Pipeline repairing method with anti-collapse and anti-flattening function

A pipeline repair and function technology, applied in the direction of pipe components, pipes/pipe joints/fittings, epoxy resin glue, etc., can solve the problems of easy collapse, hoses not resistant to negative pressure, flexible repair hose collapse and other problems, Reliable anti-collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

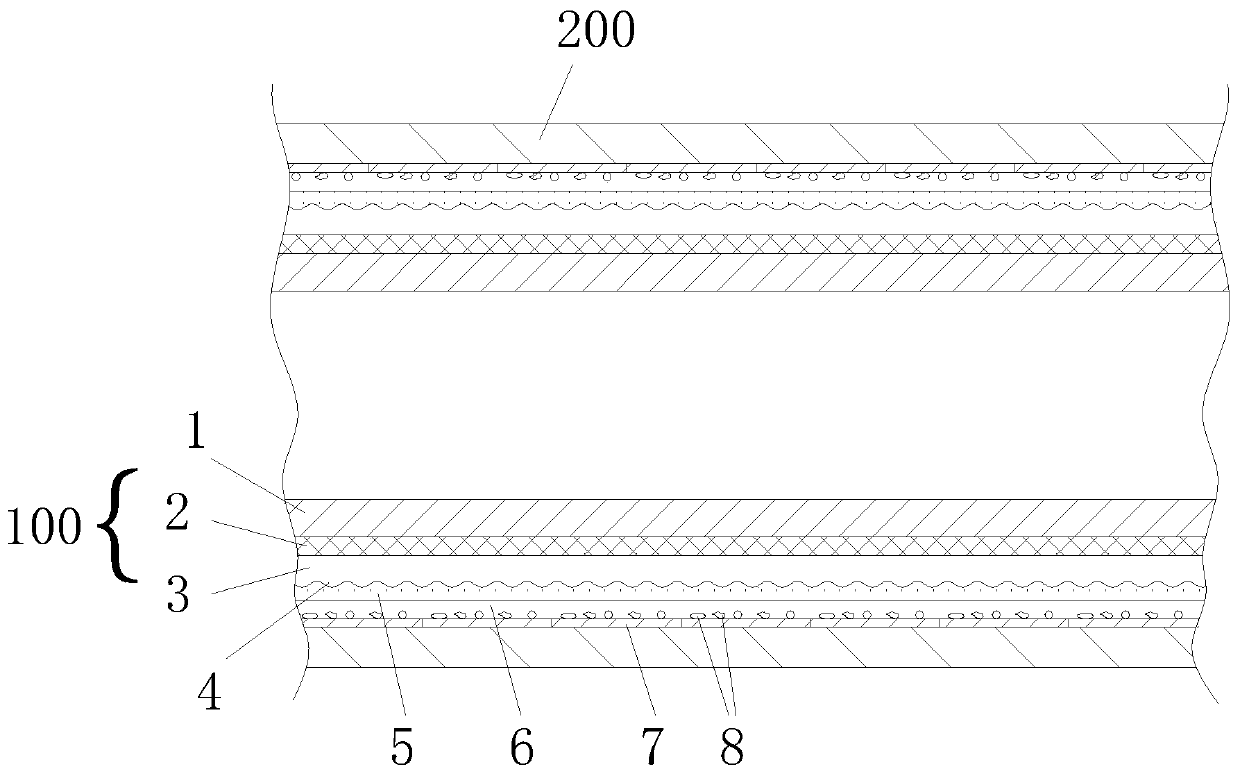

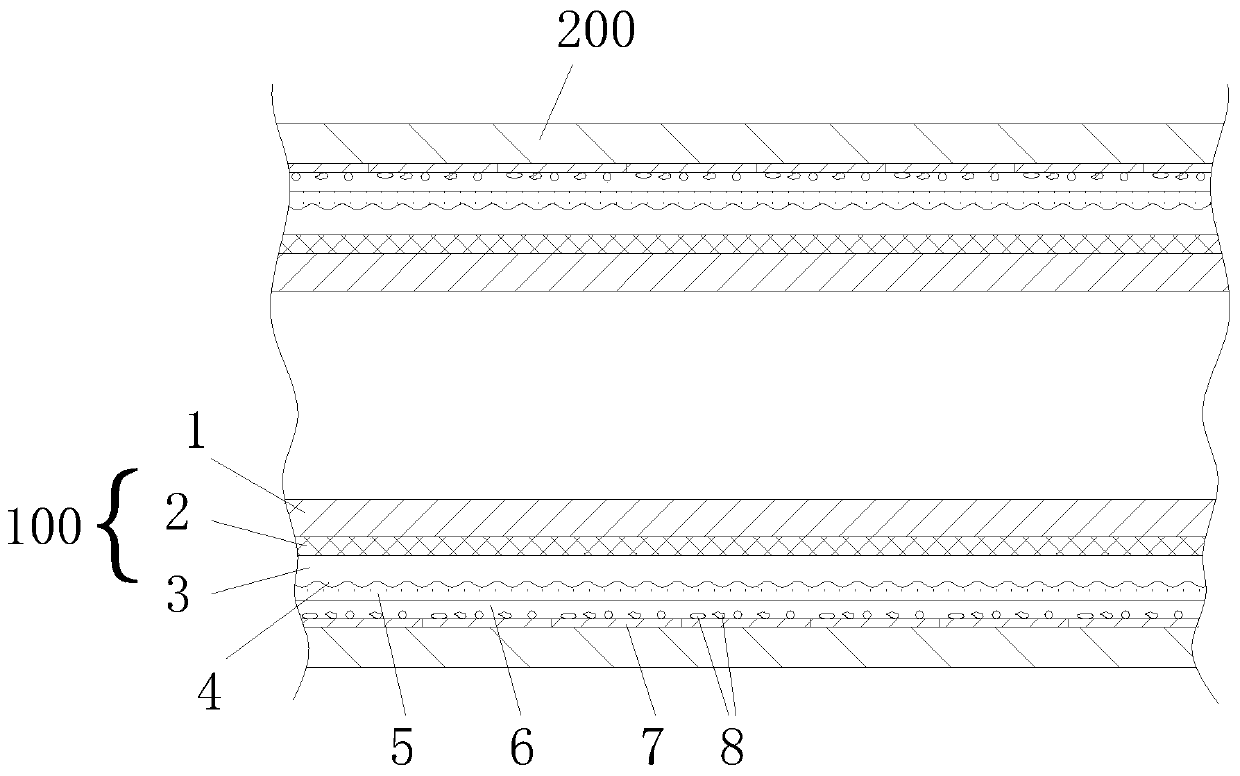

[0023] Embodiment 1: A pipeline repair method with anti-collapse function, comprising the following steps:

[0024] S1. Cover the outer surface of the flexible hose 100 with a first adhesive layer 5;

[0025] S2, winding a layer of film tape 7 with hot-melt properties on the outer surface of the flexible hose 100, the inner surface of the film tape 7 is coated with the second adhesive layer 6 and fibers for providing connection strength;

[0026] S3, pulling the flexible hose 100 wrapped with the film tape 7 into the original pipeline 200;

[0027] S4. Pass a pressurized heat source into the flexible hose 100, the pressurized heat source melts the film tape 7, and makes the first adhesive adhesive layer 5 and the second adhesive adhesive layer 6 compound to form a composite adhesive adhesive layer. The adhesive layer bonds the outer wall of the flexible hose 100 and the inner wall of the original pipeline 200 together, thereby completing the pipeline repair.

[0028] Wherein...

Embodiment 2

[0032] Embodiment 2: A pipeline repair method with an anti-collapse function. The difference from Embodiment 1 is that the epoxy resin A material is composed of the following raw materials in parts by weight: 90 parts of epoxy resin, 16 parts Aluminum oxide filler, 12 parts of polyethylene glycol, 10 parts of polycarboxylic anhydride, 40 parts of curing agent, 0.8 parts of defoaming agent, 0.5 parts of coupling agent, and 4 parts of toughening agent.

