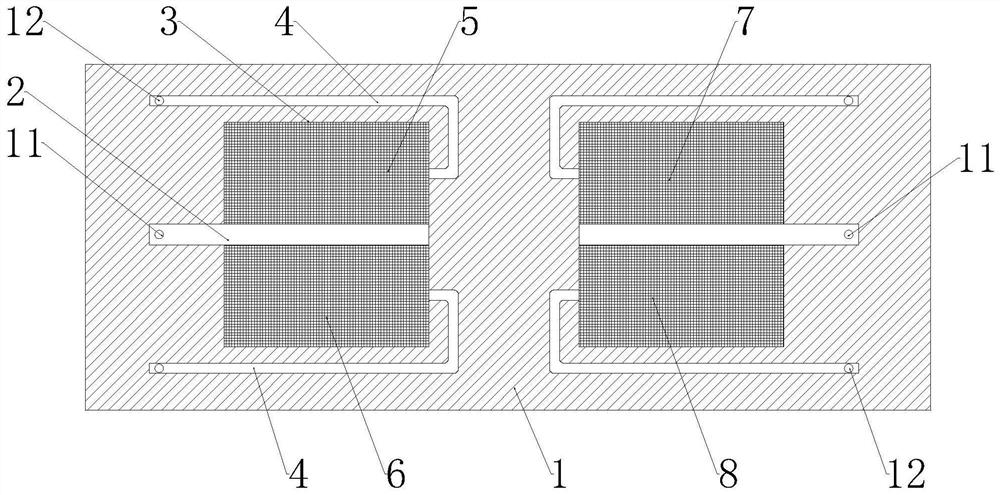

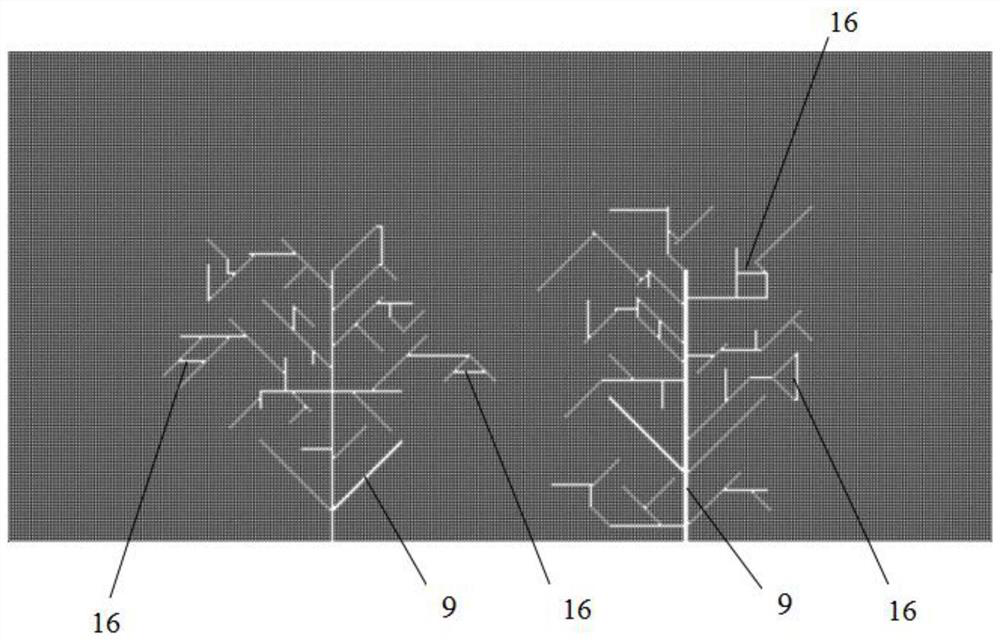

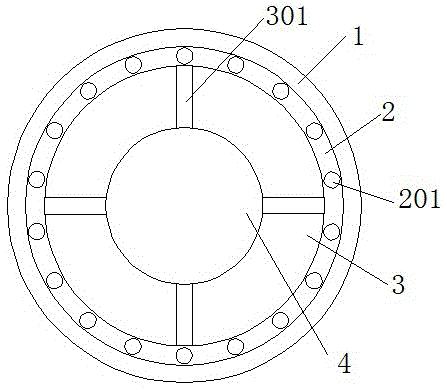

Shale reservoir post-fracturing seepage microscopic model, manufacturing method and experimental device

PendingCN113899878ARealize simulationRealize visual observationHydrodynamic testingEarth material testingPhysicsExperimental Devices

The invention belongs to the field of shale oil and gas reservoir research, relates to a shale reservoir post-fracturing seepage micro-model, a manufacturing method and an experimental device and aims to simulate a reservoir microscopic model with a micron-sized pore throat according to the characteristics of low porosity and low permeability of shale oil and gas reservoirs so as to solve the problem that the seepage characteristics of fluids in shale are difficult to observe macroscopically. The manufacturing process of the microscopic model roughly comprises three parts: firstly, manufacturing a mask, and exposing the mask to obtain a model diagram required to be used; performing exposure treatment on a substrate by using the mask, transferring an etching pattern to a photoresist, transferring the etching pattern to a chromium layer from the photoresist, and then transferring the etching pattern to the substrate; and finally, carrying out anodic bonding to manufacture the substrate, thereby obtaining the microscopic model. The microscopic model can be combined with an image acquisition device and an image display device to carry out visual research on injected fluid in the microscopic model, and the flowing condition of the fluid in a micron-sized fracture-matrix reservoir is observed.

Owner:SOUTHWEST PETROLEUM UNIV

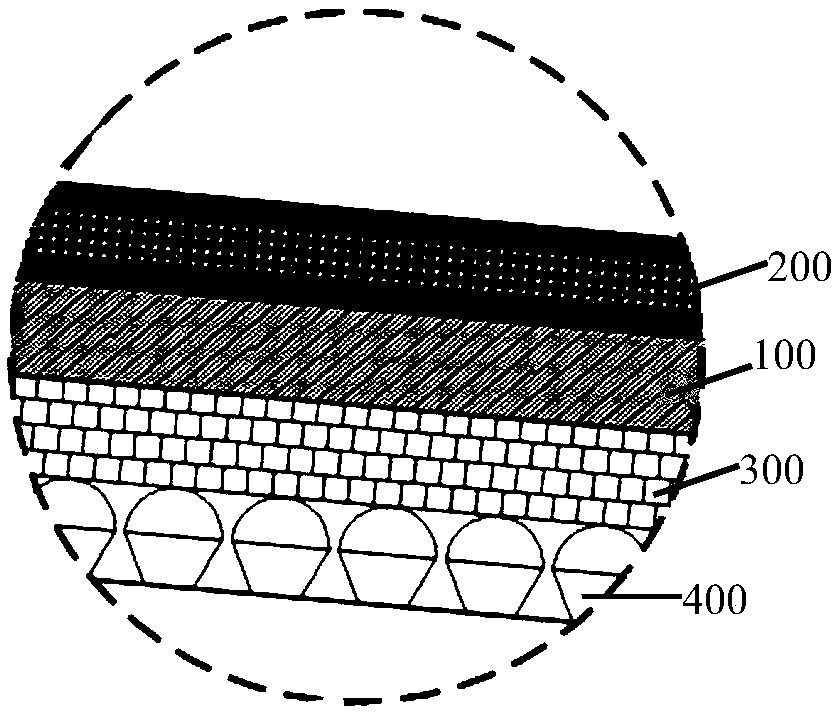

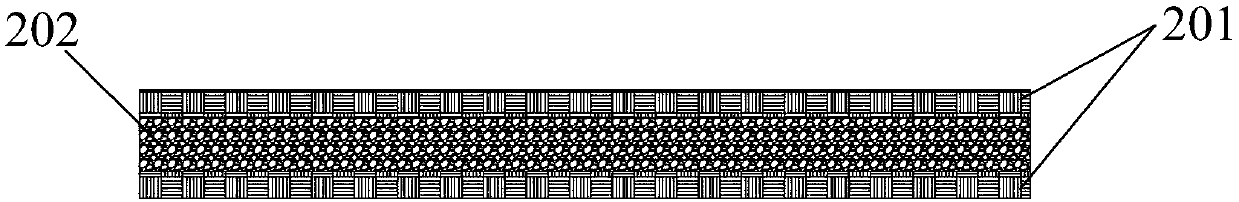

Composite body armor

ActiveCN109579618AReduce stray bulletsAvoid rib fracturesPersonal protection gearEnergy absorbingFiber layer

Composite body armor comprises a bullet absorbing layer, a protection layer, a buffering layer and an energy absorbing layer from exterior to interior. The bullet absorbing layer is used for absorbingbullets so as to avoid stray bullet generation, two carbon fiber layers and an aluminum foam layer are included, and the aluminum foam layer is sandwiched between the two carbon fiber layers. The buffering layer is used for converting point impacts into face impacts. The absorbing layer is used for absorbing deformation of the buffering layer. The composite body armor can effectively avoid straybullet generation and fighting personnel rib fracture danger caused by excessive impact force.

