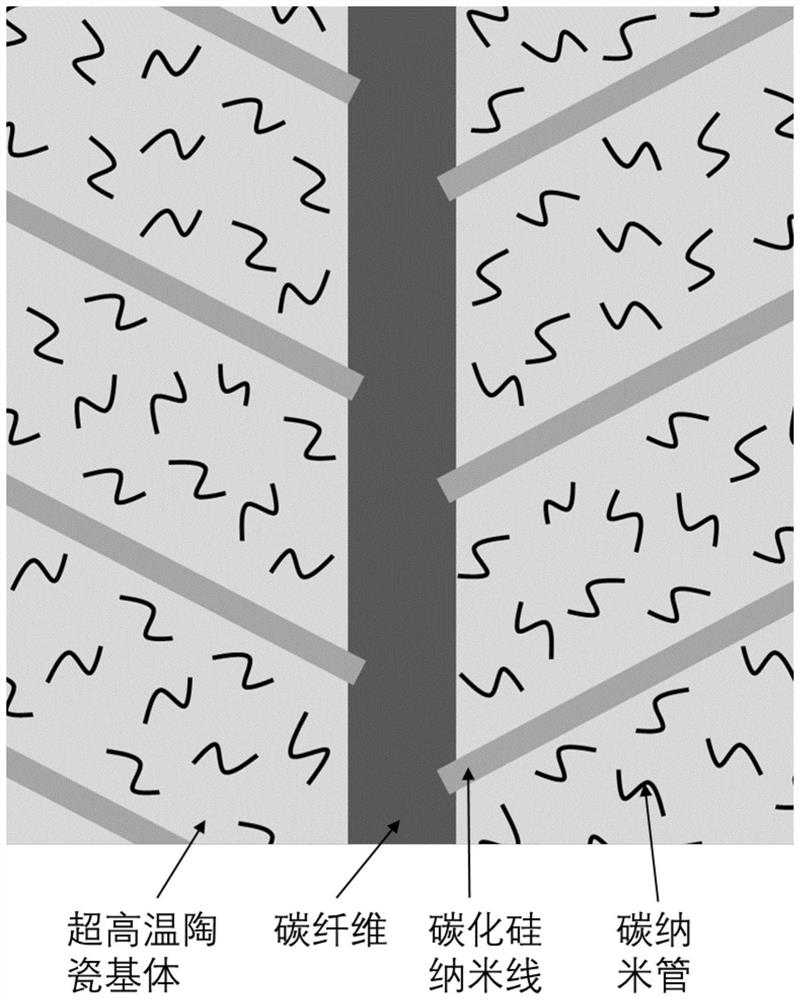

Graded toughened ultrahigh-temperature ceramic-based composite material inspired by leaves and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of graded and toughened ultra-high temperature ceramic matrix composite materials, can solve the problems of significant decrease in strength of layered ceramics, low fracture resistance and thermal shock resistance, and easy delamination. Achieve excellent thermal shock resistance, firm bonding, and increase the effect of expansion paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0017] A preparation method of hierarchically toughened ultra-high temperature ceramic matrix composites inspired by leaves. First, carbon fibers are coated with polyethersulfone coating, and then silicon carbide nanowires are grown on carbon fibers to construct primary and secondary veins. ; secondly, impregnate the carbon fiber grown with silicon carbide nanowires into the ultra-high temperature ceramic slurry containing carbon nanotubes to construct three-level leaf veins, and obtain a pre-sintered green body after drying; finally, a leaf-inspired green body is prepared by hot pressing sintering. The hierarchically toughened ultra-high temperature ceramic matrix composite material, the specific steps of which specifically include:

[0018] Coating polyethersulfone coating on carbon fibers to protect c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com