A low-cost high-performance marine riser hot-rolled steel plate and its production method

A technology for hot-rolled steel sheets and production methods, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of reduced compression deformation, reduced cooling uniformity, easy occurrence of center segregation, etc., and reaches the finishing rolling temperature. Effects of reduced range, excellent low temperature toughness, good fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

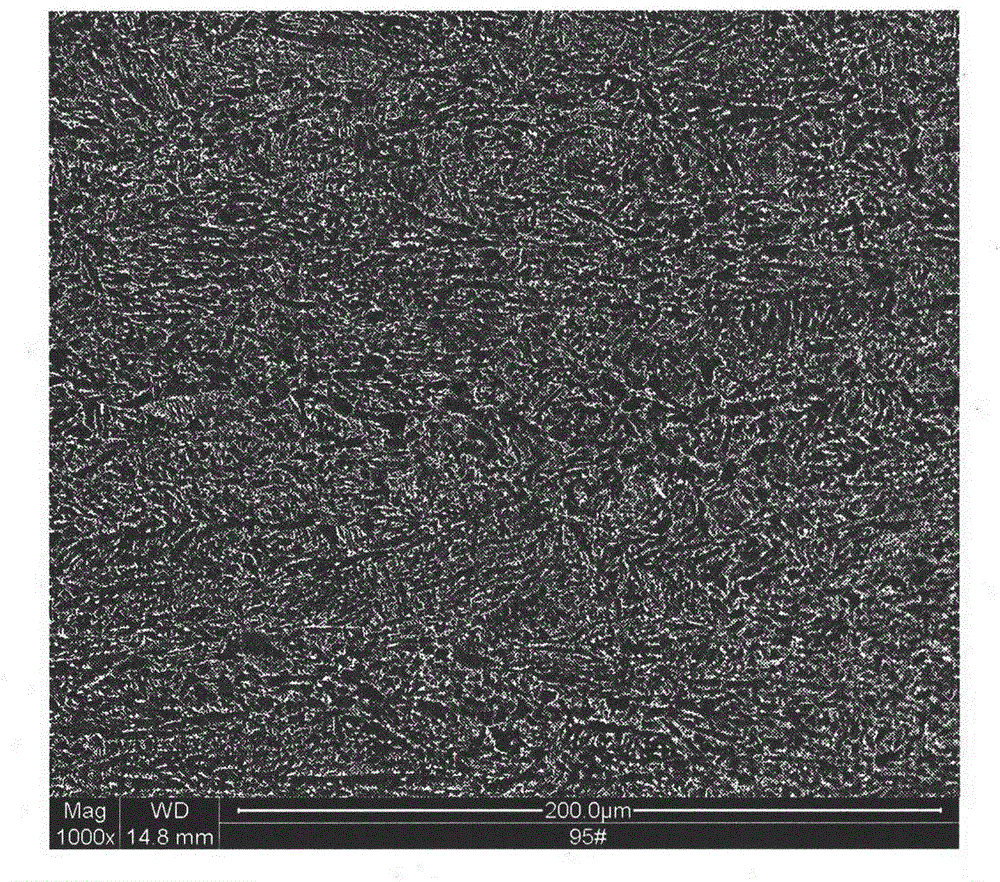

Image

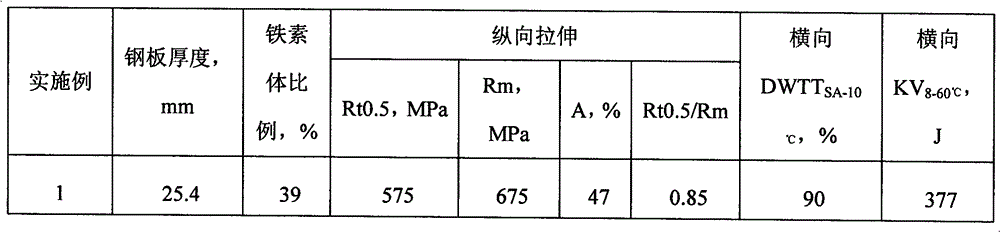

Examples

Embodiment Construction

[0026] Specific examples of the present invention are described in detail below: the chemical components used in the steel of the present invention include, by weight, C: 0.04% to 0.10%, Si: 0.10% to 0.35%, Mn: 1.55% to 1.85%, Nb : 0.02%~0.08%, Ti: 0.008%~0.020%, Al: 0.010%~0.040%, P≤0.020%, S≤0.003%, MoIIW Controlled at 0.40%~0.45%, CE PCM Controlled at 0.16%~0.21%, of which CE IIW =C+Mn / 6+(Ni+Cu) / 15+(Cr+Mo+V) / 5, CE PCM =C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B,

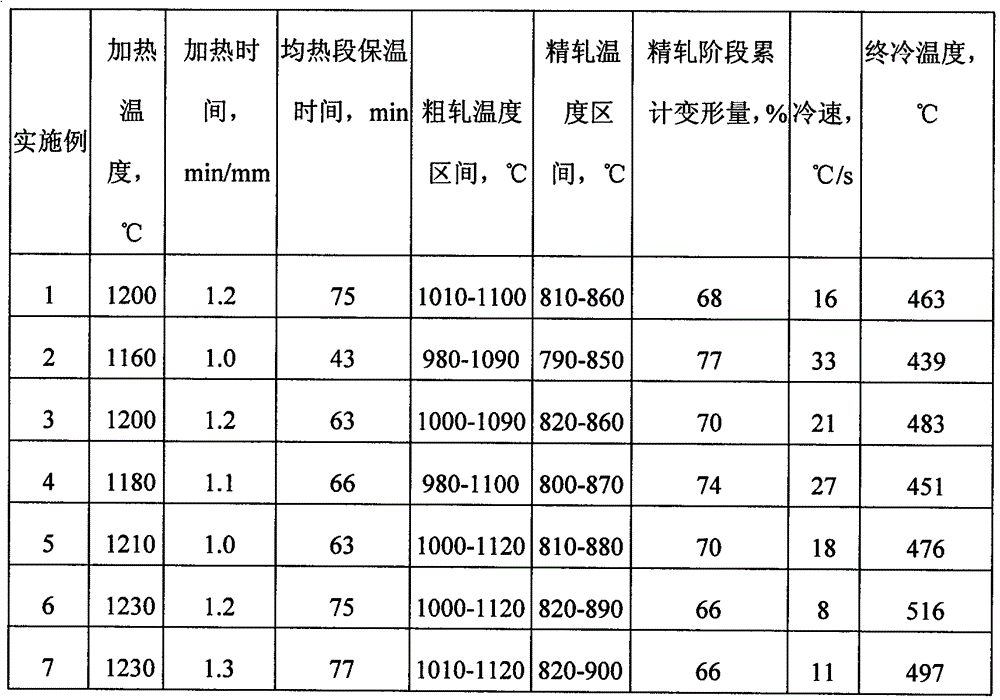

[0027] And through the following processes, the production method includes molten iron pretreatment, smelting, refining outside the furnace, continuous casting, rolling, and cooling, and is characterized in that: the heating temperature of the continuous casting slab during the rolling process is 1160-1230 ° C, and four-stage heating is adopted , where the first three sections are preheating and heating sections, heating temperature 1180-1230°C, heating time 0.7-1.0min / mm, the last section is soaking section, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com