Owner:HUAQIAO UNIVERSITY

Lifting hook protection device of crane

InactiveCN103663115AExtended service lifeReduce the number of replacementsSafety gearIndustrial engineeringEngineering

Owner:YANGZHOU CITY HUATAI ENVIRONMENT PROTECTION EQUIP MFG

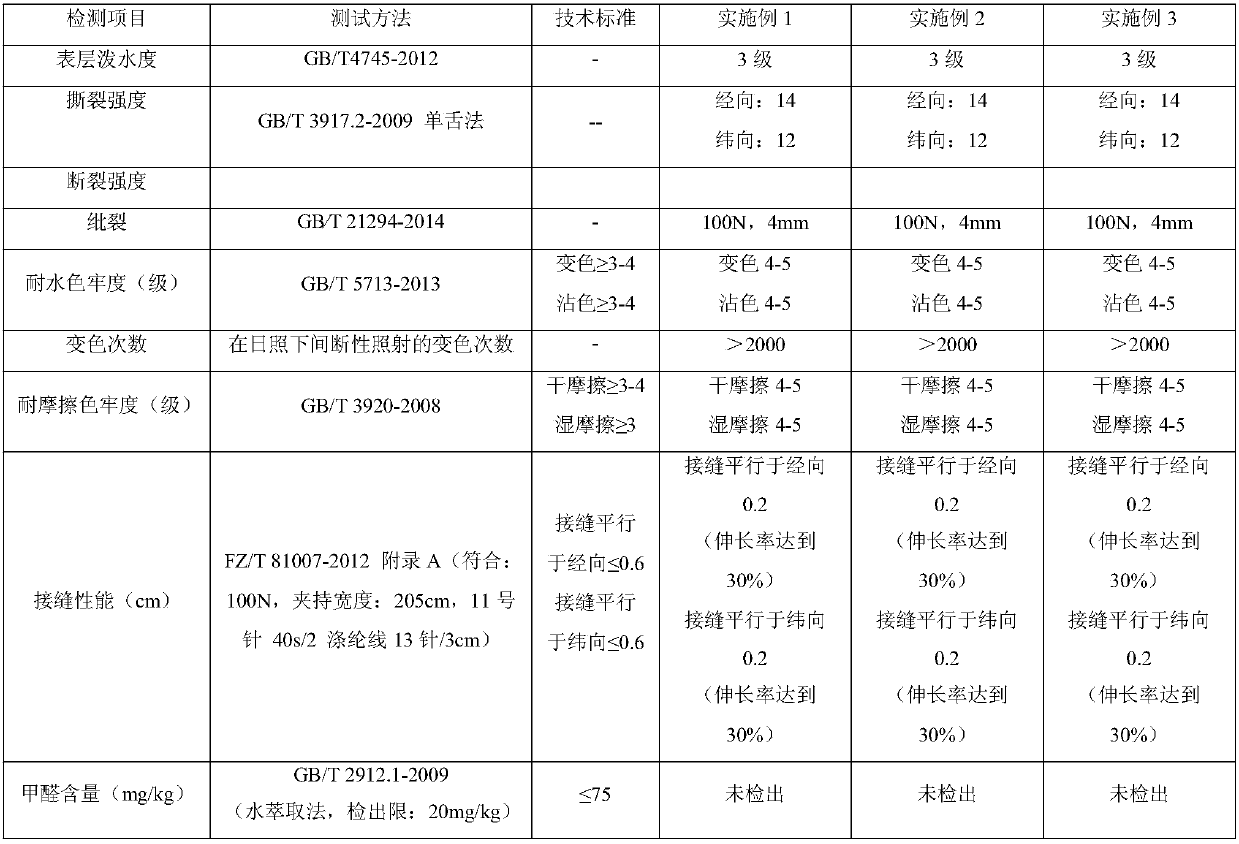

Preparation method of light sensation shell fabric

InactiveCN107780257AStrong tear resistanceStrong fracture resistanceHeating/cooling textile fabricsDry-cleaning apparatus for textilesProduct inspectionCrack resistance

The invention discloses a preparation method of a light sensation shell fabric, belonging to the technical field of shell fabrics. The preparation method of the light sensation shell fabric comprisesthe following steps: weaving and warping, carrying out filament sizing, carrying out warp tying, weaving, carrying out grey examination and desizing, dyeing, carrying out color fixation, carrying outvacuum water absorption, sizing, testing and printing, sprinkling water and sizing, carrying out finished product inspection, and packaging. The light sensation shell fabric is obtained by utilizing the novel preparation method, adopting independently developed color-changing powder and a sticky agent and combining other process steps and has strong waterproofness, high tear resistance, fracture resistance and crack resistance and strong washing resistance and color fastness to rubbing, zero formaldehyde content is detected, the light sensation shell fabric is harmless to a human body, the color-changing frequency of the light sensation shell fabric is high, color-changing effect is good, and service life is long.

Owner:晋江万兴隆染织实业有限公司

Anti-fracture instrument cable material

InactiveCN104927315AGood fracture resistanceFormula cost control is reasonablePlastic/resin/waxes insulatorsPOLYETHYLENE WAXPhosphite ester

The invention discloses an anti-fracture instrument cable material. The anti-fracture instrument cable material comprises, by weight, 20-40 parts of PBT resin, 5-10 parts of SEBS resin, 5-10 parts of trioctyl trimellitate, 5-10 parts of phosphorous ester, 3.5-5.5 parts of gamma-glycidoxy propyl trimethoxy silane, 10-20 parts of aluminium hydroxide flame retardant, 2-5 parts of polyethylene wax, 0.5-2 parts of potassium persulfate, 0.1-0.2 part of montmorillonite, 2.5-4.5 parts of zinc stearate and 0.1-0.2 part of titanium dioxide. The anti-fracture instrument cable material has more excellent anti-fracture performance, cables can be prevented from being fractured in the using and mounting processes or in various environments, and formula cost control is more reasonable.

Owner:ANHUI TIANYUAN CABLE

Film-forming material on filler for removing nitrogen from wastewater

ActiveCN101671077AHigh strengthStrong fracture resistanceTreatment with aerobic and anaerobic processesSustainable biological treatmentPolyamideNitrate nitrogen

The invention discloses film-forming material on filler for removing nitrogen from wastewater, which comprises polyamide and silicate which is nanometer inorganic substance, wherein the silicate is adhered to the polyamide. The silicate accounts for 1-2 percent of the film-forming material by weight. The filler for removing nitrogen from wastewater formed by the film-forming material can obviouslyimprove the removal rate of ammonia nitrogen and nitrate nitrogen in the wastewater and has strong ability of removing the nitrogen in the wastewater. Because the silicate which is the nanometer inorganic substance is adhered to the polyamide which is the organic substance, the strength of the film-forming material formed by the polyamide and the silicate is improved, and the breaking resistanceis strengthened, thus the film-forming material can not be broken when in use, and the nitrogen removing effect of the filler can not be affected.

Owner:JIANGSU SUJING GROUP

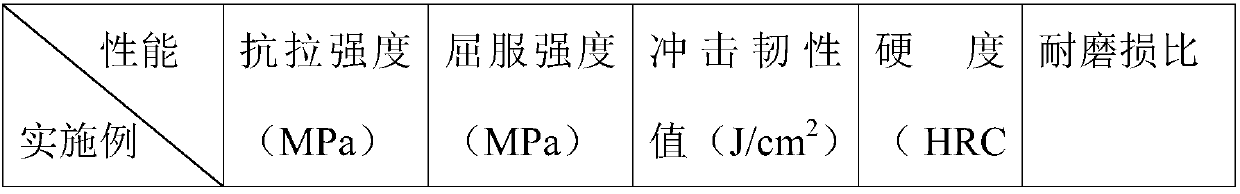

EPS input shaft

InactiveCN107937820AImprove high temperature resistanceStrong fracture resistanceFurnace typesSuperimposed coating processRare earthMaterial hardness

The invention belongs to the field of alloy steel materials and relates to an input shaft, in particular to an EPS input shaft. The EPS input shaft is made of alloy steel. The alloy steel specificallycomprises the following components of, by mass, 1.3-2.2% of C, 16.2-16.8% of Cr, 14.2-14.9% of Mo, 0.5-0.8% of Nb, 0.12-0.25% of N, 0.26-0.32% of Si, 0.34-0.39% of Mn, 1.2-1.6% of V, 0.67-0.82% of rare earth and the balance Fe. The surface of the alloy steel is sequentially coated with an aluminum layer, a mussel byssus albumen layer and a nanometer ZrC layer. According to the EPS input shaft, Vand Nb are added into the alloy steel, the abrasion resistance of the alloy steel can be improved, and the material hardness, tensile strength, yield strength and after-breaking elongation are improved.

Owner:NINGBO HONGBO MACHINERY MFG

Preparation method of zirconia ceramic rear cover of mobile phone

The invention discloses a preparation method of a zirconia ceramic rear cover of a mobile phone. The method comprises steps as follows: S1, modified zirconia powder and yttrium oxide powder are mixeduniformly, and mixed powder is obtained; S2, the mixed powder is dissolved in absolute ethyl alcohol, ammonium polyacrylate is added, wet grinding is performed for 20-36 h, and pretreated powder is obtained after drying treatment; S3, polyethylene glycol, isopropyl alcohol and zinc stearate are added to the pretreated powder, ultrasonic dispersion is performed, and tape casting slurry is obtained;S4, the tape casting slurry is subjected to vacuum defoaming, and a green body is obtained through tape casting; S5, the green body is subjected to three-stage thermal treatment and then subjected toshaping processing treatment, and the zirconia ceramic rear cover of the mobile phone is obtained. The prepared zirconia ceramic rear cover of the mobile phone has high hardness and bending strength,high anti-breaking capability, uniform texture and stable quality; the preparation method is simple, adopts a preparation process which is easy to operate, and is suitable for large-scale promotion.

