Environment-friendly antibacterial sole and preparation method thereof

An environmental protection and shoe sole material technology, applied in the field of shoe sole materials, can solve the problems of foot odor, harm to foot health, unfavorable personal hygiene, etc., achieve clean shoe environment, low price, and solve the effect of low grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

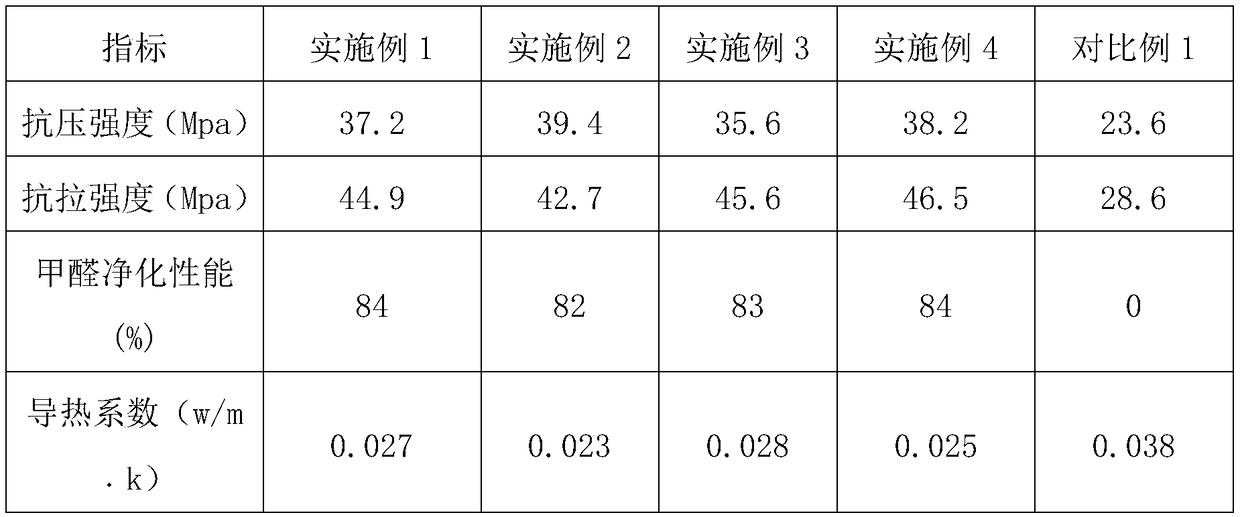

Examples

Embodiment 1

[0031] A kind of environmental protection antibacterial shoe sole material, comprises the raw material of following weight parts:

[0032] 30 parts of natural rubber, 60 parts of regenerated rubber, 2 parts of negative ion powder, 5 parts of bamboo charcoal, 3 parts of polyvinylpyrrolidone, 2 parts of tetramethylthiuram disulfide, 3 parts of tributyl citrate, nanometer dioxide 6 parts of silicon, 4 parts of silver-loaded nano titanium dioxide, 4 parts of polypropylene fiber, 1.6 parts of anti-aging agent, 2 parts of silane coupling agent and 1.8 parts of foaming agent.

[0033] The preparation method of recycled plastic is:

[0034] (a) After cleaning and recycling the waste rubber soles, send them to a pulverizer to be crushed to 10 meshes, and remove iron filings and impurities with a strong magnetic iron remover to obtain waste rubber particles;

[0035] (b) Add cleaning agent equivalent to 5% of its weight, 1% polypropylene glyceryl ether and 98% water to the waste rubber...

Embodiment 2

[0048] A kind of environmental protection antibacterial shoe sole material, comprises the raw material of following weight parts:

[0049] 40 parts of natural rubber, 70 parts of regenerated rubber, 4 parts of negative ion powder, 10 parts of bamboo charcoal, 7 parts of polyvinylpyrrolidone, 5 parts of tetramethylthiuram disulfide, 7 parts of tributyl citrate, nano-dioxide 12 parts of silicon, 8 parts of silver-loaded nano titanium dioxide, 8 parts of polypropylene fiber, 3.5 parts of anti-aging agent, 4 parts of silane coupling agent and 3.2 parts of foaming agent.

[0050] The preparation method of recycled plastic is:

[0051] (a) After cleaning and recycling the waste rubber soles, send them to a pulverizer to be pulverized to 20 meshes, and remove iron filings and impurities with a strong magnetic iron remover to obtain waste rubber particles;

[0052] (b) Add cleaning agent equivalent to 5% of its weight, 1% polypropylene glyceryl ether and 98% water to the waste rubber...

Embodiment 3

[0065] A kind of environmental protection antibacterial shoe sole material, comprises the raw material of following weight parts:

[0066] 34 parts of natural rubber, 68 parts of regenerated rubber, 3 parts of negative ion powder, 7 parts of bamboo charcoal, 6 parts of polyvinylpyrrolidone, 2.8 parts of tetramethylthiuram disulfide, 6 parts of tributyl citrate, nano-dioxide 10 parts of silicon, 7 parts of silver-loaded nano titanium dioxide, 6 parts of polypropylene fiber, 2.8 parts of anti-aging agent, 3 parts of silane coupling agent and 2.5 parts of foaming agent.

[0067] The preparation method of recycled plastic is:

[0068] (a) After cleaning and recycling the waste rubber soles, send them to a pulverizer to be pulverized to 18 meshes, and use a strong magnetic iron remover to remove iron filings and impurities to obtain waste rubber particles;

[0069] (b) Add cleaning agent equivalent to 5% of its weight, 1% polypropylene glyceryl ether and 98% water to the waste rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com