Anti-fracture composite packaging material

A composite packaging material, anti-fracture technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problem of low fracture strength of composite packaging materials, and achieve good anti-fracture effect and good anti-fracture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

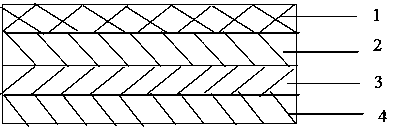

[0008] A fracture-resistant composite packaging material, the fracture-resistant composite packaging material has four layers, the first layer is a polyvinylidene chloride film 1 with a thickness of 30 microns, the second layer is a nylon film 2 with a thickness of 80 microns, and the third layer It is a dicyclopentadiene film 3 with a thickness of 55 microns, and the fourth layer is a cellulose acetate film 4 with a thickness of 90 microns. The composite packaging material is extruded and composited by four extruders to obtain a composite packaging material that is resistant to fracture. Add a portion of acrylic acetate between each layer of composite film.

Embodiment 2

[0010] A fracture-resistant composite packaging material, the fracture-resistant composite packaging material has four layers, the first layer is a polyvinylidene chloride film 1 with a thickness of 45 microns, the second layer is a nylon film 2 with a thickness of 60 microns, and the third layer It is a dicyclopentadiene film 3 with a thickness of 65 microns, and the fourth layer is a cellulose acetate film 4 with a thickness of 50 microns. The composite packaging material is extruded and composited by four extruders to obtain a composite packaging material that is resistant to fracture. Add a portion of acrylic acetate between each layer of composite film.

Embodiment 3

[0012] A fracture-resistant composite packaging material, the fracture-resistant composite packaging material has four layers, the first layer is a polyvinylidene chloride film 1 with a thickness of 60 microns, the second layer is a nylon film 2 with a thickness of 50 microns, and the third layer It is a dicyclopentadiene film 3 with a thickness of 75 microns, and the fourth layer is a cellulose acetate film 4 with a thickness of 40 microns. The composite packaging material is extruded and composited by four extruders to obtain a composite packaging material that is resistant to fracture. Add a portion of acrylic acetate between each layer of composite film.

[0013] Measured the anti-fracture effect of embodiment 1, embodiment 2, embodiment 3, embodiment 1, embodiment 2, embodiment 3 are tested with intelligent electronic tensile testing machine, embodiment 1, embodiment 2, embodiment 3 The fracture strengths are 36Mpa, 38Mpa, 39Mpa respectively, and have good fracture resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com