Owner:泉州市智通联科技发展有限公司

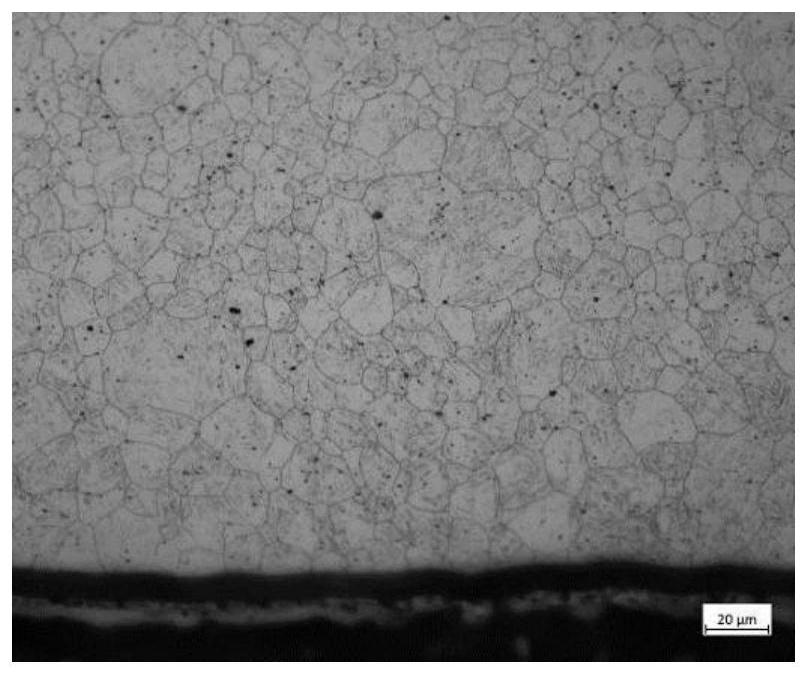

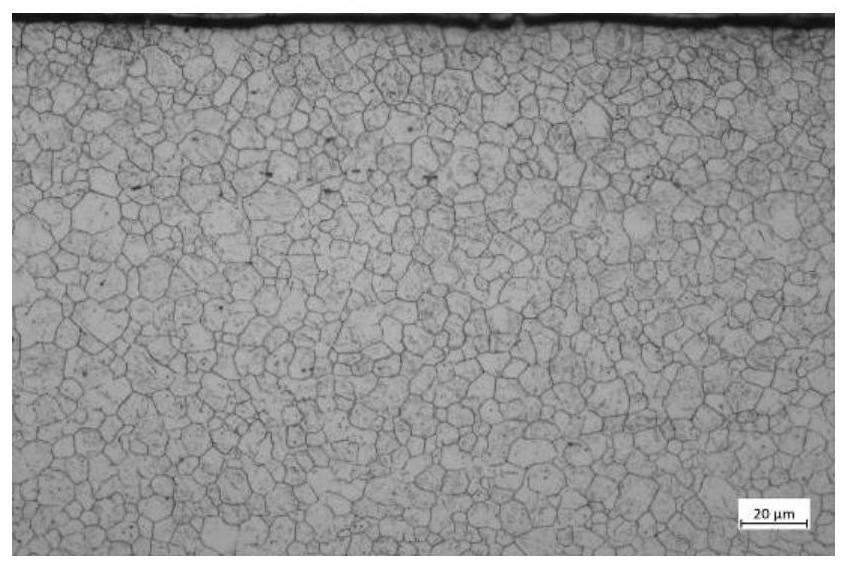

Skip-plating-free pre-coating hot-forming steel plate with low crack sensitivity and manufacturing method

ActiveCN113462962AReduced crack susceptibilityLow leakage prevention performanceHot-dipping/immersion processesCrazingMetallurgy

The invention discloses a skip-plating-free pre-coating hot-forming steel plate with low crack sensitivity and a manufacturing method and relates to the technical field of hot galvanizing. According to the skip-plating-free pre-coating hot-forming steel plate with the low crack sensitivity and the manufacturing method, the matrix steel plate comprises the following ingredients of, in percentage by mass, 0.10-0.36% of C, less than or equal to 0.5% of Si, 0.5-1.5% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 0.50% of Cr, 0.01-0.06% of Al, less than or equal to 0.15% of Nb+V+Ti, less than or equal to 0.5% of Mo and the balance Fe and inevitable impurities. By means of control of all technological process parameters and the matrix C content, a decarburized layer with the depth ranging from 5 micrometers to 10 micrometers is obtained, the steel plate matrix is made to obtain uniform ferrite and pearlite tissue, meanwhile, the cold bending performance after hot forming is improved, and the material is made to have the low crack sensitivity and the skip-plating prevention performance.

Owner:MAANSHAN IRON & STEEL CO LTD

Fracture-resistant refractory material and preparation process thereof

The invention discloses a fracture-resistant refractory material and a preparation process thereof. The refractory material is prepared from the raw materials, such as aluminum oxide-silicon oxide mixed powder, calcium oxide, magnesium oxide, manganese oxide, titanium oxide, niobium pentoxide, toughened fiber and the like, by the following steps: mixing the raw materials, ball-milling the raw material mixture in absolute ethanol, drying the raw material powder and performing dry pressing on the dry raw material powder to obtain a refractor material green body; sintering the refractor material green body, and naturally cooling to room temperature after sintering to obtain the fracture-resistant refractory material. The refractory material prepared by the preparation process has high mechanical toughness, high fracture resistance and excellent thermal shock resistance; the refractory material is simple in preparation method and is easily produced by the conventional equipment.

Owner:CHANGXING MENGYOU REFRACTORIES

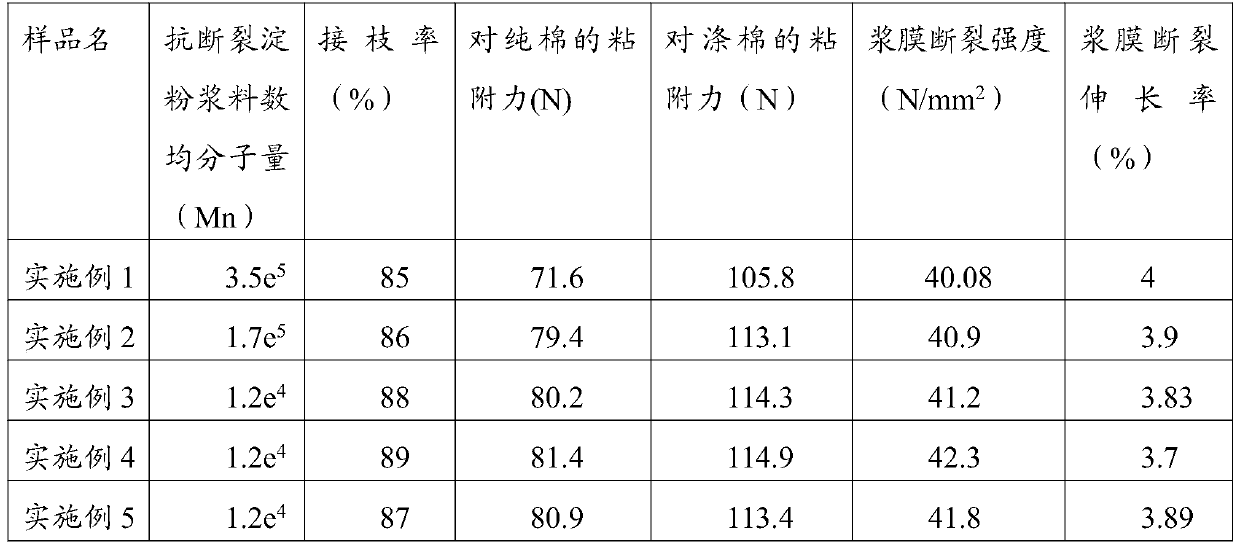

Anti-fracture starch slurry and preparation method thereof

InactiveCN109929116AAvoid the disadvantage that the self-polymerization reaction is not easy to controlMolecular chain lengthVegetal fibresSlurryCarvacryl acetate

The invention provides an anti-fracture starch sizing agent and a preparation method thereof, and belongs to the technical field of sizing agents for spinning. The method comprises the steps that cornstarch is subjected to irradiation treatment, and then water is added for gelatinization to obtain gelatinized starch; vinyl acetate, acrylic acid and an initiator are mixed for a polymerization reaction to obtain a copolymer; and the copolymer is mixed with the gelatinized starch, ammonium sulfate and sodium hydrogen sulfite are then added to initiate graft copolymerization reaction, and alkaliis added for neutralization to obtain the anti-fracture starch slurry. Acrylic acid and vinyl acetate are adopted for copolymerization, so that the reaction is easy to control, and the obtained copolymer is longer in molecular chain and better in flexibility. A redox system composed of ammonium persulfate and sodium hydrogen sulfite is adopted to initiate a graft copolymerization reaction, so thatthe method is simple to operate and high in grafting efficiency. The breaking strength of a slurry film formed by the anti-breaking starch slurry is greater than 40.08 N / mm<2>, the elongation at break is greater than 3.7%, and the anti-breaking starch slurry has good anti-breaking performance.

Owner:湖北顶新环保新材料有限公司 +1

Polybutylene terephthalate composite material and preparation method therefor

InactiveCN104987679AImprove uniformityHigh mechanical strengthPolytetramethylene terephthalateStyrene oxide

The present invention discloses a polybutylene terephthalate composite material and a preparation method therefor. The polybutylene terephthalate composite material is prepared by using the following components in parts by weight: 80-88 parts of polybutylene terephthalate, 15-25 parts of polyamide fiber, 8-14 parts of polyalkylene glycol, 5-8 parts of barium metaborate, 4-6 parts of styrene oxide, 3-8 parts of amino acid phenyl ester glycidyl, 2-4 parts of methyl isobutyl ketone, 1-2 parts of amino hydroxy ethyl diethylenetriamine, 1-2 parts of zirconium dioxide, 1-2 parts of diphenylamine and 0.5-2 parts of polydimethylsiloxane quaternary ammonium salt. The present invention also provides the preparation method for the polybutylene terephthalate composite material.

Owner:JIN BAOLI TECH SUZHOU

Kiwi fruit nursery soil formula and its preparation method

InactiveCN107517769AImprove fertilizer efficiencyImprove the growth effectGrowth substratesCulture mediaMushroomAgriculture

The invention belongs to the agricultural field, and particularly relates to a kiwi fruit nursery soil matrix. The kiwi fruit nursery soil matrix is prepared from, by weight, 45-65 parts of nature soil, 17-25 parts of turfy soil, 10-20 parts of organic fertilizer, 7-15 parts of mushroom dreg, 4-10 parts of vermiculite, 0.04-0.06 part of phoxim particle, 0.04-0.09 part of mancozeb particle. The raw materials applied to the soil formula are simple and easy to obtain; the soil can provide comprehensive nutrition for crops, and the fertilizer effect is long; the kiwi fruit nursery soil formula solves the problem of insufficient nutrition in ordinary nursery matrix.