[0033] The epoxy resin B material is composed of the following raw materials in parts by weight: 120 parts of epoxy resin, 25 parts of alumina filler, 55 parts of curing agent, 0.8 part of defoamer, 0.5 part of coupling agent , 4 parts of toughening agent. After testing, the composite adhesive layer formed by the composite hardening of the first adhesive adhesive layer 5 and the second adhesive adhesive layer 6 has a water absorption rate of less than 0.1 and a compressive strength of 3.9Kg / mm at 24 hours 2 , the impact strengt...

Embodiment 3

[0034] Embodiment 3: A pipeline repair method with anti-collapse function, the difference from Embodiment 1 is that the epoxy resin A material is composed of the following raw materials in specific weight ratios: 85 parts of epoxy resin, 15 parts parts of alumina filler, 10 parts of polyethylene glycol, 7 parts of polycarboxylic anhydride, 35 parts of curing agent, 0.7 parts of defoaming agent, 0.3 parts of coupling agent, and 3 parts of toughening agent.

[0035] The epoxy resin B material is composed of the following raw materials in specific weight ratios: 115 parts of epoxy resin, 23 parts of alumina filler, 53 parts of curing agent, 0.7 part of defoamer, 0.3 part of coupling agent, 3 parts of toughening agent. After testing, the composite adhesive layer formed by composite hardening of the first adhesive adhesive layer 5 and the second adhesive adhesive layer 6 has a water absorption rate of less than 0.1 and a compressive strength of 3.7Kg / mm in 24 hours 2 , the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com