Enhanced fiber

A reinforced fiber optic technology, applied in cladding optical fiber, light guide, optics, etc., can solve the problems of weather resistance, poor heat resistance, easy deterioration and yellowing of coating materials, and achieve good yellowing resistance and transmission The effect of low loss and strong fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

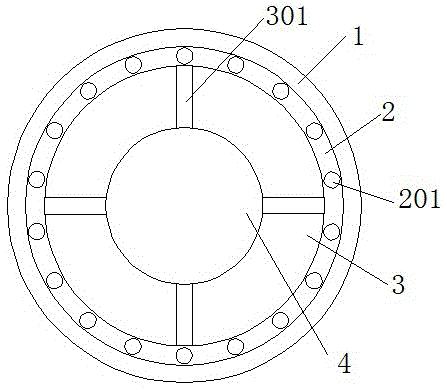

[0014] Embodiment 1: as figure 1 As shown, the reinforced optical fiber includes a core 4 and a cladding, the core 4 is composed of two doped cores 4 with different refractive indices, and the cladding surrounds the core 4 at the periphery of the core 4 , the cladding includes a primary coating layer 2 and a secondary coating layer 1 formed of an ultraviolet curable resin, the ultraviolet curable resin contains urethane acrylate and a photoinitiator and the polyisocyanate component in the urethane acrylate is aromatic Polyisocyanate-like; a reinforcing core layer 3 is arranged between the primary coating layer 2 and the fiber core 4, and the periphery of the reinforcing core layer is twisted and wrapped in the fiber core 4 in the primary coating layer 2; the The reinforcing core layer 3 is provided with a number of mutually independent reinforcing ribs 301 at intervals along the radial direction; the reinforcing ribs 301 are cross-shaped when viewed from the cross section, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com