Owner:SICHUAN HUASHENG AGRI CO LTD

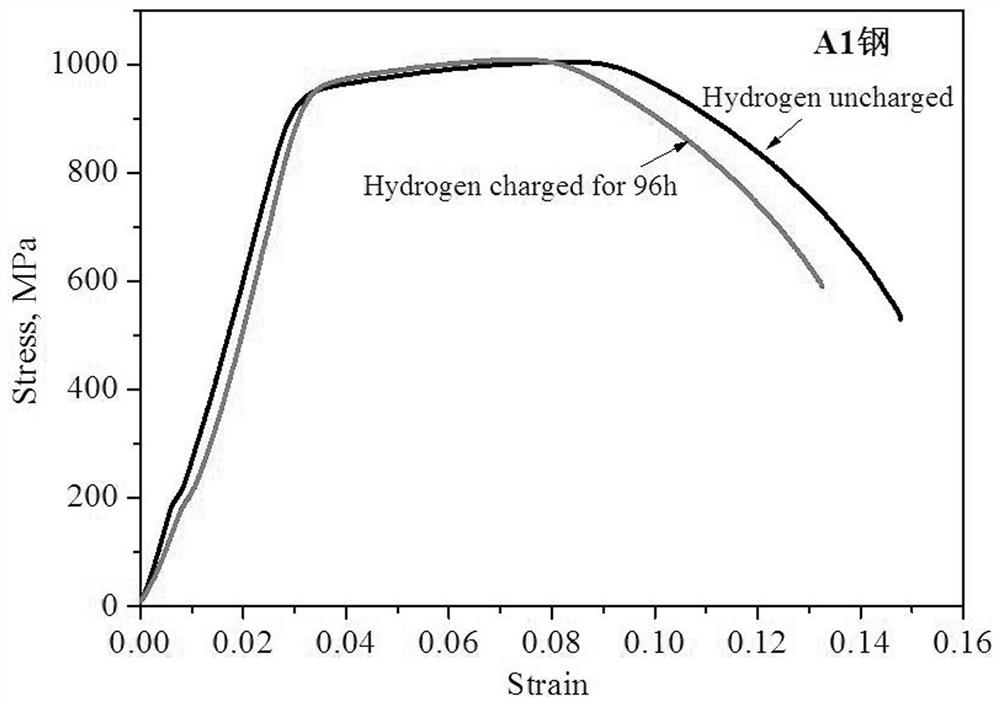

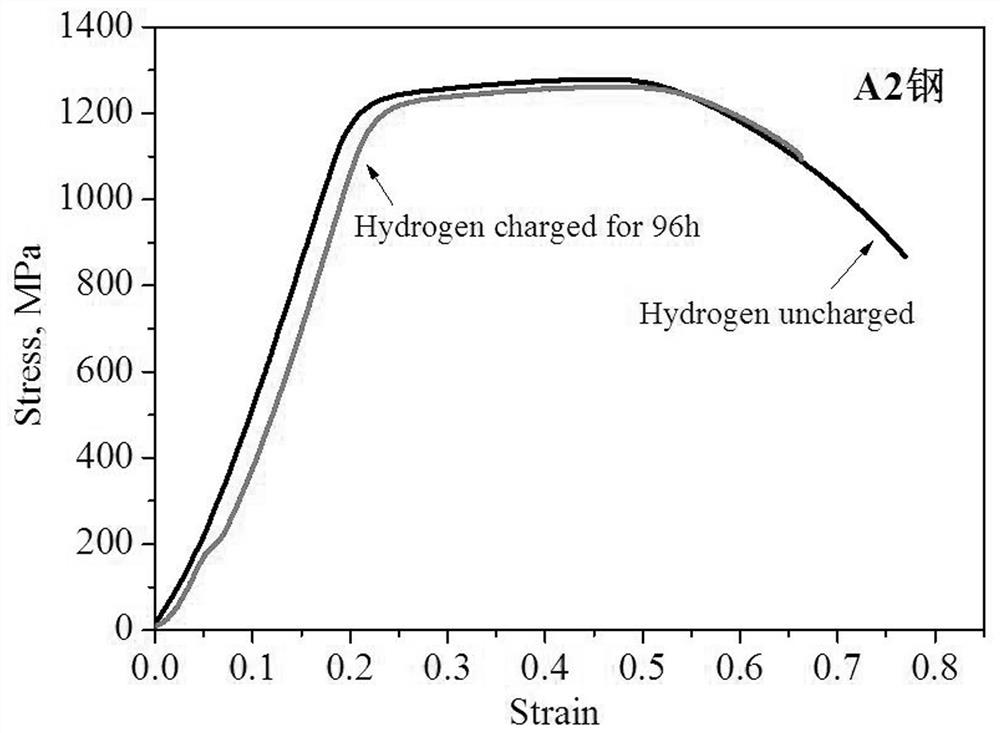

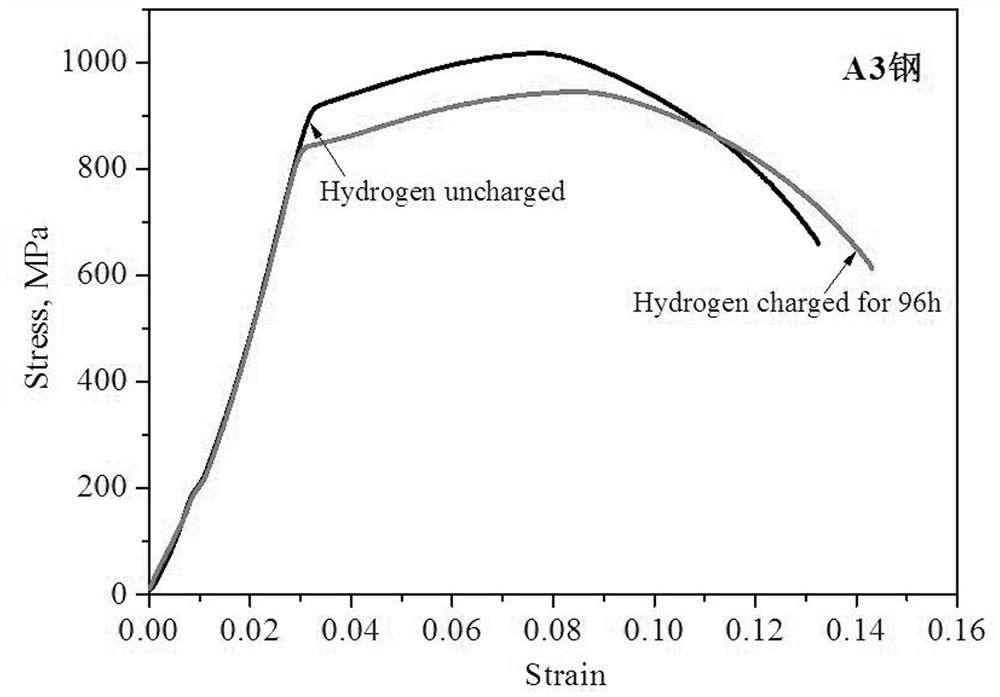

High-strength fastener for bridge in marine atmosphere and humid environments

ActiveCN114058954AImprove compactnessHigh hardnessMetal layered productsNickel alloyUltimate tensile strength

The invention discloses a high-strength fastener for a bridge in marine atmosphere and humid environments. The high-strength fastener consists of a base body and a plating layer plated on the base body. The plating layer is a cathode compact composite plating layer which is of a three-layer structure, wherein the inner plating layer and the outer plating layer are made of nickel alloy or cobalt alloy, and the middle plating layer is a unit metal plating layer. The corrosion potential of the base body is smaller than that of the inner plating layer attached to the base body; the corrosion potential of the inner plating layer attached to the base body is smaller than that of the middle plating layer; and the corrosion potential of the plating layer of the outer plating layer is smaller than that of the middle plating layer. The tensile strength and the yield strength of the high-strength fastener range from 1000 Mpa to 1200 Mpa. The product is applied to bridge component connecting devices in marine atmosphere and humid environments, and has excellent corrosion resistance and fracture resistance.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

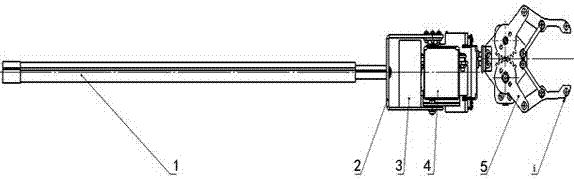

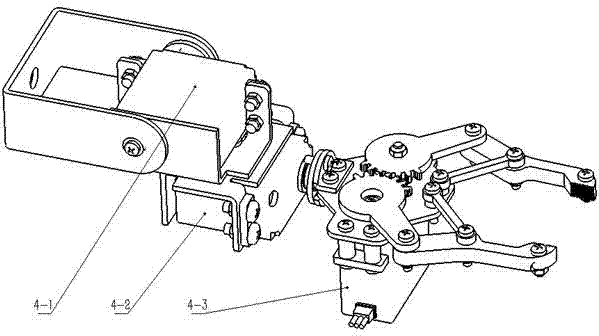

Remote pickup device controlled through mobile phone Bluetooth

The invention relates to a remote pickup device controlled through mobile phone Bluetooth. The remote pickup device controlled through the mobile phone Bluetooth comprises a telescoping mechanism capable of telescopically extending and a fixing bracket used for fixing a pickup device body, wherein the fixing bracket is arranged at the top end of the telescoping mechanism, and the pickup device body comprises a control device, a steering engine and a manipulator; the manipulator is arranged on an output shaft of the steering engine, and the steering engine is connected with the control device;a Bluetooth signal receiving and processing module is arranged in the control device; a user achieves communication with the pickup device body through the Bluetooth by means of a mobile phone and controls the manipulator to grip parts, and the telescoping mechanism controls the pickup distance of the pickup mechanism. According to the remote pickup device controlled through the mobile phone Bluetooth, after telescoping rods are pulled to a certain length, self-locking can be achieved when the adjacent telescoping rods rotate a certain angle, a mobile phone APP is started, and the manipulatoris remotely controlled to act through Bluetooth signals to grip back objects in the distance.

