Highly filled wood-plastic foaming material and preparation method thereof

A wood-plastic foaming and waste plastic technology, applied in the field of wood-plastic materials, can solve the problems of poor processability, poor mechanical properties, and high cost of wood-plastic materials, and achieve the effects of improved mechanical properties, high specific strength and low formula cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

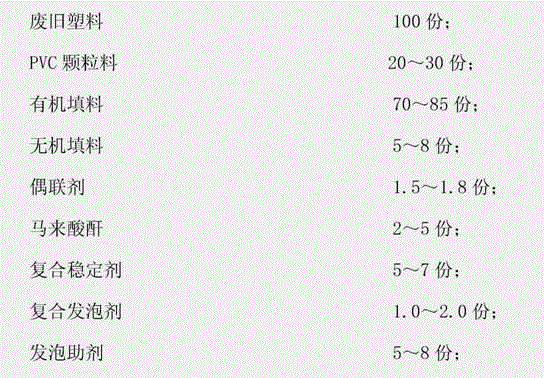

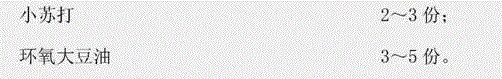

[0033] A high-filling wood-plastic foaming material, characterized in that: it is made of the following raw materials in parts by weight, and the specific proportions and raw materials are as follows: 100 parts of waste plastics, 20 parts of PVC granules, 70 parts of organic fillers, 5 parts of inorganic fillers 1.5 parts of coupling agent, 2 parts of maleic anhydride, 5 parts of composite stabilizer, 1.0 part of composite foaming agent, 5 parts of foaming aid, 2 parts of baking soda, 3 parts of epoxidized soybean oil.

[0034] Wherein, the waste plastic is waste polyvinyl chloride; the organic filler is powdery rice husk powder with a water content of ≤8% and a particle size of 50 meshes; the inorganic filler is industrial precipitation calcium carbonate and titanium dioxide , the mixture of talcum powder, its mixing ratio is: industrial precipitation calcium carbonate: titanium dioxide: talcum powder=3:0.8:2; Described composite stabilizer is calcium-zinc composite stabilizer...

Embodiment 2

[0044]A high-filling wood-plastic foaming material, characterized in that: it is made of the following raw materials in parts by weight, and the specific proportions and raw materials are as follows: 100 parts of waste plastics, 25 parts of PVC granules, 75 parts of organic fillers, 6.5 parts of inorganic fillers Parts, 1.7 parts of coupling agent, 3.5 parts of maleic anhydride, 6 parts of composite stabilizer, 1.5 parts of composite foaming agent, 6.5 parts of foaming aid, 2.5 parts of baking soda, 4 parts of epoxidized soybean oil.

[0045] Wherein, the waste plastics are waste polyethylene; the organic fillers are fibrous wood chips with a water content of ≤8% and a particle size of 55 mesh, and crop straw powder; the inorganic fillers are industrial precipitation carbonic acid The mixture of calcium, titanium dioxide and talcum powder has a mixing ratio of: industrial precipitated calcium carbonate: titanium dioxide: talcum powder=3:0.8:2; the composite stabilizer is a calc...

Embodiment 3

[0055] A high-filling wood-plastic foaming material, characterized in that it is made of the following raw materials in parts by weight, and the specific proportions and raw materials are as follows: 100 parts of waste plastics, 30 parts of PVC granules, 85 parts of organic fillers, and 8 parts of inorganic fillers Parts, 1.8 parts of coupling agent, 5 parts of maleic anhydride, 7 parts of composite stabilizer, 2.0 parts of composite foaming agent, 8 parts of foaming aid, 3 parts of baking soda, 5 parts of epoxidized soybean oil.

[0056] Wherein, the waste plastics are waste styrene; the organic fillers are powdery or fibrous crop orange stalk powder, beans, cornstarch, cotton husk, Nut shells or coconut shells; the inorganic filler is a mixture of industrial precipitated calcium carbonate, titanium dioxide, and talcum powder, and its mixing ratio is: industrial precipitated calcium carbonate: titanium dioxide: talc = 3:0.8:2; The composite stabilizer is a calcium-zinc compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com