Owner:CHINA UNIV OF MINING & TECH

Geological drill rod coupling

ActiveCN109267945AImprove connection stabilityGuaranteed stabilityDrilling rodsDrilling casingsHigh entropy alloysCoupling

The invention discloses a geological drill rod coupling, which structurally comprises a short joint, a connecting sleeve device and a high-entropy alloy layer. The geological drill rod coupling has the beneficial effects that the problem that the drill rod is easy to damage due to poor connection stability between the drill rod coupling and the drill rod is solved. By arranging the connecting sleeve device, the short-circuit body is firstly inserted into the shell, wherein the side plate, the clamping ring and the clamping claw block play a role in fixedly connecting the short-circuit body with the drill rod, and when the drill rod and the drill rod coupling rotate, the steel balls can ensure the stability of the power transmission of the drill rod and the drill rod coupling in rotation and the rigidity of the axial load is high without backlash in the coupled state, and then the butterfly-shaped spring can be automatically converted into additional compression load required for sealing if necessary, so as to reduce the continuous requirement on tightening during the use of the drill rod, and achieve the beneficial effects that the connection stability of the drill rod coupling andthe drill rod is enhanced, and the drill rod is not easy to damage.

Owner:山东兖能泰德重工有限公司

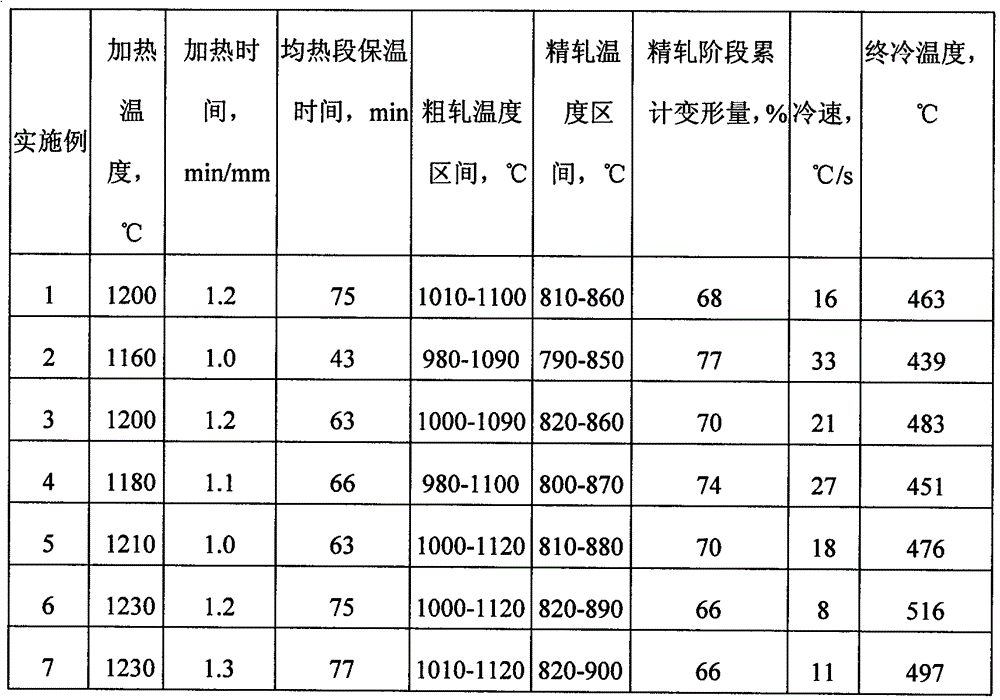

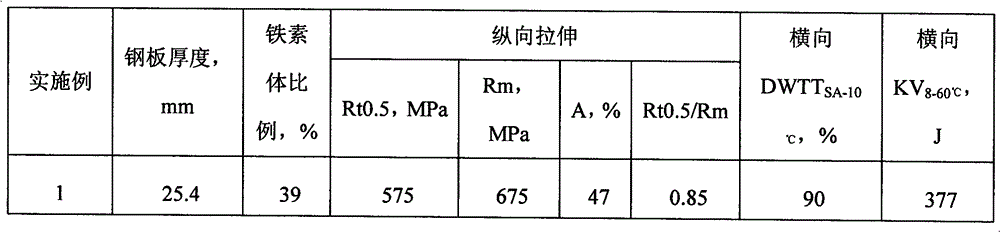

A low-cost high-performance marine riser hot-rolled steel plate and its production method

ActiveCN102851613BGood anti-collapse abilityImprove low temperature toughnessRoll mill control devicesMetal rolling arrangementsImpurityCooling temperature

The invention discloses a hot-rolled steel plate for an ocean riser with low cost and high performance and a production method thereof. The chemical components of the steel plate comprise C 0.04-0.10%, Si 0.10-0.35%, Mn 1.55-1.85%, Nb 0.02-0.08%, Ti 0.008-0.020%, Al 0.010-0.040%, P less than or equal to 0.020%, S less than or equal to 0.003%, Mo less than 0.20%, Cu less than or equal to 0.25%, Ni less than or equal to 0.30%, Cr less than or equal to 0.25%, N less than or equal to 0.008%, and the balance being Fe and unavoidable impurities, wherein Al / N is greater than or equal to 3, Ni+Cu+Mo+Cr is less than or equal to 0.70%, Nb+Ti is less than or equal to 0.09%, and Ti / N is equal to 2.5-5. CEIIW is 0.40-0.45%, CEPCM is 0.16-0.21%, casting blank heating temperature is 1,160-1,230 DEG C, four-stage heating is adopted, rough rolling temperature is 980-1,120 DEG C, fine rolling temperature is 790-900 DEG C, cooling temperature after rolling is 750-800 DEG C, cooling speed is 5-35 DEG C / s, and final cooling temperature is 430-520 DEG C. The steel plate of the invention has yield strength above 555 MPa, endwise tensile strength above 630 MPa, good cracking resistance, corrosion resistance and fatigue resistance, good comprehensive property, and low cost.

Owner:ANGANG STEEL CO LTD

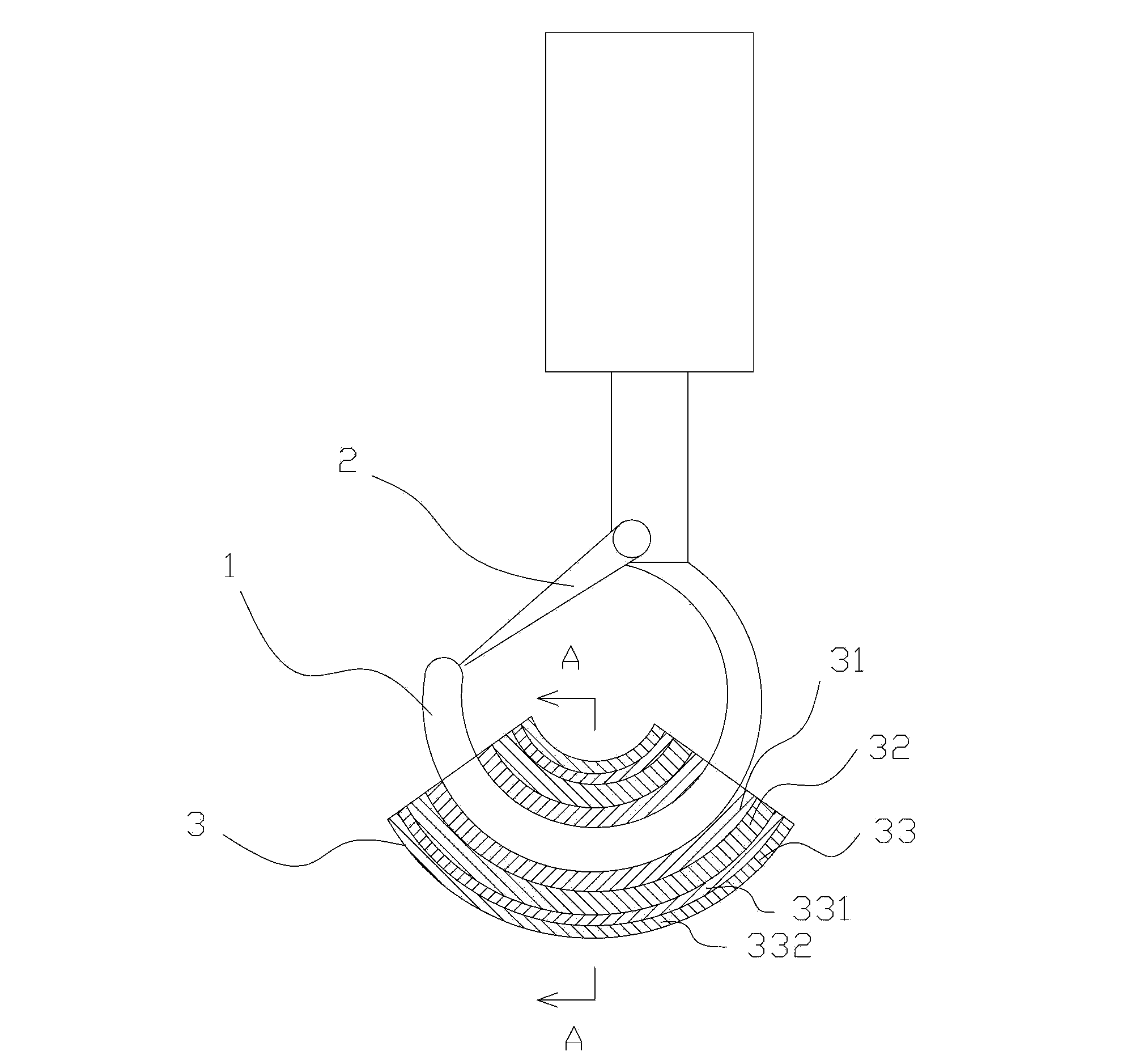

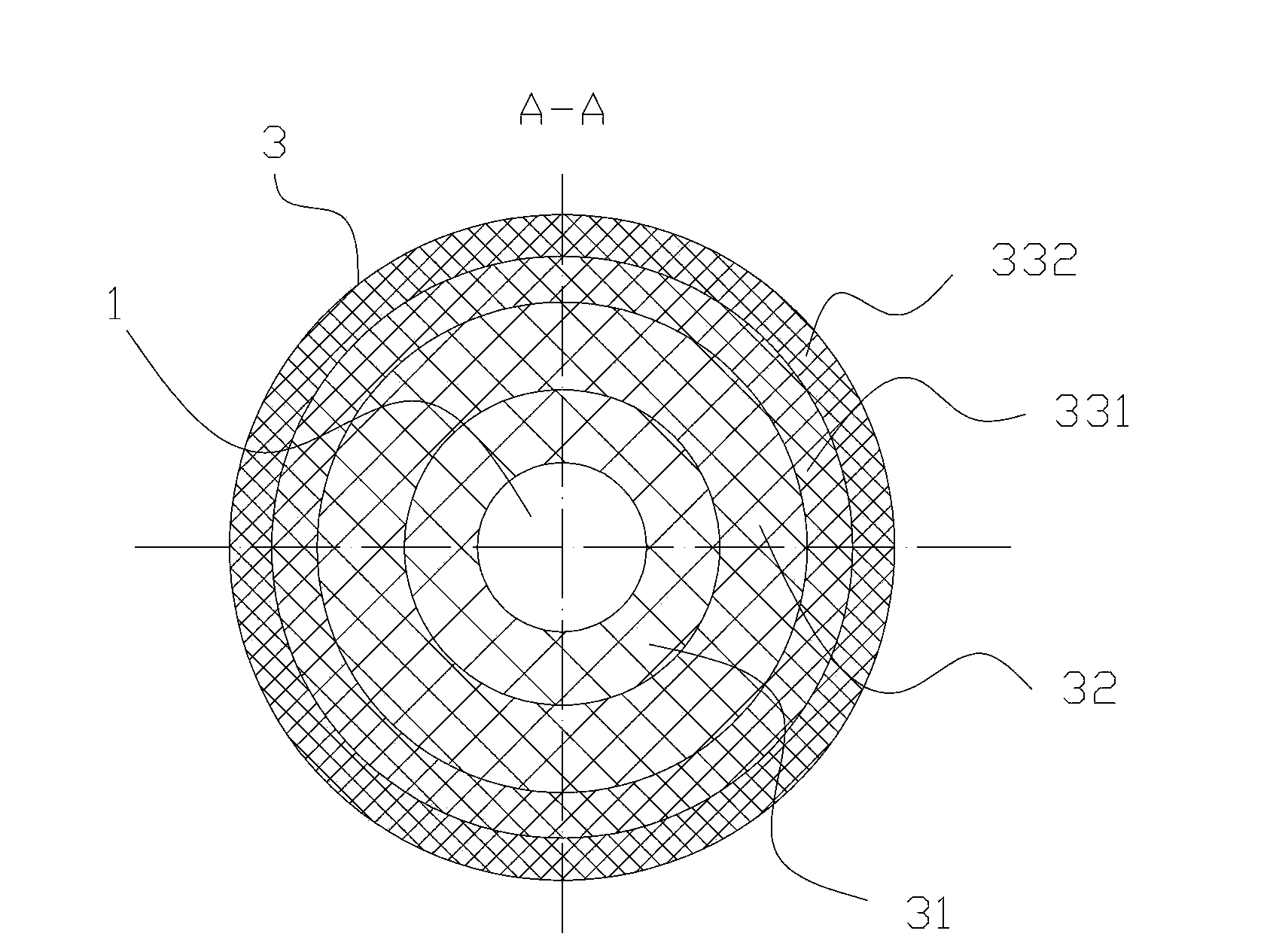

Enhanced fiber

InactiveCN105629376AGood yellowing resistanceReduce transmission lossOptical fibre with multilayer core/claddingOptical waveguide light guideFiberUV curing

The present invention relates to an enhanced fiber. The enhanced fiber comprises a fiber core and a cladding; the fiber core is composed of two fiber cores with different refractive indexes through doping, and the cladding winds the outer periphery of the fiber core; the cladding includes a one-time coated layer and a twice coated layer which are formed by ultraviolet ray curing type resin, and the ultraviolet ray curing type resin includes urethane acrylate and a photoinitiator, wherein the polyisocyanate component in the urethane acrylate is aromatic polyisocyanate; an enhanced core layer is arranged between the one-time coated layer and the fiber core, the periphery of the enhanced core layer is combined and wrapped in the fiber core of the one-time coated layer; the twice coated layer has a plurality of holes extending along the central shaft of the fiber, the residual stress in the internal areas at the inner sides of the circumcircles of the holes are compression press, and the compression press is larger than 20MPa; and the enhanced layer has good yellowing resistance, small transmission loss and high breaking ability.

Owner:WUXI NANLIGONG TECH DEV

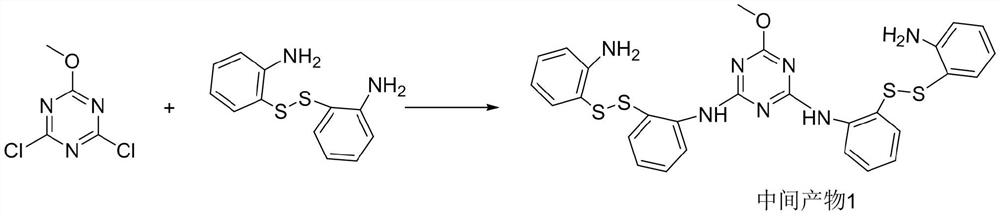

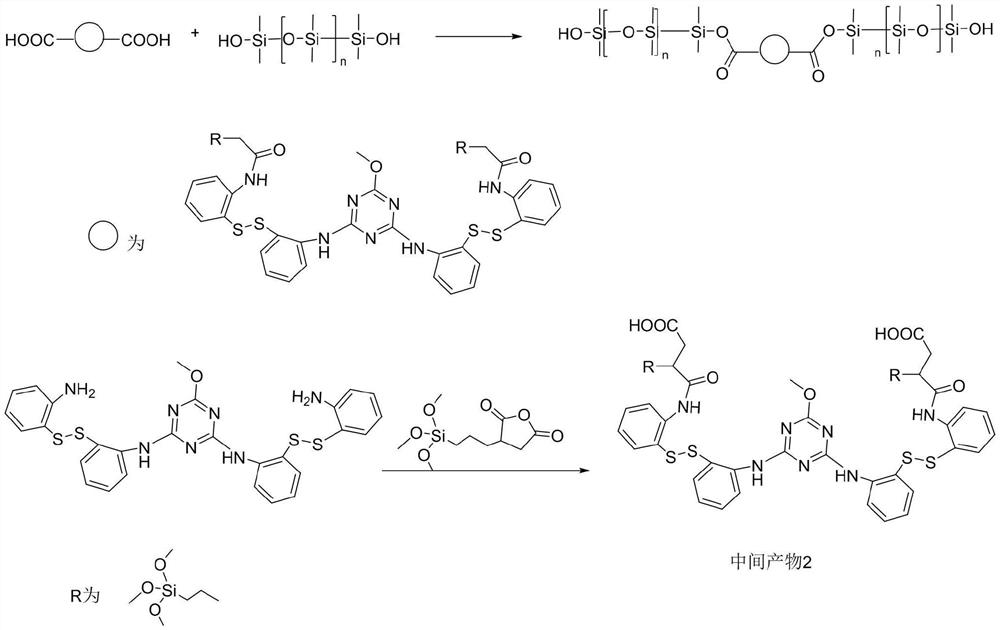

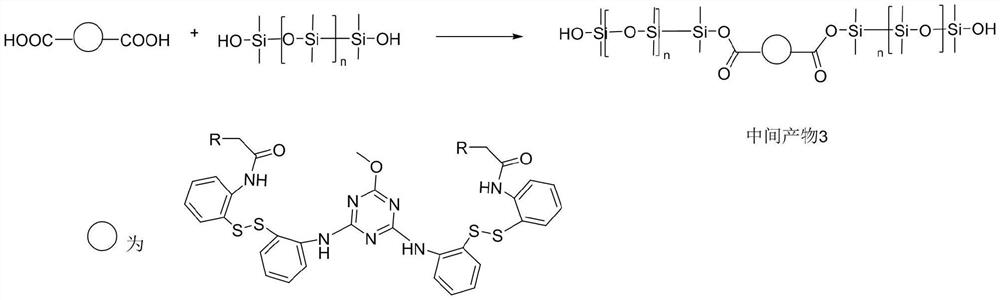

Water-resistant and fracture-resistant waterproof roll and preparation method thereof

PendingCN113372731AEvenly distributedImprove efficacyRoof covering using flexible materialsProtective foundationPolymer scienceBackbone chain

The invention discloses a water-resistant and fracture-resistant waterproof roll and a preparation method thereof, and belongs to the technical field of waterproof materials, and the water-resistant and fracture-resistant waterproof roll comprises the following components in parts by weight: 50-75 parts of asphalt, 5-16 parts of a plasticizer, 2.5-10.5 parts of an elastic aid, 12-18 parts of a flame retardant, 1.5-6.5 parts of an ultraviolet absorbent, 2.5-6.5 parts of an antioxidant and 0.5-3.5 parts of a coloring agent. 2, 4-dichloro-6-methoxy-1, 3, 5-triazine, di (o-amino) phenyl disulfide, [3-(trimethoxysilyl) propyl] succinic anhydride and hydroxyl-terminated polydimethylsiloxane are utilized to react step by step to produce the elastic auxiliary agent. The main chain of the elastic auxiliary agent is mainly composed of a flexible chain, hydrogen bonds are easily formed, an interpenetrating network is formed in a waterproof roll system, the toughness of the waterproof roll is improved, and the fracture resistance of the waterproof roll is improved.

Owner:安徽省奥佳建材有限公司

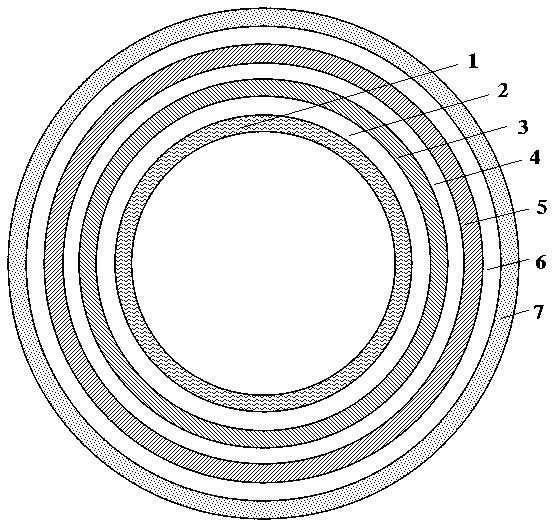

High-elasticity and high-wear-resistant extrusion exhausting peristaltic tube

The invention discloses a high-elasticity and high-wear-resistant extrusion exhausting peristaltic tube which sequentially comprises an inner rubber layer, an inner reinforcing layer, a first middle rubber layer, a middle reinforcing layer, a second middle rubber layer, an outer reinforcing layer and an outer rubber layer from inside to outside, and the inner reinforcing layer, the middle reinforcing layer and the outer reinforcing layer are all cord thread winding layers. The high-elasticity and high-wear-resistant extrusion exhausting peristaltic tube is reasonable in design and simple in structure, has the advantages of high wear resistance, high toughness, strong fracturing resistance, corrosion resistance and aging resistance, is long in service life and has the promotion significance.

Owner:河北东劲液压橡塑制品有限公司

Preparation method of high-strength glass material

InactiveCN107226616ASmall coefficient of thermal expansionImprove heat resistanceGlass furnace apparatusRoom temperatureHigh intensity

The invention discloses a preparation method of a high-strength glass material. The preparation method comprises the following steps: a, mixing TeO2, K2O, SiO2, Tm2O3, Yb2O3, Fe2O3, Er2O and Bi2O3, putting the mixture into a ball mill, and performing ball milling to obtain a material I; b, drying the material I, putting the dried material into a mixing furnace, and mixing to obtain a material II; c, guiding the material II into a mould, and clarifying to obtain a material III; d, annealing the material III, and cooling to room temperature. The glass material prepared by the preparation method provided by the invention has good fracture resistance and relatively high Vickers hardness, and the application range of the glass material can be significantly widened.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

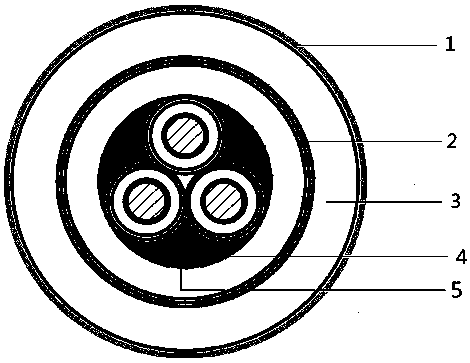

High-strength multi-performance wire cable

InactiveCN111383801AImprove performanceLow costInsulated cablesInsulated conductorsEngineeringAdhesive

The invention discloses a high-strength multi-performance wire cable. The high-strength multi-performance wire cable comprises a cable core, a coating layer, a functional layer and an outer sheath, the cable core layer is internally provided with at least one cable core, and a filler is filled between the cable core and the coating layer; and the outer side of the cable core layer is provided witha coating layer. A functional layer is arranged outside the coating layer, the functional layer is composed of a functional material and an adhesive, the functional layer is coated with an outer sheath, and the coating layer and the outer sheath contain at least one layer containing modified reinforcing fibers. According to the cable, the functional layer composed of the reinforcing net and the fireproof glue is contained, the cable has very good mechanical performance and electrical performance, the cable is not prone to deformation and more stable in form, multiple functional materials canbe added into the fireproof glue layer, and the service life of the cable can be greatly prolonged.

Owner:于长河

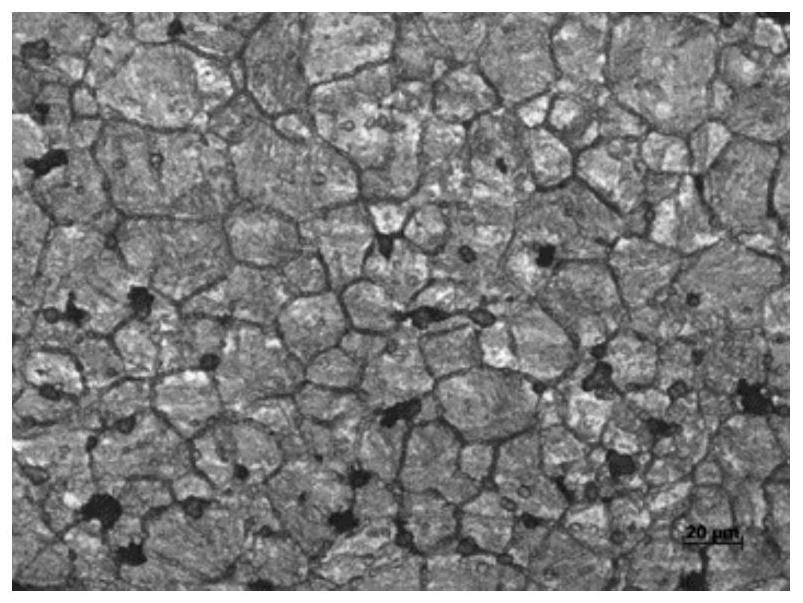

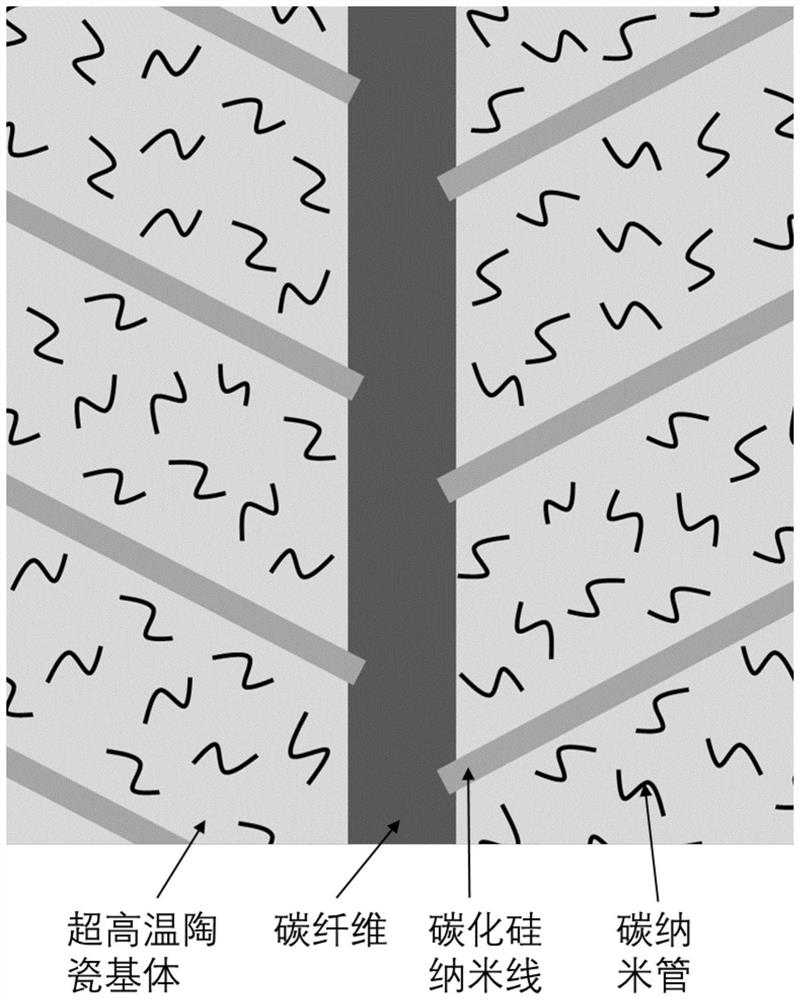

Graded toughened ultrahigh-temperature ceramic-based composite material inspired by leaves and preparation method thereof

The invention belongs to the field of ultrahigh-temperature ceramic-based composite materials, and particularly relates to a graded toughened ultrahigh-temperature ceramic-based composite material inspired by leaves and a preparation method thereof. The preparation method includes the steps that firstly, carbon fibers are coated with a polyethersulfone coating, then silicon carbide nanowires growon the carbon fibers with polyethersulfone as a carbon source, and first-level veins and second-level veins are constructed; secondly, impregnating the carbon fiber on which the silicon carbide nanowires grow into the ultrahigh-temperature ceramic slurry containing the carbon nanotubes, constructing third-stage veins, and drying to obtain a pre-sintered blank; and finally, preparing the graded toughened ultrahigh-temperature ceramic-based composite material inspired by the leaves through hot-pressing sintering. According to the special hierarchical structure, the expansion direction of crackscan be changed through mechanisms such as pulling out, debonding and bridging of the first-stage vein, the second-stage vein and the third-stage vein, the expansion path of the cracks is increased, more breaking energy is absorbed, and the prepared composite material has excellent thermal shock resistance and breaking resistance.

Owner:DALIAN UNIV OF TECH

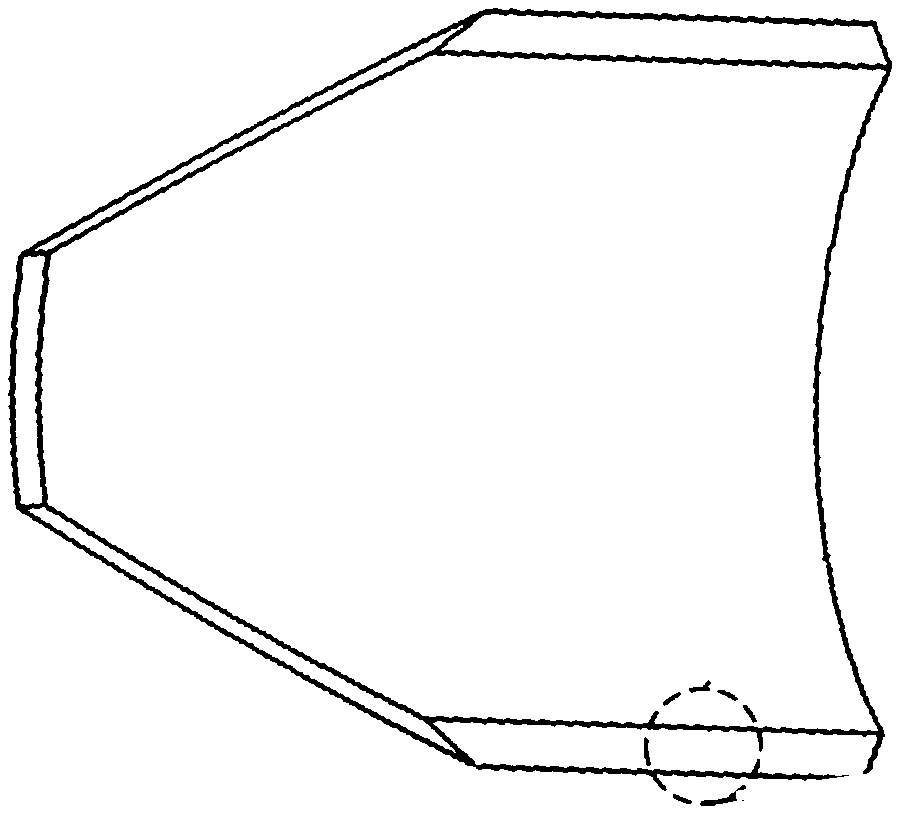

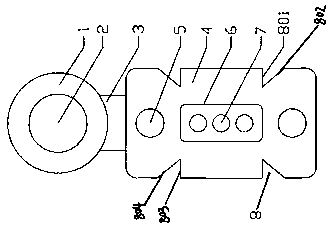

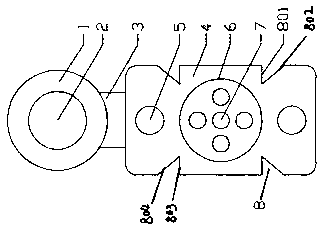

Self-supporting butterfly optical cable capable of overcoming influence of stripping grooves on protection strength of optical fiber

PendingCN110794533AStrong ability to resist external impactStrong fracture resistanceFibre mechanical structuresRight triangleEngineering

The invention discloses a self-supporting butterfly optical cable capable of overcoming influence of stripping grooves on protection strength of an optical fiber, and overcomes the influence of the stripping grooves of protective sleeves on the protection strength of the optical fiber. The self-supporting butterfly optical cable comprises an upper protective sleeve (1), a lower protective sleeve (4), a loose tube (6) and an optical fiber (7), wherein two pairs of stripping grooves (8) in the shape of a right-angled triangle are arranged symmetrically on both sides of the lower protective sleeve (4); the extension lines of the right-angled edges (801) of the two stripping grooves (8) on the lower end of the lower protective sleeve are set under the cross-sectional area of the loose tube (6); the extension lines of the right-angled edges (803) of the two stripping grooves (8) on the upper end of the lower protective sleeve (4) are set above the cross-sectional area of the loose tube (6),and the notches of the two stripping grooves on the both sides on the lower protective sleeve (4) are provided outside the outer contour lines at both ends of the cross-sectional area of the loose tube. The self-supporting butterfly optical cable provided by the invention has excellent resistance to fracture, reliable work and long service life.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

Environment-friendly antibacterial sole and preparation method thereof

InactiveCN108864638ASolving Recycling ProblemsImprove wear resistanceSolesWaste rubberTributyl citrate

The invention discloses an environment-friendly antibacterial sole material and a preparation method thereof, and relates to the field of sole materials. The environment-friendly antibacterial sole material comprises the following raw materials in parts by weight: 30 to 40 parts of natural rubber, 60 to 70 parts of recycled rubber, 2 to 4 parts of negative ion powder, 5 to 10 parts of bamboo charcoal, 3 to 7 parts of polyvinylpyrrolidone, 2 to 5 parts of tetramethylthiuram disulfide, 3 to 7 parts of tributyl citrate, 6 to 12 parts of nano-silica, 4 to 8 parts of silver-loaded nano titanium dioxide, 4 to 8 parts of polypropylene fiber, 1.6 to 3.5 parts of an anti-aging agent, 2 to 4 parts of a silane coupling agent and 1.8 to 3.2 parts of a foaming agent. Through the synergy between raw materials, the sole material disclosed by the invention has good wear resistance and toughness and excellent fracture resistance, and has good antibacterial property and humidity control property. The recycled rubber is selected as the main raw material, the price is low, the production cost is lowered, and the problem of recycling waste rubber is solved.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

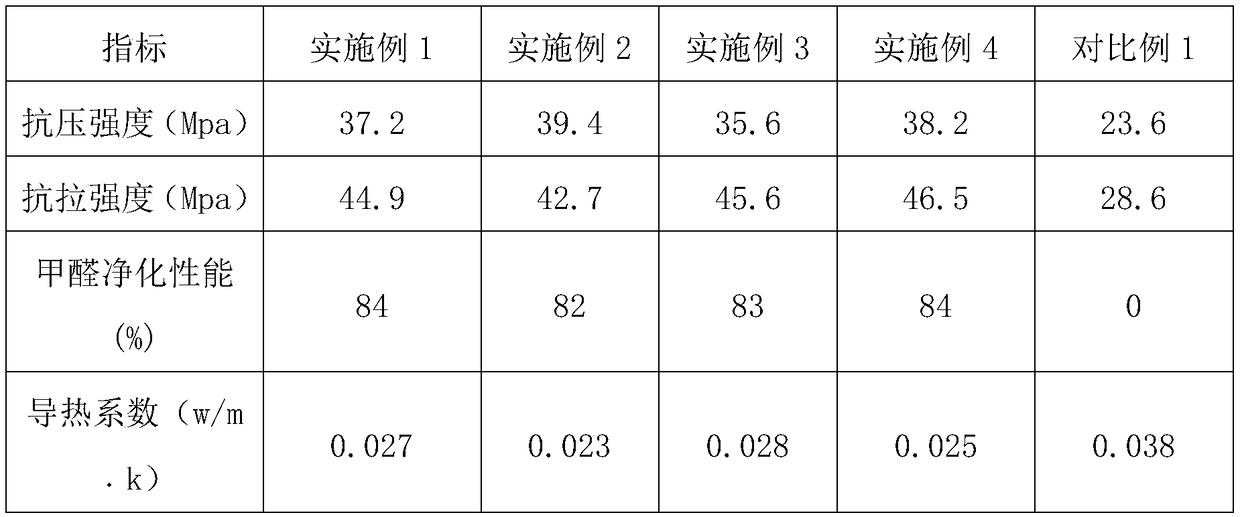

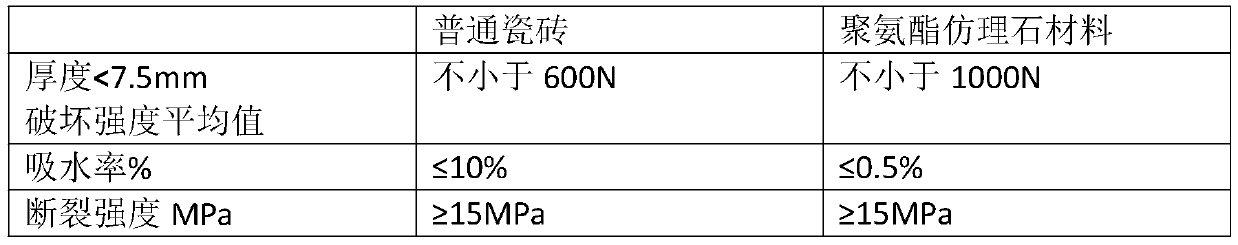

Preparation method for preparing polyurethane marble-imitated decorative material from industrial saponification waste residues

The invention relates to a method for preparing a polyurethane marble-imitated decorative material from industrial saponification waste residues. According to the method, macromolecular polyol used inthe method is polyester polyol or polyether polyol, isocyanate is used as a raw material, 3,3'-dichloro-4,4'-diaminodiphenyl methane is used as a chain extender, and industrial saponification waste residues are used as a filler. The preparation method comprises the following steps: (1) preparation of a prepolymer; (2) preparation of a chain extender component; (3) blending and molding at normal temperature; and (4) a post-curing process. According to the invention, polyurethane elastomer is used as a main raw material of the marble-imitated decorative material, and the polyurethane elastomerhas the characteristic of difficulty in breakage and overcomes the defects of easiness in breakage, difficulty in transportation and the like of conventional ceramic tiles; meanwhile, the industrial saponification waste residues are utilized, and more industrial saponification waste residues can be added under the condition of the same destructive power, so cost is saved, and environmental protection is realized; in addition, normal-temperature pouring is adopted; that is, a prepolymer component and the chain extender component are mixed and subjected to injection molding at normal temperature, so energy is saved, and environmental pollution is reduced.

Owner:HANGJIN TECHNOLOGY CO LTD

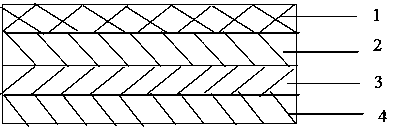

Anti-fracture composite packaging material

InactiveCN103640785AImprove fracture resistanceStrong fracture resistanceFlexible coversWrappersCelluloseCellulose acetate film

The invention discloses an anti-fracture composite packaging material. The anti-fracture composite packaging material has four layers, the first layer is a polyvinylidene chloride film of 30 microns to 60 microns in thickness, the second layer is a nylon film of 50 microns to 80 microns in thickness, the third layer is a dicyclopentadiene film of 55 microns to 75 microns in thickness, and the fourth layer is a cellulose acetate film of 40 microns to 90 microns in thickness. The composite packaging material has good anti-fracture property and the fracture strength of 36 Mpa to 39 Mpa.

Owner:WUXI HEZHONG INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com